The Recent Advances in the Mechanical Properties of Self-Standing Two-Dimensional MXene-Based Nanostructures: Deep Insights into the Supercapacitor

Abstract

:1. Introduction

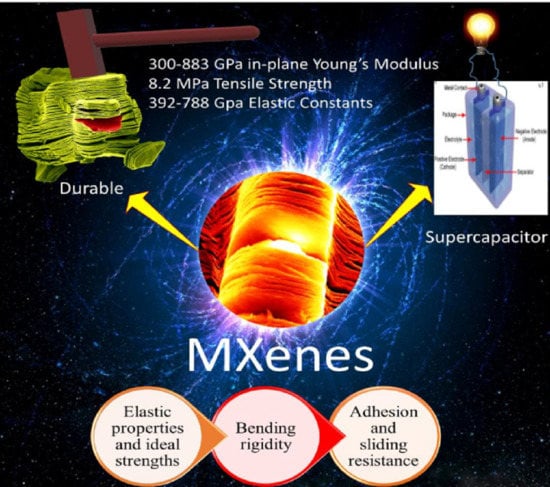

2. Mechanical Properties of Self-Standing MXenes

2.1. Elastic Properties and Ideal Strengths

2.1.1. Effect of Functional Terminations

2.1.2. Effect of the Mass of the Transition Metal

2.1.3. New Types of MXenes

2.1.4. Effect of Doping

2.1.5. Effect of Varying F/O Ratio

2.1.6. Effect of Number of Layers and Layer Thickness

2.1.7. Effect of Intercalated Ions and Electrolytes

2.2. Bending Rigidity

2.3. Interlayer Adhesion and Sliding

3. Self-Standing MXene as Electrode for Supercapacitors

4. Mechanical of Self-Standing MXenes vs. Hybrid MXenes

5. Summary and Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, M.; Zhang, R.; Chen, W. Graphene-supported nanoelectrocatalysts for fuel cells: Synthesis, properties, and applications. Chem. Rev. 2014, 114, 5117–5160. [Google Scholar] [CrossRef] [PubMed]

- Lipatov, A.; Lu, H.; Alhabeb, M.; Anasori, B.; Gruverman, A.; Gogotsi, Y.; Sinitskii, A. Elastic properties of 2D Ti3C2Tx MXene monolayers and bilayers. Sci. Adv. 2018, 4, eaat0491. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eid, K.; Sliem, M.H.; Al-Kandari, H.; Sharaf, M.A.; Abdullah, A.M. Rational synthesis of porous graphitic-like carbon nitride nanotubes codoped with Au and Pd as an efficient catalyst for carbon monoxide oxidation. Langmuir 2019, 35, 3421–3431. [Google Scholar] [CrossRef] [PubMed]

- Eid, K.; Sliem, M.H.; Abdullah, A.M. Unraveling template-free fabrication of carbon nitride nanorods codoped with Pt and Pd for efficient electrochemical and photoelectrochemical carbon monoxide oxidation at room temperature. Nanoscale 2019, 11, 11755–11764. [Google Scholar] [CrossRef] [PubMed]

- Abdu, H.I.; Eid, K.; Abdullah, A.M.; Han, Z.; Ibrahim, M.H.; Shan, D.; Chen, J.; Elzatahry, A.A.; Lu, X. Unveiling one-pot scalable fabrication of reusable carboxylated heterogeneous carbon-based catalysts from eucalyptus plant with the assistance of dry ice for selective hydrolysis of eucalyptus biomass. Renew. Energy 2020, 153, 998–1004. [Google Scholar] [CrossRef]

- Anasori, B.; Gogotsi, Y. 2D Metal. Carbides and Nitrides (MXenes): Structure, Properties and Applications; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; p. 534. [Google Scholar] [CrossRef]

- Idris Abdu, H.; Eid, K.; Abdullah, A.M.; Sliem, M.H.; Elzatahry, A.; Lu, X. Dry ice-mediated rational synthesis of edge-carboxylated crumpled graphene nanosheets for selective and prompt hydrolysis of cellulose and eucalyptus lignocellulose under ambient reaction conditions. Green Chem. 2020, 22, 5437–5446. [Google Scholar] [CrossRef]

- Deysher, G.; Shuck, C.E.; Hantanasirisakul, K.; Frey, N.C.; Foucher, A.C.; Maleski, K.; Sarycheva, A.; Shenoy, V.B.; Stach, E.A.; Anasori, B.; et al. Synthesis of Mo4VAlC4 MAX Phase and Two-Dimensional Mo4VC4 MXene with Five Atomic Layers of Transition Metals. ACS Nano 2020, 14, 204–217. [Google Scholar] [CrossRef]

- Jun, B.M.; Her, N.; Park, C.M.; Yoon, Y. Effective removal of Pb(ii) from synthetic wastewater using Ti3C2T: X MXene. Environ. Sci. Water Res. Technol. 2020, 6, 173–180. [Google Scholar] [CrossRef]

- Han, M.; Shuck, C.E.; Rakhmanov, R.; Parchment, D.; Anasori, B.; Koo, C.M.; Friedman, G.; Gogotsi, Y. Beyond Ti3C2Tx: MXenes for Electromagnetic Interference Shielding. ACS Nano 2020, 14, 5008–5016. [Google Scholar] [CrossRef]

- Amiri, A.; Chen, Y.; Bee Teng, C.; Naraghi, M. Porous nitrogen-doped MXene-based electrodes for capacitive deionization. Energy Storage Mater. 2020, 25, 731–739. [Google Scholar] [CrossRef]

- Rasool, K.; Pandey, R.P.; Rasheed, P.A.; Buczek, S.; Gogotsi, Y.; Mahmoud, K.A. Water treatment and environmental remediation applications of two-dimensional metal carbides (MXenes). Mater. Today 2019, 30, 80–102. [Google Scholar] [CrossRef]

- Ibrahim, Y.; Kassab, A.; Eid, K.; Abdullah, A.M.; Ozoemena, K.I.; Elzatahry, A. Unveiling Fabrication and Environmental Remediation of MXene-Based Nanoarchitectures in Toxic Metals Removal from Wastewater: Strategy and Mechanism. Nanomaterials 2020, 10, 885. [Google Scholar] [CrossRef] [PubMed]

- Barsoum, M.; El-Raghy, T. The MAX phases: Unique new carbide and nitride materials ternary ceramics turn out to be surprisingly soft and machinable, yet also heat-tolerant, strong and lightweight. Am. Sci. 2001, 89, 334–343. [Google Scholar] [CrossRef]

- Barsoum, M.W.; Radovic, M. Elastic and Mechanical Properties of the MAX Phases. Annu. Rev. Mater. Res. 2011, 41, 195–227. [Google Scholar] [CrossRef]

- Ling, Z.; Ren, C.E.; Zhao, M.-Q.; Yang, J.; Giammarco, J.M.; Qiu, J.; Barsoum, M.W.; Gogotsi, Y. Flexible and conductive MXene films and nanocomposites with high capacitance. Proc. Natl. Acad. Sci. USA 2014, 111, 16676. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhan, X.; Si, C.; Zhou, J.; Sun, Z. MXene and MXene-based composites: Synthesis, properties and environment-related applications. Nanoscale Horiz. 2020, 5, 235–258. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Liu, X.; Zhang, S. Towards a molecular understanding of cellulose dissolution in ionic liquids: Anion/cation effect, synergistic mechanism and physicochemical aspects. Chem. Sci. 2018, 9, 4027–4043. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, J.; Huang, Q.; Huang, H.; Mao, L.; Liu, M.; Zhang, X.; Wei, Y. Recent progress and advances in the environmental applications of MXene related materials. Nanoscale 2020, 12, 3574–3592. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Van der Bruggen, B. An MXene-based membrane for molecular separation. Environ. Sci. Nano 2020. [Google Scholar] [CrossRef]

- Zhao, P.; Jian, M.; Zhang, Q.; Xu, R.; Liu, R.; Zhang, X.; Liu, H. A new paradigm of ultrathin 2D nanomaterial adsorbents in aqueous media: Graphene and GO, MoS2, MXenes, and 2D MOFs. J. Mater. Chem. A 2019, 7, 16598–16621. [Google Scholar] [CrossRef]

- Yang, B.; She, Y.; Zhang, C.; Kang, S.; Zhou, J.; Hu, W. Nitrogen Doped Intercalation TiO2/TiN/Ti3C2Tx Nanocomposite Electrodes with Enhanced Pseudocapacitance. Nanomaterials 2020, 10, 345. [Google Scholar] [CrossRef] [Green Version]

- Yao, Z.; Sun, H.; Sui, H.; Liu, X. Construction of BPQDs/Ti3C2@TiO2 Composites with Favorable Charge Transfer Channels for Enhanced Photocatalytic Activity under Visible Light Irradiation. Nanomaterials 2020, 10, 452. [Google Scholar] [CrossRef] [Green Version]

- Fu, Z.; Wang, N.; Legut, D.; Si, C.; Zhang, Q.; Du, S.; Germann, T.C.; Francisco, J.S.; Zhang, R. Rational Design of Flexible Two-Dimensional MXenes with Multiple Functionalities. Chem. Rev. 2019, 119, 11980–12031. [Google Scholar] [CrossRef] [PubMed]

- Anasori, B.; Lukatskaya, M.R.; Gogotsi, Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nat. Rev. Mater. 2017, 2, 16098. [Google Scholar] [CrossRef]

- Kumar, K.S.; Choudhary, N.; Jung, Y.; Thomas, J. Recent Advances in Two-Dimensional Nanomaterials for Supercapacitor Electrode Applications. ACS Energy Lett. 2018, 3, 482–495. [Google Scholar] [CrossRef]

- Zha, X.H.; Luo, K.; Li, Q.; Huang, Q.; He, J.; Wen, X.; Du, S. Role of the surface effect on the structural, electronic and mechanical properties of the carbide MXenes. EPL 2015, 111, 26007. [Google Scholar] [CrossRef]

- Fu, Z.; Zhang, S.; Legut, D.; Germann, T.C.; Si, C.; Du, S.; Francisco, J.S.; Zhang, R. A synergetic stabilization and strengthening strategy for two-dimensional ordered hybrid transition metal carbides. Phys. Chem. Chem. Phys. 2018, 20, 29684–29692. [Google Scholar] [CrossRef]

- Yorulmaz, U.; Özden, A.; Perkgöz, N.K.; Ay, F.; Sevik, C. Vibrational and mechanical properties of single layer MXene structures: A first-principles investigation. Nanotechnology 2016, 27, 335702. [Google Scholar] [CrossRef]

- Zhang, H.; Fu, Z.; Zhang, R.; Zhang, Q.; Tian, H.; Legut, D.; Germann, T.C.; Guo, Y.; Du, S.; Francisco, J.S. Designing flexible 2D transition metal carbides with strain-controllable lithium storage. Proc. Natl. Acad. Sci. USA 2017, 114, E11082–E11091. [Google Scholar] [CrossRef] [Green Version]

- Si, C.; Duan, W.; Liu, Z.; Liu, F. Electronic strengthening of graphene by charge doping. Phys. Rev. Lett. 2012, 109, 226802. [Google Scholar] [CrossRef]

- Plummer, G.; Anasori, B.; Gogotsi, Y.; Tucker, G.J. Nanoindentation of monolayer Tin+1CnTx MXenes via atomistic simulations: The role of composition and defects on strength. Comput. Mater. Sci. 2019, 157, 168–174. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, J.; Yang, M.; Xie, Q.; Peng, H.; Liu, Z. Janus graphene from asymmetric two-dimensional chemistry. Nat. Commun. 2013, 4, 1443. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zha, X.-H.; Yin, J.; Zhou, Y.; Huang, Q.; Luo, K.; Lang, J.; Francisco, J.S.; He, J.; Du, S. Intrinsic Structural, Electrical, Thermal, and Mechanical Properties of the Promising Conductor Mo2C MXene. J. Phys. Chem. C 2016, 120, 15082–15088. [Google Scholar] [CrossRef]

- Peng, Q.; De, S. Outstanding mechanical properties of monolayer MoS2 and its application in elastic energy storage. Phys. Chem. Chem. Phys. 2013, 15, 19427–19437. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Wang, S.; Yuan, J.; Yang, B.; Chen, H. Modulation of the electronic and mechanical properties of phagraphene via hydrogenation and fluorination. Phys. Chem. Chem. Phys. 2017, 19, 11771–11777. [Google Scholar] [CrossRef]

- Guo, Z.; Zhou, J.; Si, C.; Sun, Z. Flexible two-dimensional Tin+1Cn (n = 1, 2 and 3) and their functionalized MXenes predicted by density functional theories. Phys. Chem. Chem. Phys. 2015, 17, 15348–15354. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Zha, X.; Chen, F.Y.; Ye, Q.; Eklund, P.; Du, S.; Huang, Q. A Two-Dimensional Zirconium Carbide by Selective Etching of Al3C3 from Nanolaminated Zr3Al3C5. Angew. Chem. Int. Ed. 2016, 55, 5008–5013. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fu, Z.H.; Zhang, Q.F.; Legut, D.; Si, C.; Germann, T.C.; Lookman, T.; Du, S.Y.; Francisco, J.S.; Zhang, R.F. Stabilization and strengthening effects of functional groups in two-dimensional titanium carbide. Phys. Rev. B 2016, 94, 104103. [Google Scholar] [CrossRef]

- Bai, Y.; Zhou, K.; Srikanth, N.; Pang, J.H.L.; He, X.; Wang, R. Dependence of elastic and optical properties on surface terminated groups in two-dimensional MXene monolayers: A first-principles study. RSC Adv. 2016, 6, 35731–35739. [Google Scholar] [CrossRef]

- Kurtoglu, M.; Naguib, M.; Gogotsi, Y.; Barsoum, M. First Principles Study of Two-dimensional Early Transition Metal Carbides. MRS Commun. 2012, 2. [Google Scholar] [CrossRef]

- Borysiuk, V.N.; Mochalin, V.N.; Gogotsi, Y. Molecular dynamic study of the mechanical properties of two-dimensional titanium carbides Tin+1Cn (MXenes). Nanotechnology 2015, 26, 265705. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Jin, W.; Wu, S.; Wang, Z. Structural, electronic and mechanical properties of two-dimensional Janus transition metal carbides and nitrides. Phys. E Low Dimens. Syst. Nanostruct. 2018, 103, 307–313. [Google Scholar] [CrossRef]

- Khazaei, M.; Ranjbar, A.; Arai, M.; Sasaki, T.; Yunoki, S. Electronic properties and applications of MXenes: A theoretical review. J. Mater. Chem. C 2017, 5, 2488–2503. [Google Scholar] [CrossRef] [Green Version]

- ÇakIr, D.; Peeters, F.M.; Sevik, C. Mechanical and thermal properties of h -MX2 (M = Cr, Mo, W.; X = O, S, Se, Te) monolayers: A comparative study. Appl. Phys. Lett. 2014, 41, 10891–10896. [Google Scholar] [CrossRef]

- Duerloo, K.A.N.; Ong, M.T.; Reed, E.J. Intrinsic Piezoelectricity in Two-Dimensional Materials. J. Phys. Chem. Lett. 2012, 3, 2871–2876. [Google Scholar] [CrossRef]

- Zhou, J.; Zha, X.; Zhou, X.; Chen, F.; Gao, G.; Wang, S.; Shen, C.; Chen, T.; Zhi, C.; Eklund, P.; et al. Synthesis and Electrochemical Properties of Two-Dimensional Hafnium Carbide. ACS Nano 2017, 11, 3841–3850. [Google Scholar] [CrossRef] [Green Version]

- Holm, A.; Park, J.; Goodman, E.D.; Zhang, J.; Sinclair, R.; Cargnello, M.; Frank, C.W. Synthesis, Characterization, and Light-Induced Spatial Charge Separation in Janus Graphene Oxide. Chem. Mater. 2018, 30, 2084–2092. [Google Scholar] [CrossRef]

- Xu, C.; Wang, L.; Liu, Z.; Chen, L.; Guo, J.; Kang, N.; Ma, X.-L.; Cheng, H.-M.; Ren, W. Large-area high-quality 2D ultrathin Mo2C superconducting crystals. Nat. Mater. 2015, 14, 1135–1141. [Google Scholar] [CrossRef]

- Chakraborty, P.; Das, T.; Nafday, D.; Saha-Dasgupta, T. Manipulating the mechanical properties of Ti2C MXene: Effect of substitutional doping. Phys. Rev. B 2017, 95, 184106. [Google Scholar] [CrossRef]

- Andrew, R.C.; Mapasha, R.E.; Ukpong, A.M.; Chetty, N. Mechanical properties of graphene and boronitrene. Phys. Rev. B 2012, 85, 125428. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Wang, S.; Zhang, S.; Yuan, J.; Yang, B.; Chen, H. Highly negative Poisson’s ratio in a flexible two-dimensional tungsten carbide monolayer. Phys. Chem. Chem. Phys. 2018, 20, 18924–18930. [Google Scholar] [CrossRef]

- Isaacs, E.B.; Marianetti, C.A. Ideal strength and phonon instability of strained monolayer materials. Phys. Rev. B 2014, 89, 184111. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Fu, Z.; Zhang, H.; Legut, D.; Germann, T.C.; Zhang, Q.; Du, S.; Francisco, J.S.; Zhang, R. Surface Electrochemical Stability and Strain-Tunable Lithium Storage of Highly Flexible 2D Transition Metal Carbides. Adv. Funct. Mater. 2018, 28, 1804867. [Google Scholar] [CrossRef]

- Radajewski, M.; Henschel, S.; Grützner, S.; Krüger, L.; Schimpf, C.; Chmelik, D.; Rafaja, D. Microstructure and mechanical properties of bulk TiN–AlN composites processed by FAST/SPS. Ceram. Int. 2016, 42, 10220–10227. [Google Scholar] [CrossRef]

- Ivashchenko, V.I.; Turchi, P.E.A.; Gonis, A.; Ivashchenko, L.A.; Skrynskii, P.L. Electronic origin of elastic properties of titanium carbonitride alloys. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2006, 37, 3391–3396. [Google Scholar] [CrossRef]

- Yang, Q.; Lengauer, W.; Koch, T.; Scheerer, M.; Smid, I. Hardness and elastic properties of Ti(CxN1−x), Zr(CxN1−x) and Hf(CxN1−x). J. Alloys Compd. 2000, 309, L5–L9. [Google Scholar] [CrossRef]

- Come, J.; Xie, Y.; Naguib, M.; Jesse, S.; Kalinin, S.V.; Gogotsi, Y.; Kent, P.R.C.; Balke, N. Nanoscale Elastic Changes in 2D Ti3C2Tx (MXene) Pseudocapacitive Electrodes. Adv. Energy Mater. 2016, 6, 1–9. [Google Scholar] [CrossRef]

- Borysiuk, V.N.; Mochalin, V.N.; Gogotsi, Y. Bending rigidity of two-dimensional titanium carbide (MXene) nanoribbons: A molecular dynamics study. Comput. Mater. Sci. 2018, 143, 418–424. [Google Scholar] [CrossRef]

- Hu, T.; Yang, J.; Li, W.; Wang, X.; Li, C. Quantifying the rigidity of 2D carbides (MXenes). Phys. Chem. Chem. Phys. 2020, 22, 2115–2121. [Google Scholar] [CrossRef]

- Suk, J.W.; Piner, R.D.; An, J.; Ruoff, R.S. Mechanical properties of monolayer graphene oxide. ACS Nano 2010, 4, 6557–6564. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Zhang, J.; Zhao, J.; Liu, F. Mechanical properties of graphene oxides. Nanoscale 2012, 4, 5910–5916. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Li, J.-X.; Du, Y.; Cui, C. First-principles study on structural, electronic and elastic properties of graphene-like hexagonal Ti2C monolayer. Comput. Mater. Sci. 2014, 83, 290–293. [Google Scholar] [CrossRef]

- Hu, T.; Hu, M.; Li, Z.; Zhang, H.; Zhang, C.; Wang, J.; Wang, X. Interlayer coupling in two-dimensional titanium carbide MXenes. Phys. Chem. Chem. Phys. 2016, 18, 20256–20260. [Google Scholar] [CrossRef]

- Zhang, H.; Fu, Z.H.; Legut, D.; Germann, T.C.; Zhang, R.F. Stacking stability and sliding mechanism in weakly bonded 2D transition metal carbides by van der Waals force. RSC Adv. 2017, 7, 55912–55919. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Ashton, M.; Ostadhossein, A.; Van Duin, A.C.T.; Hennig, R.G.; Sinnott, S.B. Computational study of low interlayer friction in Tin+1Cn (n = 1, 2, and 3) MXene. ACS Appl. Mater. Interfaces 2017, 9, 34467–34479. [Google Scholar] [CrossRef]

- Li, Y.; Huang, S.; Wei, C.; Wu, C.; Mochalin, V.N. Adhesion of two-dimensional titanium carbides (MXenes) and graphene to silicon. Nat. Commun. 2019, 10, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.-S.; Feng, X.; Cheng, H.-M. Recent advances in graphene-based planar micro-supercapacitors for on-chip energy storage. Natl. Sci. Rev. 2014, 1, 277. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Ma, Y.; Zhang, X.; Abdolhosseinzadeh, S.; Sheng, H.; Lan, W.; Pakdel, A.; Heier, J.; Nüesch, F. Two-Dimensional Transition Metal Carbides and Nitrides (MXenes): Synthesis, Properties, and Electrochemical Energy Storage Applications. Energy Environ. Mater. 2020, 3, 29–55. [Google Scholar] [CrossRef]

- Zhang, C.; Nicolosi, V. Graphene and MXene-based transparent conductive electrodes and supercapacitors. Energy Storage Mater. 2019, 16, 102–125. [Google Scholar] [CrossRef]

- Jiang, Q.; Lei, Y.; Liang, H.; Xi, K.; Xia, C.; Alshareef, H.N. Review of MXene electrochemical microsupercapacitors. Energy Storage Mater. 2020, 27, 78–95. [Google Scholar] [CrossRef]

- Wang, K.; Zheng, B.; Mackinder, M.; Baule, N.; Qiao, H.; Jin, H.; Schuelke, T.; Fan, Q.H. Graphene wrapped MXene via plasma exfoliation for all-solid-state flexible supercapacitors. Energy Storage Mater. 2019, 20, 299–306. [Google Scholar] [CrossRef]

- Rakhi, R.B.; Ahmed, B.; Hedhili, M.N.; Anjum, D.H.; Alshareef, H.N. Effect of Postetch Annealing Gas Composition on the Structural and Electrochemical Properties of Ti2CTx MXene Electrodes for Supercapacitor Applications. Chem. Mater. 2015, 27, 5314–5323. [Google Scholar] [CrossRef] [Green Version]

- Tao, Q.; Dahlqvist, M.; Lu, J.; Kota, S.; Meshkian, R.; Halim, J.; Palisaitis, J.; Hultman, L.; Barsoum, M.W.; Persson, P.O.Å.; et al. Two-dimensional Mo1.33C MXene with divacancy ordering prepared from parent 3D laminate with in-plane chemical ordering. Nat. Commun. 2017, 8, 14949. [Google Scholar] [CrossRef] [PubMed]

- Lukatskaya, M.R.; Mashtalir, O.; Ren, C.E.; Dall’Agnese, Y.; Rozier, P.; Taberna, P.L.; Naguib, M.; Simon, P.; Barsoum, M.W.; Gogotsi, Y. Cation Intercalation and High Volumetric Capacitance of Two-Dimensional Titanium Carbide. Science 2013, 341, 1502–1505. [Google Scholar] [CrossRef] [Green Version]

- Ghidiu, M.; Lukatskaya, M.R.; Zhao, M.-Q.; Gogotsi, Y.; Barsoum, M.W. Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature 2014, 516, 78–81. [Google Scholar] [CrossRef] [PubMed]

- Lukatskaya, M.R.; Kota, S.; Lin, Z.; Zhao, M.-Q.; Shpigel, N.; Levi, M.D.; Halim, J.; Taberna, P.-L.; Barsoum, M.W.; Simon, P.; et al. Ultra-high-rate pseudocapacitive energy storage in two-dimensional transition metal carbides. Nat. Energy 2017, 2, 1–6. [Google Scholar] [CrossRef]

- Shan, Q.; Mu, X.; Alhabeb, M.; Shuck, C.E.; Pang, D.; Zhao, X.; Chu, X.-F.; Wei, Y.; Du, F.; Chen, G.; et al. Two-dimensional vanadium carbide (V2C) MXene as electrode for supercapacitors with aqueous electrolytes. Electrochem. Commun. 2018, 96, 103–107. [Google Scholar] [CrossRef]

- Halim, J.; Kota, S.; Lukatskaya, M.R.; Naguib, M.; Zhao, M.-Q.; Moon, E.J.; Pitock, J.; Nanda, J.; May, S.J.; Gogotsi, Y.; et al. Synthesis and Characterization of 2D Molybdenum Carbide (MXene). Adv. Funct. Mater. 2016, 26, 3118–3127. [Google Scholar] [CrossRef]

- Dall’Agnese, Y.; Lukatskaya, M.R.; Cook, K.M.; Taberna, P.-L.; Gogotsi, Y.; Simon, P. High capacitance of surface-modified 2D titanium carbide in acidic electrolyte. Electrochem. Commun. 2014, 48, 118–122. [Google Scholar] [CrossRef] [Green Version]

- Zhan, C.; Sun, W.; Kent, P.R.C.; Naguib, M.; Gogotsi, Y.; Jiang, D.-E. Computational Screening of MXene Electrodes for Pseudocapacitive Energy Storage. J. Phys. Chem. C 2019, 123, 315–321. [Google Scholar] [CrossRef]

- Zhan, C.; Naguib, M.; Lukatskaya, M.; Kent, P.R.; Gogotsi, Y.; Jiang, D.-E. Understanding the MXene pseudocapacitance. J. Phys. Chem. Lett. 2018, 9, 1223–1228. [Google Scholar] [CrossRef] [PubMed]

- Boota, M.; Anasori, B.; Voigt, C.; Zhao, M.Q.; Barsoum, M.W.; Gogotsi, Y. Pseudocapacitive Electrodes Produced by Oxidant-Free Polymerization of Pyrrole between the Layers of 2D Titanium Carbide (MXene). Adv. Mater. (Deerfield Beach, Fla) 2016, 28, 1517–1522. [Google Scholar] [CrossRef]

- Wang, X.; Kajiyama, S.; Iinuma, H.; Hosono, E.; Oro, S.; Moriguchi, I.; Okubo, M.; Yamada, A. Pseudocapacitance of MXene nanosheets for high-power sodium-ion hybrid capacitors. Nat. Commun. 2015, 6, 6544. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Hou, Y.; Wang, F.; Lohe, M.R.; Zhuang, X.; Niu, L.; Feng, X. Flexible All-Solid-State Supercapacitors with High Volumetric Capacitances Boosted by Solution Processable MXene and Electrochemically Exfoliated Graphene. Adv. Energy Mater. 2017, 7, 1601847. [Google Scholar] [CrossRef] [Green Version]

- Tang, Q.; Zhou, Z.; Shen, P. Are MXenes Promising Anode Materials for Li Ion Batteries? Computational Studies on Electronic Properties and Li Storage Capability of Ti3C2 and Ti3C2X2 (X = F, OH) Monolayer. J. Am. Chem. Soc. 2012, 134, 16909–16916. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, H.; Wang, B.; Shen, C.; Zhang, C.; Hu, Q.; Zhou, A.; Liu, B. Synthesis and electrochemical performance of Ti3C2Tx with hydrothermal process. Electron. Mater. Lett. 2016, 12, 702–710. [Google Scholar] [CrossRef]

- Couly, C.; Alhabeb, M.; Van Aken, K.L.; Kurra, N.; Gomes, L.; Navarro-Suárez, A.M.; Anasori, B.; Alshareef, H.N.; Gogotsi, Y. Asymmetric Flexible MXene-Reduced Graphene Oxide Micro-Supercapacitor. Adv. Electron. Mater. 2018, 4, 1700339. [Google Scholar] [CrossRef] [Green Version]

- Fu, Q.; Wang, X.; Zhang, N.; Wen, J.; Li, L.; Gao, H.; Zhang, X. Self-assembled Ti3C2Tx/SCNT composite electrode with improved electrochemical performance for supercapacitor. J. Colloid Interface Sci. 2018, 511, 128–134. [Google Scholar] [CrossRef]

- Jiang, Q.; Wu, C.; Wang, Z.; Wang, A.C.; He, J.-H.; Wang, Z.L.; Alshareef, H.N. MXene electrochemical microsupercapacitor integrated with triboelectric nanogenerator as a wearable self-charging power unit. Nano Energy 2018, 45, 266–272. [Google Scholar] [CrossRef] [Green Version]

- Xia, Q.X.; Shinde, N.M.; Yun, J.M.; Zhang, T.; Mane, R.S.; Mathur, S.; Kim, K.H. Bismuth Oxychloride/MXene symmetric supercapacitor with high volumetric energy density. Electrochim. Acta 2018, 271, 351–360. [Google Scholar] [CrossRef]

- Zhang, C.; Kremer, M.P.; Seral-Ascaso, A.; Park, S.-H.; McEvoy, N.; Anasori, B.; Gogotsi, Y.; Nicolosi, V. Stamping of Flexible, Coplanar Micro-Supercapacitors Using MXene Inks. Adv. Funct. Mater. 2018, 28, 1705506. [Google Scholar] [CrossRef]

- Hu, M.; Li, Z.; Zhang, H.; Hu, T.; Zhang, C.; Wu, Z.; Wang, X. Self-assembled Ti3C2Tx MXene film with high gravimetric capacitance. Chem. Commun. 2015, 51, 13531–13533. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Zhu, J.; Yang, C.; Wang, F. Enhanced Capacitive Performance Based on Diverse Layered Structure of Two-Dimensional Ti3C2MXene with Long Etching Time. J. Electrochem. Soc. 2016, 163, A1975–A1982. [Google Scholar] [CrossRef]

- Mashtalir, O.; Lukatskaya, M.R.; Kolesnikov, A.I.; Raymundo-Piñero, E.; Naguib, M.; Barsoum, M.W.; Gogotsi, Y. The effect of hydrazine intercalation on the structure and capacitance of 2D titanium carbide (MXene). Nanoscale 2016, 8, 9128–9133. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; Wen, J.; Zhang, N.; Wu, L.; Zhang, M.; Lin, S.; Gao, H.; Zhang, X. Free-standing Ti3C2Tx electrode with ultrahigh volumetric capacitance. RSC Adv. 2017, 7, 11998–12005. [Google Scholar] [CrossRef] [Green Version]

- Wen, Y.; Rufford, T.E.; Chen, X.; Li, N.; Lyu, M.; Dai, L.; Wang, L. Nitrogen-doped Ti3C2Tx MXene electrodes for high-performance supercapacitors. Nano Energy 2017, 38, 368–376. [Google Scholar] [CrossRef]

- Kurra, N.; Ahmed, B.; Gogotsi, Y.; Alshareef, H.N. MXene-on-Paper Coplanar Microsupercapacitors. Adv. Energy Mater. 2016, 6, 1601372. [Google Scholar] [CrossRef]

- Wang, Y.; Dou, H.; Wang, J.; Ding, B.; Xu, Y.; Chang, Z.; Hao, X. Three-dimensional porous MXene/layered double hydroxide composite for high performance supercapacitors. J. Power Sources 2016, 327, 221–228. [Google Scholar] [CrossRef]

- Li, J.; Yuan, X.; Lin, C.; Yang, Y.; Xu, L.; Du, X.; Xie, J.; Lin, J.; Sun, J. Achieving High Pseudocapacitance of 2D Titanium Carbide (MXene) by Cation Intercalation and Surface Modification. Adv. Energy Mater. 2017, 7, 1602725. [Google Scholar] [CrossRef]

- Zhao, M.-Q.; Ren, C.E.; Ling, Z.; Lukatskaya, M.R.; Zhang, C.; Van Aken, K.L.; Barsoum, M.W.; Gogotsi, Y. Flexible MXene/Carbon Nanotube Composite Paper with High Volumetric Capacitance. Adv. Mater. 2015, 27, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Ren, C.E.; Maleski, K.; Hatter, C.B.; Anasori, B.; Urbankowski, P.; Sarycheva, A.; Gogotsi, Y. Flexible MXene/Graphene Films for Ultrafast Supercapacitors with Outstanding Volumetric Capacitance. Adv. Funct. Mater. 2017, 27, 1701264. [Google Scholar] [CrossRef]

- Dall’Agnese, Y.; Rozier, P.; Taberna, P.-L.; Gogotsi, Y.; Simon, P. Capacitance of two-dimensional titanium carbide (MXene) and MXene/carbon nanotube composites in organic electrolytes. J. Power Sources 2016, 306, 510–515. [Google Scholar] [CrossRef] [Green Version]

- Yan, P.; Zhang, R.; Jia, J.; Wu, C.; Zhou, A.; Xu, J.; Zhang, X. Enhanced supercapacitive performance of delaminated two-dimensional titanium carbide/carbon nanotube composites in alkaline electrolyte. J. Power Sources 2015, 284, 38–43. [Google Scholar] [CrossRef]

- Zhu, J.; Tang, Y.; Yang, C.; Wang, F.; Cao, M. Composites of TiO2Nanoparticles Deposited on Ti3C2MXene Nanosheets with Enhanced Electrochemical Performance. J. Electrochem. Soc. 2016, 163, A785–A791. [Google Scholar] [CrossRef]

- Tian, Y.; Yang, C.; Que, W.; Liu, X.; Yin, X.; Kong, L.B. Flexible and freestanding 2D titanium carbide film decorated with manganese oxide nanoparticles as a high volumetric capacity electrode for supercapacitor. J. Power Sources 2017, 359, 332–339. [Google Scholar] [CrossRef]

- Zhu, M.; Huang, Y.; Deng, Q.; Zhou, J.; Pei, Z.; Xue, Q.; Huang, Y.; Wang, Z.; Li, H.; Huang, Q.; et al. Highly Flexible, Freestanding Supercapacitor Electrode with Enhanced Performance Obtained by Hybridizing Polypyrrole Chains with MXene. Adv. Energy Mater. 2016, 6, 1600969. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, W.; Yuan, H.; Jin, C.; Zhang, L.; Huang, H.; Liang, C.; Xia, Y.; Zhang, J.; Gan, Y.; et al. Pillared Structure Design of MXene with Ultralarge Interlayer Spacing for High-Performance Lithium-Ion Capacitors. ACS Nano 2017, 11, 2459–2469. [Google Scholar] [CrossRef] [Green Version]

- Lin, Z.; Barbara, D.; Taberna, P.-L.; Van Aken, K.L.; Anasori, B.; Gogotsi, Y.; Simon, P. Capacitance of Ti3C2Tx MXene in ionic liquid electrolyte. J. Power Sources 2016, 326, 575–579. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Mathis, T.S.; Li, K.; Lin, Z.; Vlcek, L.; Torita, T.; Osti, N.C.; Hatter, C.; Urbankowski, P.; Sarycheva, A.; et al. Influences from solvents on charge storage in titanium carbide MXenes. Nat. Energy 2019, 4, 241–248. [Google Scholar] [CrossRef]

- Sobolčiak, P.; Ali, A.; Hassan, M.K.; Helal, M.I.; Tanvir, A.; Popelka, A.; Al-Maadeed, M.A.; Krupa, I.; Mahmoud, K.A. 2D Ti3C2Tx (MXene)-reinforced polyvinyl alcohol (PVA) nanofibers with enhanced mechanical and electrical properties. PLoS ONE 2017, 12, e0183705. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, N.-N.; Wang, H.; Wang, Y.-Y.; Wei, Y.-H.; Si, J.-Y.; Yuen, A.C.Y.; Xie, J.-S.; Yu, B.; Zhu, S.-E.; Lu, H.-D.; et al. Robust, Lightweight, Hydrophobic, and Fire-Retarded Polyimide/MXene Aerogels for Effective Oil/Water Separation. ACS Appl. Mater. Interfaces 2019, 11, 40512–40523. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, L.; Li, C. Highly Stable, Transparent, and Conductive Electrode of Solution-Processed Silver Nanowire-Mxene for Flexible Alternating-Current Electroluminescent Devices. Ind. Eng. Chem. Res. 2019, 58, 21485–21492. [Google Scholar] [CrossRef]

- Sambyal, P.; Iqbal, A.; Hong, J.; Kim, H.; Kim, M.-K.; Hong, S.M.; Han, M.; Gogotsi, Y.; Koo, C.M. Ultralight and Mechanically Robust Ti3C2Tx Hybrid Aerogel Reinforced by Carbon Nanotubes for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2019, 11, 38046–38054. [Google Scholar] [CrossRef] [PubMed]

- Abualrejal, M.M.; Eid, K.; Tian, R.; Liu, L.; Chen, H.; Abdullah, A.M.; Wang, Z. Rational synthesis of three-dimensional core–double shell upconversion nanodendrites with ultrabright luminescence for bioimaging application. Chem. Sci. 2019, 10, 7591–7599. [Google Scholar] [CrossRef]

- Abualrejal, M.M.; Eid, K.; Abdullah, A.M.; Numan, A.A.; Chen, H.; Zhang, H.; Wang, Z. Smart design of exquisite multidimensional multilayered sand-clock-like upconversion nanostructures with ultrabright luminescence as efficient luminescence probes for bioimaging application. Microchim. Acta 2020, 187, 1–13. [Google Scholar] [CrossRef]

- Wu, F.; Eid, K.; Abdullah, A.M.; Niu, W.; Wang, C.; Lan, Y.; Elzatahry, A.A.; Xu, G. Unveiling One-Pot Template-Free Fabrication of Exquisite Multidimensional PtNi Multicube Nanoarchitectonics for the Efficient Electrochemical Oxidation of Ethanol and Methanol with a Great Tolerance for CO. ACS Appl. Mater. Interfaces 2020, 12, 31309–31318. [Google Scholar] [CrossRef]

- Eid, K.; Sliem, M.H.; Jlassi, K.; Eldesoky, A.S.; Abdo, G.G.; Al-Qaradawi, S.Y.; Sharaf, M.A.; Abdullah, A.M.; Elzatahry, A.A. Precise fabrication of porous one-dimensional gC3N4 nanotubes doped with Pd and Cu atoms for efficient CO oxidation and CO2 reduction. Inorg. Chem. Commun. 2019, 107, 107460. [Google Scholar] [CrossRef]

| Materials | Morphology | Preparation Method (Experimentally/Theoretically) | Measurements | Elastic Constants c11 [GPa] | Young’s Modulus E [GPa] | Strains along Uniaxial x (εx) | Strengths along Uniaxial x (σx) [GPa] | Ref. |

|---|---|---|---|---|---|---|---|---|

| Ti3C2H2 | 2D unit cell | Theoretical calculations | VASP/PBE | 419 | 392 | - | - | [27] |

| Zr3C2O2 | 2D hexagonal lattice | Etching Al layers in Zr3AlC5 | DFT | 392.9 | - | - | - | [28] |

| Ti2C | 2D sheets | Theoretical calculations | VASP | 609 | - | - | - | [29] |

| Ti2CO2 | 2D sheets | Theoretical calculations | Nanoindentation process | - | 983 | - | - | [30] |

| Ta2C | 2D sheets | Theoretical calculations | CASTEP/Wu-Cohen | 788 | - | - | - | [31] |

| Ti2C | 2D sheets | Theoretical calculations | MD | - | 597 | - | - | [32] |

| Mo2C | 2D sheets | Chemical vapor deposition | VASP | - | 312 | - | - | [33] |

| Ti2CO2 | 2D sheets | Etching Al layers in Ti2AlC2 | VASP/PBE | 745 | 570 | 0.28 | 56 | [34] |

| W2C | 2D sheets | Theoretical calculations | VASP/PBE | 781.9 | - | 0.16 | 65.6 | [35] |

| Materials | Morphology | Preparation method | Measurements | c11 (N/m) | E (N/m) | εx | σx (N/m) | Ref. |

| Ti3C2O2 | 2D unit cell | Theoretical calculations | VASP/PBE | 379 | 347 | - | - | [27] |

| W2HfC2O2 | 2D unit cell | Theoretical Calculations | VASP/PBE | - | - | - | 47.3 | [34] |

| Mo2CO2 | hexagonal unit cell | Theoretical calculations | VASP/PBE | 361 | 302 | - | - | [35] |

| Ti2CO2 | 2D sheets | Theoretical Calculations | DFT | - | 241 | 0.24 | 30.7 | [36] |

| MAX Phase MXene-Hybrid | Material Composition | Synthesis/Characterization Methods | Morphology | Performance | Ref. |

|---|---|---|---|---|---|

| Ti3AlC2 | Ti3C2Tx | HF etching/TEM, SEM, CA, XRD, EIS | Nanosheets | 517 F/g at 1 A/g | [16] |

| Ti3AlC2 | Ti3C2Tx | HF etching/EIS, XRD | Paper | 340 F/cm3 at 1 A/g | [76] |

| Ti3AlC2 | Ti3C2Tx-P | HCl–LiF/SEM, TEM, FTIR | Paper | 416 F/g at 5 mV/s | [84] |

| Ti3AlC2 | Ti3C2Tx | HCl–LiF/XRD, TEM, SEM | Nanosheets | 900 F/cm3 at 2 mV/s | [77] |

| Ti3AlC2 | Ti3C2Tx-EG | HF etching/XRD, TEM, SEM | Nanosheets | 33 F/cm2 at 2 mV/s | [86] |

| Ti3AlC2 | Ti3C2Tx | HF etching/NA | Film | 528 F/cm3 at 2 mV/s | [87] |

| Ti3AlC2 | Ti3C2Tx | NH4F-hydrothermal/XRD, SEM, Raman, XPS | Nanosheets | 141 F/g at 2 A/g | [88] |

| Ti3AlC2 | Ti3C2Tx-rGO | HCl–LiF/XRD, SEM | Nanosheets | 8.6 mWh/cm3 at 0.2 W/cm3 | [89] |

| Ti3AlC2 | Ti3C2Tx-CNT | HCl–LiF/XRD, SEM, TEM | Nanosheets | 314 F/cm3 at 1.7 mg/cm2 | [90] |

| Ti3AlC2 | Ti3C2Tx | HF etching/NA | Nanosheets | 2.8 mWh/cm3 at 0.225 W/cm3 | [91] |

| Ti3AlC2 | BiOCl-Ti3C2Tx | HF etching/XRD, SEM, TEM, XPS | Nanosheets | 397 F/cm3 at 1 A/g | [92] |

| Ti3AlCN | Ti3C2Tx | HCl–LiF/TEM, AFM, SEM | Nanosheets | 61 mF/cm2 at 5 μA/cm2 | [93] |

| Freestanding Ti3C2Tx and Ti2CTx MXenes | ||||||

|---|---|---|---|---|---|---|

| Electrode | Electrolyte | Scan Rate/Current Density | Initial Capacitance (IC) | Cycle Number (CN) | Capacity After Cycles (AC) | Ref. |

| Ti2CTx | 30 wt % KOH | 10 A g−1 | 51 F g −1 | 6000 | 93% | [74] |

| Ti3C2Tx | 1 M KOH | 1 A g −1 | 350 F cm−3 | 10,000 | ∼94% | [76] |

| Ti3C2Tx | 1 M H2SO4 | 5 A g −1 | 415 F cm−3 | 10,000 | ∼100% | [81] |

| Ti3C2Tx | 1 M H2SO4 | 10 A g −1 | 900 F cm−3 | 10,000 | ∼100% | [77] |

| Ti3C2Tx | 1 M H2SO4 | 10 A g −1 | 499 F g −1 | 10,000 | ∼100% | [94] |

| Ti3C2Tx | 6 M KOH | 5 A g −1 | 118 F g−1 | 5000 | ∼100% | [95] |

| Ti3C2Tx | 1 M H2SO4 | 5 A g −1 | 215 F g−1 | 10,000 | ∼100% | [96] |

| Ti3C2Tx | 1 M H2SO4 | 5 A g −1 | 892 F g−1 | 10,000 | ∼100% | [97] |

| N-Ti3C2Tx | 1 M H2SO4 | 50 mv s −1 | 192 F g −1 | 10,000 | 92% | [98] |

| Ti3C2Tx/paper | 1 M H2SO4 | 2 mA cm−2 | 25 mF cm−2 | 10,000 | 92% | [99] |

| Ti3C2Tx/3D porous layered double hydroxide | 6 M KOH | 1 A g−1 | 1061 F g−1 | 4000 | 70% | [100] |

| 400-KOH-Ti3C2Tx | 1 M H2SO4 | 1 A g−1 | 517 F g−1 | 10,000 | >99% | [101] |

| Ti3C2Tx MXenes Hybrid Composites | ||||||

| Electrode | Electrolyte | Scan Rate/Current Density | Initial Capacitance (IC) | Cycle Number (CN) | Capacity After Cycles (AC) | Ref. |

| Ti3C2Tx/PVA | 1 M KOH | 5 A g −1 | ∼370 F cm−3 | 10,000 | ∼85% | [16] |

| PPy/Ti3C2Tx | 1 M H2SO4 | 100 mV s−1 | ∼250 F g−1 | 25,000 | 92% | [84] |

| Ti3C2Tx/SWCNT | 1 M MgSO4 | 5 A g −1 | 345 F cm−3 | 10,000 | ∼100% | [102] |

| Ti3C2Tx/rGO | 3 M H2SO4 | 100 mV s−1 | 777 F cm−3 | 20,000 | ∼100% | [103] |

| Ti3C2Tx/CNT | 1 M EMITFSI | 1 A g−1 | ∼80 F g−1 | 1000 | ∼90% | [104] |

| Ti3C2Tx/CNT | 6 M KOH | 10 mv s−1 | ∼384 F g−1 | 10,000 | ∼100% | [105] |

| TiO2/Ti3C2Tx | 6 M KOH | 5 mV s−1 | 143 F g−1 | 3000 | ∼96% | [106] |

| MnOx/Ti3C2Tx | 1 M Li2SO 4 | 2 mV s−1 | 602 F cm−3 | 10,000 | 89.8% | [107] |

| PPy/Ti3C2Tx | 0.5 M H2SO4 | 1 mA cm−2 | 406 F cm−3 | 20,000 | ∼96% | [108] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim, Y.; Mohamed, A.; Abdelgawad, A.M.; Eid, K.; Abdullah, A.M.; Elzatahry, A. The Recent Advances in the Mechanical Properties of Self-Standing Two-Dimensional MXene-Based Nanostructures: Deep Insights into the Supercapacitor. Nanomaterials 2020, 10, 1916. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10101916

Ibrahim Y, Mohamed A, Abdelgawad AM, Eid K, Abdullah AM, Elzatahry A. The Recent Advances in the Mechanical Properties of Self-Standing Two-Dimensional MXene-Based Nanostructures: Deep Insights into the Supercapacitor. Nanomaterials. 2020; 10(10):1916. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10101916

Chicago/Turabian StyleIbrahim, Yassmin, Ahmed Mohamed, Ahmed M. Abdelgawad, Kamel Eid, Aboubakr M. Abdullah, and Ahmed Elzatahry. 2020. "The Recent Advances in the Mechanical Properties of Self-Standing Two-Dimensional MXene-Based Nanostructures: Deep Insights into the Supercapacitor" Nanomaterials 10, no. 10: 1916. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10101916