Surface Wettability of ZnO-Loaded TiO2 Nanotube Array Layers

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Surface Morphology. SEM and AFM Results

3.2. Layer Crystallinity. XRD Results

3.3. Elemental and Chemical Composition. XPS Results

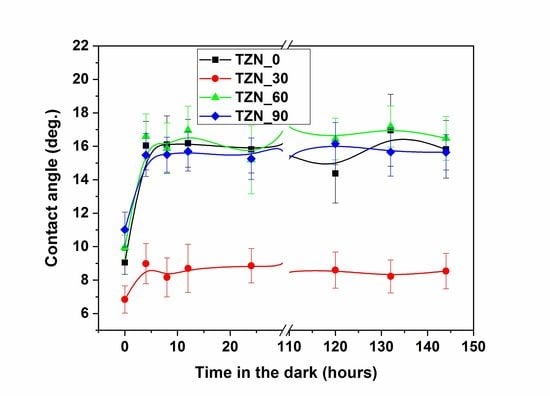

3.4. Surface Wettability. Contact Angle

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Roy, P.; Berger, S.; Schmuki, P. TiO2 Nanotubes. Angew. Chem. Int. Ed. 2011, 50, 2904–2939. [Google Scholar] [CrossRef]

- Zama, I.; Martelli, C.; Gorni, G. Preparation of TiO2 paste starting from organic colloidal suspension for semi-transparent DSSC photo-anode application. Mat. Sci. Semicond. Proc. 2017, 61, 137–144. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Arumugam, S.; Tudor, J.; Beeby, S. Investigation of low temperature processed titanium dioxide (TiO2) films for printed dye sensitized solar cells (DSSCs) for large area flexible applications. Mater. Today Proc. 2018, 5, 13846–13854. [Google Scholar] [CrossRef]

- Marandi, M.; Bayat, S.; Naeimi, S.S.M. Hydrothermal growth of a composite TiO2 hollow spheres/TiO2 nanorods powder and its application in high performance dye-sensitized solar cells. J. Electroanal. Chem. 2019, 833, 143–150. [Google Scholar] [CrossRef]

- AL-Baradi, A.M. Sputtered and heat-treated TiO2 electrodes for dye-sensitized solar cells applications. Results Phys. 2020, 17, 103109. [Google Scholar] [CrossRef]

- Doubi, Y.; Hartiti, B.; Hicham, L.; Fadili, S.; Batan, A.; Tahri, M.; Belfhaili, A.; Thevnin, P. Effect of annealing time on structural and optical properties of TiO2 thin films elaborated by spray pyrolysis technique for future gas sensor application. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, S.; Zheng, J. Biosynthesis of TiO2 nanoparticles and their application for treatment of brain injury-An in-vitro toxicity study towards central nervous system. J. Photoch. Photobio. B 2019, 194, 1–5. [Google Scholar] [CrossRef]

- Xiu, Z.; Guo, M.; Zhao, T.; Pan, K.; Xing, Z.; Li, Z.; Zhou, W. Recent advances in Ti3+ self-doped nanostructured TiO2 visible light photocatalysts for environmental and energy applications. Chem. Eng. J. 2020, 382, 123011. [Google Scholar] [CrossRef]

- Tsvetkov, N.; Larina, L.; Kang, J.K.; Shevaleevskiy, O. Sol-Gel Processed TiO2 Nanotube Photoelectrodes for Dye-Sensitized Solar Cells with Enhanced Photovoltaic Performance. Nanomaterials 2020, 10, 296. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.-Y.; Rho, W.-Y.; Lee, S.K.; Kim, S.H.; Hahn, Y.-B. TiO2 Nanoparticles/nanotubes for efficient light harvesting in perovskite solar cells. Nanomaterials 2019, 9, 326. [Google Scholar] [CrossRef] [Green Version]

- Macak, J.M.; Hildebrand, H.; Martens-Jahns, U.; Schmuki, P. Mecanistic aspects and growth of large diameter self-organized TiO2 nanotubes. J. Electroanal. Chem. 2008, 621, 254–266. [Google Scholar] [CrossRef]

- Regonini, D.; Bowen, C.R.; Jaroenworaluck, A.; Stevens, R. A review of growth mechanism, structure and crystallinity of anodized TiO2 nanotubes. Mater. Sci. Eng. R Rep. 2013, 74, 377–406. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Nguyen, N.T.; Özkan, S.; Schmuki, P. Anodic TiO2 nanotube layers: Why does self-organized growth occur—A mini review. Electrochem. Commun. 2014, 46, 157–162. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.; Du, K.; Wang, K. Surface wettability of TiO2 nanotube arrays prepared by electrochemical anodization. Appl. Surf. Sci. 2016, 388, 313–320. [Google Scholar] [CrossRef]

- Endo, R.; Siriwardena, H.D.; Kondo, A.; Yamamoto, C.; Shimomura, M. Structural and chemical analysis of TiO2 nanotube surface for dye-sensitized solar cells. Appl. Surf. Sci. 2018, 439, 954–962. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, Y.; Yi, A.; Zhu, M.; Li, W.; Fu, N. Facile fabrication of open-ended TiO2 nanotube arrays with large area for efficient dye-sensitized solar cells. Electrochim. Acta 2019, 299, 339–345. [Google Scholar] [CrossRef]

- Dobromir, M.; Apetrei, R.P.; Rebegea, S.; Manole, A.V.; Nica, V.; Luca, D. Synthesis and characterization of RF sputtered WO3/TiO2 bilayers. J. Surf. Coat. Technol. 2016, 285, 197–202. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, C. TiO2 Coated ZnO Nanorods by Mist Chemical Vapor Deposition for application as Photoanodes for Dye-Sensitized Solar Cells. Nanomaterials 2019, 9, 1339. [Google Scholar] [CrossRef] [Green Version]

- Garner, S.M.; O’Rear, E.A.; Khajotia, S.S.; Florez, F.L.E. The Applicability of a Drop Penetration Method to Measure Contact Angles on TiO2 and ZnO Nanoparticles. Nanomaterials 2020, 10, 1099. [Google Scholar] [CrossRef]

- Xiujuan, L.; Chang, W.; Ning, X.; Ming, J.; Ruina, L.; Jing, H.; Qiong, L.; Zhiping, L.; Lin, L.; Weilin, X.; et al. Novel ZnO-TiO2 nanocomposite arrays on Ti fabric for enhanced photocatalytic application. J. Mol. Struct. 2017, 1148, 347–355. [Google Scholar]

- Lin, L.; Yang, Y.; Men, L.; Wang, X.; He, D.; Chai, Y.; Zhao, B.; Ghoshroy, S.; Tang, Q. A highly efficient TiO2@ZnO n–p–n heterojunction nanorod photocatalyst. Nanoscale 2013, 5, 588–593. [Google Scholar] [CrossRef] [PubMed]

- Sreedhar, A.; Jung, H.; Kwon, J.H.; Yi, J.; Sohn, Y.; Gwag, J.S. Novel composite ZnO/TiO2 thin film photoanodes for enhanced visible-light-driven photoelectrochemical water splitting activity. J. Electroanal. Chem. 2017, 804, 92–98. [Google Scholar] [CrossRef]

- Çırak, B.B.; Caglar, B.; Kılınç, T.; Karadeniz, S.M.; Erdoğan, Y.; Kılıç, S.; Kahveci, E.; Ekinci, A.E.; Çırak, Ç. Synthesis and characterization of ZnO nanorice decorated TiO2 nanotubes for enhanced photocatalytic activity. Mater. Res. Bull. 2019, 109, 160–167. [Google Scholar] [CrossRef]

- Aydın, E.B.; Sıgırcık, G. Preparations of different ZnO nanostructures on TiO2 nanotube via electrochemical method and its application in hydrogen production. Int. J. Hydrog. Energ. 2019, 44, 11488–11502. [Google Scholar] [CrossRef]

- Sanchez-Tovar, R.; Blasco-Tamarit, E.; Fernandez-Domene, R.M.; Villanueva-Pascul, M.; Garcia-Anton, J. Electrochemical formation of novel TiO2-ZnO hybrid nanostructures for photoelectrochemical water splitting application. Surf. Coat. Technol. 2020, 388, 125605. [Google Scholar] [CrossRef]

- Sarkar, A.; Singh, A.K.; Khan, G.G.; Sarkar, D.; Mandal, K. TiO2/ZnO core/shell nano-heterostructure arrays as photo-electrodes with enhanced visible light photoelectrochemical performance. RSC Adv. 2014, 4, 55629–55634. [Google Scholar] [CrossRef]

- Ng, S.; Kubersky, P.; Krbal, M.; Prikryl, J.; Gärtnerova, V.; Moravkova, D.; Sopha, H.; Zazpe, R.; Yam, F.K.; Jäger, A.; et al. ZnO coated 1D TiO2 nanotube layers: Efficient photo-electrochemical and gas sensing heterojunction. Adv. Eng. Mater. 2018, 20, 1700589. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.-C.; Chou, C.-Y.; Yi, S.-R.; Chen, H.-D. Deposition of heterojunction of ZnO on hydrogenated TiO2 nanotube arrays by atomic layer deposition for enhanced photoelectrochemical water splitting. Int. J. Hydrog. Energ. 2019, 44, 28685–28697. [Google Scholar] [CrossRef]

- Singh, K.J.; Sahni, M.; Rajoriya, M. Study of structural, optical and semiconducting properties of TiO2 thin film deposited by RF magnetron sputtering. Mater. Today Proc. 2019, 12, 565–572. [Google Scholar] [CrossRef]

- Chen, X.; Bai, R.; Huang, M. Optical properties of amorphous Ta2O5 thin films deposited by RF magnetron sputtering. Opt. Mater. 2019, 97, 109404. [Google Scholar] [CrossRef]

- Luca, D.; Mardare, D.; Iacomi, F.; Teodorescu, C.M. Increasing surface hydrophilicity of titania thin films by doping. Appl. Surf. Sci. 2006, 252, 6122–6126. [Google Scholar] [CrossRef]

- Yan, X.; Zou, X.; Cao, W. ZnO/TiO2 core–brush nanostructure: Processing, microstructure and enhanced photocatalytic activity. J. Mater. Chem. 2012, 22, 5629. [Google Scholar] [CrossRef]

- Manole, A.; Dăscăleanu, V.; Dobromir, M.; Luca, D. Combining degradation and contact angle data in assessing the photocatalytic TiO2:N surface. Surf. Interface Anal. 2010, 42, 947–954. [Google Scholar] [CrossRef]

- Gonçalves, R.S.; Barrozo, P.; Brito, G.L.; Viana, B.C.; Cunha, F. The effect of thickness on optical, structural and growth mechanism of ZnO thin film prepared by magnetron sputtering. Thin Solid Films 2018, 661, 40–45. [Google Scholar] [CrossRef]

- Mendil, D.; Challali, F.; Touam, T.; Chelouche, A.; Souici, A.H.; Ouhenia, S.; Djouadi, D. Influence of growth time and substrate type on the microstructure and luminescence properties of ZnO thin films deposited by RF sputtering. J. Lumin. 2019, 215, 116631. [Google Scholar] [CrossRef]

- Kim, H.-K.; Chung, K.-B.; Kal, J. Comparison of ZnO buffer layers prepared by spin coating or RF magnetron sputtering for application in inverted organic solar cells. J. Alloy. Compd. 2019, 778, 487–495. [Google Scholar] [CrossRef]

- Spurr, R.A.; Myers, H. Quantitative Analysis of Anatase-Rutile Mixtures with an X-Ray Diffractometer. Anal. Chem. 1957, 29, 760–762. [Google Scholar] [CrossRef]

- Cullity, B.D.; Stock, S.R. Elements of X-ray Diffraction, 3rd ed.; Prentice-Hall: New York, NY, USA, 2001. [Google Scholar]

- Albu, S.P.; Ghicov, A.; Aldabergenova, S.; Drechesel, P.; LeClere, D.; Thompson, G.E.; Macak, J.M.; Schmuki, P. Formation of double-walled TiO2 nanotubes and robust anatase membranes. Adv. Mater. 2008, 20, 4135–4139. [Google Scholar]

- Albu, S.P.; Schmuki, P. TiO2 nanotubes grown in different organic electrolytes: Two-size self-organization, single vs. double-walled tubes, and giant diameters. Phys. Status Solidi RRL 2010, 4, 215–217. [Google Scholar] [CrossRef]

- Moulder, J.F.; Stickle, W.F.; Sobol, P.E.; Bomben, K.D. Handbook of X-ray Photoelectron Spectroscopy; ULVAC-PHI: Chikasaki, Japan; Physical Electronics: Chanhassen, MN, USA, 1995; pp. 45, 73, 89. [Google Scholar]

- Teodorescu-Soare, C.T.; Catrinescu, C.; Dobromir, M.; Stoian, G.; Arvinte, A.; Luca, D. Growth and characterization of TiO2 nanotube arrays under dynamic anodization. Photocatalytic activity. J. Electroanal. Chem. 2018, 823, 388–396. [Google Scholar] [CrossRef]

- Fujishima, A.; Zhang, X.; Tryk, D.A. TiO2 photocatalysis and related surface phenomena. Surf. Sci. Rep. 2008, 63, 515–582. [Google Scholar] [CrossRef]

- Hashimoto, S.; Tanaka, A.; Murata, A.; Sakurada, T. Formulation for XPS spectral change of oxides by ion bombardment as a function of sputtering time. Surf. Sci. 2004, 556, 22–32. [Google Scholar] [CrossRef]

- Fu, Y.; Du, H.; Zhang, S.; Huang, W. XPS characterization of surface and interfacial structure of sputtered TiNi films on Si substrate. Mat. Sci. Eng. A Struct. 2005, 403, 25–31. [Google Scholar] [CrossRef]

- Foix, D.; Martinez, H.; Pradel, A.; Ribes, M.; Gonbeau, D. XPS valence band spectra and theoretical calculations for investigations on thiogermanate and thiosilicate glasses. Chem. Phys. 2006, 323, 606–616. [Google Scholar] [CrossRef]

- Farsinezhad, S.; Sharma, H.; Shankar, K. Interfacial band alignment for photocatalytic charge separation in TiO2 nanotube arrays coated with CuPt nanoparticles. Phys. Chem. Chem. Phys. 2015, 17, 29723–29733. [Google Scholar] [CrossRef] [Green Version]

- Biswas, S.; Hossain, M.F.; Shahjahan, M.; Takahashi, K.; Takahashi, T. Investigation of photocatalytic activity of TiO2/WO3 bilayered thin films with various amounts of WO3 exposed surface. J. Vac. Sci. Technol. A 2009, 27, 880–884. [Google Scholar] [CrossRef]

- Wenzel, R.N. Surface roughness and contact angle. J. Phys. Chem. 1949, 53, 1466–1467. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Myint, M.T.Z.; Kumar, N.S.; Hornyak, G.L.; Dutta, J. Hydrophobic/hydrophilic switching on zinc oxide micro-textured surface. Appl. Surf. Sci. 2013, 264, 344–348. [Google Scholar] [CrossRef]

- Balaur, E.; Macak, J.M.; Tsuchiya, H.; Schmuki, P. Wetting behaviour of layers of TiO2 nanotubes with different diameters. J. Matter. Chem. 2005, 15, 4488–4491. [Google Scholar] [CrossRef]

- Doohun, K.; Macak, M.; Schimidt-Stein, F.; Schmuki, P. Capillary effects, wetting behavior and photo-induced tube filling of TiO2 nanotube layers. Nanotechnology 2008, 19, 305710. [Google Scholar]

| Sample | RMS Roughness (nm) | D (nm) | WA |

|---|---|---|---|

| TZN_0 | 37.4 | 26.1 | 0.702 |

| TZN_30 | 63.2 | 25.0 | 0.727 |

| TZN_60 | 37.2 | 22.5 | 0.706 |

| TZN_90 | 34.4 | 22.6 | 0.726 |

| Sample | Ti (at%) | O in O-Ti bonds (at%) | Zn (at%) |

|---|---|---|---|

| TZN_0 | 41.5 | 58.5 | - |

| TZN_30 | 32.4 | 58.3 | 9.3 |

| TZN_60 | 29.6 | 54.8 | 15.6 |

| TZN_90 | 25.1 | 50.7 | 24.2 |

| Sample | O - Ti/OH | Ti2+/Ti4+ | Ti3+/Ti4+ |

|---|---|---|---|

| TZN_0 | 2.718 | 0.170 | 0.400 |

| TZN_30 | 3.805 | 0.153 | 0.392 |

| TZN_60 | 4.420 | 0.120 | 0.361 |

| TZN_90 | 4.109 | 0.039 | 0.261 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobromir, M.; Konrad-Soare, C.T.; Stoian, G.; Semchenko, A.; Kovalenko, D.; Luca, D. Surface Wettability of ZnO-Loaded TiO2 Nanotube Array Layers. Nanomaterials 2020, 10, 1901. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10101901

Dobromir M, Konrad-Soare CT, Stoian G, Semchenko A, Kovalenko D, Luca D. Surface Wettability of ZnO-Loaded TiO2 Nanotube Array Layers. Nanomaterials. 2020; 10(10):1901. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10101901

Chicago/Turabian StyleDobromir, Marius, Claudia Teodora Konrad-Soare, George Stoian, Alina Semchenko, Dmitry Kovalenko, and Dumitru Luca. 2020. "Surface Wettability of ZnO-Loaded TiO2 Nanotube Array Layers" Nanomaterials 10, no. 10: 1901. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10101901