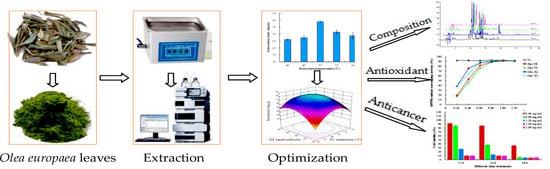

Optimization of Ultrasound-Assisted Extraction of Flavonoids from Olive (Olea europaea) Leaves, and Evaluation of Their Antioxidant and Anticancer Activities

Abstract

:1. Introduction

2. Results and Discussion

2.1. Single Factor Experiment

2.1.1. Effect of Extraction Temperature

2.1.2. Effect of Ultrasound Power

2.1.3. Effect of Extraction Time

2.1.4. Effect of Liquid-Solid Ratio

2.2. Response Surface Optimization of Flavonoids

2.2.1. Analysis of Extraction Model

2.2.2. Analysis of Response Surface

2.2.3. Optimization of Extraction Conditions

2.3. Analysis of Flavonoid Compositions

2.4. Assay of Antioxidant Activity

2.4.1. Reducing Power

2.4.2. DPPH Radical Scavenging Activity

2.4.3. Superoxide Radical Scavenging Activity

2.5. Assay of Cell Viability

3. Material and Methods

3.1. Materials and Chemicals

3.2. Ultrasound-Assisted Extraction (UAE)

3.3. Response Surface Methodology (RSM) Design

3.4. Determination of Total Flavonoids

3.5. HPLC Analysis

3.6. Antioxidant Activity Assays

3.6.1. Reducing Power

3.6.2. DPPH Radical Scavenging Activity

3.6.3. Superoxide Radical-Scavenging Activity

3.7. Anticancer Activity Assays

3.7.1. Cell Culture

3.7.2. Cell Viability

3.8. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Deng, J.; Xu, Z.; Xiang, C.; Liu, J.; Zhou, L.; Li, T.; Yang, Z.; Ding, C. Comparative evaluation of maceration and ultrasonic-assisted extraction of phenolic compounds from fresh olives. Ultrason. Sonochem. 2017, 37, 328–334. [Google Scholar] [CrossRef] [PubMed]

- Xiang, C.; Xu, Z.; Liu, J.; Li, T.; Yang, Z.; Ding, C. Quality, composition, and antioxidant activity of virgin olive oil from introduced varieties at Liangshan. LWT Food Sci. Technol. 2017, 78, 226–234. [Google Scholar] [CrossRef]

- Şahin, S.; Samli, R.; Tan, A.; Barba, F.J.; Chemat, F.; Cravotto, G.; Lorenzo, J.M. Solvent-Free Microwave-Assisted Extraction of Polyphenols from Olive Tree Leaves: Antioxidant and Antimicrobial Properties. Molecules 2017, 22, 1056. [Google Scholar] [CrossRef] [PubMed]

- Xie, P.J. Study on High-Value Utilization of Olive Leaf and Its Meachanism. Ph.D Thesis, Chinese Academy of Forestry, Beijing, China, 2015. [Google Scholar]

- Özcan, M.M.; Matthäus, B. A review: Benefit and bioactive properties of olive (Olea europaea L.) leaves. Eur. Food Res. Technol. 2016, 243, 1–11. [Google Scholar] [CrossRef]

- Şahin, S.; Bilgin, M. Olive tree (Olea europaea L.) leaf as a waste by-product of table olive and olive oil industry: A review. J. Sci. Food Agric. 2018, 98, 1271–1279. [Google Scholar] [CrossRef] [PubMed]

- Khaliq, A.; Sabir, S.M.; Ahmad, S.D.; Boligon, A.A.; Athayde, M.L.; Jabbar, A.; Qamar, I.; Khan, A. Antioxidant activities and phenolic composition of olive (Olea europaea) leaves. J. Appl. Bot. Food Qual. 2015, 88, 16–21. [Google Scholar]

- Goulas, V.; Papoti, V.T.; Exarchou, V.; Tsimidou, M.Z.; Gerothanassis, I.P. Contribution of flavonoids to the overall radical scavenging activity of olive (Olea europaea L.) leaf polar extracts. J. Agric. Food Chem. 2010, 58, 3303–3308. [Google Scholar] [CrossRef] [PubMed]

- Lockyer, S.; Yaqoob, P.; Spencer, J.P.E.; Rowland, I.; Lockyer, S.; Yaqoob, P.; Spencer, J.P.E.; Rowland, I.; Lockyer, S.; Yaqoob, P. Olive leaf phenolics and cardiovascular risk reduction: Physiological effects and mechanisms of action. Nutr. Aging 2012, 1, 125–140. [Google Scholar]

- Kiritsakis, A.; Shahidi, F.; Anousakis, C. Antioxidants of Olive Oil, Olive Leaves, and Their Bioactivity; Olives and Olive Oil as Functional Foods: Bioactivity, Chemistry and Processing; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; pp. 367–382. [Google Scholar]

- Milanizadeh, S.; Bigdeli, M.R.; Rasoulian, B.; Amani, D. The effects of olive leaf extract on antioxidant enzymes activity and tumor growth in breast cancer. Thrita 2014, 3, e12914. [Google Scholar] [CrossRef]

- Rodrigues, F.; Pimentel, F.B.; Oliveira, M.B.P.P. Olive by-products: Challenge application in cosmetic industry. Ind. Crops. Prod. 2015, 70, 116–124. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Q.; Wu, Y.; Chen, G.; Yue, W.; Liang, Q. Response surface optimized ultrasonic-assisted extraction of flavonoids from Sparganii rhizoma and evaluation of their in vitro antioxidant activities. Molecules 2012, 17, 6769–6783. [Google Scholar] [CrossRef] [PubMed]

- Nadeem, M.; Ubaid, N.; Qureshi, T.M.; Munir, M.; Mehmood, A. Effect of ultrasound and chemical treatment on total phenol, flavonoids and antioxidant properties on carrot-grape juice blend during storage. Ultrason. Sonochem. 2018, 45, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Zheng, J.; Gan, R.Y.; Zhou, T.; Xu, D.P.; Li, H.B. Optimization of Ultrasound-Assisted Extraction of Antioxidants from the Mung Bean Coat. Molecules 2017, 22, 638. [Google Scholar] [CrossRef] [PubMed]

- Shirzad, H.; Niknam, V.; Taheri, M.; Ebrahimzadeh, H. Ultrasound-assisted extraction process of phenolic antioxidants from Olive leaves: A nutraceutical study using RSM and LC–ESI–DAD–MS. J. Food Sci. Technol. 2017, 54, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Altıok, E.; Bayçın, D.; Bayraktar, O.; Ülkü, S. Isolation of polyphenols from the extracts of olive leaves (Olea europaea L.) by adsorption on silk fibroin. Sep. Purif. Technol. 2008, 62, 342–348. [Google Scholar] [CrossRef]

- Patist, A.; Bates, D. Ultrasonic innovations in the food industry: From the laboratory to commercial production. Innov. Food Sci. Emerg. 2008, 9, 147–154. [Google Scholar] [CrossRef]

- Li, R.; Chen, W.C.; Wang, W.P.; Tian, W.Y.; Zhang, X.G. Extraction, characterization of Astragalus polysaccharides and its immune modulating activities in rats with gastric cancer. Carbohydr. Polym. 2009, 78, 738–742. [Google Scholar] [CrossRef]

- Al-Dhabi, N.A.; Ponmurugan, K.; Maran, J.P. Development and validation of ultrasound-assisted solid-liquid extraction of phenolic compounds from waste spent coffee grounds. Ultrason. Sonochem. 2017, 34, 206–213. [Google Scholar] [CrossRef] [PubMed]

- Shen, S.; Chen, D.; Li, X.; Li, T.; Yuan, M.; Zhou, Y.; Ding, C. Optimization of extraction process and antioxidant activity of polysaccharides from leaves of Paris polyphylla. Carbohydr. Polym. 2014, 104, 80. [Google Scholar] [CrossRef] [PubMed]

- Brahmi, F.; Mechri, B.; Dhibi, M.; Hammami, M. Variations in phenolic compounds and antiradical scavenging activity of Olea europaea leaves and fruits extracts collected in two different seasons. Ind. Crops Prod. 2013, 49, 256–264. [Google Scholar] [CrossRef]

- Sánchezrabaneda, F.; Jáuregui, O.; Lamuelaraventós, R.M.; Bastida, J.; Viladomat, F.; Codina, C. Identification of phenolic compounds in artichoke waste by high-performance liquid chromatography-tandem mass spectrometry. J. Chromatogr. A 2003, 1008, 57–72. [Google Scholar] [CrossRef]

- Abaza, L.; Taamalli, A.; Román, D.A.; Carretero, A.S.; Gutièrrez, A.F.; Zarrouk, M.; Youssef, N.B. Changes in phenolic composition in olive tree parts according to development stage. Food Res. Int. 2016, 100, 454–461. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Kim, B.G.; Ko, J.H.; Lee, Y.; Hur, H.G.; Lim, Y.; Ahn, J.H. Molecular cloning, expression, and characterization of a flavonoid glycosyltransferase from Arabidopsis thaliana. Plant Sci. 2006, 170, 897–903. [Google Scholar] [CrossRef]

- Brahmi, F.; Mechri, B.; Dabbou, S.; Dhibi, M.; Hammami, M. The efficacy of phenolics compounds with different polarities as antioxidants from olive leaves depending on seasonal variations. Ind. Crops Prod. 2012, 38, 146–152. [Google Scholar] [CrossRef]

- Arabshahi-Delouee, S.; Urooj, A. Antioxidant properties of various solvent extracts of mulberry (Morus indica L.) leaves. Food Chem. 2007, 102, 1233–1240. [Google Scholar] [CrossRef]

- Tohidi, B.; Rahimmalek, M.; Arzani, A. Essential oil composition, total phenolic, flavonoid contents, and antioxidant activity of Thymus species collected from different regions of Iran. Food Chem. 2017, 220, 153. [Google Scholar] [CrossRef] [PubMed]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Gülçin, I.; Mshvildadze, V.; Gepdiremen, A.; Elias, R. Screening of antiradical and antioxidant activity of monodesmosides and crude extract from Leontice smirnowii tuber. Phytomedicine 2006, 13, 343–351. [Google Scholar] [CrossRef] [PubMed]

- De, M.S.; Festa, C.; Zollo, F.; Nini, A.; Antenucci, L.; Raimo, G.; Iorizzi, M. Antioxidant activity and chemical components as potential anticancer agents in the olive leaf (Olea europaea L. cv Leccino.) decoction. Anti-Cancer Agent. Med. 2014, 14, 1376–1385. [Google Scholar]

- Chun, O.K.; Daeok Kim, A.; Chang, Y.L. Superoxide radical scavenging activity of the major polyphenols in fresh plums. J. Agric. Food Chem. 2003, 51, 8067–8072. [Google Scholar] [CrossRef] [PubMed]

- Bouaziz, M.; Grayer, R.J.; Simmonds, M.S.; Damak, M.; Sayadi, S. Identification and antioxidant potential of flavonoids and low molecular weight phenols in olive cultivar chemlali growing in Tunisia. J. Agric. Food Chem. 2005, 53, 236–241. [Google Scholar] [CrossRef] [PubMed]

- Quirantespiné, R.; Zurek, G.; Barrajóncatalán, E.; Bäßmann, C.; Micol, V.; Seguracarretero, A.; Fernándezgutiérrez, A. A metabolite-profiling approach to assess the uptake and metabolism of phenolic compounds from olive leaves in SKBR3 cells by HPLC-ESI-QTOF-MS. J. Pharm. Biomed. Anal. 2013, 72, 121–126. [Google Scholar] [CrossRef] [PubMed]

- Boss, A.; Bishop, K.S.; Marlow, G.; Barnett, M.P.; Ferguson, L.R. Evidence to Support the Anti-Cancer Effect of Olive Leaf Extract and Future Directions. Nutrients 2016, 8, 513. [Google Scholar] [CrossRef] [PubMed]

- Meda, A.; Lamien, C.E.; Romito, M.; Millogo, J.; Nacoulma, O.G. Determination of the total phenolic, flavonoid and proline contents in Burkina Fasan honey, as well as their radical scavenging activity. Food Chem. 2005, 91, 571–577. [Google Scholar] [CrossRef]

- Moein, M.R.; Moein, S.; Ahmadizadeh, S. Radical scavenging and reducing power of Salvia mirzayanii subfractions. Molecules 2008, 13, 2804–2813. [Google Scholar] [CrossRef] [PubMed]

- Jia, Z.; Tang, M.; Wu, J. The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem. 1999, 64, 555–559. [Google Scholar]

Sample Availability: Samples of the flavonoids extract are available from the authors. |

| Run | Extraction Variables | Extraction Yield of Flavonoids (mg RE/g) | |||

|---|---|---|---|---|---|

| X1 Temperature (°C) | X2 Power (W) | X3 Time (min) | X4 Liquid-Solid Ratio (mL/g) | ||

| 1 | −1(45) | −1(240) | 0(50) | 0(40) | 66.12 |

| 2 | 0(50) | −1(240) | 0(50) | 1(50) | 69.84 |

| 3 | −1(45) | 0(270) | −1(40) | 0(40) | 66.72 |

| 4 | 0(50) | 1(300) | 0(50) | −1(30) | 66.23 |

| 5 | 1(55) | 0(270) | 1(60) | 0(40) | 66.87 |

| 6 | −1(45) | 0(270) | 0(50) | 1(50) | 68.26 |

| 7 | 1(55) | 0(270) | 0(50) | −1(30) | 66.16 |

| 8 | 0(50) | −1(240) | −1(40) | 0(40) | 68.77 |

| 9 | 0(50) | 0(270) | −1(40) | −1(30) | 66.15 |

| 10 | 0(50) | 0(270) | 1(60) | 1(50) | 67.52 |

| 11 | −1(45) | 0(270) | 1(60) | 0(40) | 62.98 |

| 12 | −1(45) | 1(300) | 0(50) | 0(40) | 64.89 |

| 13 | 0(50) | 0(270) | −1(40) | 1(50) | 67.84 |

| 14 | 0(50) | 0(270) | 0(50) | 0(40) | 74.91 |

| 15 | 0(50) | 1(300) | 1(60) | 0(40) | 66.30 |

| 16 | 0(50) | −1(240) | 1(60) | 0(40) | 67.31 |

| 17 | 1(55) | 1(300) | 0(50) | 0(40) | 66.24 |

| 18 | 0(50) | 0(270) | 0(50) | 0(40) | 74.90 |

| 19 | 0(50) | 0(270) | 1(60) | −1(30) | 65.16 |

| 20 | 1(55) | 0(270) | 0(50) | 1(50) | 66.30 |

| 21 | 1(55) | −1(240) | 0(50) | 0(40) | 66.37 |

| 22 | 0(50) | 1(300) | 0(50) | 1(50) | 67.40 |

| 23 | 0(50) | 0(270) | 0(50) | 0(40) | 74.57 |

| 24 | 1(55) | 0(270) | −1(60) | 0(40) | 64.67 |

| 25 | 0(50) | −1(240) | 0(50) | −1(30) | 66.00 |

| 26 | 0(50) | 0(270) | 0(50) | 0(40) | 74.91 |

| 27 | 0(50) | 1(300) | −1(40) | 0(40) | 66.60 |

| 28 | 0(50) | 0(270) | 0(50) | 0(40) | 74.67 |

| 29 | −1(45) | 0(270) | 0(50) | −1(30) | 62.82 |

| Predicted | 50.10 | 267.32 | 49.62 | 41.64 | 74.93 |

| Experimental | 50.00 | 270.00 | 50.00 | 41.00 | 74.95 |

| Source | Sum of Squares | df | Mean Square | F-value | p-Value |

|---|---|---|---|---|---|

| Model | 348.72 | 14 | 24.91 | 285.81 | 0.0001 *** |

| X1 | 1.94 | 1 | 1.94 | 22.21 | 0.0003 *** |

| X2 | 3.8 | 1 | 3.8 | 43.57 | 0.0001 *** |

| X3 | 1.77 | 1 | 1.77 | 20.32 | 0.0005 *** |

| X4 | 17.86 | 1 | 17.86 | 204.94 | 0.0001 *** |

| X1X2 | 0.3 | 1 | 0.3 | 3.47 | 0.0836 ns |

| X1X3 | 8.82 | 1 | 8.82 | 101.21 | 0.0001 *** |

| X1X4 | 7.02 | 1 | 7.02 | 80.58 | 0.0001 *** |

| X2X3 | 0.34 | 1 | 0.34 | 3.86 | 0.0696 ns |

| X2X4 | 1.78 | 1 | 1.78 | 20.45 | 0.0005 *** |

| X3X4 | 0.11 | 1 | 0.11 | 1.29 | 0.2755 ns |

| X12 | 178.28 | 1 | 178.28 | 2045.69 | 0.0001 *** |

| X22 | 81.01 | 1 | 81.01 | 929.49 | 0.0001 *** |

| X32 | 113.41 | 1 | 113.41 | 1301.31 | 0.0001 *** |

| X42 | 95.28 | 1 | 95.28 | 1093.29 | 0.0001 *** |

| Lack of Fit | 1.12 | 10 | 0.11 | 4.31 | 0.0860 ns |

| Residual | 1.22 | 14 | 0.087 | - | - |

| Pure Error | 0.1 | 4 | 0.026 | - | - |

| Cor Total | 349.94 | 28 | - | - | - |

| R2 | 0.9965 | - | - | - | - |

| R2adj | 0.9930 | - | - | - | - |

| C.V.% | 0.44 | - | - | - | - |

| CP | CE | CC | April | July | ||

|---|---|---|---|---|---|---|

| AL | YL | AL | YL | |||

| Total flavonoids content | y=0.1793x − 0.0012 | 0.9993 | 74.81 ± 0.91a | 58.17 ± 2.12b | 48.29 ± 1.41c | 34.06 ± 4.02 d |

| Rutin | y =1915.3x + 2.6063 | 0.9988 | 0.85 ± 0.02a | 0.59 ± 0.01c | 0.68 ± 0.01b | 0.43 ± 0.01d |

| Luteolin-4’-O-glucoside | y =256.15x + 7.0455 | 0.9981 | 31.02 ± 0.48a | 19.16 ± 0.37c | 24.20 ± 0.36b | 23.15 ± 0.85b |

| Apigenin-7-O-glucoside | y =2745.8x + 0.1299 | 1.0000 | 2.06 ± 0.04a | 1.00 ± 0.02d | 1.53 ± 0.01b | 1.11 ± 0.01c |

| Luteolin | y =3157.00x − 5.0318 | 0.9997 | 0.16 ± 0.001b | 0.60 ± 0.006a | 0.07 ± 0.0010d | 0.13 ± 0.004c |

| Quercetin | y = 4910.80x − 3.6071 | 0.9989 | nd | 0.0021 ± 0.00004 | nd | 0.0008 ± 0.00004 |

| Apigenin | y = 378228x − 1.0121 | 0.9991 | nd | 0.038 ± 0.0005 | nd | nd |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Qu, J.; Luo, S.; Feng, S.; Li, T.; Yuan, M.; Huang, Y.; Liao, J.; Yang, R.; Ding, C. Optimization of Ultrasound-Assisted Extraction of Flavonoids from Olive (Olea europaea) Leaves, and Evaluation of Their Antioxidant and Anticancer Activities. Molecules 2018, 23, 2513. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules23102513

Wang B, Qu J, Luo S, Feng S, Li T, Yuan M, Huang Y, Liao J, Yang R, Ding C. Optimization of Ultrasound-Assisted Extraction of Flavonoids from Olive (Olea europaea) Leaves, and Evaluation of Their Antioxidant and Anticancer Activities. Molecules. 2018; 23(10):2513. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules23102513

Chicago/Turabian StyleWang, Bixia, Jipeng Qu, Siyuan Luo, Shiling Feng, Tian Li, Ming Yuan, Yan Huang, Jinqiu Liao, Ruiwu Yang, and Chunbang Ding. 2018. "Optimization of Ultrasound-Assisted Extraction of Flavonoids from Olive (Olea europaea) Leaves, and Evaluation of Their Antioxidant and Anticancer Activities" Molecules 23, no. 10: 2513. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules23102513