Nanoporous Stainless Steel Materials for Body Implants—Review of Synthesizing Procedures

Abstract

:1. Introduction

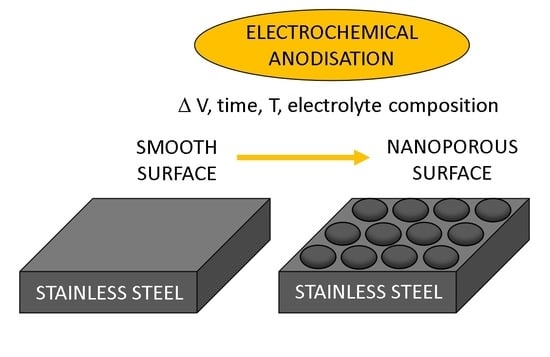

2. Literature Survey

3. Correlations between the Anodisation Parameters and the Surface Treatment

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lodhi, M.; Deen, K.; Greenlee-Wacker, M.; Haider, W. Additively manufactured 316L stainless steel with improved corrosion resistance and biological response for biomedical applications. Addit. Manuf. 2019, 27, 8–19. [Google Scholar] [CrossRef]

- Thangaraj, B.; TS Nellaiappan, S.N.; Kulandaivelu, R.; Lee, M.H.; Nishimura, T. A facile method to modify the characteristics and corrosion behavior of 304 stainless steel by surface nanostructuring toward biomedical applications. ACS Appl. Mater. Interfaces 2015, 7, 17731–17747. [Google Scholar] [CrossRef] [PubMed]

- Andersen, P.J. Stainless steels. In Biomaterials Science; Elsevier: Amsterdam, The Netherlands, 2020; pp. 249–255. [Google Scholar]

- Resnik, M.; Benčina, M.; Levičnik, E.; Rawat, N.; Iglič, A.; Junkar, I. Strategies for improving antimicrobial properties of stainless steel. Materials 2020, 13, 2944. [Google Scholar] [CrossRef]

- Santos, A.; Aw, M.S.; Bariana, M.; Kumeria, T.; Wang, Y.; Losic, D. Drug-releasing implants: Current progress, challenges and perspectives. J. Mater. Chem. B 2014, 2, 6157–6182. [Google Scholar] [CrossRef] [PubMed]

- Lyndon, J.A.; Boyd, B.J.; Birbilis, N. Metallic implant drug/device combinations for controlled drug release in orthopaedic applications. J. Control. Release 2014, 179, 63–75. [Google Scholar] [CrossRef] [PubMed]

- Gulati, K.; Ivanovski, S. Dental implants modified with drug releasing titania nanotubes: Therapeutic potential and developmental challenges. Expert Opin. Drug Deliv. 2017, 14, 1009–1024. [Google Scholar] [CrossRef] [PubMed]

- Barik, A.; Chakravorty, N. Targeted drug delivery from titanium implants: A review of challenges and approaches. Expert Opin. Drug Deliv. 2019, 125, 1–17. [Google Scholar]

- Kadambi, P.; Luniya, P.; Dhatrak, P. Current advancements in polymer/polymer matrix composites for dental implants: A systematic review. Mater. Today Proc. 2021, 46, 740–745. [Google Scholar] [CrossRef]

- Biesiekierski, A.; Wang, J.; Gepreel, M.A.-H.; Wen, C. A new look at biomedical Ti-based shape memory alloys. Acta Biomater. 2012, 8, 1661–1669. [Google Scholar] [CrossRef]

- Padiyar, N. Nickel allergy-Is it a cause of concern in everyday dental practice? Sch. J. 2011, 2. [Google Scholar]

- Wataha, J.C.; Drury, J.L.; Chung, W.O. Nickel alloys in the oral environment. Expert Opin. Drug Deliv. 2013, 10, 519–539. [Google Scholar] [CrossRef] [PubMed]

- Chu, C.; Wang, R.; Hu, T.; Yin, L.; Pu, Y.; Lin, P.; Wu, S.; Chung, C.Y.; Yeung, K.; Chu, P.K. Surface structure and biomedical properties of chemically polished and electropolished NiTi shape memory alloys. Mater. Sci. Eng. C 2008, 28, 1430–1434. [Google Scholar] [CrossRef]

- Junkar, I.; Zaplotnik, R.; Benčina, M.; Mozetič, M. Method for treatment medical devices made from nickel—Titanium (NiTi) alloys. U.S. patent number 11,208,720, 4 April 2020. [Google Scholar]

- Vesel, A.; Drenik, A.; Elersic, K.; Mozetic, M.; Kovac, J.; Gyergyek, T.; Stockel, J.; Varju, J.; Panek, R.; Balat-Pichelin, M. Oxidation of Inconel 625 superalloy upon treatment with oxygen or hydrogen plasma at high temperature. Appl. Surf. Sci. 2014, 305, 674–682. [Google Scholar] [CrossRef]

- Junkar, I.; Kulkarni, M.; Benčina, M.; Kovač, J.; Mrak-Poljšak, K.; Lakota, K.; Sodin-Šemrl, S.n.; Mozetič, M.; Iglič, A. Titanium dioxide nanotube Arrays for cardiovascular stent applications. ACS Omega 2020, 5, 7280–7289. [Google Scholar] [CrossRef] [PubMed]

- Benčina, M.; Rawat, N.; Lakota, K.; Sodin-Šemrl, S.; Iglič, A.; Junkar, I. Bio-Performance of Hydrothermally and Plasma-Treated Titanium: The New Generation of Vascular Stents. Int. J. Mol. Sci. 2021, 22, 11858. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, M.; Mazare, A.; Gongadze, E.; Perutkova, Š.; Kralj-Iglič, V.; Milošev, I.; Schmuki, P.; Iglič, A.; Mozetič, M. Titanium nanostructures for biomedical applications. Nanotechnology 2015, 26, 062002. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, M.; Flašker, A.; Lokar, M.; Mrak-Poljšak, K.; Mazare, A.; Artenjak, A.; Čučnik, S.; Kralj, S.; Velikonja, A.; Schmuki, P. Binding of plasma proteins to titanium dioxide nanotubes with different diameters. Int. J. Nanotechnol. 2015, 10, 1359. [Google Scholar]

- Huang, H.-H.; Wu, C.-P.; Sun, Y.-S.; Lee, T.-H. Improvements in the corrosion resistance and biocompatibility of biomedical Ti–6Al–7Nb alloy using an electrochemical anodization treatment. Thin Solid Film. 2013, 528, 157–162. [Google Scholar] [CrossRef]

- Lee, K.; Mazare, A.; Schmuki, P. One-dimensional titanium dioxide nanomaterials: Nanotubes. Chem. Rev. 2014, 114, 9385–9454. [Google Scholar] [CrossRef]

- Iwai, M.; Kikuchi, T.; Suzuki, R.O. High-speed galvanostatic anodizing without oxide burning using a nanodimpled aluminum surface for nanoporous alumina fabrication. Appl. Surf. Sci. 2021, 537, 147852. [Google Scholar] [CrossRef]

- Cao, J.; Gao, Z.; Wang, C.; Muzammal, H.M.; Wang, W.; Gu, Q.; Dong, C.; Ma, H.; Wang, Y. Morphology evolution of the anodized tin oxide film during early formation stages at relatively high constant potential. Surf. Coat. Technol. 2020, 388, 125592. [Google Scholar] [CrossRef]

- Suzuki, Y.; Kawahara, K.; Kikuchi, T.; Suzuki, R.O.; Natsui, S. Corrosion-resistant porous alumina formed via anodizing aluminum in etidronic acid and its pore-sealing behavior in boiling water. J. Electrochem. Soc. 2019, 166, C261. [Google Scholar] [CrossRef]

- Tucker, B.S.; Aliakbarshirazi, S.; Vijayan, V.M.; Thukkaram, M.; De Geyter, N.; Thomas, V. Nonthermal plasma processing for nanostructured biomaterials and tissue engineering scaffolds: A mini review. Curr. Opin. Biomed. Eng. 2021, 17, 100259. [Google Scholar] [CrossRef]

- Benčina, M.; Junkar, I.; Zaplotnik, R.; Valant, M.; Iglič, A.; Mozetič, M. Plasma-induced crystallization of TiO2 nanotubes. Materials 2019, 12, 626. [Google Scholar] [CrossRef]

- Tsuchiya, H.; Suzumura, T.; Terada, Y.; Fujimoto, S. Formation of self-organized pores on type 316 stainless steel in organic solvents. Electrochim. Acta 2012, 82, 333–338. [Google Scholar] [CrossRef]

- Gongadze, E.; Kabaso, D.; Bauer, S.; Slivnik, T.; Schmuki, P.; Van Rienen, U.; Iglič, A. Adhesion of osteoblasts to a nanorough titanium implant surface. Int. J. Nanotechnol. 2011, 6, 1801. [Google Scholar]

- Pan, H.-A.; Liang, J.-Y.; Hung, Y.-C.; Lee, C.-H.; Chiou, J.-C.; Huang, G.S. The spatial and temporal control of cell migration by nanoporous surfaces through the regulation of ERK and integrins in fibroblasts. Biomaterials 2013, 34, 841–853. [Google Scholar] [CrossRef]

- Sjöström, T.; Dalby, M.J.; Hart, A.; Tare, R.; Oreffo, R.O.; Su, B. Fabrication of pillar-like titania nanostructures on titanium and their interactions with human skeletal stem cells. Acta Biomater. 2009, 5, 1433–1441. [Google Scholar] [CrossRef]

- Dalby, M.; Riehle, M.; Johnstone, H.; Affrossman, S.; Curtis, A. In vitro reaction of endothelial cells to polymer demixed nanotopography. Biomaterials 2002, 23, 2945–2954. [Google Scholar] [CrossRef]

- Dalby, M.J.; Andar, A.; Nag, A.; Affrossman, S.; Tare, R.; McFarlane, S.; Oreffo, R.O. Genomic expression of mesenchymal stem cells to altered nanoscale topographies. J. R. Soc. Interface 2008, 5, 1055–1065. [Google Scholar] [CrossRef]

- Dalby, M.; Giannaras, D.; Riehle, M.; Gadegaard, N.; Affrossman, S.; Curtis, A. Rapid fibroblast adhesion to 27 nm high polymer demixed nano-topography. Biomaterials 2004, 25, 77–83. [Google Scholar] [CrossRef]

- Dalby, M.J.; Gadegaard, N.; Oreffo, R.O. Harnessing nanotopography and integrin–matrix interactions to influence stem cell fate. Nat. Mater. 2014, 13, 558–569. [Google Scholar] [CrossRef]

- Ni, S.; Sun, L.; Ercan, B.; Liu, L.; Ziemer, K.; Webster, T.J. A mechanism for the enhanced attachment and proliferation of fibroblasts on anodized 316L stainless steel with nano-pit arrays. J. Biomed. Mater. Res. Part B Appl. Biomater. 2014, 102, 1297–1303. [Google Scholar] [CrossRef] [PubMed]

- Ni, S.; Sun, L.; Ercan, B.; Liu, L.; Ziemer, K.; Webster, T.J. Enhanced Attachment and Proliferation of Fibroblasts on Anodized 316L Stainless Steel with Nano-pit Arrays. MRS Online Proc. Libr. (OPL) 2014, 1626. [Google Scholar]

- Tsuchiya, H. Formation of self-organized pore arrays on metallic substrates by anodization and their applications. Mater. Sci. Forum 2014, 783–786, 2034–2039. [Google Scholar] [CrossRef]

- Khaw, J.S.; Bowen, C.R.; Cartmell, S.H. Effect of TiO2 Nanotube Pore Diameter on Human Mesenchymal Stem Cells and Human Osteoblasts. Nanomaterials 2020, 10, 2117. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Zou, D.; Han, Y.; Liu, R.; Tian, C. Self-organised nanoporous anodic films on superaustenitic stainless steel. Mater. Res. Innov. 2014, 18, S4-747–S4-750. [Google Scholar] [CrossRef]

- Ban, G.-H.; Rungraeng, N.; Li, Y.; Jun, S. Nanoporous stainless steel surfaces for anti-bacterial adhesion performances. Trans. ASABE 2018, 61, 1175–1179. [Google Scholar] [CrossRef]

- Narendrakumar, K.; Kulkarni, M.; Addison, O.; Mazare, A.; Junkar, I.; Schmuki, P.; Sammons, R.; Iglič, A. Adherence of oral streptococci to nanostructured titanium surfaces. Dent. Mater. 2015, 31, 1460–1468. [Google Scholar] [CrossRef]

- Farrag, H.H.; Sayed, S.Y.; Allam, N.K.; Mohammad, A.M. Emerging nanoporous anodized stainless steel for hydrogen production from solar water splitting. J. Clean. Prod. 2020, 274, 122826. [Google Scholar] [CrossRef]

- Bae, I.; Lim, K.-S.; Park, J.-K.; Song, J.H.; Oh, S.-H.; Kim, J.-W.; Zhang, Z.; Park, C.; Koh, J.-T. Evaluation of cellular response and drug delivery efficacy of nanoporous stainless steel material. Biomater. Res. 2021, 25, 1–8. [Google Scholar] [CrossRef]

- Rodriguez-Contreras, A.; Bello, D.G.; Flynn, S.; Variola, F.; Wuest, J.D.; Nanci, A. Chemical nanocavitation of surfaces to enhance the utility of stainless steel as a medical material. Colloids Surf. B Biointerfaces 2018, 161, 677–687. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, R.; Zhou, X.; Hu, G. Experimental investigation on optimal anodising parameters of nanopore preparation process on the stainless steel surface. Corros. Eng. Sci. Technol. 2020, 55, 513–519. [Google Scholar] [CrossRef]

| SS Composition | Electrolyte | Time (min) | Voltage (V) | Temperature (°C) | Average Pore Diameter (nm) | Morphology/Pore Distribution | Ref. |

|---|---|---|---|---|---|---|---|

| 316 | 10 vol. % perchloric acid in ethylene glycol | 5 | 20 | 25 1 | 36 | Ordered pore arrays. | [27] |

| 10 vol. % perchloric acid in ethylene glycol | 5 | 30 | 25 | 140 | Ordered pore arrays. | ||

| 10 vol. % perchloric acid in ethylene glycol | 5 | 40 | 25 | 210 | Ordered pore arrays. | ||

| 10 vol. % perchloric acid in ethylene glycol | 5 | 50 | 25 | 270 | Ordered pore arrays. | ||

| 10 vol. % perchloric acid in ethylene glycol | 5 | 60 | 25 | 345 | Ordered pore arrays. | ||

| 10 vol. % perchloric acid in ethanol | 5 | 60 | 25 | 100 | Ordered pore arrays. | ||

| 10 vol. % perchloric acid in acetic acid | 5 | 60 | 25 | 300 | Ordered pore arrays—more defined as with ethanol in the electrolyte. | ||

| Water-free ethylene glycol containing lithium perchlorate | 5 | 40 | 25 | 150 | Ordered pore arrays. | ||

| Water-added ethylene glycol containing lithium perchlorate | 5 | 40 | 25 | 300 | Ordered pore arrays—more defined as with water-free electrolyte. | ||

| 316L | 5.3 vol. % perchloric acid in ethylene glycol monobutylether | 30 | 30 | 5–10 | 40 | Well controlled and highly defined. | [29] |

| 5.3 vol. % perchloric acid in ethylene glycol monobutylether | 30 | 45 | 5–10 | 75 | Well controlled and highly defined. | ||

| 5.3 vol. % perchloric acid in ethylene glycol monobutylether | 30 | 60 | 5–10 | 160 | Well controlled and highly defined. | ||

| 5.3 vol. % perchloric acid in ethylene glycol monobutylether | 30 | 70 | 5–10 | 185 | Well controlled and highly defined. | ||

| 5.3 vol. % perchloric acid in ethylene glycol monobutylether | 30 | 75 | 5–10 | 210 | Well controlled and highly defined. | ||

| 316L | 5 vol. % perchloric acid in ethylene glycol | N/A | 20 | N/A | 0 | No pores observed. | [36] |

| 5 vol. % perchloric acid in ethylene glycol | N/A | 30 | N/A | 25 | Uniform nanoporous honeycomb morphology and long-range order. | ||

| 5 vol. % perchloric acid in ethylene glycol | N/A | 40 | N/A | 50 | Uniform nanoporous honeycomb morphology and long-range order. | ||

| 5 vol. % perchloric acid in ethylene glycol | N/A | 50 | N/A | 60 | Uniform nanoporous honeycomb morphology and long-range order. | ||

| 316 | 10 vol. % perchloric acid in ethylene glycol | 5 | 50 | 25 2 | 210 | Ordered pore arrays. | [37] |

| Ethylene glycol containing sodium perchlorate | N/A | 60 | 25 | 260 | Ordered pore arrays. | ||

| Ethylene glycol containing sodium perchlorate and water (app. 5 vol. %) | N/A | 60 | 25 | 330 | Ordered pore arrays. | ||

| Ethylene glycol containing sodium perchlorate and water (app. 12 vol. %) | N/A | 60 | 25 | 350 | Ordered pore arrays. | ||

| Ethylene glycol containing sodium perchlorate and water (app. 20 vol. %) | N/A | 60 | 25 | 0 | No pores observed. | ||

| 316 | 10 vol.% perchloric acid in ethylene glycol | 0.83 | 50 | 4 | 200 | Orderly nanopores. | [39] |

| 904L | 10 vol. % perchloric acid in ethylene glycol | 10 | 30 | 4 | 76 | Regular and orderly nanoporous morphology | |

| 10 vol. % perchloric acid in ethylene glycol | 10 | 30 | 12 | 90 | Regular and orderly nanoporous morphology | ||

| 10 vol. % perchloric acid in ethylene glycol | 10 | 30 | 30 | 125 | Regular and orderly nanoporous morphology | ||

| 10 vol.% perchloric acid in ethylene glycol | 10 | 20 | 4 | 40 | Orderly nanoporpous morphology. | ||

| 10 vol. % perchloric acid in ethylene glycol | 10 | 30 | 4 | 80 | Orderly nanoporous morphology. | ||

| 10 vol. % perchloric acid in ethylene glycol | 10 | 40 | 4 | 200 | Less orderly nanoporous morphology as with voltage of 20 V and 30 V. | ||

| 10 vol. % perchloric acid in ethylene glycol | 10 | 50 | 4 | 100–200 | Unorderly morphology with individual nanopores; nanoporous anodic films almost dissolved. | ||

| 10 vol. % perchloric acid in ethylene glycol | 0.83 | 50 | 4 | 100–200 | Unorderly morphology with individual nanopores. | ||

| 316L | 5 wt.% perchloric acid in anhydrous ethylene glycol solution | 10 | 40 | N/A | 50 | Nanoporous surface. Before anodisation the samples were electropolished in a mixture solution of phosphoric acid and sulfuric acid (60%:40% v/v), at an applied potential of 3.5 V, at 80°C for 10 min. | [40] |

| 35 | 50 | 80 | |||||

| 316 | A mixture of equal volumes of H2SO4 and aqueous H2O2 | N/A | N/A | 0 3 | 17.6 ± 7.1 | Nanotopography; crystalline mesoporous layer of oxide on the surface. | [44] |

| 304 | A mixture of equal volumes of H2SO4 and aqueous H2O2 | N/A | N/A | 0 | 16.4 ± 4.2 | Nanotopography; crystalline mesoporous layer of oxide on the surface. | |

| 316L | 5 vol. % perchloric acid in ethylene glycol | 10 | 30 | 0 4 | 120 | Regular arrays of surface pores/Self-organized surface nanopores. | [42] |

| 5 vol. % perchloric acid in ethylene glycol | 10 | 30 | 0 | 40 | Regular arrays of surface pores/Self-organized surface nanopores. | ||

| 5 vol. % perchloric acid in ethylene glycol | 10 | 35 | 0 | 70 | Regular arrays of surface pores/Self-organized surface nanopores. | ||

| 5 vol. % perchloric acid in ethylene glycol | 10 | 40 | 0 | 110 | Regular arrays of surface pores/Self-organized surface nanopores. | ||

| 5 vol. % perchloric acid in ethylene glycol | 11 | 40 | 0 | 50–200 | Destroyed morphology with individual nanopores. | ||

| 5 vol. % perchloric acid in ethylene glycol | 0.33 | 40 | 0 | 20 | Partially destroyed morphology. | ||

| 5 vol. % perchloric acid in ethylene glycol | 10 | 40 | 25 | 0 | Destroyed morphology, no pores observed. | ||

| 3 vol. % perchloric acid in ethylene glycol | 10 | 40 | 0 | 0 | No pores observed. | ||

| 10 vol. % perchloric acid in ethylene glycol | 10 | 40 | 0 | 0 | No pores observed. | ||

| 304 | Nitric acid concentration 90 mL L−1, thiourea concentration 3.5 g L−1, sodium chloride concentration 20 g L−1 | 2 | 5.0 | N/A | N/A | Nanopore structure with an average porosity of 36.75%. | [45] |

| 316L | 1 M H2SO4 and 1.0 wt.% hydrofluoric acid solutions with a pH of 2–3 | N/A | N/A | 25 5 | 100 | Nanopores. Before anodisation the samples were electropolished in a H2SO4, at 50 °C, at a constant voltage of 10 V and 10 A for 10 min. | [43] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benčina, M.; Junkar, I.; Vesel, A.; Mozetič, M.; Iglič, A. Nanoporous Stainless Steel Materials for Body Implants—Review of Synthesizing Procedures. Nanomaterials 2022, 12, 2924. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12172924

Benčina M, Junkar I, Vesel A, Mozetič M, Iglič A. Nanoporous Stainless Steel Materials for Body Implants—Review of Synthesizing Procedures. Nanomaterials. 2022; 12(17):2924. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12172924

Chicago/Turabian StyleBenčina, Metka, Ita Junkar, Alenka Vesel, Miran Mozetič, and Aleš Iglič. 2022. "Nanoporous Stainless Steel Materials for Body Implants—Review of Synthesizing Procedures" Nanomaterials 12, no. 17: 2924. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12172924