Recent Advances in Microfluidic Paper-Based Analytical Devices toward High-Throughput Screening

Abstract

:1. Introduction

2. Fabrication of µPADs

2.1. Paper-Based Dontinuous-Flow Microfluidics Devices

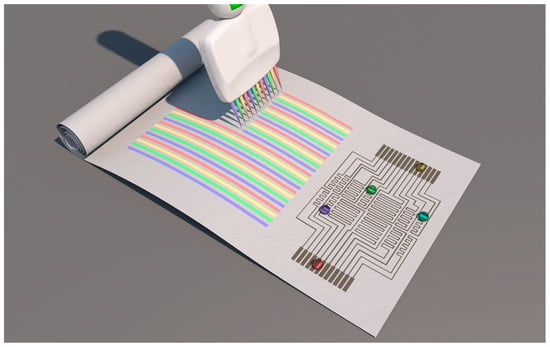

2.1.1. Methods for Rapid Fabrication

2.1.2. Integrated Functionalities

2.1.3. Reproducibility and Mass Production

2.2. Paper-Based Digital Microfluidic Devices

3. Detection Techniques

3.1. Colorimetric Technique

3.2. Electrochemical Detection

3.3. Chemiluminescence Detection

3.4. Electrochemiluminescence Detection

4. Applications of µPADs

4.1. µPADs for Nucleic Acid Amplification and Detection

4.2. µPADs for Detection of Bacterial Infection

4.3. µPADs for Drug Screening

4.4. µPADs for Environmental Monitoring

| Analyte | Sample Type | Detection Method | Detection Limit | Ref. |

|---|---|---|---|---|

| Clinical diagnostics | ||||

| Glucose Dopamine Uric acid | Human serum | Electrochemical | 0.05 mM 0.5 µM 5.0 µM | [78] |

| Ebola virus (three distinct RNA sequences) | Blood | Colorimetric | 107 copies/µL | [178] |

| Helicobacter pylori (bacteria) Hepatitis B Human Immunoglobulin G. | Colorimetric | 30 µg/mL 3 µg/mL 300 ng/mL | [191] | |

| DNA targets | Blood | Colorimetric | 102 copies | [192] |

| Lactate Glucose Uric acid | Not specified | Colorimetric Electrochemical | 190 µM 0.18 mM 0.11 mM | [160] |

| N. meningitides genomic DNA arrays | Not specified | Colorimetric | 4.4 nM | [193] |

| Hydrogen peroxide Glucose | Serum Urine Wine | Electrochemiluminescence | 0.041 mM 0.03 mM | [154] |

| Glucose | Not specified | Colorimetric | Not specified | [135] |

| Glucose Creatinine Uric acid | Urine | Electrochemical | 0.12 mM 0.084 mM 0.012 mM | [138] |

| Carcinoembryonic antigens (CEA) Carcinoma antigen 125 (CA-125) Alpha-fetoprotein (AFP) | Human serum | Chemiluminescence | 0.1 ng/mL | [183] |

| Carcinoembryonic antigen (CEA) Neuronspecific enolase (NSE) | Serum | Electrochemical | 2 pg/mL 10 pg/mL | [136] |

| Copeptin, Heart-type fatty-acid-binding protein (h-FABP) Cardiac troponin I (cTnI) | Human serum | Chemiluminescence | 0.40 pg/mL 0.32 pg/mL 0.50 pg/mL | [145] |

| Glucose | Urine | Electrochemical | 0.03 mM | [137] |

| Norepinephrine (NE) Serotonin P-aminophenol (pAP) | Not specified | Electrochemical | 1.2 µM 1.2 µM 0.38 µM | [139] |

| Copeptin Heart-type fatty-acid-binding protein (h-FABP), Cardiac troponin I (cTnI) | Human serum | Chemiluminescence | 0.40 pg/mL 0.32 pg/mL 0.50 pg/mL | [145] |

| Acinetobacter baumannii Escherichia coli Staphylococcus aureus | Bacterial cells | Colorimetric | 103 CFU/µL 104 CFU/µL 105 CFU/µL | [184] |

| Carcinoembryonic antigen (CEA) Prostate-specific antigen (PSA) | Human serum | Electrochemiluminescence | 0.07 ng/ML 0.03 ng/mL | [152] |

| Glucose Creatinine Uric acid | Urine | Electrochemical | 0.12 mM 0.084 mM 0.012 mM | [138] |

| Glucose Lactate | Serum | Colorimetric | 0.31 mM 0.29 mM | [159] |

| Drug analysis and screening | ||||

| Cycloheximide Etoposide Camptothecin | Cell apoptosis | Electrochemical | 12.5 µM 12.5 µM 1.5 µM | [184] |

| Doxorubicin (DOX) | Anticancer drug | Colorimetric | 4 µg/mL | [128] |

| Cocaine Morphine Methamphetamine | Blood | Colorimetric | 37.5 ng/mL | [26] |

| Paracetamol (PAR) Caffeine (CAF) Ascorbic acid (AA) | Drug | Electrochemical | 0.04 mM 0.22 mM 0.40 mM | [25] |

| Ascorbic acid Glucose Nitrite | Beverages | Colorimetric | 1.47 µM 20 mM 0.06 mM | [15] |

| Environmental monitoring | ||||

| Co Cu Fe Mn Cr Ni | Airborne PM | Colorimetric | 8.16 ng 45.84 ng 0.0186 ng 10.08 ng 0.0152 ng 80.40 ng | [158] |

| Ni(II) Cu(II) Cr(VI) | Lake water | Colorimetric | 4.8 mg/L 1.6 mg/L 0.18 mg/L | [189] |

| Lead (Pb) Barium (Ba) Antimony (Sb) Zinc (Zn) Aluminum (Al) Iron (Fe) Magnesium (Mg) | Water | Colorimetric | 250 ppm 250 ppm 250 ppm 25 ppm 250 ppm 400 ppm 250 ppm | [190] |

| Methyl paraoxon | Not specified | Colorimetric | 10 µM | [82] |

| Food and beverage analysis | ||||

| Ascorbic acid Glucose Nitrite | Beverages | Colorimetric | 1.47 µM 20 mM 0.06 mM | [15] |

| β agonist | Swine hair | Chemiluminescence | 1.0 nM | [194] |

5. Conclusions and Future Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Tarn, M.D.; Pamme, N. Microfluidics. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering; Elsevier Inc.: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Picó, Y. Chemical Analysis of Food: Techniques and Applications; Academic Press: San Diego, CA, USA, 2012. [Google Scholar] [CrossRef]

- Terry, S.C.; Jerman, J.H.; Angell, J.B. A gas chromatographic air analyzer fabricated on a silicon wafer. IEEE Trans. Electron Devices 1979, 26, 1880–1886. [Google Scholar] [CrossRef]

- Song, Y.; Cheng, D.; Zhao, L.; Lei, K.F. Introduction: The Origin, Current Status, and Future of Microfluidics. In Microfluidics: Fundamental, Devices and Applications; Wiley-VCH: Weinheim, Germany, 2018; pp. 1–18. [Google Scholar]

- Castaño-Álvarez, M.; Pozo-Ayuso, D.F.; Fernández-la-Villa, A. Integrated microfluidic electrochemical sensors to enhance automated flow analysis systems. In Laboratory Methods in Dynamic Electroanalysis; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 161–170. [Google Scholar]

- Martinez, A.W.; Phillips, S.T.; Butte, M.J.; Whitesides, G.M. Patterned Paper as a Platform for Inexpensive, Low-Volume, Portable Bioassays. Angew. Chem. Int. Ed. 2007, 46, 1318–1320. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruecha, N.; Rangkupan, R.; Rodthongkum, N.; Chailapakul, O. Novel paper-based cholesterol biosensor using graphene/polyvinylpyrrolidone/polyaniline nanocomposite. Biosens. Bioelectron. 2014, 52, 13–19. [Google Scholar] [CrossRef]

- Ruecha, N.; Shin, K.; Chailapakul, O.; Rodthongkum, N. Label-free paper-based electrochemical impedance immunosensor for human interferon gamma detection. Sens. Actuators B Chem. 2019, 279, 298–304. [Google Scholar] [CrossRef]

- Boobphahom, S.; Ruecha, N.; Rodthongkum, N.; Chailapakul, O.; Remcho, V.T. A copper oxide-ionic liquid/reduced graphene oxide composite sensor enabled by digital dispensing: Non-enzymatic paper-based microfluidic determination of creatinine in human blood serum. Anal. Chim. Acta 2019, 1083, 110–118. [Google Scholar] [CrossRef] [PubMed]

- Jampasa, S.; Lae-ngee, P.; Patarakul, K.; Ngamrojanavanich, N.; Chailapakul, O.; Rodthongkum, N. Electrochemical immunosensor based on gold-labeled monoclonal anti-LipL32 for leptospirosis diagnosis. Biosens. Bioelectron. 2019, 142, 111539. [Google Scholar] [CrossRef]

- Ruecha, N.; Rodthongkum, N.; Cate, D.M.; Volckens, J.; Chailapakul, O.; Henry, C.S. Sensitive electrochemical sensor using a graphene–polyaniline nanocomposite for simultaneous detection of Zn (II), Cd (II), and Pb (II). Anal. Chim. Acta 2015, 874, 40–48. [Google Scholar] [CrossRef]

- Karita, S.; Kaneta, T. Acid–Base Titrations Using Microfluidic Paper-Based Analytical Devices. Anal. Chem. 2014, 86, 12108–12114. [Google Scholar] [CrossRef]

- Karita, S.; Kaneta, T. Chelate titrations of Ca2+ and Mg2+ using microfluidic paper-based analytical devices. Anal. Chim. Acta 2016, 924, 60–67. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zuo, P.; Ye, B.-C. A low-cost and simple paper-based microfluidic device for simultaneous multiplex determination of different types of chemical contaminants in food. Biosens. Bioelectron. 2015, 68, 14–19. [Google Scholar] [CrossRef]

- Prasad, A.; Tran, T.; Gartia, M.R. Multiplexed Paper Microfluidics for Titration and Detection of Ingredients in Beverages. Sensors 2019, 19, 1286. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Busa, L.S.A.; Mohammadi, S.; Maeki, M.; Ishida, A.; Tani, H.; Tokeshi, M. Advances in Microfluidic Paper-Based Analytical Devices for Food and Water Analysis. Micromachines 2016, 7, 86. [Google Scholar] [CrossRef] [PubMed]

- Moon, H.; Cho, S.K.; Garrell, R.L.; Kim, C.-J.C. Low voltage electrowetting-on-dielectric. J. Appl. Phys. 2002, 92, 4080–4087. [Google Scholar] [CrossRef]

- Ko, H.; Lee, J.; Kim, Y.; Lee, B.; Jung, C.-H.; Choi, J.-H.; Kwon, O.-S.; Shin, K. Active Digital Microfluidic Paper Chips with Inkjet-Printed Patterned Electrodes. Adv. Mater. 2014, 26, 2335–2340. [Google Scholar] [CrossRef]

- Fobel, R.; Kirby, A.E.; Ng, A.H.; Farnood, R.R.; Wheeler, A.R. Paper microfluidics goes digital. Adv. Mater. 2014, 26, 2838–2843. [Google Scholar] [CrossRef]

- Yamada, K.; Shibata, H.; Suzuki, K.; Citterio, D. Toward practical application of paper-based microfluidics for medical diagnostics: State-of-the-art and challenges. Lab Chip 2017, 17, 1206–1249. [Google Scholar] [CrossRef]

- Noviana, E.; McCord, C.P.; Clark, K.M.; Jang, I.; Henry, C.S. Electrochemical paper-based devices: Sensing approaches and progress toward practical applications. Lab Chip 2020, 20, 9–34. [Google Scholar] [CrossRef]

- Rodriguez, N.M.; Wong, W.S.; Liu, L.; Dewar, R.; Klapperich, C.M. A fully integrated paperfluidic molecular diagnostic chip for the extraction, amplification, and detection of nucleic acids from clinical samples. Lab A Chip 2016, 16, 753–763. [Google Scholar] [CrossRef]

- Horst, A.L.; Rosenbohm, J.M.; Kolluri, N.; Hardick, J.; Gaydos, C.A.; Cabodi, M.; Klapperich, C.M.; Linnes, J.C. A paperfluidic platform to detect Neisseria gonorrhoeae in clinical samples. Biomed. Microdevices 2018, 20, 35. [Google Scholar] [CrossRef] [Green Version]

- Alkasir, R.S.J.; Ornatska, M.; Andreescu, S. Colorimetric Paper Bioassay for the Detection of Phenolic Compounds. Anal. Chem. 2012, 84, 9729–9737. [Google Scholar] [CrossRef]

- de Oliveira, T.R.; Fonseca, W.T.; de Oliveira Setti, G.; Faria, R.C. Fast and flexible strategy to produce electrochemical paper-based analytical devices using a craft cutter printer to create wax barrier and screen-printed electrodes. Talanta 2019, 195, 480–489. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Zhang, W.; Yang, J.; Hu, B.; Cao, F.; Zheng, W.; Chen, Y.; Jiang, X. Skiving stacked sheets of paper into test paper for rapid and multiplexed assay. Sci. Adv. 2017, 3, eaao4862. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gale, B.K.; Jafek, A.R.; Lambert, C.J.; Goenner, B.L.; Moghimifam, H.; Nze, U.C.; Kamarapu, S.K. A review of current methods in microfluidic device fabrication and future commercialization prospects. Inventions 2018, 3, 60. [Google Scholar] [CrossRef] [Green Version]

- Cate, D.M.; Adkins, J.A.; Mettakoonpitak, J.; Henry, C.S. Recent Developments in Paper-Based Microfluidic Devices. Anal. Chem. 2015, 87, 19–41. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Si, J.; Li, Z. Fabrication techniques for microfluidic paper-based analytical devices and their applications for biological testing: A review. Biosens. Bioelectron. 2016, 77, 774–789. [Google Scholar] [CrossRef]

- Lim, H.; Jafry, A.T.; Lee, J. Fabrication, flow control, and applications of microfluidic paper-based analytical devices. Molecules 2019, 24, 2869. [Google Scholar] [CrossRef] [Green Version]

- Soum, V.; Park, S.; Brilian, I.A.; Kwon, O.-S.; Shin, K. Programmable Paper-Based Microfluidic Devices for Biomarker Detections. Micromachines 2019, 10, 516. [Google Scholar] [CrossRef] [Green Version]

- Jang, I.; Berg, K.E.; Henry, C.S. Viscosity measurements utilizing a fast-flow microfluidic paper-based device. Sens. Actuators B Chem. 2020, 319, 128240. [Google Scholar] [CrossRef]

- Altundemir, S.; Uguz, A.K.; Ulgen, K. A review on wax printed microfluidic paper-based devices for international health. Biomicrofluidics 2017, 11. [Google Scholar] [CrossRef]

- Weng, C.-H.; Chen, M.-Y.; Shen, C.-H.; Yang, R.-J. Colored wax-printed timers for two-dimensional and three-dimensional assays on paper-based devices. Biomicrofluidics 2014, 8, 066502. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Shi, W.; Qin, J.; Lin, B. Fabrication and Characterization of Paper-Based Microfluidics Prepared in Nitrocellulose Membrane by Wax Printing. Anal. Chem. 2010, 82, 329–335. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, W.; Zheng, W.; Cao, F.; Jiang, X. Inkjet-printed barcodes for a rapid and multiplexed paper-based assay compatible with mobile devices. Lab Chip 2017, 17, 3874–3882. [Google Scholar] [CrossRef] [PubMed]

- Shibata, H.; Hiruta, Y.; Citterio, D. Fully inkjet-printed distance-based paper microfluidic devices for colorimetric calcium determination using ion-selective optodes. Analyst 2019, 144, 1178–1186. [Google Scholar] [CrossRef]

- Henares, T.G.; Yamada, K.; Takaki, S.; Suzuki, K.; Citterio, D. “Drop-slip” bulk sample flow on fully inkjet-printed microfluidic paper-based analytical device. Sens. Actuators B Chem. 2017, 244, 1129–1137. [Google Scholar] [CrossRef]

- Asano, H.; Shiraishi, Y. Development of paper-based microfluidic analytical device for iron assay using photomask printed with 3D printer for fabrication of hydrophilic and hydrophobic zones on paper by photolithography. Anal. Chim. Acta 2015, 883, 55–60. [Google Scholar] [CrossRef] [PubMed]

- Dungchai, W.; Chailapakul, O.; Henry, C.S. Electrochemical Detection for Paper-Based Microfluidics. Anal. Chem. 2009, 81, 5821–5826. [Google Scholar] [CrossRef] [PubMed]

- Olkkonen, J.; Lehtinen, K.; Erho, T. Flexographically Printed Fluidic Structures in Paper. Anal. Chem. 2010, 82, 10246–10250. [Google Scholar] [CrossRef]

- Rosqvist, E.; Niemelä, E.; Frisk, J.; Öblom, H.; Koppolu, R.; Abdelkader, H.; Soto Véliz, D.; Mennillo, M.; Venu, A.P.; Ihalainen, P.; et al. A low-cost paper-based platform for fast and reliable screening of cellular interactions with materials. J. Mater. Chem. B 2020, 8, 1146–1156. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Tian, J.; Nguyen, T.; Shen, W. Paper-Based Microfluidic Devices by Plasma Treatment. Anal. Chem. 2008, 80, 9131–9134. [Google Scholar] [CrossRef]

- Mora, M.F.; Garcia, C.D.; Schaumburg, F.; Kler, P.A.; Berli, C.L.A.; Hashimoto, M.; Carrilho, E. Patterning and Modeling Three-Dimensional Microfluidic Devices Fabricated on a Single Sheet of Paper. Anal. Chem. 2019, 91, 8298–8303. [Google Scholar] [CrossRef] [PubMed]

- Raj, N.; Breedveld, V.; Hess, D.W. Fabrication of fully enclosed paper microfluidic devices using plasma deposition and etching. Lab A Chip 2019, 19, 3337–3343. [Google Scholar] [CrossRef] [PubMed]

- He, P.J.W.; Katis, I.N.; Eason, R.W.; Sones, C.L. Engineering fluidic delays in paper-based devices using laser direct-writing. Lab A Chip 2015, 15, 4054–4061. [Google Scholar] [CrossRef] [PubMed]

- Hecht, L.; van Rossum, D.; Dietzel, A. Femtosecond-laser-structured nitrocellulose membranes for multi parameter Point-of-Care tests. Microelectron. Eng. 2016, 158, 52–58. [Google Scholar] [CrossRef]

- Rahimi, R.; Htwe, S.S.; Ochoa, M.; Donaldson, A.; Zieger, M.; Sood, R.; Tamayol, A.; Khademhosseini, A.; Ghaemmaghami, A.M.; Ziaie, B. A paper-based in vitro model for on-chip investigation of the human respiratory system. Lab Chip 2016, 16, 4319–4325. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Xu, C.; Lin, S.; Luo, J.; Wu, M.; Yang, F. A simple paper-based sensor fabricated by selective wet etching of silanized filter paper using a paper mask. Biomicrofluidics 2014, 8, 056504. [Google Scholar] [CrossRef]

- Sameenoi, Y.; Nongkai, P.N.; Nouanthavong, S.; Henry, C.S.; Nacapricha, D. One-step polymer screen-printing for microfluidic paper-based analytical device (μPAD) fabrication. Analyst 2014, 139, 6580–6588. [Google Scholar] [CrossRef]

- Lamas-Ardisana, P.J.; Martínez-Paredes, G.; Añorga, L.; Grande, H.J. Glucose biosensor based on disposable electrochemical paper-based transducers fully fabricated by screen-printing. Biosens. Bioelectron. 2018, 109, 8–12. [Google Scholar] [CrossRef]

- de Oliveira, R.A.G.; Camargo, F.; Pesquero, N.C.; Faria, R.C. A simple method to produce 2D and 3D microfluidic paper-based analytical devices for clinical analysis. Anal. Chim. Acta 2017, 957, 40–46. [Google Scholar] [CrossRef]

- Thuo, M.M.; Martinez, R.V.; Lan, W.-J.; Liu, X.; Barber, J.; Atkinson, M.B.J.; Bandarage, D.; Bloch, J.-F.; Whitesides, G.M. Fabrication of Low-Cost Paper-Based Microfluidic Devices by Embossing or Cut-and-Stack Methods. Chem. Mater. 2014, 26, 4230–4237. [Google Scholar] [CrossRef] [Green Version]

- Jafry, A.T.; Lim, H.; Sung, W.-K.; Lee, J. Flexible time–temperature indicator: A versatile platform for laminated paper-based analytical devices. Microfluid. Nanofluidics 2017, 21, 57. [Google Scholar] [CrossRef]

- Liu, N.; Xu, J.; An, H.-J.; Phan, D.-T.; Hashimoto, M.; Lew, W.S. Direct spraying method for fabrication of paper-based microfluidic devices. J. Micromech. Microeng. 2017, 27, 104001. [Google Scholar] [CrossRef] [Green Version]

- Lam, T.; Devadhasan, J.P.; Howse, R.; Kim, J. A Chemically Patterned Microfluidic Paper-based Analytical Device (C-µPAD) for Point-of-Care Diagnostics. Sci. Rep. 2017, 7, 1188. [Google Scholar] [CrossRef] [Green Version]

- Wu, F.Y.; Wang, M. A Portable Smartphone-Based Sensing System Using a 3D-Printed Chip for On-Site Biochemical Assays. Sensors 2018, 18, 4002. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martinez, A.W.; Phillips, S.T.; Whitesides, G.M. Three-dimensional microfluidic devices fabricated in layered paper and tape. Proc. Natl. Acad. Sci. USA 2008, 105, 19606. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ge, L.; Wang, S.; Song, X.; Ge, S.; Yu, J. 3D Origami-based multifunction-integrated immunodevice: Low-cost and multiplexed sandwich chemiluminescence immunoassay on microfluidic paper-based analytical device. Lab Chip 2012, 12, 3150–3158. [Google Scholar] [CrossRef]

- Gharaghani, F.M.; Akhond, M.; Hemmateenejad, B. A three-dimensional origami microfluidic device for paper chromatography: Application to quantification of Tartrazine and Indigo carmine in food samples. J. Chromatogr. A 2020, 1621, 461049. [Google Scholar] [CrossRef]

- Jiao, Y.; Du, C.; Zong, L.; Guo, X.; Han, Y.; Zhang, X.; Li, L.; Zhang, C.; Ju, Q.; Liu, J.; et al. 3D vertical-flow paper-based device for simultaneous detection of multiple cancer biomarkers by fluorescent immunoassay. Sens. Actuators B Chem. 2020, 306, 127239. [Google Scholar] [CrossRef]

- Qi, J.; Li, B.; Wang, X.; Zhang, Z.; Wang, Z.; Han, J.; Chen, L. Three-dimensional paper-based microfluidic chip device for multiplexed fluorescence detection of Cu2+ and Hg2+ ions based on ion imprinting technology. Sens. Actuators B Chem. 2017, 251, 224–233. [Google Scholar] [CrossRef]

- Cao, Q.; Liang, B.; Tu, T.; Wei, J.; Fang, L.; Ye, X. Three-dimensional paper-based microfluidic electrochemical integrated devices (3D-PMED) for wearable electrochemical glucose detection. Rsc Adv. 2019, 9, 5674–5681. [Google Scholar] [CrossRef] [Green Version]

- Sechi, D.; Greer, B.; Johnson, J.; Hashemi, N. Three-Dimensional Paper-Based Microfluidic Device for Assays of Protein and Glucose in Urine. Anal. Chem. 2013, 85, 10733–10737. [Google Scholar] [CrossRef] [Green Version]

- Park, C.; Han, Y.D.; Kim, H.V.; Lee, J.; Yoon, H.C.; Park, S. Double-sided 3D printing on paper towards mass production of three-dimensional paper-based microfluidic analytical devices (3D-μPADs). Lab A Chip 2018, 18, 1533–1538. [Google Scholar] [CrossRef]

- Chiang, C.-K.; Kurniawan, A.; Kao, C.-Y.; Wang, M.-J. Single step and mask-free 3D wax printing of microfluidic paper-based analytical devices for glucose and nitrite assays. Talanta 2019, 194, 837–845. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Gao, Q.; Wu, W.-B.; Nie, J.; Fu, J.-Z. 3D Printed Paper-Based Microfluidic Analytical Devices. Micromachines 2016, 7, 108. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nie, J.; Gao, Q.; Qiu, J.-J.; Sun, M.; Liu, A.; Shao, L.; Fu, J.-z.; Zhao, P.; He, Y. 3D printed Lego ® -like modular microfluidic devices based on capillary driving. Biofabrication 2018, 10, 035001. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Gao, Q.; Nie, J.; Fu, J.-z.; He, Y. From Microfluidic Paper-Based Analytical Devices to Paper-Based Biofluidics with Integrated Continuous Perfusion. Acs Biomater. Sci. Eng. 2017, 3, 601–607. [Google Scholar] [CrossRef]

- Puneeth, S.B.; Goel, S. Novel 3D Printed Microfluidic Paper-Based Analytical Device with Integrated Screen-Printed Electrodes for Automated Viscosity Measurements. IEEE Trans. Electron Devices 2019, 66, 3196–3201. [Google Scholar] [CrossRef]

- Fu, X.; Xia, B.; Ji, B.; Lei, S.; Zhou, Y. Flow controllable three-dimensional paper-based microfluidic analytical devices fabricated by 3D printing technology. Anal. Chim. Acta 2019, 1065, 64–70. [Google Scholar] [CrossRef]

- Sousa, L.R.; Duarte, L.C.; Coltro, W.K.T. Instrument-free fabrication of microfluidic paper-based analytical devices through 3D pen drawing. Sens. Actuators B Chem. 2020, 312, 128018. [Google Scholar] [CrossRef]

- Mani, N.K.; Prabhu, A.; Biswas, S.K.; Chakraborty, S. Fabricating Paper Based Devices Using Correction Pens. Sci. Rep. 2019, 9, 1752. [Google Scholar] [CrossRef]

- Nie, J.; Zhang, Y.; Lin, L.; Zhou, C.; Li, S.; Zhang, L.; Li, J. Low-Cost Fabrication of Paper-Based Microfluidic Devices by One-Step Plotting. Anal. Chem. 2012, 84, 6331–6335. [Google Scholar] [CrossRef]

- Bruzewicz, D.A.; Reches, M.; Whitesides, G.M. Low-Cost Printing of Poly(dimethylsiloxane) Barriers to Define Microchannels in Paper. Anal. Chem. 2008, 80, 3387–3392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nuchtavorn, N.; Macka, M. A novel highly flexible, simple, rapid and low-cost fabrication tool for paper-based microfluidic devices (μPADs) using technical drawing pens and in-house formulated aqueous inks. Anal. Chim. Acta 2016, 919, 70–77. [Google Scholar] [CrossRef] [PubMed]

- Ghaderinezhad, F.; Amin, R.; Temirel, M.; Yenilmez, B.; Wentworth, A.; Tasoglu, S. High-throughput rapid-prototyping of low-cost paper-based microfluidics. Sci. Rep. 2017, 7, 3553. [Google Scholar] [CrossRef] [PubMed]

- Ruecha, N.; Lee, J.; Chae, H.; Cheong, H.; Soum, V.; Preechakasedkit, P.; Chailapakul, O.; Tanev, G.; Madsen, J.; Rodthongkum, N.; et al. Paper-Based Digital Microfluidic Chip for Multiple Electrochemical Assay Operated by a Wireless Portable Control System. Adv. Mater. Technol. 2017, 2, 1600267. [Google Scholar] [CrossRef]

- Soum, V.; Kim, Y.; Park, S.; Chuong, M.; Ryu, R.S.; Lee, H.S.; Tanev, G.; Madsen, J.; Kwon, O.-S.; Shin, K. Affordable Fabrication of Conductive Electrodes and Dielectric Films for a Paper-Based Digital Microfluidic Chip. Micromachines 2019, 10, 109. [Google Scholar] [CrossRef] [Green Version]

- Abadian, A.; Sepehri Manesh, S.; Jafarabadi Ashtiani, S. Hybrid paper-based microfluidics: Combination of paper-based analytical device (µPAD) and digital microfluidics (DMF) on a single substrate. Microfluid Nanofluidics 2017, 21, 65. [Google Scholar] [CrossRef]

- Yafia, M.; Shukla, S.; Najjaran, H. Fabrication of digital microfluidic devices on flexible paper-based and rigid substrates via screen printing. J. Micromech. Microeng. 2015, 25, 057001. [Google Scholar] [CrossRef]

- Jafry, A.T.; Lee, H.; Tenggara, A.P.; Lim, H.; Moon, Y.; Kim, S.H.; Lee, Y.; Kim, S.M.; Park, S.; Byun, D.; et al. Double-sided electrohydrodynamic jet printing of two-dimensional electrode array in paper-based digital microfluidics. Sens. Actuators B-Chem. 2019, 282, 831–837. [Google Scholar] [CrossRef]

- Abadian, A.; Jafarabadi-Ashtiani, S. Paper-based digital microfluidics. Microfluid. Nanofluidics 2014, 16, 989–995. [Google Scholar] [CrossRef]

- He, Y.; Wu, Y.; Fu, J.-Z.; Wu, W.-B. Fabrication of paper-based microfluidic analysis devices: A review. Rsc. Adv. 2015, 5, 78109–78127. [Google Scholar] [CrossRef]

- Govindarajan, A.V.; Ramachandran, S.; Vigil, G.D.; Yager, P.; Böhringer, K.F. Microfluidic origami for point-of-care extraction of nucleic acids from viscous samples. In Proceedings of the 2011 IEEE 24th International Conference on Micro Electro Mechanical Systems, Cancun, Mexico, 23–27 January 2011; pp. 932–935. [Google Scholar]

- Reboud, J.; Xu, G.L.; Garrett, A.; Adriko, M.; Yang, Z.G.; Tukahebwa, E.M.; Rowell, C.; Cooper, J.M. Paper-based microfluidics for DNA diagnostics of malaria in low resource underserved rural communities. Proc. Natl. Acad. Sci. USA 2019, 116, 4834–4842. [Google Scholar] [CrossRef] [Green Version]

- Kunkel, H.G.; Tiselius, A. Electrophoresis of proteins on filter paper. J. Gen. Physiol. 1951, 35, 89–118. [Google Scholar] [CrossRef] [PubMed]

- Nanthasurasak, P.; Cabot, J.M.; See, H.H.; Guijt, R.M.; Breadmore, M.C. Electrophoretic separations on paper: Past, present, and future-A review. Anal. Chim. Acta 2017, 985, 7–23. [Google Scholar] [CrossRef] [PubMed]

- Tiselius, A. A new apparatus for electrophoretic analysis of colloidal mixtures. Trans. Faraday Soc. 1937, 33, 524–531. [Google Scholar] [CrossRef]

- Moghadam, B.Y.; Connelly, K.T.; Posner, J.D. Two Orders of Magnitude Improvement in Detection Limit of Lateral Flow Assays Using Isotachophoresis. Anal. Chem. 2015, 87, 1009–1017. [Google Scholar] [CrossRef] [Green Version]

- Rosenfeld, T.; Bercovici, M. 1000-fold sample focusing on paper-based microfluidic devices. Lab Chip 2014, 14, 4465–4474. [Google Scholar] [CrossRef] [PubMed]

- Ge, L.; Wang, S.; Ge, S.; Yu, J.; Yan, M.; Li, N.; Huang, J. Electrophoretic separation in a microfluidic paper-based analytical device with an on-column wireless electrogenerated chemiluminescence detector. Chem. Commun. 2014, 50, 5699–5702. [Google Scholar] [CrossRef]

- Chagas, C.L.S.; de Souza, F.R.; Cardoso, T.M.G.; Moreira, R.C.; da Silva, J.A.F.; de Jesus, D.P.; Coltro, W.K.T. A fully disposable paper-based electrophoresis microchip with integrated pencil-drawn electrodes for contactless conductivity detection. Anal. Methods 2016, 8, 6682–6686. [Google Scholar] [CrossRef]

- Luo, L.; Li, X.; Crooks, R.M. Low-Voltage Origami-Paper-Based Electrophoretic Device for Rapid Protein Separation. Anal. Chem. 2014, 86, 12390–12397. [Google Scholar] [CrossRef]

- Li, X.; Luo, L.; Crooks, R.M. Low-voltage paper isotachophoresis device for DNA focusing. Lab Chip 2015, 15, 4090–4098. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Lee, K.H.; Han, S.I.; Lee, D.; Chung, S.; Lee, D.; Lee, J.H. Origami-paper-based device for microvesicle/exosome preconcentration and isolation. Lab Chip 2019, 19, 3917–3921. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Wei, Z.; Zhao, H.; Jia, J.; Chen, Z.; Zhang, S.; Ouyang, Z.; Ma, X.; Zhang, X. In Situ Ion-Transmission Mass Spectrometry for Paper-Based Analytical Devices. Anal. Chem. 2016, 88, 10805–10810. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Niu, J.-C.; Zhou, T.; Niu, L.-L.; Xie, Z.-S.; Fang, F.; Yang, F.-Q.; Wu, Z.-Y. Simultaneous pre-concentration and separation on simple paper-based analytical device for protein analysis. Anal. Bioanal. Chem. 2018, 410, 1689–1695. [Google Scholar] [CrossRef] [PubMed]

- Soum, V.; Park, S.; Brilian, A.I.; Choi, J.Y.; Lee, Y.; Kim, W.; Kwon, O.S.; Shin, K. Quantitatively controllable fluid flows with ballpoint-pen-printed patterns for programmable photo-paper-based microfluidic devices. Lab Chip 2020, 20, 1601–1611. [Google Scholar] [CrossRef] [PubMed]

- Ye, H.H.; Xia, X.H. Enhancing the sensitivity of colorimetric lateral flow assay (CLFA) through signal amplification techniques. J. Mater. Chem. B 2018, 6, 7102–7111. [Google Scholar] [CrossRef]

- Songok, J.; Toivakka, M. Enhancing Capillary-Driven Flow for Paper-Based Microfluidic Channels. Acs Appl. Mater Interfaces 2016, 8, 30523–30530. [Google Scholar] [CrossRef] [PubMed]

- Renault, C.; Li, X.; Fosdick, S.E.; Crooks, R.M. Hollow-channel paper analytical devices. Anal. Chem. 2013, 85, 7976–7979. [Google Scholar] [CrossRef]

- Rivas, L.; Medina-Sanchez, M.; de la Escosura-Muniz, A.; Merkoci, A. Improving sensitivity of gold nanoparticle-based lateral flow assays by using wax-printed pillars as delay barriers of microfluidics. Lab Chip 2014, 14, 4406–4414. [Google Scholar] [CrossRef]

- Giokas, D.L.; Tsogas, G.Z.; Vlessidis, A.G. Programming fluid transport in paper-based microfluidic devices using razor-crafted open channels. Anal. Chem. 2014, 86, 6202–6207. [Google Scholar] [CrossRef]

- Channon, R.B.; Nguyen, M.P.; Scorzelli, A.G.; Henry, E.M.; Volckens, J.; Dandy, D.S.; Henry, C.S. Rapid flow in multilayer microfluidic paper-based analytical devices. Lab A Chip 2018, 18, 793–802. [Google Scholar] [CrossRef]

- Toley, B.J.; McKenzie, B.; Liang, T.; Buser, J.R.; Yager, P.; Fu, E. Tunable-delay shunts for paper microfluidic devices. Anal. Chem. 2013, 85, 11545–11552. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fu, E.; Downs, C. Progress in the development and integration of fluid flow control tools in paper microfluidics. Lab A Chip 2017, 17, 614–628. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.T.; Hahn, K.Y.; Kim, S.M. Recent Advances of Fluid Manipulation Technologies in Microfluidic Paper-Based Analytical Devices (μPADs) toward Multi-Step Assays. Micromachines 2020, 11, 269. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruecha, N.; Chailapakul, O.; Suzuki, K.; Citterio, D. Fully Inkjet-Printed Paper-Based Potentiometric Ion-Sensing Devices. Anal. Chem. 2017, 89, 10608–10616. [Google Scholar] [CrossRef]

- da Costa, T.H.; Song, E.; Tortorich, R.P.; Choi, J.-W. A Paper-Based Electrochemical Sensor Using Inkjet-Printed Carbon Nanotube Electrodes. Ecs J. Solid State Sci. Technol. 2015, 4, S3044–S3047. [Google Scholar] [CrossRef]

- Yukird, J.; Soum, V.; Kwon, O.-S.; Shin, K.; Chailapakul, O.; Rodthongkum, N. 3D paper-based microfluidic device: A novel dual-detection platform of bisphenol A. Analyst 2020. [Google Scholar] [CrossRef]

- Soum, V.; Cheong, H.; Kim, K.; Kim, Y.; Chuong, M.; Ryu, S.R.; Yuen, P.K.; Kwon, O.-S.; Shin, K. Programmable Contact Printing Using Ballpoint Pens with a Digital Plotter for Patterning Electrodes on Paper. Acs Omega 2018, 3, 16866–16873. [Google Scholar] [CrossRef]

- Mullane, K.; Curtis, M.J.; Williams, M. Chapter 1—Reproducibility in Biomedical Research. In Research in the Biomedical Sciences; Williams, M., Curtis, M.J., Mullane, K., Eds.; Academic Press: San Diego, CA, USA, 2018; pp. 1–66. [Google Scholar] [CrossRef]

- de Tarso Garcia, P.; Garcia Cardoso, T.M.; Garcia, C.D.; Carrilho, E.; Tomazelli Coltro, W.K. A handheld stamping process to fabricate microfluidic paper-based analytical devices with chemically modified surface for clinical assays. Rsc Adv. 2014, 4, 37637–37644. [Google Scholar] [CrossRef]

- Li, Z.; Liu, H.; He, X.; Xu, F.; Li, F. Pen-on-paper strategies for point-of-care testing of human health. Trac. Trends Anal. Chem. 2018, 108, 50–64. [Google Scholar] [CrossRef]

- Kiran, D.R. Chapter 13—Types of production situations. In Production Planning and Control; Kiran, D.R., Ed.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 181–193. [Google Scholar] [CrossRef]

- Akyazi, T.; Basabe-Desmonts, L.; Benito-Lopez, F. Review on microfluidic paper-based analytical devices towards commercialisation. Anal. Chim. Acta 2018, 1001, 1–17. [Google Scholar] [CrossRef]

- Dungchai, W.; Chailapakul, O.; Henry, C.S. A low-cost, simple, and rapid fabrication method for paper-based microfluidics using wax screen-printing. Analyst 2011, 136, 77–82. [Google Scholar] [CrossRef] [PubMed]

- Nelson, W.C.; Kim, C.-J.C. Droplet Actuation by Electrowetting-on-Dielectric (EWOD): A Review. J. Adhes. Sci. Technol. 2012, 26, 1747–1771. [Google Scholar] [CrossRef] [Green Version]

- Tanev, G.; Madsen, J. A correct-by-construction design and programming approach for open paper-based digital microfluidics. In Proceedings of the 2017 Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS (DTIP), Bordeaux, France, 29 May–1 June 2017; pp. 1–6. [Google Scholar]

- Liu, H.; Dharmatilleke, S.; Maurya, D.K.; Tay, A.A.O. Dielectric materials for electrowetting-on-dielectric actuation. Microsyst. Technol. 2009, 16, 449. [Google Scholar] [CrossRef]

- Liana, D.D.; Raguse, B.; Gooding, J.J.; Chow, E. Recent advances in paper-based sensors. Sensors 2012, 12, 11505–11526. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mahmoudi, T.; Tazehkand, A.P.; Pourhassan-Moghaddam, M.; Alizadeh-Ghodsi, M.; Ding, L.; Baradaran, B.; Bazaz, S.R.; Jin, D.; Warkiani, M.E. PCR-free Paper-based Nanobiosensing Platform for Visual Detection of Telomerase Activity via Gold Enhancement. Microchem. J. 2020. [Google Scholar] [CrossRef]

- Alizadeh, N.; Salimi, A.; Hallaj, R. Mimicking peroxidase-like activity of Co3O4-CeO2 nanosheets integrated paper-based analytical devices for detection of glucose with smartphone. Sens. Actuators B Chem. 2019, 288, 44–52. [Google Scholar] [CrossRef]

- Li, F.; Wang, X.; Liu, J.; Hu, Y.; He, J. Double-layered microfluidic paper-based device with multiple colorimetric indicators for multiplexed detection of biomolecules. Sens. Actuators B Chem. 2019, 288, 266–273. [Google Scholar] [CrossRef]

- Dhawane, M.; Deshpande, A.; Jain, R.; Dandekar, P. Colorimetric point-of-care detection of cholesterol using chitosan nanofibers. Sens. Actuators B Chem. 2019, 281, 72–79. [Google Scholar] [CrossRef]

- Li, F.; Hu, Y.; Li, Z.; Liu, J.; Guo, L.; He, J. Three-dimensional microfluidic paper-based device for multiplexed colorimetric detection of six metal ions combined with use of a smartphone. Anal. Bioanal. Chem. 2019, 411, 6497–6508. [Google Scholar] [CrossRef]

- Hong, B.; Xue, P.; Wu, Y.; Bao, J.; Chuah, Y.J.; Kang, Y. A concentration gradient generator on a paper-based microfluidic chip coupled with cell culture microarray for high-throughput drug screening. Biomed. Microdevices 2016, 18, 21. [Google Scholar] [CrossRef]

- Huang, J.-Y.; Lin, H.-T.; Chen, T.-H.; Chen, C.-A.; Chang, H.-T.; Chen, C.-F. Signal amplified gold nanoparticles for cancer diagnosis on paper-based analytical devices. Acs Sens. 2018, 3, 174–182. [Google Scholar] [CrossRef]

- Faham, S.; Khayatian, G.; Golmohammadi, H.; Ghavami, R. A paper-based optical probe for chromium by using gold nanoparticles modified with 2, 2′-thiodiacetic acid and smartphone camera readout. Microchim. Acta 2018, 185, 374. [Google Scholar] [CrossRef]

- Trofimchuk, E.; Nilghaz, A.; Sun, S.; Lu, X. Determination of norfloxacin residues in foods by exploiting the coffee-ring effect and paper-based microfluidics device coupling with smartphone-based detection. J. Food Sci. 2020, 85, 736–743. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Yang, J.; Xu, H.; Cao, B.; Qin, Q.; Liao, X.; Wo, Y.; Jin, Q.; Cui, D. Smartphone-imaged multilayered paper-based analytical device for colorimetric analysis of carcinoembryonic antigen. Anal. Bioanal. Chem. 2020, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Samiei, E.; Tabrizian, M.; Hoorfar, M. A review of digital microfluidics as portable platforms for lab-on a-chip applications. Lab A Chip 2016, 16, 2376–2396. [Google Scholar] [CrossRef]

- Jang, I.; Ko, H.; You, G.; Lee, H.; Paek, S.; Chae, H.; Lee, J.H.; Choi, S.; Kwon, O.-S.; Shin, K.; et al. Application of paper EWOD (electrowetting-on-dielectrics) chip: Protein tryptic digestion and its detection using MALDI-TOF mass spectrometry. Biochip J. 2017, 11, 146–152. [Google Scholar] [CrossRef]

- Atabakhsh, S.; Ashtiani, S.J. Thermal actuation and confinement of water droplets on paper-based digital microfluidics devices. Microfluid. Nanofluidics 2018, 22, 43. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, J.; Liu, J.; Sun, S.; Xiong, Y.; Ma, Y.; Yan, S.; Yang, Y.; Yin, H.; Cai, X. Label-free microfluidic paper-based electrochemical aptasensor for ultrasensitive and simultaneous multiplexed detection of cancer biomarkers. Biosens. Bioelectron. 2019, 136, 84–90. [Google Scholar] [CrossRef] [PubMed]

- Fava, E.L.; Silva, T.A.; do Prado, T.M.; de Moraes, F.C.; Faria, R.C.; Fatibello-Filho, O. Electrochemical paper-based microfluidic device for high throughput multiplexed analysis. Talanta 2019, 203, 280–286. [Google Scholar] [CrossRef]

- Fava, E.L.; Prado, T.M.d.; Silva, T.A.; Cruz de Moraes, F.; Faria, R.C.; Fatibello-Filho, O. New disposable electrochemical paper-based microfluidic device with multiplexed electrodes for biomarkers determination in urine sample. Electroanalysis 2020. [Google Scholar] [CrossRef]

- Nantaphol, S.; Kava, A.A.; Channon, R.B.; Kondo, T.; Siangproh, W.; Chailapakul, O.; Henry, C.S. Janus electrochemistry: Simultaneous electrochemical detection at multiple working conditions in a paper-based analytical device. Anal. Chim. Acta 2019, 1056, 88–95. [Google Scholar] [CrossRef]

- Mettakoonpitak, J.; Volckens, J.; Henry, C.S. Janus Electrochemical Paper-Based Analytical Devices for Metals Detection in Aerosol Samples. Anal. Chem. 2019, 92, 1439–1446. [Google Scholar] [CrossRef] [PubMed]

- Dryden, M.D.; Rackus, D.D.; Shamsi, M.H.; Wheeler, A.R. Integrated digital microfluidic platform for voltammetric analysis. Anal. Chem. 2013, 85, 8809–8816. [Google Scholar] [CrossRef] [PubMed]

- Karuwan, C.; Sukthang, K.; Wisitsoraat, A.; Phokharatkul, D.; Patthanasettakul, V.; Wechsatol, W.; Tuantranont, A. Electrochemical detection on electrowetting-on-dielectric digital microfluidic chip. Talanta 2011, 84, 1384–1389. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Z.; Cheong, H.; Kwon, O.-S.; Yao, H.; Ho, T.-Y.; Shin, K.; Li, B.; Schlichtmann, U.; Cai, Y. Control-fluidic codesign for paper-based digital microfluidic biochips. In Proceedings of the 2016 IEEE/ACM International Conference on Computer-Aided Design (ICCAD), Austin, TX, USA, 23 January 2017; pp. 1–8. [Google Scholar]

- Wang, Q.; Ji, W.; Li, Z.; Cheong, H.; Kwon, O.-S.; Yao, H.; Ho, T.-Y.; Shin, K.; Li, B.; Schlichtmann, U. Integrated Control-Fluidic Codesign Methodology for Paper-Based Digital Microfluidic Biochips. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 2019, 39, 613–625. [Google Scholar] [CrossRef]

- Yang, R.; Li, F.; Zhang, W.; Shen, W.; Yang, D.; Bian, Z.; Cui, H. Chemiluminescence Immunoassays for Simultaneous Detection of Three Heart Disease Biomarkers Using Magnetic Carbon Composites and Three-Dimensional Microfluidic Paper-Based Device. Anal. Chem. 2019, 91, 13006–13013. [Google Scholar] [CrossRef]

- Han, X.; Cao, M.; Wu, M.; Wang, Y.-J.; Yu, C.; Zhang, C.; Yu, H.; Wei, J.-F.; Li, L.; Huang, W. A paper-based chemiluminescence immunoassay device for rapid and high-throughput detection of allergen-specific IgE. Analyst 2019, 144, 2584–2593. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Liu, J.; Guo, L.; Wang, J.; Zhang, K.; He, J.; Cui, H. High-resolution temporally resolved chemiluminescence based on double-layered 3D microfluidic paper-based device for multiplexed analysis. Biosens. Bioelectron. 2019, 141, 111472. [Google Scholar] [CrossRef]

- Alahmad, W.; Uraisin, K.; Nacapricha, D.; Kaneta, T. A miniaturized chemiluminescence detection system for a microfluidic paper-based analytical device and its application to the determination of chromium (III). Anal. Methods 2016, 8, 5414–5420. [Google Scholar] [CrossRef]

- Guo, X.; Guo, Y.; Liu, W.; Chen, Y.; Chu, W. Fabrication of paper-based microfluidic device by recycling foamed plastic and the application for multiplexed measurement of biomarkers. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2019, 223, 117341. [Google Scholar] [CrossRef]

- Sardesai, N.P.; Kadimisetty, K.; Faria, R.; Rusling, J.F. A microfluidic electrochemiluminescent device for detecting cancer biomarker proteins. Anal. Bioanal. Chem. 2013, 405, 3831–3838. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ge, L.; Yan, J.; Song, X.; Yan, M.; Ge, S.; Yu, J. Three-dimensional paper-based electrochemiluminescence immunodevice for multiplexed measurement of biomarkers and point-of-care testing. Biomaterials 2012, 33, 1024–1031. [Google Scholar] [CrossRef]

- Sun, X.; Li, B.; Tian, C.; Yu, F.; Zhou, N.; Zhan, Y.; Chen, L. Rotational paper-based electrochemiluminescence immunodevices for sensitive and multiplexed detection of cancer biomarkers. Anal. Chim. Acta 2018, 1007, 33–39. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, S.-N. Graphite paper-based bipolar electrode electrochemiluminescence sensing platform. Biosens. Bioelectron. 2017, 94, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Wang, D.; Zhang, C. A novel paperfluidic closed bipolar electrode-electrochemiluminescence sensing platform: Potential for multiplex detection at crossing-channel closed bipolar electrodes. Sens. Actuators B Chem. 2018, 270, 341–352. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, Y.; Wang, Y.; Ge, S.; Liu, H.; Yan, M.; Yu, J. A paper-based electrochemiluminescence electrode as an aptamer-based cytosensor using PtNi@ carbon dots as nanolabels for detection of cancer cells and for in situ screening of anticancer drugs. Microchim. Acta 2016, 183, 1873–1880. [Google Scholar] [CrossRef]

- Feng, Q.; Chen, H.; Xu, J. Disposable paper-based bipolar electrode array for multiplexed electrochemiluminescence detection of pathogenic DNAs. Sci. China Chem. 2015, 58, 810–818. [Google Scholar] [CrossRef]

- Shamsi, M.H.; Choi, K.; Ng, A.H.; Chamberlain, M.D.; Wheeler, A.R. Electrochemiluminescence on digital microfluidics for microRNA analysis. Biosens. Bioelectron. 2016, 77, 845–852. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, H.; Jia, Y.; Dong, H.; Fan, L.; Zheng, J. Multiplex quantification of metals in airborne particulate matter via smartphone and paper-based microfluidics. Anal. Chim. Acta 2018, 1044, 110–118. [Google Scholar] [CrossRef]

- Kim, S.; Kim, D.; Kim, S. Simultaneous quantification of multiple biomarkers on a self-calibrating microfluidic paper-based analytic device. Anal. Chim. Acta 2020, 1097, 120–126. [Google Scholar] [CrossRef]

- Xu, W.; Fu, K.; Bohn, P.W. Electrochromic sensor for multiplex detection of metabolites enabled by closed bipolar electrode coupling. Acs Sens. 2017, 2, 1020–1026. [Google Scholar] [CrossRef] [PubMed]

- Mathay, C.; Hamot, G.; Henry, E.; Mommaerts, K.; Thorlaksdottir, A.; Trouet, J.; Betsou, F. Method Validation for Extraction of Nucleic Acids from Peripheral Whole Blood. Biopreservation Biobanking 2016, 14, 520–529. [Google Scholar] [CrossRef] [PubMed]

- Ghaheri, M.; Kahrizi, D.; Yari, K.; Babaie, A.; Suthar, R.; Kazemi, E. A comparative evaluation of four DNA extraction protocols from whole blood sample. Cell. Mol. Biol. 2016, 62, 120–124. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Chen, F.; Li, Q.; Wang, L.; Fan, C. Isothermal Amplification of Nucleic Acids. Chem. Rev. 2015, 115, 12491–12545. [Google Scholar] [CrossRef]

- Shen, C.-H. Chapter 9—Amplification of Nucleic Acids. In Diagnostic Molecular Biology; Shen, C.-H., Ed.; Academic Press: San Diego, CA, USA, 2019; pp. 215–247. [Google Scholar] [CrossRef]

- Tang, R.H.; Yang, H.; Gong, Y.; You, M.L.; Liu, Z.; Choi, J.R.; Wen, T.; Qu, Z.G.; Mei, Q.B.; Xu, F. A fully disposable and integrated paper-based device for nucleic acid extraction, amplification and detection. Lab A Chip 2017, 17, 1270–1279. [Google Scholar] [CrossRef]

- Ciftci, S.; Neumann, F.; Hernández-Neuta, I.; Hakhverdyan, M.; Bálint, Á.; Herthnek, D.; Madaboosi, N.; Nilsson, M. A novel mutation tolerant padlock probe design for multiplexed detection of hypervariable RNA viruses. Sci. Rep. 2019, 9, 2872. [Google Scholar] [CrossRef]

- Ye, X.; Xu, J.; Lu, L.J.; Li, X.X.; Fang, X.E.; Kong, J.L. Equipment-free nucleic acid extraction and amplification on a simple paper disc for point-of-care diagnosis of rotavirus A. Anal. Chim. Acta 2018, 1018, 78–85. [Google Scholar] [CrossRef]

- Deng, H.; Zhou, X.; Liu, Q.; Li, B.; Liu, H.; Huang, R.; Xing, D. Paperfluidic chip device for small RNA extraction, amplification, and multiplexed analysis. Acs Appl. Mater. Interfaces 2017, 9, 41151–41158. [Google Scholar] [CrossRef]

- Liang, L.; Lan, F.; Yin, X.; Ge, S.; Yu, J.; Yan, M. Metal-enhanced fluorescence/visual bimodal platform for multiplexed ultrasensitive detection of microRNA with reusable paper analytical devices. Biosens. Bioelectron. 2017, 95, 181–188. [Google Scholar] [CrossRef]

- Sun, X.; Wang, H.; Jian, Y.; Lan, F.; Zhang, L.; Liu, H.; Ge, S.; Yu, J. Ultrasensitive microfluidic paper-based electrochemical/visual biosensor based on spherical-like cerium dioxide catalyst for miR-21 detection. Biosens. Bioelectron. 2018, 105, 218–225. [Google Scholar] [CrossRef]

- Song, Y.; Gyarmati, P.; Araújo, A.C.; Lundeberg, J.; Brumer, H.; Ståhl, P.L. Visual Detection of DNA on Paper Chips. Anal. Chem. 2014, 86, 1575–1582. [Google Scholar] [CrossRef] [PubMed]

- Ahn, H.; Batule, B.S.; Seok, Y.; Kim, M.-G. Single-Step Recombinase Polymerase Amplification Assay Based on a Paper Chip for Simultaneous Detection of Multiple Foodborne Pathogens. Anal. Chem. 2018, 90, 10211–10216. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.R.; Hu, J.; Tang, R.; Gong, Y.; Feng, S.; Ren, H.; Wen, T.; Li, X.; Wan Abas, W.A.B.; Pingguan-Murphy, B.; et al. An integrated paper-based sample-to-answer biosensor for nucleic acid testing at the point of care. Lab A Chip 2016, 16, 611–621. [Google Scholar] [CrossRef] [PubMed]

- Kaur, N.; Toley, B.J. Paper-based nucleic acid amplification tests for point-of-care diagnostics. Analyst 2018, 143, 2213–2234. [Google Scholar] [CrossRef]

- Mao, K.; Min, X.; Zhang, H.; Zhang, K.; Cao, H.; Guo, Y.; Yang, Z. Paper-based microfluidics for rapid diagnostics and drug delivery. J. Control. Release 2020. [Google Scholar] [CrossRef]

- Dong, T.; Wang, G.A.; Li, F. Shaping up field-deployable nucleic acid testing using microfluidic paper-based analytical devices. Anal. Bioanal. Chem. 2019, 411, 4401–4414. [Google Scholar] [CrossRef]

- Xu, G.; Nolder, D.; Reboud, J.; Oguike, M.C.; van Schalkwyk, D.A.; Sutherland, C.J.; Cooper, J.M. Paper-Origami-Based Multiplexed Malaria Diagnostics from Whole Blood. Angew. Chem. Int. Ed. 2016, 55, 15250–15253. [Google Scholar] [CrossRef]

- Magro, L.; Jacquelin, B.; Escadafal, C.; Garneret, P.; Kwasiborski, A.; Manuguerra, J.-C.; Monti, F.; Sakuntabhai, A.; Vanhomwegen, J.; Lafaye, P.; et al. Paper-based RNA detection and multiplexed analysis for Ebola virus diagnostics. Sci. Rep. 2017, 7, 1347. [Google Scholar] [CrossRef]

- Teengam, P.; Siangproh, W.; Tuantranont, A.; Vilaivan, T.; Chailapakul, O.; Henry, C.S. Multiplex Paper-Based Colorimetric DNA Sensor Using Pyrrolidinyl Peptide Nucleic Acid-Induced AgNPs Aggregation for Detecting MERS-CoV, MTB, and HPV Oligonucleotides. Anal. Chem. 2017, 89, 5428–5435. [Google Scholar] [CrossRef] [Green Version]

- Bender, A.T.; Borysiak, M.D.; Levenson, A.M.; Lillis, L.; Boyle, D.S.; Posner, J.D. Semiquantitative Nucleic Acid Test with Simultaneous Isotachophoretic Extraction and Amplification. Anal. Chem. 2018, 90, 7221–7229. [Google Scholar] [CrossRef]

- Kaarj, K.; Akarapipad, P.; Yoon, J.Y. Simpler, Faster, and Sensitive Zika Virus Assay Using Smartphone Detection of Loop-mediated Isothermal Amplification on Paper Microfluidic Chips. Sci. Rep. 2018, 8. [Google Scholar] [CrossRef] [PubMed]

- Phillips, E.A.; Moehling, T.J.; Ejendal, K.F.K.; Hoilett, O.S.; Byers, K.M.; Basing, L.A.; Jankowski, L.A.; Bennett, J.B.; Lin, L.-K.; Stanciu, L.A.; et al. Microfluidic rapid and autonomous analytical device (microRAAD) to detect HIV from whole blood samples. Lab A Chip 2019, 19, 3375–3386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, J.; Li, W.; Ban, L.; Du, W.; Feng, X.; Liu, B.-F. A paper-based device with an adjustable time controller for the rapid determination of tumor biomarkers. Sens. Actuators B Chem. 2018, 254, 855–862. [Google Scholar] [CrossRef]

- Wang, C.-H.; Wu, J.-J.; Lee, G.-B. Screening of highly-specific aptamers and their applications in paper-based microfluidic chips for rapid diagnosis of multiple bacteria. Sens. Actuators B Chem. 2019, 284, 395–402. [Google Scholar] [CrossRef]

- Su, M.; Ge, L.; Ge, S.; Li, N.; Yu, J.; Yan, M.; Huang, J. based electrochemical cyto-device for sensitive detection of cancer cells and in situ anticancer drug screening. Anal. Chim. Acta 2014, 847, 1–9. [Google Scholar] [CrossRef]

- Meredith, N.A.; Quinn, C.; Cate, D.M.; Reilly, T.H.; Volckens, J.; Henry, C.S. Paper-based analytical devices for environmental analysis. Analyst 2016, 141, 1874–1887. [Google Scholar] [CrossRef]

- Kung, C.T.; Hou, C.Y.; Wang, Y.N.; Fu, L.M. Microfluidic paper-based analytical devices for environmental analysis of soil, air, ecology and river water. Sens. Actuators B-Chem. 2019, 301. [Google Scholar] [CrossRef]

- Kebbekus, B.B.; Mitra, S. Environmental chemical analysis, 1st ed.; Blackie Academic and Professional: London, UK, 1998; p. 330. [Google Scholar]

- Sun, X.; Li, B.; Qi, A.; Tian, C.; Han, J.; Shi, Y.; Lin, B.; Chen, L. Improved assessment of accuracy and performance using a rotational paper-based device for multiplexed detection of heavy metals. Talanta 2018, 178, 426–431. [Google Scholar] [CrossRef]

- Chabaud, K.R.; Thomas, J.L.; Torres, M.N.; Oliveira, S.; McCord, B.R. Simultaneous colorimetric detection of metallic salts contained in low explosives residue using a microfluidic paper-based analytical device (µPAD). Forensic Chem. 2018, 9, 35–41. [Google Scholar] [CrossRef]

- Seth, M.; Buza, J. Multiplex paper-based designs for point-of-care (POC) diagnostics. Int. J. Res. Med Sci. 2017, 5, 5052. [Google Scholar] [CrossRef] [Green Version]

- Seok, Y.; Joung, H.-A.; Byun, J.-Y.; Jeon, H.-S.; Shin, S.J.; Kim, S.; Shin, Y.-B.; Han, H.S.; Kim, M.-G. A paper-based device for performing loop-mediated isothermal amplification with real-time simultaneous detection of multiple DNA targets. Theranostics 2017, 7, 2220. [Google Scholar] [CrossRef] [PubMed]

- Rivas, L.; Reuterswärd, P.; Rasti, R.; Herrmann, B.; Mårtensson, A.; Alfvén, T.; Gantelius, J.; Andersson-Svahn, H. A vertical flow paper-microarray assay with isothermal DNA amplification for detection of Neisseria meningitidis. Talanta 2018, 183, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Luo, Y.; Yue, X.; Wu, J.; Wu, R.; Qiao, Y.; Peng, Q.; Shi, B.; Lin, B.; Li, W. A novel microfluidic paper-based analytical device based on chemiluminescence for determination of β-agonists in Swine Hair. Anal. Methods 2020. [Google Scholar] [CrossRef]

- Zhou, J.R.; Li, B.W.; Qi, A.J.; Shi, Y.J.; Qi, J.; Xu, H.Z.; Chen, L.X. ZnSe quantum dot based ion imprinting technology for fluorescence detecting cadmium and lead ions on a three-dimensional rotary paper-based microfluidic chip. Sens. Actuators B-Chem. 2020, 305. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, C.S.; Xing, D. Paper-based bipolar electrode-electrochemiluminescence (BPE-ECL) device with battery energy supply and smartphone read-out: A handheld ECL system for biochemical analysis at the point-of-care level. Sens. Actuators B-Chem. 2016, 237, 308–317. [Google Scholar] [CrossRef]

- Mabbott, S.; Fernandes, S.C.; Schechinger, M.; Cote, G.L.; Faulds, K.; Mace, C.R.; Graham, D. Detection of cardiovascular disease associated miR-29a using paper-based microfluidics and surface enhanced Raman scattering. Analyst 2020, 145, 983–991. [Google Scholar] [CrossRef]

- Burklund, A.; Saturley-Hall, H.K.; Franchina, F.A.; Hill, J.E.; Zhang, J.X.J. Printable QR code paper microfluidic colorimetric assay for screening volatile biomarkers. Biosens. Bioelectron. 2019, 128, 97–103. [Google Scholar] [CrossRef]

| P-CMF Devices | ||||

|---|---|---|---|---|

| Method | Usage | Materials | Equipment | References |

| Wax Printing | Creating hydrophobic barriers | Wax | Wax printer; Hot plate | [32,33,34,35] |

| Inkjet Printing | Creating hydrophobic barriers, patterning electrodes, high-resolution, printing and conductive patterns | Alkyl ketene dimer (AKD)/UV-curable acrylate ink/hydrophobic sol–gel, polystyrene, etc. | Inkjet printer | [36,37,38] |

| Photolithography | Create channels by photoresist | Photoresist and developer, photomask | Photolithography equipment | [6,39,40] |

| Flexographic Printing | Creating hydrophobic barriers and layers on paper substrates | Polystyrene ink/PDMS ink | Roll-to-roll flexography units | [41,42] |

| Plasma Treatment | Creating 2D and 3D channels; surface modification (change of hydrophilicity) | AKD/ octadecyltrichlorosilane (OTS)/pentafluoroethane (PFE) monomer; metal mask | Vacuum plasma reactor | [43,44,45] |

| Laser Treatment | Cutting, engraving, inducing photopolymerization | Photopolymer (for the purpose of photopolymerization) | Laser cutting and engraving machine | [46,47,48] |

| Wet Etching | Creating hydrophobic barriers | Trimethoxy-octadecyl silane (TMOS) and NaOH solutions, paper mask | Hot plate or oven (for heating) | [49] |

| Screen Printing | Creating hydrophobic barriers and electrodes (for electrochemical detection) | Wax/polystyrene/conductive ink; screen stencil | Hot plate or oven (for heating) | [50,51] |

| Cutting and Shaping | Creating hydrophilic channels as designed | Adhesive sheet (for fixing) | Knife plotter/digital craft cutter | [52,53,54] |

| Spraying | Creating hydrophobic area | Mask, back supporting plate, hydrophobic coating material, permanent magnetic and screws (for fixing) | None | [55] |

| Chemical Vapor Deposition | Creating hydrophobic channels | Trichlorosilane | Vacuum chamber, heat block, hot plate | [56] |

| Embossing | Creating 3D open channels | Acrylonitrile butadiene styrene (ABS) dies, liquid ethanol, RFSiCl3 | 3D printer/laser cutting machine for fabrication of dies | [53,57] |

| Stacking | Creating 3D channels, flow control | Layers of 2D patterned paper, double-sided adhesive tape | None | [53,58] |

| Origami Folding | Creating 3D channels, flow control | Wax patterning panels, binding clip | Wax printer | [59,60,61,62,63,64] |

| 3D Printing | Creating 3D channels | Paraffin wax/photocurable resin | 3D printer with a custom-made extruder | [65,66,67,68,69,70,71] |

| Pen Writing | Creating fluid barriers | Acrylate-based resin, titanium dioxide, permanent marker ink | 3D pen, correction pen, | [72,73,74] |

| Digital Plotting | Creating fluid barriers | PDMS, permanent marker ink | [75,76,77] | |

| P-DMF Devices | ||||

| Inkjet Printing/Chemical Vapor Deposition (CVD) | Patterning electrodes/creating dielectric layer | AgNP; CNT/parylene-C-Teflon | Inkjet printer/vapor deposition chamber; spin coater | [19,78] |

| Ballpoint Pen Printing/Wrapping | Patterning electrodes/creating dielectric layer | AgNP/plastic wrap–silicon oil | Conductive ballpoint pen; plotter | [79] |

| Screen Printing/Taping | Patterning electrodes/creating dielectric | Carbon; silver/adhesive tape-nevosil | Screen print | [80,81] |

| Microsyringe Dispensing/Spin Coating | Patterning electrodes/creating dielectric layer | AgNP/ PDMSsilicon oil | Microsyringe dispenser/spin coater | [82] |

| Spraying/Taping | Patterning electrodes/creating dielectric layer | Graphite/tape-nevosil | Spray | [83] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boobphahom, S.; Nguyet Ly, M.; Soum, V.; Pyun, N.; Kwon, O.-S.; Rodthongkum, N.; Shin, K. Recent Advances in Microfluidic Paper-Based Analytical Devices toward High-Throughput Screening. Molecules 2020, 25, 2970. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25132970

Boobphahom S, Nguyet Ly M, Soum V, Pyun N, Kwon O-S, Rodthongkum N, Shin K. Recent Advances in Microfluidic Paper-Based Analytical Devices toward High-Throughput Screening. Molecules. 2020; 25(13):2970. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25132970

Chicago/Turabian StyleBoobphahom, Siraprapa, Mai Nguyet Ly, Veasna Soum, Nayoon Pyun, Oh-Sun Kwon, Nadnudda Rodthongkum, and Kwanwoo Shin. 2020. "Recent Advances in Microfluidic Paper-Based Analytical Devices toward High-Throughput Screening" Molecules 25, no. 13: 2970. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25132970