Synthesis and Performance of Double-Chain Quaternary Ammonium Salt Glucosamide Surfactants

Abstract

:1. Introduction

2. Results and Discussion

2.1. Structure Identification

2.2. Surface Tension

2.3. Wettability Study

2.4. Emulsifying Performance

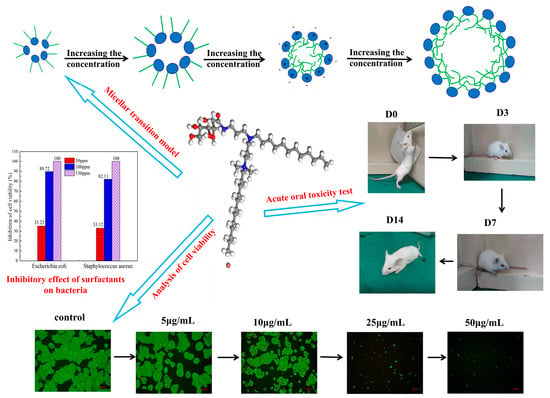

2.5. Aggregation Behavior in Aqueous Solution

2.6. Analysis of Cell Viability

2.7. Acute Oral Toxicity Test Results

2.8. Antibacterial Properties of the Surfactants

3. Materials and Methods

3.1. Materials

3.2. Equipment

3.3. Sample Synthesis

3.4. Equilibrium Surface Tension Measurement

3.5. Wettability Test

3.6. Emulsifying Performance

3.7. Dynamic Surface Tension Measurement

3.8. Transmission Electron Microscopy (TEM)

3.9. Dynamic Light Scattering Experiment

3.10. Cytotoxicity Test

3.11. Acute Oral Toxicity Test

3.12. Antimicrobial Activity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability Statement

References

- Norouzpour, M.; Nabipour, M.; Azdarpour, A.; Akhondzadeh, H.; Santos, R.M.; Keshavarz, A. Experimental investigation of the effect of a quinoa-derived saponin-based green natural surfactant on enhanced oil recovery. Fuel 2022, 318, 123652–123661. [Google Scholar] [CrossRef]

- Cao, J.; He, G.; Ning, X.; Chen, X.; Fan, L.; Yang, M.; Yin, Y.; Cai, W. Preparation and properties of O-chitosan quaternary ammonium salt/polyvinyl alcohol/graphene oxide dual self- healing hydrogel. Carbohydr. Polym. 2022, 287, 119318–119325. [Google Scholar] [CrossRef]

- Ding, H.; Jiang, Y.; Wang, Y.; Ju, H.; Geng, T. Distributions of counterions on adsorption and aggregation behavior of Gemini quaternary ammonium salt. J. Mol. Liq. 2021, 342, 117495–117501. [Google Scholar] [CrossRef]

- Li, X.L. Selective flocculation performance of amphiphilic quaternary ammonium salt in kaolin and bentonite suspensions. Colloids Surf. A Physicochem. Eng. Asp. 2022, 636, 128140–128149. [Google Scholar] [CrossRef]

- He, D.; Tan, Y.; Li, P.; Luo, Y.; Zhu, Y.; Yu, Y.; Chen, J.; Ning, N.; Zhang, S. Surface charge-convertible quaternary ammonium salt-based micelles for in vivo infection therapy. Chin. Chem. Lett. 2021, 32, 1743–1746. [Google Scholar] [CrossRef]

- Elhaj, E.; Wang, H.J.; Gu, Y.L. Functionalized quaternary ammonium salt ionic liquids (FQAILs) as an economic and efficient catalyst for synthesis of glycerol carbonate from glycerol and dimethyl carbonate. Mol. Catal. 2019, 468, 19–28. [Google Scholar] [CrossRef]

- Zhou, C.C.; Wang, Y.L. Structure-activity relationship of cationic surfactants as antimicrobial agents. Curr. Opin. Colloid Interface Sci. 2020, 45, 28–43. [Google Scholar] [CrossRef]

- Zhang, S.; Ding, S.; Yu, J.; Chen, X.; Lei, Q.; Fang, W. Antibacterial activity, in vitro cytotoxicity and cell cycle arrest of gemini quaternary ammonium surfactants. Langmuir 2015, 31, 12161–12169. [Google Scholar] [CrossRef] [PubMed]

- Vargas-Ruiz, S.; Lutzki, J.; von Klitzing, R.; Hellweg, T.; Wellert, S. Wetting of planar solid surfaces by bicontinuous sugar surfactant-based microemulsions. Colloid Polym. Sci. 2017, 295, 2183–2190. [Google Scholar] [CrossRef]

- Vargas-Ruiz, S.; Soltwedel, O.; Micciulla, S.; Sreij, R.; Feoktystov, A.; von Klitzing, R.; Hellweg, T.; Wellert, S. Sugar surfactant based microemulsions at solid surfaces: Influence of the oil type and surface polarity. Langmuir 2016, 32, 11928–11938. [Google Scholar] [CrossRef] [PubMed]

- Esmaeilian, N.; Malek, R.M.A.; Arami, M.; Mazaheri, F.M.; Dabir, B. Environmentally friendly sugar-based cationic surfactant as a new auxiliary in polyacrylonitrile dyeing. Colloids Surf. A Physicochem. Eng. Asp. 2018, 552, 103–109. [Google Scholar] [CrossRef]

- Negm, N.A.; Mohamed, A.S. Synthesis, Characterization and Biological Activity of Sugar-Based Gemini Cationic Amphiphiles. J. Surfactants Deterg. 2008, 11, 215–221. [Google Scholar] [CrossRef]

- Hussain, S.M.S.; Kamal, M.S.; Murtaza, M. Synthesis of novel ethoxylated quaternary ammonium gemini surfactants for enhanced oil recovery application. Energies 2019, 12, 1731. [Google Scholar] [CrossRef] [Green Version]

- Menger, F.M.; Littau, C.A. Gemini surfactants: A new class of self-assembling molecules. J. Am. Chem. Soc. 1993, 115, 10083–10090. [Google Scholar] [CrossRef]

- Zhi, L.F.; Li, Q.X.; Li, Y.L.; Song, Y.B. Synthesis, Adsorption and Aggregation Properties of New Saccharide-Cationic Surfactants. Colloids Surf. A Physicochem. Eng. Asp. 2013, 436, 684–692. [Google Scholar] [CrossRef]

- Zhi, L.; Li, Q.; Li, Y.; Song, Y. Adsorption and Aggregation Properties of Novel Star-shaped Gluconamide-type Cationic Surfactants in Aqueous Solution. Colloid Polym. Sci. 2014, 292, 1041–1050. [Google Scholar] [CrossRef]

- Fainerman, V.B.; Miller, R.; Aksenenko, E.V.; Makievski, A.V. Equilibrium adsorption properties of single and mixed surfactant solutions. Stud. Interface Sci. 2001, 13, 189–285. [Google Scholar]

- Cao, Y.P.; Yang, W.G.; Jiang, Y.J.; Ju, H.B.; Wang, Y.K.; Gen, T. Effect of molecular structure on properties of cationic Gemini surfactants. Appl. Chem. 2021, 50, 2979–2984. [Google Scholar]

- Chai, J.; Cui, X.; Zhang, X.; Song, M.; Wang, J.; Lu, J. Adsorption equilibrium and dynamic surface tension of alkyl polyglucosides and their mixed surfactant systems with CTAB and SDS in the surface of aqueous solutions. J. Mol. Liq. 2018, 264, 442–450. [Google Scholar] [CrossRef]

- Gao, T.; Rosen, M.J. Dynamic surface tension of aqueous surfactant solutions: 7.physical significance of dynamic parameters and the induction period. J. Colloid Interface Sci. 1995, 172, 242–248. [Google Scholar] [CrossRef]

- Eastoe, J.; Dalton, J.S.; Rogueda, P.G.A. Dynamic surface tensions of nonionic surfactant solutions. J. Colloid Interface Sci. 1997, 188, 423–430. [Google Scholar] [CrossRef]

- Eastoe, J.; Dalton, J.S.; Rogueda, P.G.A. Evidence for activation-diffusion controlled dynamic surface tension with a nonionic surfactant. Langmuir 1998, 14, 979–981. [Google Scholar] [CrossRef]

- Alami, E.; Holmberg, K. Heterogemini surfactants based on fatty acid synthesis and interfacial properties. Colloid Interface Sci. 2001, 239, 230–240. [Google Scholar] [CrossRef] [PubMed]

- Takamatsu, Y.; Iwata, N.; Tsubone, K.; Torigoe, K. Synthesis and aqueous solution properties of novel anionic heterogemini surfactants containing a phosphate headgroup. J. Colloid Interface Sci. 2009, 338, 229–235. [Google Scholar] [CrossRef] [PubMed]

- Eastoe, J.; Dalton, J.S. Dynamic surface tension and adsorption mechanisms of surfactants at the air-water interface. Adv. Colloid Interface Sci. 2000, 85, 103–144. [Google Scholar] [CrossRef]

- Wang, G.Y.; Qu, W.S.; Du, Z.P.; Wang, W.X.; Li, Q.X. Adsorpion and aggregation behaviors of tetrasiloxane-tailed gemini surfactants with (EO) m spacers. J. Phys. Chem. B 2013, 117, 3154–3160. [Google Scholar]

- Souza, J.C.; Neckel, I.T.; Varalda, J.; Ribeiro, E.; Schreiner, W.H.; Mosca, D.H.; Sierakowski, M.R.; Fernandes, V.; Ouerghi, A. Wettability effect of graphene-based surfaces on silicon carbide and their influence on hydrophobicity of nanocrystalline cerium oxide films. Colloid Interface Sci. 2015, 441, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Paria, S.; Biswal, N.R.; Chaudhuri, R.G. Surface tension, adsorption, and wetting behaviors of natural surfactants on a PTFE surface. AIChE J. 2015, 61, 655–663. [Google Scholar] [CrossRef]

- Szymczyk, K.; Zdziennicka, A.; Krawczyk, J.; Jańczuk, B. Correlation between wetting, adhesion and adsorption in the polymer-aqueous solutions of ternary surfactant mixtures-air systems. Appl. Surf. Sci. 2014, 288, 488–496. [Google Scholar] [CrossRef]

- Shah, V.; Bharatiya, B.; Shukla, A.D.; Mukherjee, T.; Shah, D.O. Adsorption of nonionic Brij and Tween surfactants at PTFE-water and air- water interfaces: Investigations on wetting, dispersion stability, foaming and drug solubilization. Colloids Surf. A Physicochem. Eng. Asp. 2016, 508, 159–166. [Google Scholar] [CrossRef]

- Cox, M.; Weerasooriya, U. Impact of molecular structure on the performance of methyl ester ethoxylates. J. Surf. Det. 1998, 1, 11–12. [Google Scholar] [CrossRef]

- Wu, W.; Hettiarachchy, N.S. Foaming and emulsifying properties of soy protein isolate and hydrolysates in skin and hair care peoducts. J. Surfactants Deterg. 1998, 1, 241–246. [Google Scholar] [CrossRef]

- Nowicki, J. Emulsion properties and phase equilibrium and of new asymmetric gemini surfactants consisting of fatty acid esters of polyethoxylated alchol or phenol. J. Surfactants Deterg. 2010, 13, 195–199. [Google Scholar] [CrossRef]

- Jaeger, D.A.; Li, B.; Clark, J.T. Cleavable double-chain surfactants with one cationic and one anionic head group that form vesicles. Langmuir 1996, 12, 24314–24316. [Google Scholar] [CrossRef]

- Zhi, L.; Shi, X.; Zhang, E.; Pan, Y.; Li, X.; Wang, H.; Liu, W. Synthesis and properties of stellate lactosamide quaternary ammonium surfactants. Colloids Surf. A Physicochem. Eng. Asp. 2021, 628, 127317–127332. [Google Scholar] [CrossRef]

- Hu, D.Y.; Li, G.; Chen, Y. Study on Cytotoxicity of Several Surfactants. Chin. Pharm. 2006, 9, 294–296. [Google Scholar]

- Schoberl, P. Okolog isch relevante daten von tensiden in waschund reinigungsm itteln. Tenside. Surf. Det. 1998, 25, 86–98. [Google Scholar]

- Caillier, L.; de Givenchy, E.T.; Levy, R.; Vandenberghe, Y.; Géribaldi, S.; Guittard, F. Synthesis and antimicrobial properties of polymerizable quaternary ammoniums. Eur. J. Med. Chem. 2009, 44, 3201–3208. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.B.; Li, Q.X.; Li, Y.L.; Zhi, L.F. Self-aggregation and antimicrobial activity of alkylguandidum salts. Colloids Surf. A Physicochem. Eng. Asp. 2012, 393, 11–16. [Google Scholar] [CrossRef]

- Devinsky, F.; Lacko, I.; Bittererova, F. Relationship between structure, surface activity and micelle formation of some new bisquaternary isosteres of 1,5-pentanediammonium dibromides. J. Colloid. Interface Sci. 1986, 114, 314. [Google Scholar] [CrossRef]

- Haldar, J.; Kondaiah, P.; Bhattacharya, S. Synthesis and antibacterial properties of novel hydrolyzable cationic amphiphiles. Incorporation of multiple head groups leads to impressive antibacterial activity. J. Med. Chem. 2005, 48, 3823–3831. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.P.; Yang, W.G.; Jiang, Y.J.; Wang, Y.K.; Ju, H.T.; Gen, T. Synthesis and properties of a zwitterionic Gemini surfactant. Fine Chem. 2021, 38, 335–341. [Google Scholar]

| Surfactant | CMC (mmol/L) | γcmc (mN/m) | pC20 | CMC/C20 | Γmax (mol·cm−2) | Amin (Å2) |

|---|---|---|---|---|---|---|

| C8DDGPB | 0.101 | 27.25 | 4.67 | 4.76 | 2.92 × 10−10 | 56.9 |

| C10DDGPB | 0.118 | 25.46 | 4.66 | 5.41 | 2.33 × 10−10 | 71.3 |

| C12DDGPB | 0.142 | 29.36 | 4.86 | 10.37 | 1.28 × 10−10 | 129.8 |

| C14DDGPB | 0.193 | 30.9 | 4.31 | 3.96 | 1.40 × 10−10 | 118.6 |

| C16DDGPB | 1.267 | 44.81 | 3.21 | 2.05 | 1.50 × 10−11 | 1107.3 |

| C12DGPB a | 4.75 | 28.36 | 3.69 | 23.41 | 1.449 × 10−10 | 114.6 |

| C14DGPB a | 0.7 | 30.26 | 4.16 | 10.13 | 1.991 × 10−10 | 83.5 |

| C12DBGB b | 0.71 | 27.61 | 4.64 | 30.87 | 1.226 × 10−10 | 135 |

| C14DBGB b | 0.51 | 27.12 | 4.74 | 28.33 | 0.878 × 10−10 | 189 |

| Sample | Dshort (m2s−1) | Dlong (m2s−1) | Dlong/Dshort |

|---|---|---|---|

| C8DDGPB | 1.028 × 10−11 | 4.603 × 10−12 | 0.4478 |

| C10DDGPB | 8.483 × 10−12 | 1.852 × 10−12 | 0.2183 |

| C12DDGPB | 8.426 × 10−12 | 7.999 × 10−14 | 0.0095 |

| C14DDGPB | 2.089 × 10−12 | 1.163 × 10−14 | 0.0056 |

| C16DDGPB | 1.267 × 10−12 | 1.299 × 10−14 | 0.0103 |

| Group | Gender | Exposure Dose(mg/Kg·BW) | Number of Animals (Only) | Weight (g) | Number of Dead Animals (Only) | Mortality (%) | ||

|---|---|---|---|---|---|---|---|---|

| D0 | D7 | D14 | ||||||

| C12DDGPB | ♂ | 5000 | 10 | 20.2 ± 0.7 | 27.9 ± 1.2 | 34.0 ± 1.7 | 10 | 100 |

| ♀ | 10 | 19.2 ± 0.8 | 27.1 ± 1.2 | 33.4 ± 1.8 | 10 | 100 | ||

| ♂ | 1000 | 10 | 20.2 ± 0.7 | 25.9 ± 1.7 | 33.0 ± 1.7 | 0 | 0 | |

| ♀ | 10 | 19.0 ± 0.7 | 25.4 ± 1.3 | 32.5 ± 1.6 | 0 | 0 | ||

| ♂ | 100 | 10 | 20.2 ± 0.7 | 24.5 ± 1.5 | 32.8 ± 1.4 | 0 | 0 | |

| ♀ | 10 | 19.2 ± 0.6 | 24.4 ± 1.4 | 31.4 ± 1.2 | 0 | 0 | ||

| C10DDGPB | ♂ | 5000 | 10 | 20.2 ± 0.7 | 27.9 ± 1.2 | 34.1 ± 1.7 | 5 | 50 |

| ♀ | 10 | 19.5 ± 0.8 | 27.2 ± 1.2 | 33.6 ± 1.8 | 6 | 60 | ||

| ♂ | 1000 | 10 | 20.2 ± 0.7 | 26.3 ± 1.7 | 33.1 ± 1.7 | 0 | 0 | |

| ♀ | 10 | 19.2 ± 0.7 | 25.5 ± 1.3 | 32.7 ± 1.6 | 0 | 0 | ||

| ♂ | 100 | 10 | 20.2 ± 0.7 | 25.5 ± 1.5 | 32.9 ± 1.4 | 0 | 0 | |

| ♀ | 10 | 19.2 ± 0.6 | 25.3 ± 1.4 | 31.6 ± 1.2 | 0 | 0 | ||

| 1227 | ♂ | 5000 | 10 | 20.5 ± 0.7 | 27.8 ± 1.2 | 34.1 ± 1.5 | 10 | 100 |

| ♀ | 10 | 19.2 ± 0.8 | 27.2 ± 1.2 | 33.2 ± 1.2 | 10 | 100 | ||

| ♂ | 1000 | 10 | 20.3 ± 0.7 | 25.2 ± 1.7 | 33.1 ± 1.6 | 10 | 100 | |

| ♀ | 10 | 19.1 ± 0.7 | 25.1 ± 1.3 | 32.4 ± 1.6 | 10 | 100 | ||

| ♂ | 100 | 10 | 20.1 ± 0.7 | 24.2 ± 1.5 | 32.7 ± 1.4 | 0 | 0 | |

| ♀ | 10 | 19.0 ± 0.6 | 24.3 ± 1.4 | 31.1 ± 1.2 | 0 | 0 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhi, L.; Shi, X.; Zhang, E.; Gao, C.; Gai, H.; Wang, H.; Liu, Z.; Zhang, T. Synthesis and Performance of Double-Chain Quaternary Ammonium Salt Glucosamide Surfactants. Molecules 2022, 27, 2149. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules27072149

Zhi L, Shi X, Zhang E, Gao C, Gai H, Wang H, Liu Z, Zhang T. Synthesis and Performance of Double-Chain Quaternary Ammonium Salt Glucosamide Surfactants. Molecules. 2022; 27(7):2149. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules27072149

Chicago/Turabian StyleZhi, Lifei, Xiufang Shi, Erzhuang Zhang, Chuangji Gao, Haocheng Gai, Hui Wang, Zhenmin Liu, and Tieming Zhang. 2022. "Synthesis and Performance of Double-Chain Quaternary Ammonium Salt Glucosamide Surfactants" Molecules 27, no. 7: 2149. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules27072149