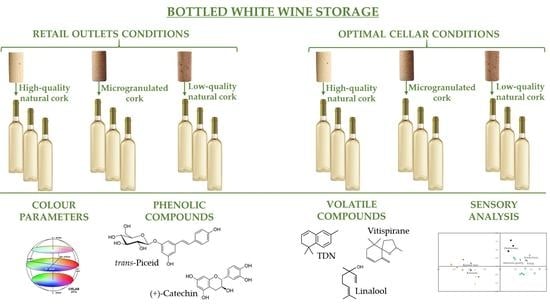

Evaluation of the Storage Conditions and Type of Cork Stopper on the Quality of Bottled White Wines

Abstract

:1. Introduction

2. Results and Discussion

2.1. Conventional Enological Parameters

2.2. Color Related Parameters and Phenolic Compounds

2.3. Volatile Compounds and Sensorial Profile

3. Materials and Methods

3.1. Cork Samples

3.2. Storage Conditions

3.3. Conventional Analysis and Color Parameters

3.4. Analysis of Phenolic Compounds

3.5. Analysis of Volatile Compounds

3.6. Sensorial Analysis

3.7. Statistical Analysis

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Silva, M.A.; Julien, M.; Jourdes, M.; Teissedre, P.L. Impact of closures on wine post-bottling developments: A review. Eur. Food Res. Technol. 2011, 233, 905–914. [Google Scholar] [CrossRef]

- Escudero, A.; Asensio, E.; Cacho, J.; Ferreira, V. Sensory and chemical changes of young white wines stored under oxygen. An assessment of the role played by aldehydes and some other important odorants. Food Chem. 2002, 77, 325–331. [Google Scholar] [CrossRef]

- Pérez-Coello, M.S.; González Viñas, M.A.; García Romero, E.; Díaz-Maroto, M.C.; Cabezudo, M.D. Influence of storage temperature on the volatile compounds of young white wines. Food Control. 2003, 14, 301–306. [Google Scholar] [CrossRef]

- Blake, A.; Kotseridis, Y.; Brindle, I.D.; Inglis, D.; Sears, M.; Pickering, G. Effect of closure and packaging type on 3-alkyl-2-methoxypyrazines and other impact odorant of Riesling and Cabernet Franc wines. J. Agric. Food Chem. 2009, 57, 4680–4690. [Google Scholar] [CrossRef] [PubMed]

- Skouroumounis, G.K.; Kwiatkowski, M.J.; Francis, I.L.; Oakey, H.; Capone, D.; Duncan, B.; Sefton, M.A.; Waters, E.J. The impact of closure type and storage conditions on the composition, colour and flavour properties of a Riesling and a wooden Chardonnay wine during five years’storage. Aust. J. Grape Wine Res. 2005, 11, 369–384. [Google Scholar] [CrossRef]

- Lopes, P.; Silva, M.A.; Pons, A.; Tominaga, T.; Lavigne, V.; Saucier, C.; Darriet, P.; Teissedre, P.L.; Dubourdieu, D. Impact of oxygen dissolved at bottling and transmitted through closures on the composition and sensory properties of a Sauvignon Blanc wine during bottle storage. J. Agric. Food Chem. 2009, 57, 10261–10270. [Google Scholar] [CrossRef]

- Ugliano, M. Oxygen contribution to wine aroma evolution during bottle aging. J. Agric. Food Chem. 2013, 61, 6125–6136. [Google Scholar] [CrossRef]

- Coetzee, C.; du Toit, W.J. Sauvignon blanc wine: Contribution of aging and oxygen on aromatic and non-aromatic compounds and sensory composition—A review. S. Afr. J. Enol. Vitic. 2015, 36, 347–365. [Google Scholar] [CrossRef] [Green Version]

- Coetzee, C.; Van Wyngaard, E.; Suklje, K.; Silva Ferreira, A.C.; du Toir, W.J. Chemical and sensory study on the evolution of aromatic and nonaromatic compounds during the progressive oxidative storage of a Sauvignon blanc wine. J. Agric. Food Chem. 2016, 64, 7979–7993. [Google Scholar] [CrossRef]

- Kwiatkowski, M.; Skouroumounis, G.K.; Lattey, K.A.; Waters, E.J. The impact of closures, including screw cap with three different headspace volumes, on the composition, colour and sensory properties of a Cabernet Sauvignon wine during two years’storage. Aust. J. Grape Wine Res. 2007, 13, 81–94. [Google Scholar] [CrossRef]

- Ugliano, M.; Dieval, J.B.; Siebert, T.; Kwiatkowski, M.; Aagaard, O.; Vidal, S.; Waters, E.J. Oxygen consumption and development of volatile sulfur compounds during bottle aging of two shiraz wines. Influence of pre- and prostbottling controlled oxygen exposure. J. Agric. Food Chem. 2012, 60, 8561–8570. [Google Scholar] [CrossRef] [PubMed]

- Scrimgeour, N.; Nordestgaard, S.; Lloyd, N.D.R.; Wilkese, E.N. Exploring the effect of elevated storage temperature on wine composition. Aust. J. Grape Wine Res. 2015, 21, 713–722. [Google Scholar] [CrossRef]

- Giuffrida de Esteban, M.L.; Ubeda, C.; Heredia, F.J.; Catania, A.A.; Assof, M.V.; Fanzone, M.L.; Jofre, V.P. Impact of closure type and storage temperature on chemical and sensory composition of Malbec wines (Mendoza, Argentina) during aging in bottle. Food Res. Int. 2019, 125, 108553. [Google Scholar] [CrossRef] [PubMed]

- Hopter, H.; Buffon, P.A.; Ebeler, S.E.; Heymann, H. The combined effects of storage temperature and packaging on the sensory, chemical, and physical properties of a Cabernet Sauvignon wine. J. Agric. Food Chem. 2012, 61, 3320–3334. [Google Scholar]

- Mafata, M.; Brand, J.; Panzeri, V.; Kidd, M.; Buica, A. A multivariate approach to evaluating the chemical and sensorial evolution of South African Sauvignon Blanc and Chenin Blanc wines under different bottle storage conditions. Food Res. Int. 2019, 125, 108515. [Google Scholar] [CrossRef]

- Maujeau, A.; Seguin, N. Contribution à l’étude des gouts de lumière dans les vins de Champagne. 3-Les réactions photochimiques responsables del goûts de lumière dans le vin de Champagne. Sci. Aliment. 1983, 3, 589–601. [Google Scholar]

- Dias, D.A.; Smith, T.A.; Ghiggino, K.P.; Scollary, G.R. The role of light, temperature and wine bottle colour on pigment enhancement in white wine. Food Chem. 2012, 135, 2934–2941. [Google Scholar] [CrossRef]

- Clark, A.C.; Dias, D.A.; Smith, T.A.; Ghiggino, K.P.; Scollary, G.R. Iron (III) tartrate as a potential precursor of light-induced oxidative degradation of white wine: Studies in a model wine system. J. Agric. Food Chem. 2011, 59, 3575–3581. [Google Scholar] [CrossRef]

- Chatonnet, P.; Labadie, D. Caractéristiques physiques et comportement vis-à-vis de l’oxidation du vin de différents types de bouchons chevilles. Rev. Oenolog. 2003, 106, 13–20. [Google Scholar]

- Cejudo-Bastante, M.J.; Hermosín-Gutiérrez, I.; Castro-Vázquez, L.I.; Pérez-Coello, M.S. Hyperoxygenation and bottle storage of chardonnay white wines: Effects on color-related phenolics, volatile composition, and sensory characteristics. J. Agric. Food Chem. 2011, 59, 4171–4182. [Google Scholar] [CrossRef]

- Hernanz, D.; Gallo, V.; Recamales, A.F.; Meléndez-Martínez, A.J.; González-Miret, M.L.; Heredia, F.J. Effect of storage on the phenolic content, volatile composition and colour of white wines from the varieties Zalema and Colombard. Food Chem. 2009, 113, 530–537. [Google Scholar] [CrossRef]

- Brajkovich, M.; Tibbits, N.; Peron, G.; Lund, C.M.; Dykes, S.I.; Kilmartin, P.A.; Nicolau, L. Effect of screwcap and cork closures on SO2 levels and aromas in a Sauvignon Blanc wine. J. Agric. Food Chem. 2005, 53, 10006–10011. [Google Scholar] [CrossRef] [PubMed]

- Sioumis, N.; Kallithraka, S.; Makris, D.P.; Kefalas, P. Kinetics of browning onset in white wines: Influence of principal redox-active polyphenols and impact on the reducing capacity. Food Chem. 2006, 94, 98–104. [Google Scholar] [CrossRef]

- Pérez-Magariño, S.; González San José, M.L. Influence of commercial pectolytic preparations on the composition and storage evolution of Albillo white wine. Int. J. Food Sci. Technol. 2001, 36, 789–796. [Google Scholar] [CrossRef]

- Singleton, V.L. Oxygen with phenols and related reactions in musts, wines and model systems: Observations and practical implication. Am. J. Enol. Vitic. 1987, 38, 69–76. [Google Scholar]

- Clark, A.C.; Prenzler, P.D.; Scollary, G.R. Impact of the condition of storage of tartaric acid solutions on the production and stability of glyoxylic acid. Food Chem. 2007, 102, 905–916. [Google Scholar] [CrossRef]

- Kolouchová, I.; Zámostný, P.; Bělohlav, Z.; Melzoch, K.; Siříšťová, L. Red Wine as Resveratrol Protective System. Czech J. Food Sci. 2004, 22, 166–168. [Google Scholar] [CrossRef] [Green Version]

- Souza, J.F.; Nascimento, M.A.S.; Silva Linhares, M.S.; Dutra, M.C.P.; dos Santos Lima, M.; Pereira, G.E. Evolution of phenolic compound profiles and antioxidant activity of Syrah red and sparkling Moscatel wines stored in bottles of different colors. Beverages 2018, 4, 89. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro de Lima, M.T.; Waffo-Téguo, P.; Teissedre, P.L.; Pujolas, A.; Vercauteren, J.; Cabanis, J.C.; Mérillon, J.M. Determination of stilbenes (trans-astringin, cis- and trans-piceid, and cis- and trans-resveratrol) in Portuguese wines. J. Agric. Food Chem. 1999, 47, 2666–2670. [Google Scholar] [CrossRef]

- Guerrero, R.F.; Valls-Fonayet, J.; Richard, T.; Cantos-Villar, E. A rapid quantification of stilbene content in wine by ultra-high pressure liquid chromatography—Mass spectrometry. Food Control. 2020, 108, 106821. [Google Scholar] [CrossRef]

- Marchante, L.; Loarce, L.; Izquierdo-Cañas, P.M.; Alañón, M.E.; García-Romero, E.; Pérez-Coello, M.S.; Díaz-Maroto, M.C. Natural extracts from grape seed and stem by-products in combination with colloidal silver as alternative preservatives to SO2 for white wines: Effects on chemical composition and sensorial properties. Food Res. Int. 2019, 125, 108594. [Google Scholar] [CrossRef] [PubMed]

- Sako, M.; Hosokawa, H.; Ito, T.; Iinuma, M. Regioselective oxidative coupling of 4-hydroxystilbenes: Synthesis of resveratrol and epsilon-viniferin (E)-dehydrodimers. J. Org. Chem. 2004, 69, 2598–2600. [Google Scholar] [CrossRef] [PubMed]

- Trela, B.C.; Waterhouse, A.L. Resveratrol: Isomeric molar absorptivities and stability. J. Agric. Food Chem. 1996, 44, 1253–1257. [Google Scholar] [CrossRef]

- Sánchez-Palomo, E.; Gómez García-Carpintero, E.; Alonso-Villegas, R.; González-Viñas, M.A. Characterization of aroma compounds of Verdejo white wines from the La Mancha region by odour activity values. Flavour Fragr. J. 2010, 25, 456–462. [Google Scholar] [CrossRef]

- Robinson, A.L.; Mueler, M.; Heymann, H.; Ebeler, S.E.; Boss, P.K.; Solomon, P.S.; Trengove, R.D. Effect of simulated shipping conditions on sensory attributes and volatile composition of commercial white and red wines. Am. J. Enol. Vitic. 2010, 61, 337–347. [Google Scholar]

- Bayonove, C.; Baumes, R.; Crouzet, J.; Günata, Z. Aromas. In Enología: Fundamentos Científicos y Tecnológicos; Flanzy, C., Ed.; AMV Ediciones, Mundi Prensa: Madrid, Spain, 2000; pp. 137–176. [Google Scholar]

- Silva Ferreira, A.C.; Guedes de Pinho, P.; Rodrigues, P.; Hogg, T. Kinetics of oxidative degradation of white wines and how they are affected by selected technological parameters. J. Agric. Food Chem. 2002, 50, 5919–5924. [Google Scholar] [CrossRef] [PubMed]

- Mizuskina, K.; Takashima, K.; Takahashi, T.; Totsuka, A. Effects of middle and higher boiling sulfur compounds on wine flavor. Nippon Jozo Kyokaishi. 1990, 85, 120–126. [Google Scholar]

- Recamales, A.F.; Gallo, V.; Hernanz, D.; González-Miret, M.L.; Heredia, F.J. Effect of time and storage conditions on major volatile compounds of Zalema white wine. J. Food Qual. 2011, 34, 100–110. [Google Scholar] [CrossRef]

- Ling, M.Q.; Xie, H.; Hua, Y.B.; Cai, J.; Li, S.Y.; Lan, Y.B.; Li, R.N.; Duan, C.Q.; Shi, Y. Flavor profile evolution of bottle aged rosé and white wines sealed with different closures. Molecules 2019, 24, 836. [Google Scholar] [CrossRef] [Green Version]

- Rapp, A.; Marais, J. The shelf life of wine: Changes in aroma substances during storage and ageing of white wines. In Shelf Life Studies of Foods and Beverages. Chemical, Biological, Physical and Nutritional Aspects; Charalambous, G., Ed.; Elsevier: Amsterdam, The Netherlands, 1993; pp. 891–923. [Google Scholar]

- Moreira, N.; Lopes, P.; Ferreira, H.; Cabral, M.; Guedes de Pinho, P. Sensory attributes and volatile composition of a dry white wine under different packing configurations. J. Food Sci. Technol. 2018, 55, 424–430. [Google Scholar] [CrossRef]

- UNE 56921 Standard. Natural Cork Stoppers for Still Wines. Test Methods and Specifications; AENOR: Madrid, Spain, 2003. [Google Scholar]

- O.I.V. Compendium of International Methods of Wine and Must Analysis; International Organization of Vine and Wine: Paris, France, 2014. [Google Scholar]

- Rebello, L.P.G.; Lago-Vanzela, E.S.; Barcia, M.T.; Ramos, A.M.; Stringheta, P.C.; Da-Silva, R.; Castillo-Muñoz, N.; Gómez-Alonso, S.; Hermosín-Gutiérrez, I. Phenolic composition of the berry parts of hybrid grape cultivar BRS Violeta (BRS Rubea x IAC 1398-21) using HPLC-DAD-ESI-MS/MS. Food Res. Int. 2013, 54, 354–366. [Google Scholar] [CrossRef]

| Conventional Parameter | Value (n = 3) |

|---|---|

| alcoholic degree (% v/v) | 11.9 ± 0.0 |

| total acidity (g/L) | 5.03 ± 0.05 |

| pH | 3.27 ± 0.00 |

| total SO2 (mg/L) | 36.0 ± 1.7 |

| free SO2 (mg/L) | 19.5 ± 0.5 |

| glucose and fructose (g/L) | 1.75 ± 0.01 |

| acetic acid (g/L) | 0.08 ± 0.01 |

| malic acid (g/L) | 1.60 ± 0.00 |

| citric acid (g/L) | 0.33 ± 0.02 |

| tartaric acid (g/L) | 2.14 ± 0.07 |

| succinic acid (g/L) | 0.60 ± 0.02 |

| lactic acid (g/L) | 0.02 ± 0.01 |

| glycerol (g/L) | 5.69 ± 0.20 |

| meso-butanediol (g/L) | 0.10 ± 0.01 |

| levo-butanediol (g/L) | 0.23 ± 0.01 |

| Wine before Bottling | Light Exposure/24 ± 2 °C | Darkness/12 °C | |||||

|---|---|---|---|---|---|---|---|

| SUP | THR | MGR | SUP | THR | MGR | ||

| Flavan-3-ols (mg/L) | |||||||

| (+)-catechin | 3.96 c ± 0.24 | 1.26 a ± 0.11 | 1.14 a ± 0.12 | 1.26 a ± 0.07 | 2.65 b ± 0.08 | 2.41 b ± 0.11 | 2.66 b ± 0.16 |

| (−)-epicatechin | 2.64 d ± 0.02 | 0.43 a ± 0.03 | 0.40 a ± 0.05 | 0.42 a ± 0.04 | 1.40 c ± 0.03 | 1.27 b ± 0.07 | 1.40 c ± 0.06 |

| (+)-gallocatechin | 0.87 d ± 0.01 | 0.40 a ± 0.00 | 0.36 a ± 0.03 | 0.37 a ± 0.03 | 0.68 c ± 0.04 | 0.57 b ± 0.03 | 0.64 c ± 0.02 |

| (−)-epigallocatechin | 0.16 c ± 0.00 | 0.05 a ± 0.02 | 0.04 a ± 0.01 | 0.05 a ± 0.01 | 0.11 b ± 0.01 | 0.10 b ± 0.01 | 0.12 b ± 0.02 |

| procyanidin B1 | 0.70 c ± 0.03 | 0.02 a ± 0.00 | 0.02 a ± 0.00 | 0.03 a ± 0.00 | 0.41 b ± 0.03 | 0.37 b ± 0.02 | 0.40 b ± 0.05 |

| procyanidin B2 | 0.29 c ± 0.01 | 0.02 a ± 0.00 | 0.01 a ± 0.00 | 0.02 a ± 0.00 | 0.19 b ± 0.02 | 0.18 b ± 0.02 | 0.19 b ± 0.02 |

| procyanidin unknown | 0.20 d ± 0.00 | 0.01 a ± 0.00 | 0.01 a ± 0.01 | 0.01 a ± 0.00 | 0.08 c ± 0.01 | 0.07 b ± 0.01 | 0.07 b ± 0.01 |

| monomers glycosides | 3.24 c ± 0.00 | 2.36 a ± 0.14 | 2.23 a ± 0.11 | 2.28 a ± 0.04 | 2.76 b ± 0.10 | 2.67 b ± 0.08 | 2.83 b ± 0.16 |

| Stilbenes (µg/L) | |||||||

| trans-piceid | 54.0 a ± 0.3 | 391.9 b ± 27.1 | 435.2 c ± 23.6 | 393.8 b ± 21.3 | 61.1 a ± 2.5 | 62.5 a ± 0.8 | 67.5 a ± 3.5 |

| cis-piceid | 512.8 d ± 3.6 | 153.5 b ± 4.2 | 85.4 a ± 5.2 | 135.2 b ± 8.9 | 526.1 d ± 10.8 | 483.8 c ± 14.8 | 498.6 c,d ± 19.2 |

| trans-resveratrol | 614.0 d ± 9.5 | 180.2 b ± 9.2 | 97.6 a ± 17.2 | 182.6 b ± 6.6 | 629.7 d ± 17.7 | 554.3 c ± 22.3 | 608.1 d ± 22.1 |

| cis-resveratrol | 64.9 c ± 2.7 | 24.7 b ± 2.5 | 13.3 a ± 1.7 | 17.3 a,b ± 2.7 | 95.2 d ± 5.9 | 72.0 c ± 6.9 | 91.6 d ± 5.0 |

| Color parameters | |||||||

| L* | 96.80 a,b,c ± 0.12 | 97.03 b,c ± 0.06 | 97.40 c ± 0.13 | 97.23 c ± 0.12 | 96.56 a,b ± 0.08 | 96.45 a,b ± 0.31 | 96.30 a,b ± 0.58 |

| a* | −0.63 a ± 0.04 | −0.66 a ± 0.07 | −0.60 a ± 0.08 | −0.72 a ± 0.04 | −0.42 b ± 0.02 | −0.41 b ± 0.06 | −0.40 b ± 0.11 |

| b* | 4.35 a ± 0.30 | 12.81 c ± 0.17 | 12.72 c ± 0.30 | 12.69 c ± 0.20 | 9.94 b ± 0.21 | 10.75 c ± 0.17 | 10.45 b,c ± 0.64 |

| color intensity (CI) | 0.16 a ± 0.00 | 0.24 b ± 0.00 | 0.22 b ± 0.01 | 0.23 b ± 0.00 | 0.22 b ± 0.01 | 0.23 b ± 0.01 | 0.23 b ± 0.03 |

| C*ab | 2.45 a ± 0.11 | 4.09 c ± 0.05 | 4.34 c ± 0.12 | 4.23 c ± 0.13 | 3.20 b ± 0.02 | 3.30 b ± 0.17 | 3.16 b ± 0.24 |

| A 420 nm (a.u.) | 0.10 a ± 0.00 | 0.18 c ± 0.00 | 0.18 c ± 0.00 | 0.18 c ± 0.00 | 0.15 b ± 0.00 | 0.16 b ± 0.01 | 0.16 b ± 0.01 |

| Wine Before Bottling | Light Exposure/24 ± 2 °C | Darkness/12 °C | |||||

|---|---|---|---|---|---|---|---|

| SUP | THR | MGR | SUP | THR | MGR | ||

| Major volatile compounds (mg/L) | |||||||

| acetaldehyde | 38.5 c ± 0.7 | 31.2 b ± 1.8 | 28.5 a ± 1.5 | 27.4 a ± 2.2 | 36.0 c ± 0.2 | 32.3 b ± 0.1 | 33.5 b ± 2.1 |

| ethyl acetate | 75.5 d ± 0.7 | 37.1 b ± 4.1 | 29.5 a ± 1.7 | 30.7 a ± 2.0 | 70.3 c,d ± 2.4 | 68.0 c ± 3.6 | 73.9 c,d ± 3.4 |

| methanol | 104.6 d ± 3.9 | 68.5 c ± 1.7 | 63.6 a,b,c ± 2.7 | 67.3 b,c ± 3.1 | 59.0 a ± 1.4 | 61.0 a,b ± 0.1 | 63.7 a,b,c ± 4.7 |

| diacetyl | 1.4 b ± 0.30 | nd a | nd a | nd a | nd a | nd a | nd a |

| ethyl butyrate | 0.8 b ± 0.05 | nd a | nd a | nd a | nd a | nd a | nd a |

| propanol | 62.5 a,b ± 0.1 | 66.4 c ± 2.3 | 61.3 a ± 1.3 | 62.4 a,b ± 2.2 | 63.0 a,b ± 2.2 | 68.9 c ± 0.3 | 64.6 a,b ± 2.2 |

| isobutanol | 23.9 c ± 3.2 | 13.6 a,b ± 1.8 | 12.6 a,b ± 2.3 | 13.8 a,b ± 3.3 | 14.7 a,b ± 2.0 | 17.6 b ± 1.9 | 10.4 a ± 1.7 |

| isoamyl acetate | 6.4 c ± 0.4 | 0.2 a ± 0.1 | 0.2 a ± 0.1 | 0.1 a ± 0.0 | 2.7 b ± 0.1 | 2.5 b ± 0.3 | 2.5 b ± 0.2 |

| 1-butanol | 0.7 a ± 0.2 | 0.7 a ± 0.2 | 0.6 a ± 0.1 | 0.8 a ± 0.3 | 0.9 a ± 0.2 | 0.5 a ± 0.1 | 0.7 a ± 0.3 |

| isoamyl alcohol | 192.3 c ± 2.0 | 174.4 b ± 4.2 | 169.8 a,b ± 6.9 | 172.8 b ± 4.1 | 157.3 a ± 5.1 | 167.0 a,b ± 5.1 | 167.6 a,b ± 8.9 |

| acetoin | 8.9 d ± 0.1 | 0.1 a ± 0.0 | 0.1 a ± 0.0 | 0.1 a ± 0.0 | 2.1 c ± 0.42 | 1.3 b ± 0.2 | 2.4 c ± 0.2 |

| ethyl lactate | 7.5 a ± 0.4 | 19.5 c ± 1.4 | 20.5 c ± 1.6 | 21.1 c ± 2.0 | 14.2 b ± 0.9 | 16.6 b ± 1.3 | 15.3 b ± 1.2 |

| Minor volatile compounds (µg/L) | |||||||

| Esters | |||||||

| ethyl hexanoate | 661.4 b ± 39.7 | 546.8 a,b ± 68.3 | 551.9 a,b ± 70.0 | 576.7 a,b ± 34.8 | 591.6 a,b ± 56.9 | 595.4 a,b ± 63.3 | 503.9 a ± 38.4 |

| ethyl pyruvate | 34.6 b ± 6.3 | 31.4 a,b ± 8.4 | 26.3 a,b ± 5.2 | 23.4 a,b ± 9.3 | 19.9 a,b ± 7.8 | 20.2 a,b ± 2.1 | 16.1 a ± 2.8 |

| hexyl acetate | 257.2 d ± 6.3 | 18.0 a ± 5.1 | 24.3 a ± 8.2 | 28.8 a ± 7.2 | 138.7 c ± 10.4 | 152.3 c ± 13.1 | 112.6 b ± 18.2 |

| ethyl 2-hydroxy-3-methylbutyrate | 2.9 a ± 0.2 | 7.2 b ± 0.5 | 7.3 b ± 0.5 | 7.7 b ± 0.2 | 2.8 a ± 0.2 | 2.8 a ± 0.1 | 2.5 a ± 0.5 |

| ethyl octanoate | 1626.1 c ± 9.3 | 560.5 b ± 89.8 | 428.8 a ± 50.5 | 440.0 a ± 73.9 | 601.2 b ± 23.3 | 423.3 a ± 35.2 | 595.2 b ± 72.2 |

| methyl 2-hydroxy-4-methylpentanoate | 4.1 c ± 0.4 | 2.3 b ± 0.4 | 2.1 b ± 0.1 | 2.2 b ± 0.2 | 1.1 a ± 0.1 | 1.2 a ± 0.1 | 1.0 a ± 0.1 |

| ethyl 3-hydroxybutyrate | 104.6 b ± 2.5 | 43.5 a ± 1.9 | 43.8 a ± 2.7 | 46.2 a ± 2.3 | 49.0 a ± 2.4 | 49.6 a ± 3.7 | 48.3 a ± 10.5 |

| ethyl 2-hydroxy-4-methylpentanoate | 28.9 a ± 4.7 | 80.3 a ± 42.8 | 58.8 a ± 12.8 | 84.1 a ± 43.4 | 33.7 a ± 1.8 | 28.3 a ± 1.9 | 34.8 a ± 12.3 |

| diethyl malonate | 2.5 a ± 0.1 | 6.7 b ± 0.0 | 7.0 c ± 0.2 | 6.7 b ± 0.2 | 2.6 a ± 0.1 | 2.6 a ± 0.1 | 2.7 a ± 0.2 |

| ethyl decanoate | 431.8 e ± 4.7 | 78.0 c ± 9.3 | 30.7 a ± 6.6 | 29.5 a ± 8.8 | 101.9 d ± 12.1 | 54.8 b ± 11.3 | 68.9 b,c ± 15.1 |

| ethyl 4-hydroxybutyrate | 278.2 c ± 1.7 | 24.0 a ± 0.9 | 22.4 a ± 2.5 | 21.8 a ± 0.4 | 56.7 b ± 6.1 | 57.5 b ± 1.8 | 55.3 b ± 2.7 |

| 1,3-propanediol diacetate | 50.0 c ± 4.2 | 2.2 a ± 0.3 | 2.2 a ± 0.2 | 2.1 a ± 0.1 | 10.7 b ± 0.8 | 10.1 b ± 0.2 | 9.5 b ± 0.1 |

| ethyl 3-hydroxyhexanoate | 2.7 c ± 0.1 | 2.4 b ± 0.1 | 2.3 b ± 0.1 | 2.2 b ± 0.1 | 1.5 a ± 0.1 | 1.5 a ± 0.1 | 1.5 a ± 0.1 |

| ethyl succinate | 3288.8 a ± 996.6 | 10398.5 c ± 990.9 | 10385.3 c ± 913.3 | 9051.2 a,c ± 1246.3 | 7100.7 a ± 1214.6 | 8395.3 a,c ± 475.6 | 7262.3 a ± 808.8 |

| ethyl glutarate | 21.7 a ± 1.8 | 98.4 c ± 0.6 | 95.7 c ± 7.8 | 93.6 c ± 6.6 | 47.9 b ± 3.8 | 48.2 b ± 4.9 | 43.9 b ± 6.8 |

| C6 alcohols | |||||||

| 1-hexanol | 1808.0 a ± 57.2 | 1973.1 a ± 211.3 | 2017.6 a ± 137.5 | 2058.1 a ± 61.2 | 1920.5 a ± 239.8 | 2000.3 a ± 105.0 | 1669.0 a ± 61.3 |

| cis-3-hexen-1-ol | 216.4 a ± 4.1 | 238.8 a ± 31.7 | 243.4 a ± 18.0 | 243.5 a ± 12.0 | 227.8 a ± 23.4 | 247.5 a ± 12.9 | 218.7 a ± 21.3 |

| trans-2-hexen-1-ol | 5.0 b ± 0.3 | 3.0 a ± 0.6 | 3.6 a ± 0.7 | 3.0 a ± 0.2 | 7.9 c ± 0.4 | 8.0 c ± 0.5 | 8.2 c ± 1.3 |

| cis-2-hexen-1-ol | 34.4 a ± 3.0 | 32.3 a ± 3.5 | 30.9 a ± 2.2 | 29.9 a ± 2.2 | 28.4 a ± 3.0 | 29.3 a ± 2.9 | 28.7 a ± 4.0 |

| Benzenic compounds | |||||||

| benzaldehyde | 34.0 a ± 1.1 | 35.5 a ± 4.1 | 37.9 a ± 5.1 | 35.8 a ± 2.1 | 39.9 a ± 3.4 | 42.3 a ± 2.8 | 37.0 a ± 1.9 |

| 2-phenylethyl acetate | 582.0 c ± 2.8 | 21.5 a ± 1.5 | 23.0 a ± 1.4 | 20.7 a ± 0.7 | 178.0 b ± 13.4 | 181.4 b ± 5.8 | 175.8 b ± 1.7 |

| guaiacol | 10.1 c ± 0.4 | 8.3 b,c ± 1.4 | 8.1 b,c ± 1.4 | 6.8 a,b ± 1.3 | 5.3 a ± 0.7 | 7.3 a,b ± 0.4 | 6.2 a,b ±0.8 |

| benzyl alcohol | 221.9 a ± 4.3 | 263.0 a ± 96.1 | 309.8 a ± 99.9 | 186.5 a ± 22.5 | 251.5 a ± 19.6 | 272.9 a ± 45.4 | 286.9 a ± 67.3 |

| phenyl ethyl alcohol | 8384.9 a ± 802.5 | 7914.4 a ± 3082.9 | 9311.7 a ± 1997.6 | 9234.5 a ± 3182.7 | 9166.7 a ± 933.2 | 8556.5 a ± 1506.6 | 8724.8 a ± 1375.6 |

| 4-vinylguaiacol | 564.9 b ± 49.3 | 624.2 b ± 66.5 | 509.5 b ± 14.6 | 550.7 b ± 96.6 | 330.6 a ± 77.4 | 373.5 a ± 34.0 | 402.5 a ± 35.6 |

| Terpenes | |||||||

| trans-linalool oxide | 2.6 b ± 0.3 | 7.4 c ± 0.1 | 7.5 c ± 0.2 | 7.5 c ± 0,1 | 1.9 a ± 0.2 | 1.9 a ± 0.1 | 1.8 a ± 0.2 |

| cis-linalool oxide | 1.9 a ± 0.3 | 4.3 b ± 0.2 | 4.2 b ± 0.2 | 3.9 b ± 0.4 | 1.4 a ± 0.1 | 1.4 a ± 0.1 | 1.4 a ± 0.1 |

| linalool | 5.0 c ± 0.4 | 0.6 a ± 0.2 | 0.5 a ± 0.1 | 0.6 a ± 0.1 | 3.8 b ± 0.4 | 3.6 b ± 0.0 | 3.5 b ± 0.2 |

| hotrienol | 2.4 a,b ± 0.0 | 3.1 b ± 0.8 | 2.8 b ± 0.8 | 3.0 b ± 0.3 | 1.3 a ± 0.4 | 1.4 a ± 0.2 | 1.3 a ± 0.3 |

| α-terpineol | 6.0 a ± 0.1 | 29.8 b ± 4.6 | 27.2 b ± 3.6 | 27.7 b ± 3.8 | 11.8 a ± 2.0 | 12.4 a ± 0.3 | 11.9 a ± 3.0 |

| citronellol | 3.4 b ± 0.2 | 1.7 a ± 0.4 | 1.6 a ± 0.2 | 1.5 a ± 0.1 | 1.5 a ± 0.1 | 1.5 a ± 0.0 | 1.5 a ± 0.2 |

| trans-geraniol | 1.7 a ± 0.3 | 1.3 a ± 0.2 | 1.5 a ± 0.3 | 1.3 a ± 0.1 | 1.2 a ± 0.2 | 1.4 a ± 0.2 | 1.3 a ± 0.1 |

| hydroxylinalool | 3.4 c ± 0.1 | 2.1 a,b ± 0.2 | 1.5 a ± 0.2 | 1.6 a ± 0.1 | 2.6 b ± 0.3 | 2.7 b ± 0.2 | 2.7 b ± 0.6 |

| geranic acid | 22.1 c ± 1.2 | 10.1 b ± 1.4 | 8.6 b,a ± 0.3 | 7.3 a ± 0.3 | 9.9 b ± 0.4 | 6.7 a ± 0.7 | 7.1 a ± 0.6 |

| C13-norisoprenoids | |||||||

| vitispirane | 0.7 a ± 0.1 | 6.9 c ± 0.8 | 6.3 b,c ± 0.7 | 5.8 b ± 0.5 | 0.6 a ± 0.0 | 0.6 a ± 0.0 | 0.7 a ± 0.1 |

| β-damascenone | 13.4 b ± 0.6 | 7.3 a ± 0.7 | 6.7 a ± 0.7 | 6.1 a ± 0.5 | 6.4 a ± 1.0 | 5.3 a ± 0.8 | 5.9 a ± 0.1 |

| α-ionone | 1.1 a ± 0.3 | 1.0 a ± 0.2 | 0.9 a ± 0.3 | 1.0 a ± 0.1 | 0.8 a ± 0.3 | 0.6 a ± 0.3 | 0.7 a ± 0.2 |

| TDN | 9.7 a ± 0.2 | 24.7 b ± 4.9 | 23.3 b ± 7.4 | 25.7 b ± 2.4 | 8.8 a ± 2.5 | 9.2 a ± 1.7 | 9.9 a ± 2.3 |

| 3-oxo-α-ionol | 82.0 b ± 10.9 | 45.0 a ± 3.5 | 45.1 a ± 3.0 | 40.6 a ± 4.8 | 43.2 a ± 5.0 | 41.1 a ± 2.8 | 41.2 a ± 3.6 |

| Lactones | |||||||

| γ-butyrolactone | 12.7 a ± 2.1 | 11.7 a ± 12.2 | 7.9 a ± 4.0 | 13.9 a ± 14.6 | 15.4 a ± 2.0 | 16.0 a ± 2.6 | 13.4 a ± 1.4 |

| γ-caprolactone | 1.4 a ± 0.1 | 2.4 b ± 0.3 | 2.3 b ± 0.3 | 2.2 b ± 0.1 | 2.2 b ± 0.1 | 2.3 b ± 0.1 | 2.4 b ± 0.1 |

| γ-nonalactone | 12.4 a ± 0.7 | 18.9 c ± 0.9 | 15.8 b ± 2.2 | 17.6 b,c ± 1.2 | 11.2 a ± 1.2 | 9.9 a ± 0.5 | 10.1 a ± 0.7 |

| pantolactone | 0.03 a ± 0.00 | 0.08 b ± 0.01 | 0.08 b ± 0.01 | 0.07 b ± 0.00 | 0.03 c ± 0.00 | 0.03 c ± 0.00 | 0.03 c ± 0.00 |

| γ-decalactone | 512.9 a ± 29.3 | 817.9 b ± 84.0 | 775.1 b ± 52.4 | 776.3 b ± 37.0 | 484.5 a ± 52.3 | 434.7 a ± 5.2 | 446.7 a ± 32.0 |

| Furan and pyran compounds | |||||||

| furfural | 23.9 a ± 2.1 | 156.4 b ± 19.4 | 154.6 b ± 21.6 | 167.2 b ± 9.3 | 21.3 a ± 11.8 | 18.0 a ± 7.9 | 11.9 a ± 2.9 |

| furanyl ethanone | 4.0 a ± 0.4 | 15.1 b ± 1.3 | 15.3 b ± 1.5 | 16.2 b ± 0.5 | 3.9 a ± 0.3 | 4.0 a ± 0.3 | 4.3 a ± 0.8 |

| ethyl 2-furoate | 13.9 a ± 0.2 | 94.7 c ± 2.3 | 95.8 c ± 3.5 | 97.0 c ± 3.2 | 32.3 b ± 1.3 | 33.9 b ± 3.1 | 29.6 b ± 0.9 |

| 5-ethoxymethylfurfural | 88.6 a ± 2.0 | 198.3 c ± 13.6 | 192.9 c ± 18.2 | 192.7 c ± 18.0 | 130.8 b ± 8.0 | 142.2 b ± 4.8 | 121.0 b ± 11.3 |

| furaneol | 1.4 a ± 0.2 | 3.5 b ± 0.5 | 3.4 b ± 0.6 | 2.9 a,b ± 0.5 | 2.2 a ± 0.2 | 2.6 a ± 0.1 | 2.6 a ± 0.1 |

| maltol | 29.1 a ± 2.0 | 25.5 a ± 5.2 | 22.9 a ± 2.2 | 25.2 a ± 7.6 | 31.7 a ± 10.8 | 23.4 a ± 6.8 | 19.5 a ± 5.9 |

| 5-hydroxymethylfurfural | 4.4 a ± 0.1 | 47.0 b ± 5.5 | 47.0 b ± 4.8 | 44.4 b ± 3.0 | 7.8 a ± 0.8 | 7.3 a ± 0.9 | 8.5 a ± 0.6 |

| Acids | |||||||

| butyric acid | 226.9 a ± 5.7 | 385.6 a ± 242.7 | 272.9 a ± 112.0 | 231.4 a ± 159.2 | 221.9 a ± 6.7 | 317.2 a ± 196.2 | 234.4 a ± 44.0 |

| hexanoic acid | 5847.9 a ± 300.0 | 5544.9 a ± 276.8 | 5443.1 a ± 277.0 | 5176.0 a ± 180.5 | 5114.5 a ± 1064.0 | 5617.3 a ± 198.6 | 5004.1 a ± 945.3 |

| octanoic acid | 4516.3 a ± 155.4 | 4339.8 a ± 1649.4 | 3073.2 a ± 1210.7 | 3191.2 a ± 1121.1 | 4956.1 a ± 782.6 | 4409.9 a ± 1288.5 | 4984.3 a ± 1361.7 |

| decanoic acid | 745.1 b ± 13.7 | 496.7 a,b ± 36.5 | 464.2 a,b ± 82.5 | 379.5 a ± 128.4 | 747.3 b ± 193.2 | 538.2 a,b ± 148.5 | 637.4 a,b ± 82.2 |

| methyl propanoic acid | 4.3 a ± 0.1 | 5.0 a ± 4.1 | 2.6 a ± 1.0 | 2.7 a ± 0.6 | 3.1 a ± 0.3 | 3.3 a ± 0.6 | 4.2 a ± 0.9 |

| Sulfur compounds | |||||||

| 2-mercaptoethanol | 1.7 c ± 0.3 | 1.2 b ± 0.3 | 1.1 b ± 0.1 | 0.9 a,b ± 0.1 | 0.6 a ± 0.1 | 0.9 a,b ± 0.1 | 0.9 a,b ± 0.1 |

| 2-methyl-dihydro-thiophen-3-one | 100.0 b ±5.6 | 43.3 a ± 2.3 | 43.7 a ± 5.0 | 46.9 a ± 1.8 | 44.1 a ± 4.1 | 46.8 a ± 4.8 | 45.8 a ± 11.9 |

| ethyl 3-methylthiopropanoate | 0.7 b ± 0.0 | 0.9 c ± 0.0 | 0.9 c ± 0.1 | 0.9 c ± 0.0 | 0.5 a ± 0.0 | 0.5 a ± 0.0 | 0.5 a ± 0.1 |

| methionol | 65.4 b ± 0.4 | 69.5 b ± 6.6 | 61.6 b ± 2.7 | 65.7 b ± 2.5 | 48.5 a ± 2.6 | 52.0 a ± 4.9 | 53.5 a ± 6.9 |

| 3-methylthiopropanoic acid | 7.5 b ± 2.4 | 2.5 a ± 0.5 | 2.4 a ± 0.2 | 2.5 a ± 0.2 | 1.8 a ± 0.1 | 2.3 a ± 1.2 | 2.9 a ± 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz-Maroto, M.C.; López Viñas, M.; Marchante, L.; Alañón, M.E.; Díaz-Maroto, I.J.; Pérez-Coello, M.S. Evaluation of the Storage Conditions and Type of Cork Stopper on the Quality of Bottled White Wines. Molecules 2021, 26, 232. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26010232

Díaz-Maroto MC, López Viñas M, Marchante L, Alañón ME, Díaz-Maroto IJ, Pérez-Coello MS. Evaluation of the Storage Conditions and Type of Cork Stopper on the Quality of Bottled White Wines. Molecules. 2021; 26(1):232. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26010232

Chicago/Turabian StyleDíaz-Maroto, María Consuelo, Manuel López Viñas, Lourdes Marchante, María Elena Alañón, Ignacio Javier Díaz-Maroto, and María Soledad Pérez-Coello. 2021. "Evaluation of the Storage Conditions and Type of Cork Stopper on the Quality of Bottled White Wines" Molecules 26, no. 1: 232. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26010232