Management of Fruit Industrial By-Products—A Case Study on Circular Economy Approach

Abstract

:1. Introduction

2. Circular Economy—Essential to the World?

2.1. Global Drivers towards Circular Economy

2.2. Circular Economy

Circular Economy Implementation Levels

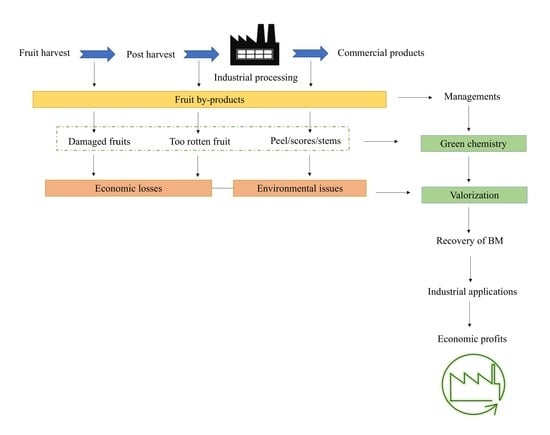

3. Fruit Processing and By-Product Production

3.1. Apple

3.2. Tomato

3.3. Banana

3.4. Mango

3.5. Citrus fruits

3.6. Pineapple

3.7. Grape

3.8. Melon

4. Fruit By-Product Management: Valorisation of the Development of New Value-Added Products

4.1. Added-Value Products and Bioproducts Derived from Fruit By-Products

4.2. Antioxidant Extracts

4.2.1. Phenolic Compounds

4.2.2. Pigments

4.2.3. Dietary Fibre

4.2.4. Essential Oils

4.3. Enzymes

5. Economic and Business Approach

5.1. Case Study: Pineapple Industrialization Approach to the Circular Economy

5.1.1. Micro Level Implementation

5.1.2. Meso Level Implementation

6. Conclusions and Future Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sznida, E. The EU’s Path toward Sustainable Development Goals—Responsible Consumption and Production. SSRN Electron. J. 2018. [Google Scholar] [CrossRef]

- Imbert, E. Food waste valorization options: Opportunities from the bioeconomy. Open Agric. 2017, 2, 195–204. [Google Scholar] [CrossRef]

- Wadhwa, M.; Bakshi, S.P.M. Utilization of Fruit and Vegetable Wastes as Livestock Feed and as Substrates for Generation of Other Value-Added Products; Rap Publication, 4 in FAO: Rome, Italy, 2013. [Google Scholar]

- Banerjee, S.; Ranganathan, V.; Patti, A.; Arora, A. Valorisation of pineapple wastes for food and therapeutic applications. Trends Food Sci. Technol. 2018, 82, 60–70. [Google Scholar] [CrossRef]

- Tadmor, Y.; Burger, J.; Yaakov, I.; Feder, A.; Libhaber, S.E.; Portnoy, V.; Meir, A.; Tzuri, G.; Sa’ar, U.; Rogachev, I.; et al. Genetics of flavonoid, carotenoid, and chlorophyll pigments in melon fruit rinds. J. Agric. Food Chem. 2010, 58, 10722–10728. [Google Scholar] [CrossRef] [PubMed]

- European Environment Agency. Circular Economy in Europe; European Environment Agency: Copenhagen, Denmark, 2016. [Google Scholar]

- Tuck, C.O.; Pérez, E.; Horváth, I.T.; Sheldon, R.A.; Poliakoff, M. Valorization of biomass: Deriving more value from waste. Science 2012, 337, 695–699. [Google Scholar] [CrossRef] [PubMed]

- Johnston, R.B. The 2030 Agenda for sustainable development. In Proceedings of the Sixth International Congress on Arsenic in the Environment (As2016), Stockholm, Sweden, 19–23 June 2016; pp. 12–14. [Google Scholar]

- Anastas, P.T.; Beach, E.S. Green Chemistry: The emergence of a transformative framework. Green Chem. Lett. Rev. 2007, 1.1, 9–24. [Google Scholar] [CrossRef] [Green Version]

- Matharu, A.S.; de Melo, E.M.; Houghton, J.A. Opportunity for high value-added chemicals from food supply chain wastes. Bioresour. Technol. 2016, 215, 123–130. [Google Scholar] [CrossRef]

- Taylor, P. Evaluating land-use suitability of an industrial city in northeast China. Int. J. Sustain. Dev. World Ecol. 2010, 15, 37–41. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- MacArthur, E. Towards the circular economy. Folia Oecol. 2013, 40, 201–205. [Google Scholar]

- Geng, Y.; Côté, R.P. Scavengers and decomposers in an eco-industrial park. Int. J. Sustain. Dev. World Ecol. 2002, 9, 333–340. [Google Scholar] [CrossRef]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring circular economy strategies through index methods: A critical analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Liguori, R.; Faraco, V. Biological processes for advancing lignocellulosic waste biorefinery by advocating circular economy. Bioresour. Technol. 2016, 215, 13–20. [Google Scholar] [CrossRef] [PubMed]

- Winkler, H. Closed-loop production systems—A sustainable supply chain approach. CIRP J. Manuf. Sci. Technol. 2011, 4, 243–246. [Google Scholar] [CrossRef]

- Noronha, J. Scavengers and Decomposers in an Industrial Park System: A Case Study of Burnside Industrial Park. Master’s Thesis, Dalhousie University, Halifax, NS, Canada, 1999. [Google Scholar]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- da Silva, A.C.; Jorge, N. Bioactive compounds of oils extracted from fruits seeds obtained from agroindustrial waste. Eur. J. Lipid Sci. Technol. 2017, 119, 1–5. [Google Scholar] [CrossRef]

- John, I.; Yaragarla, P.; Muthaiah, P.; Ponnusamy, K.; Appusamy, A. Statistical optimization of acid catalyzed steam pretreatment of citrus peel waste for bioethanol production. Resour. Technol. 2017, 3, 429–433. [Google Scholar] [CrossRef]

- Raji, Z.; Khodaiyan, F.; Rezaei, K.; Kiani, H. International Journal of Biological Macromolecules Extraction optimization and physicochemical properties of pectin from melon peel. Int. J. Biol. Macromol. 2017, 98, 709–716. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, A.K. Exploitation of Food Industry Waste for High-Value Products. Trends Biotechnol. 2016, 34, 58–69. [Google Scholar] [CrossRef] [Green Version]

- Ho, K.K.; Ferruzzi, M.G.; Liceaga, A.M.; Martín-González, M.F.S. Microwave-assisted extraction of lycopene in tomato peels: Effect of extraction conditions on all-trans and cis-isomer yields. LWT-Food Sci. Technol. 2015, 62, 160–168. [Google Scholar] [CrossRef]

- Palacios, S.; Ruiz, H.A.; Ramos-Gonzalez, R.; Martínez, J.; Segura, E.; Aguilar, M.; Aguilera, A.; Michelena, G.; Aguilar, C.; Ilyina, A. Comparison of physicochemical pretreatments of banana peels for bioethanol production. Food Sci. Biotechnol. 2017, 26, 993–1001. [Google Scholar] [CrossRef] [PubMed]

- Kareem, S.; Rahman, R. Utilization of banana peels for citric acid production by Aspergillus niger. Agric. Biol. J. N. Am. 2011, 4, 384–387. [Google Scholar] [CrossRef]

- Rojas, R.; Alvarez-Pérez, O.B.; Contreras-Esquivel, J.C.; Vicente, A.; Flores, A.; Sandoval, J.; Aguilar, C.N. Valorisation of Mango Peels: Extraction of Pectin and Antioxidant and Antifungal Polyphenols. Waste Biomass Valorization 2018, 11, 89–98. [Google Scholar] [CrossRef] [Green Version]

- Atef, A.M.; Abou-Zaid, N.; Ibrahim, I.; Ramadan, M.T.; Nadir, A. Quality evaluation of sheets, jam and juice from prickly pear and melon blends. Life Sci. J. 2013, 10, 200–208. [Google Scholar]

- Taghizadeh-alisaraei, A.; Hosseini, S.H.; Ghobadian, B.; Motevali, A. Biofuel production from citrus wastes: A feasibility study in Iran. Renew. Sustain. Energy Rev. 2017, 69, 1100–1112. [Google Scholar] [CrossRef]

- Negro, V.; Mancini, G.; Ruggeri, B.; Fino, D. Bioresource Technology Citrus waste as feedstock for bio-based products recovery: Review on limonene case study and energy valorization. Bioresour. Technol. 2016, 214, 806–815. [Google Scholar] [CrossRef]

- Coelho, D.F.; Silveira, E.; Junior, A.P.; Tambourgi, E.B. Bromelain purification through unconventional aqueous two-phase system (PEG/ammonium sulphate). Bioprocess Biosyst. Eng. 2013, 36, 185–192. [Google Scholar] [CrossRef]

- Campos, D.A.; Coscueta, E.R.; Valetti, N.W.; Pastrana-Castro, L.M.; Teixeira, J.A.; Picó, G.A.; Pintado, M.M. Optimization of bromelain isolation from pineapple byproducts by polysaccharide complex formation. Food Hydrocoll. 2019, 87, 792–804. [Google Scholar] [CrossRef] [Green Version]

- Campos, D.A.; Ribeiro, T.B.; Teixeira, J.A.; Pastrana, L.; Pintado, M.M. Integral valorisation of pineapple (Ananas comosus L.) by-products through a green chemistry approach towards added value ingredients. Foods 2020, 9, 60. [Google Scholar] [CrossRef] [Green Version]

- Deng, Q.; Penner, M.H.; Zhao, Y. Chemical composition of dietary fiber and polyphenols of five different varieties of wine grape pomace skins. Food Res. Int. 2011, 44, 2712–2720. [Google Scholar] [CrossRef]

- Cevallos-Casals, B.A.; Byrne, D.; Okie, W.R.; Cisneros-Zevallos, L. Selecting new peach and plum genotypes rich in phenolic compounds and enhanced functional properties. Food Chem. 2006, 96, 273–280. [Google Scholar] [CrossRef]

- Costa, J.R.; Amorim, M.; Vilas-Boas, A.; Tonon, R.V.; Cabral, L.M.; Pastrana, L.; Pintado, M. Impact of: In vitro gastrointestinal digestion on the chemical composition, bioactive properties, and cytotoxicity of Vitis vinifera L. cv. Syrah grape pomace extract. Food Funct. 2019, 10, 1856–1869. [Google Scholar] [CrossRef] [PubMed]

- Vishwakarma, V.K.; Gupta, J.K.; Upadhyay, P.K. Pharmacological importance of Cucumis melo L.: An overview. Asian J. Pharm. Clin. Res. 2017, 10, 8–12. [Google Scholar] [CrossRef]

- Fundo, J.F.; Miller, F.A.; Garcia, E.; Santos, J.R.; Silva, C.L.M.; Brandão, T.R.S. Physicochemical characteristics, bioactive compounds and antioxidant activity in juice, pulp, peel and seeds of Cantaloupe melon. J. Food Meas. Charact. 2018, 12, 292–300. [Google Scholar] [CrossRef]

- Mallek-Ayadi, S.; Bahloul, N.; Kechaou, N. Chemical composition and bioactive compounds of Cucumis melo L. seeds: Potential source for new trends of plant oils. Process Saf. Environ. Prot. 2018, 113, 68–77. [Google Scholar] [CrossRef]

- Gagaoua, M.; Hoggas, N.; Hafid, K. Three phase partitioning of zingibain, a milk-clotting enzyme from Zingiber officinale Roscoe rhizomes. Int. J. Biol. Macromol. 2015, 73, 245–252. [Google Scholar] [CrossRef]

- Gagaoua, M.; Ziane, F.; Rabah, S.N.; Boucherba, N.; El, A.A.; Bouanane-Darenfed, A.; Hafid, K. Three phase partitioning, a scalable method for the purification and recovery of cucumisin, a milk-clotting enzyme, from the juice of Cucumis melo var. reticulatus. Int. J. Biol. Macromol. 2017, 102, 515–525. [Google Scholar] [CrossRef]

- Serna, L.V.D.; Toro, J.C.S.; Loaiza, S.S.; Perez, Y.C.; Alzate, C.A.C. Agricultural Waste Management Through Energy Producing Biorefineries: The Colombian Case. Waste Biomass Valorization 2016, 7, 789–798. [Google Scholar] [CrossRef]

- Torres-León, C.; Ramirez, N.; Londoño, L.; Martinez, G.; Diaz, R.; Navarro, V.; Alvarez-Pérez, O.B.; Picazo, B.; Villarreal, M.; Ascacio, J.; et al. Food waste and byproducts: An opportunity to minimize malnutrition and hunger in developing countries. Front. Sustain. Food Syst. 2018, 2, 52. [Google Scholar]

- Dey, T.B.; Chakraborty, S.; Jain, K.K.; Sharma, A.; Kuhad, R.C. Antioxidant phenolics and their microbial production by submerged and solid state fermentation process: A review. Trends Food Sci. Technol. 2016, 53, 60–74. [Google Scholar]

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef] [Green Version]

- Savatovi, S.M.; Gordana, S.Ć.; Jasna, M.Č. Utilisation of tomato waste as a source of polyphenolic. Acta Period. Technol. 2010, 203, 187–194. [Google Scholar] [CrossRef]

- Forgács, G.; Pourbafrani, M.; Niklasson, C.; Taherzadeh, M.J.; Hováth, I.S. Methane production from citrus wastes: Process development and cost estimation. J. Chem. Technol. Biotechnol. 2012, 87, 250–255. [Google Scholar] [CrossRef]

- Martínez-ávila, G.C.; Aguilera-carbó, A.F.; Rodríguez-herrera, R. Fungal enhancement of the antioxidant properties of grape waste. Ann. Microbiol. 2012, 62, 923–930. [Google Scholar] [CrossRef]

- Larios, R.; Juan, C.; Figueroa, B.; Prado, A.; Rosa, B.; Jasso, M.R. Valorization of Grapefruit By-Products as Solid Support for Solid-State Fermentation to Produce Antioxidant Bioactive Extracts. Waste Biomass Valorization 2019, 10, 763–769. [Google Scholar] [CrossRef]

- John, I.; Muthukumar, K.; Arunagiri, A.; John, I. A review on the potential of citrus waste for D- Limonene, pectin, and bioethanol production. Int. J. Green Energy 2017, 14, 599–612. [Google Scholar] [CrossRef]

- Silva, J.D.; de França, P.R.L.; Porto, T.S. Optimized extraction of polygalacturonase from Aspergillus aculeatus URM4953 by aqueous two-phase systems PEG/Citrate. J. Mol. Liq. 2018, 263, 81–88. [Google Scholar] [CrossRef]

- Bonesi, M.; Saab, A.M.; Tenuta, M.C.; Leporini, M.; Saab, M.J.; Loizzo, M.R.; Tundis, R. Screening of traditional Lebanese medicinal plants as antioxidants and inhibitors of key enzymes linked to type 2 diabetes. Plant Biosyst. 2019. [Google Scholar] [CrossRef]

- Górnaś, P.; Rudzińska, M. Seeds recovered from industry by-products of nine fruit species with a high potential utility as a source of unconventional oil for biodiesel and cosmetic and pharmaceutical sectors. Ind. Crop. Prod. 2016, 83, 329–338. [Google Scholar] [CrossRef]

- Morais, D.R.; Rotta, E.M.; Sargi, S.C.; Schmidt, E.M.; Bonafe, E.G.; Eberlin, M.N.; Sawaya, A.C.; Visentainer, J.V. Antioxidant activity, phenolics and UPLC-ESI(-)-MS of extracts from different tropical fruits parts and processed peels. Food Res. Int. 2015, 77, 392–399. [Google Scholar] [CrossRef]

- Sepúlveda, L.; Aguilera-Carbó, A.; Ascacio-Valdés, J.A.; Rodríguez-Herrera, R.; Martínez-Hernández, J.L.; Aguilar, C.N. Optimization of ellagic acid accumulation by Aspergillus niger GH1 in solid state culture using pomegranate shell powder as a support. Process Biochem. 2012, 47, 2199–2203. [Google Scholar] [CrossRef]

- Da Silva, L.M.R.; De Figueiredo, E.A.T.; Ricardo, N.M.P.S.; Vieira, I.G.P.; De Figueiredo, R.W.; Brasil, I.M.; Gomes, C.L. Quantification of bioactive compounds in pulps and by-products of tropical fruits from Brazil. Food Chem. 2014, 143, 398–404. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nunes, M.A.; Costa, A.S.; Bessada, S.; Santos, J.; Puga, H.; Alves, R.C.; Freitas, V.; Oliveira, M.B.P. Olive pomace as a valuable source of bioactive compounds: A study regarding its lipid- and water-soluble components. Sci. Total Environ. 2018, 644, 229–236. [Google Scholar] [CrossRef] [PubMed]

- Carocho, M.; Morales, P.; Ferreira, I.C.F.R. Antioxidants: Reviewing the chemistry, food applications, legislation and role as preservatives. Trends Food Sci. Technol. 2018, 71, 107–120. [Google Scholar] [CrossRef] [Green Version]

- Faustino, M.; Veiga, M.; Sousa, P.; Costa, E.M.; Silva, S.; Pintado, M. Agro-food byproducts as a new source of natural food additives. Molecules 2019, 24, 1056. [Google Scholar] [CrossRef] [Green Version]

- Munene, C.N. Analysis of Consumer Attitudes and Their Willingness to Pay for Functional Foods. Master’s Thesis, Louisiana State University, Baton Rouge, LA, USA, 2006. [Google Scholar]

- Balasundram, N.; Sundram, K.; Samman, S. Phenolic compounds in plants and agri-industrial by-products: Antioxidant activity, occurrence, and potential uses. Food Chem. 2006, 99, 191–203. [Google Scholar] [CrossRef]

- Rice-Evans, C.A.; Miller, N.J.; Paganga, G. Structure-antioxidant activity relationships of flavonoids and phenolic acids. Free Radic. Biol. Med. 1996, 20, 933–956. [Google Scholar] [CrossRef]

- Altunkaya, A.; Hedegaard, R.V.; Harholt, J.; Brimer, L.; Gökmen, V.; Skibsted, L.H. Palatability and chemical safety of apple juice fortified with pomegranate peel extract. Food Funct. 2013, 4, 1468–1473. [Google Scholar] [CrossRef]

- Adiamo, O.Q.; Ghafoor, K.; Al-Juhaimi, F.; Babiker, E.E.; Ahmed, I.A.M. Thermosonication process for optimal functional properties in carrot juice containing orange peel and pulp extracts. Food Chem. 2018, 245, 79–88. [Google Scholar] [CrossRef]

- Kulichová, J.; Buaong, M.; Balík, J.; Híc, P.; Tříska, J.; Vrchotová, N. Juices enriched with phenolic extracts from grapes. Czech J. Food Sci. 2018, 36, 261–267. [Google Scholar] [CrossRef] [Green Version]

- Larrosa, M.; Llorach, R.; Carlos, J.; Toma, F.A. Increase of antioxidant activity of tomato juice upon functionalisation with vegetable byproduct extracts. LWT-Food Sci. Technol. 2002, 542, 532–542. [Google Scholar] [CrossRef]

- Roldán, E.; Sánchez-Moreno, C.; de Ancos, B.; Cano, M.P. Characterisation of onion (Allium cepa L.) by-products as food ingredients with antioxidant and antibrowning properties. Food Chem. 2008, 108, 907–916. [Google Scholar] [CrossRef]

- Villarreal, M.A.P. Revalorization of Waste Grape Skins from Juice Industry as a New Enological Product in the Doctoral Program of Enology. Ph.D. Thesis, University of Castilla-La Mancha, Albacete, Spain, 2012. [Google Scholar]

- Boo, H.O.; Hwang, S.J.; Bae, C.S.; Park, S.H.; Heo, B.G.; Gorinstein, S. Extraction and characterization of some natural plant pigments. Ind. Crop. Prod. 2012, 40, 129–135. [Google Scholar] [CrossRef]

- Taghvaei, M.; Jafari, S.M. Application and stability of natural antioxidants in edible oils in order to substitute synthetic additives. J. Food Sci. Technol. 2015, 52, 1272–1282. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, D.; Yan, J.; Tang, P.; Li, S.; Xu, K.; Li, H. Binding properties and structure-affinity relationships of food antioxidant butylated hydroxyanisole and its metabolites with lysozyme. Food Chem. 2015, 188, 370–376. [Google Scholar] [CrossRef]

- Williams, G.M.; Iatropoulos, M.J.; Whysner, J. Safety assessment of butylated hydroxyanisole and butylated hydroxytoluene as antioxidant food additives. Food Chem. Toxicol. 1999, 37, 1027–1038. [Google Scholar] [CrossRef]

- Trigo, J.P.; Alexandre, E.M.C.; Saraiva, J.A.; Pintado, M.E. High value-added compounds from fruit and vegetable by-products—Characterization, bioactivities, and application in the development of novel food products. Crit. Rev. Food Sci. Nutr. 2019. [Google Scholar] [CrossRef]

- Pathak, D.; Majumdar, J.; Raychaudhuri, U.; Chakraborty, R. Characterization of physicochemical properties in whole wheat bread after incorporation of ripe mango peel. J. Food Meas. Charact. 2016, 10, 554–561. [Google Scholar] [CrossRef]

- Maner, S.; Sharma, A.K.; Banerjee, K. Wheat Flour Replacement by Wine Grape Pomace Powder Positively Affects Physical, Functional and Sensory Properties of Cookies. Proc. Natl. Acad. Sci. India Sect. B-Biol. Sci. 2017, 87, 109–113. [Google Scholar] [CrossRef]

- Martins, S.; Mussatto, S.I.; Martínez-Avila, G.; Montañez-Saenz, J.; Aguilar, C.N.; Teixeira, J.A. Bioactive phenolic compounds: Production and extraction by solid-state fermentation: A review. Biotechnol. Adv. 2011, 29, 365–373. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Silva, M.A.; Albuquerque, T.G.; Alves, R.C.; Oliveira, M.B.P.P.; Costa, H.S. Melon (Cucumis melo L.) by-products: Potential food ingredients for novel functional foods? Trends Food Sci. Technol. 2018. [Google Scholar] [CrossRef]

- McGhie, T.K.; Hunt, M.; Barnett, L.E. Cultivar and growing region determine the antioxidant polyphenolic concentration and composition of apples grown in New Zealand. J. Agric. Food Chem. 2005, 53, 3065–3070. [Google Scholar] [CrossRef] [PubMed]

- Peixoto, C.M.; Dias, M.I.; Alves, M.J.; Calhelha, R.C.; Barros, L.; Pinho, S.P.; Ferreira, I.C. Grape pomace as a source of phenolic compounds and diverse bioactive properties. Food Chem. 2018, 253, 132–138. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khan, M.K.; Abert-Vian, M.; Fabiano-Tixier, A.S.; Dangles, O.; Chemat, F. Ultrasound-assisted extraction of polyphenols (flavanone glycosides) from orange (Citrus sinensis L.) peel. Food Chem. 2010, 119, 851–858. [Google Scholar] [CrossRef]

- Laur, L.M.; Tian, L. Provitamin A and vitamin C contents in selected California-grown cantaloupe and honeydew melons and imported melons. J. Food Compos. Anal. 2011, 24, 194–201. [Google Scholar] [CrossRef]

- Tanumihardjo, S.A. Carotenoids and Human Health; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Fernandes, I.; Faria, A.; Calhau, C.; de Freitas, V.; Mateus, N. Bioavailability of anthocyanins and derivatives. J. Funct. Foods 2014, 7, 54–66. [Google Scholar] [CrossRef]

- Norberto, S.; Silva, S.; Meireles, M.; Faria, A.; Pintado, M.; Calhau, C. Blueberry anthocyanins in health promotion: A metabolic overview. J. Funct. Foods 2013, 5, 1518–1528. [Google Scholar] [CrossRef]

- Mateus, N.; Freitas, V. Anthocyanins as food colorants; Springer: New York, NY, USA, 2008. [Google Scholar]

- Macagnan, F.T.; dos Santos, L.R.; Roberto, B.S.; de Moura, F.A.; Bizzani, M.; da Silva, L.P. Biological properties of apple pomace, Orange bagasse and passion fruit peel as alternative sources of dietary fibre. Bioact. Carbohydr. Diet. Fibre 2015, 6, 1–6. [Google Scholar] [CrossRef]

- Quiles, A.; Campbell, G.M.; Struck, S.; Rohm, H.; Hernando, I. Fiber from fruit pomace: A review of applications in cereal-based products. Food Rev. Int. 2018, 34, 162–181. [Google Scholar] [CrossRef]

- Vidal, S.; Williams, P.; O’Neill, M.A.; Pellerin, P. Polysaccharides from grape berry cell walls. Part I: Tissue distribution and structural characterization of the pectic polysaccharides. Carbohydr. Polym. 2001, 45, 315–323. [Google Scholar] [CrossRef]

- Al-Sayed, H.M.A.; Ahmed, A.R. Utilization of watermelon rinds and sharlyn melon peels as a natural source of dietary fiber and antioxidants in cake. Ann. Agric. Sci. 2013, 58, 83–95. [Google Scholar] [CrossRef] [Green Version]

- Bakkali, F.; Averbeck, S.; Averbeck, D.; Idaomar, M. Biological effects of essential oils—A review. Food Chem. Toxicol. 2008, 46, 446–475. [Google Scholar] [CrossRef] [PubMed]

- Burt, S. Essential oils: Their antibacterial properties and potential applications in foods—A review. Int. J. Food Microbiol. 2004, 94, 223–253. [Google Scholar] [CrossRef]

- Smith-Palmer, A.; Stewart, J.; Fyfe, L. The potential application of plant essential oils as natural food preservatives in soft cheese. Food Microbiol. 2001, 18, 463–470. [Google Scholar] [CrossRef]

- Pateiro, M.; Barba, F.J.; Domínguez, R.; Sant’Ana, A.S.; Khaneghah, A.M.; Gavahian, M.; Gómez, B.; Lorenzo, J.M. Essential oils as natural additives to prevent oxidation reactions in meat and meat products: A review. Food Res. Int. 2018, 113, 156–166. [Google Scholar] [CrossRef]

- Javed, S.; Javaid, A.; Mahmood, Z.; Javaid, A.; Nasim, F. Biocidal activity of citrus peel essential oils against some food spoilage bacteria. J. Med. Plants Res. 2011, 5, 3697–3701. [Google Scholar]

- Choi, J.M.; Han, S.S.; Kim, H.S. Industrial applications of enzyme biocatalysis: Current status and future aspects. Biotechnol. Adv. 2015, 33, 1443–1454. [Google Scholar] [CrossRef]

- Campos, D.A.; Valetti, N.W.; Oliveira, A.; Pastrana-Castro, L.M.; Teixeira, J.A.; Pintado, M.M.; Picó, G. Platform design for extraction and isolation of Bromelain: Complex formation and precipitation with carrageenan. Process Biochem. 2017, 54, 156–161. [Google Scholar] [CrossRef] [Green Version]

- Hedayati, G.; Ani, A.M. Optimization of proteolytical activity of melon juice concentrate using response surface methodology (RSM). Agro Food Ind. Technol. 2015, 26, 66–71. [Google Scholar]

- Ascacio-valdés, J.A.; Buenrostro, J.J.; de Cruz, R.; Sepúlveda, L. Fungal biodegradation of pomegranate ellagitannins. J. Basic Microbiol. 2014, 54, 28–34. [Google Scholar] [CrossRef] [PubMed]

- Niinimaki, K. Sustainable Fashion in a Circular Economy; Aalto University: Espoo, Finland, 2018; p. 253. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). Food Wastage Footprint; FAO: Rome, Italy, 2013. [Google Scholar]

- Seguí, L.G.; Maupoey, P.F. An integrated approach for pineapple waste valorisation. Bioethanol production and bromelain extraction from pineapple residues. J. Clean. Prod. 2018, 172, 1224–1231. [Google Scholar] [CrossRef]

| Source | By-Product | Value-Added Product | Industry | Reference |

|---|---|---|---|---|

| Sweet lime | Peel | Bioethanol and enzymes | Biofuel | [22] |

| Melon | Peel | Pectin | Cosmetic and pharmaceutical | [23] |

| Tomato | Peel | Lycopene | Pharmaceutical | [25] |

| Banana | Peel | Bioethanol | Biofuel | [26] |

| Pear | Sheets | Fiber, minerals and vitamins | Food suppliers | [29] |

| Pineapple | Stem, barks and leaves | Enzyme (bromelain) | Meat and pharmaceutical | [32] |

| Pineapple | Peel and core | Enzyme (bromelain) | Meat and pharmaceutical | [33] |

| Grape | Pomace skin | Fiber and antioxidant | Food suppliers | [35] |

| Peach and plum | Bagasse | Antioxidants | Nutraceutical | [36] |

| Melon | Peel and seeds | Antioxidants | Nutraceutical | [39] |

| Melon | seeds | Essential oils | Food suppliers | [40] |

| Melon | Pulp | Enzyme (cucumisin) | Dairy | [42] |

| Fruit | By-Product | Methodology | Bioproducts | Reference |

|---|---|---|---|---|

| Banana | Peel | SSF by Aspergillus niger | Citric acid | [27] |

| Mango | Peel | Autoclave | Pectin and polyphenols | [28] |

| Tomato | Bagasse | Ultrasonic bath and high-performance homogenizer | Polyphenolic Antioxidants | [47] |

| Orange | Peel | Steam explosion | Limonene | [48] |

| Grape | Skin | SSF | Polyphenolic antioxidants | [49] |

| Grape | Bagasse | SSF | Polyphenolic antioxidants | [50] |

| Orange | Peel | Enzymatic and chemical hydrolysis | Pectin and Limonene | [51] |

| Passion fruit | Peel flour | Aqueous two phases systems | Polygalacturonase | [52] |

| Melon | Seeds | Extraction with n-hexane | Antioxidant oils | [53] |

| Watermelon | Seeds | Ultrasound treatment | Fatty acids, tocopherols | [54] |

| Avocado | Peel | Ethanolic extraction | Phenolic antioxidants | [55] |

| Pomegranate | Husk | SSF | Ellagic acid | [56] |

| Papaya | Peel | Extraction with n-hexane | Carotenoids, anthocyanins | [57] |

| Olive | Pomace | Multi-frequency Multimode Modulated ultrasonic | Phenolic antioxidants | [58] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Campos, D.A.; Gómez-García, R.; Vilas-Boas, A.A.; Madureira, A.R.; Pintado, M.M. Management of Fruit Industrial By-Products—A Case Study on Circular Economy Approach. Molecules 2020, 25, 320. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25020320

Campos DA, Gómez-García R, Vilas-Boas AA, Madureira AR, Pintado MM. Management of Fruit Industrial By-Products—A Case Study on Circular Economy Approach. Molecules. 2020; 25(2):320. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25020320

Chicago/Turabian StyleCampos, Débora A., Ricardo Gómez-García, Ana A. Vilas-Boas, Ana Raquel Madureira, and Maria Manuela Pintado. 2020. "Management of Fruit Industrial By-Products—A Case Study on Circular Economy Approach" Molecules 25, no. 2: 320. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25020320