Nanocelluloses: Natural-Based Materials for Fiber-Reinforced Cement Composites. A Critical Review

Abstract

:1. Introduction

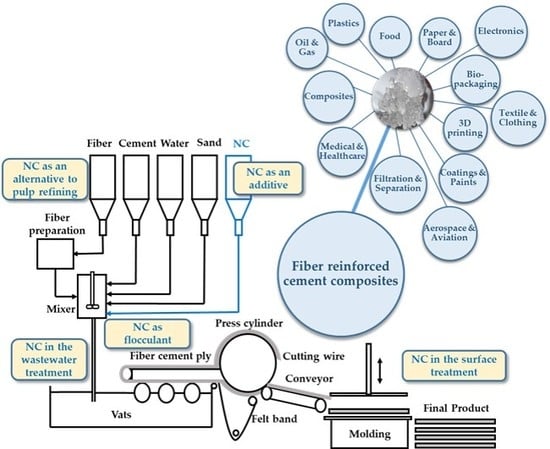

2. Nanocelluloses in the Cement and Fiber-Cement Industry

2.1. Use of NC as a Reinforcing Raw Material to Reduce Pulp Refining Requirements

2.2. Use of NC as an Additive

2.2.1. Mechanical Improvement

- The bridging of microcracks;

- The increase of fiber–matrix interaction;

- The increase of hardening kinetics near the NC surface;

- The protection of the fiber lumen from mineralization; and

- The decrease of autogeneous shrinkage.

2.2.2. Rheology Modifier

2.3. Interaction with Other Components

2.4. Understanding the Effect of Nanocelluloses

3. Further Applications to the C-FCC Production Process

3.1. Surface Treatment of Fiber Cement Boards

3.2. Use of NC as a Flocculant

3.3. Wastewater Treatment

4. Market and Sustainability

4.1. Sustainability

4.2. Market

5. Future Research Requirements

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, Z.-S.; Zhou, X.; Wang, X.; Guo, P. Mechanical behavior of multilayer GO carbon-fiber cement composites. Constr. Build. Mater. 2018, 159, 205–212. [Google Scholar] [CrossRef]

- Qiu, J.; Lim, X.N.; Yang, E.-H. Fatigue-induced in-situ strength deterioration of micro-polyvinyl alcohol (PVA) fiber in cement matrix. Cem. Concr. Compos. 2017, 82, 128–136. [Google Scholar] [CrossRef]

- Beglarigale, A.; Yazıcı, H. Electrochemical corrosion monitoring of steel fiber embedded in cement based composites. Cem. Concr. Compos. 2017, 83, 427–446. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; CRC Press: London, UK, 1990. [Google Scholar]

- Balaguru, P.N.; Shah, S.P. Fiber-Reinforced Cement Composites, 1st ed.; Mc Graw Hill International Editions: New York, NY, USA, 1992. [Google Scholar]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Morton, J.H.; Cooke, T.; Akers, S. Performance of slash pine fibers in fiber cement products. Constr. Build. Mater. 2010, 24, 165–170. [Google Scholar] [CrossRef]

- Savastano, H., Jr.; Warden, P.G.; Coutts, R. Mechanically pulped sisal as reinforcement in cementitious matrices. Cem. Concr. Compos. 2003, 25, 311–319. [Google Scholar] [CrossRef]

- Mohr, B.; Nanko, H.; Kurtis, K. Durability of kraft pulp fiber–cement composites to wet/dry cycling. Cem. Concr. Compos. 2005, 27, 435–448. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; Scrivener, K.; England, G.L.; Ghavami, K. Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.A.; Barra, M. Fiber-matrix interactions in cement mortar composites reinforced with cellulosic fibers. Cellulose 2011, 18, 281–289. [Google Scholar] [CrossRef]

- Kawashima, S.; Shah, S.P. Early-age autogenous and drying shrinkage behavior of cellulose fiber-reinforced cementitious materials. Cem. Concr. Compos. 2011, 33, 201–208. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef]

- Blanco, A.; Monte, M.C.; Campano, C.; Balea, A.; Merayo, N.; Negro, C. Nanocellulose for industrial use: Cellulose nanofibers (CNF), cellulose nanocrystals (CNC), and bacterial cellulose (BC). In Handbook of Nanomaterials for Industrial Applications; Elsevier: Newark, NJ, USA, 2018; pp. 74–126. [Google Scholar]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindstrom, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A new family of nature-based materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef] [PubMed]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- Mondal, S. Preparation, properties and applications of nanocellulosic materials. Carbohyd. Polym. 2017, 163, 301–316. [Google Scholar] [CrossRef] [PubMed]

- Lindström, T. Aspects on nanofibrillated cellulose (NFC) processing, rheology and NFC-film properties. Curr. Opin. Colloid Interface Sci. 2017, 29, 68–75. [Google Scholar] [CrossRef]

- kumar Mishra, R.; Sabu, A.; Tiwari, S.K. Materials chemistry and the futurist eco-friendly applications of nanocellulose: Status and prospect. J. Saudi Chem. Soc. 2018, 22, 949–978. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated cellulose—Its barrier properties and applications in cellulosic materials: A review. Carbohyd. Polym. 2012, 90, 735–764. [Google Scholar] [CrossRef]

- Khalil, H.A.; Davoudpour, Y.; Islam, M.N.; Mustapha, A.; Sudesh, K.; Dungani, R.; Jawaid, M. Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohyd. Polym. 2014, 99, 649–665. [Google Scholar] [CrossRef]

- Chirayil, C.J.; Mathew, L.; Thomas, S. Review of recent research in nano cellulose preparation from different lignocellulosic fibers. Rev. Adv. Mater. Sci. 2014, 37, 20–28. [Google Scholar]

- Phanthong, P.; Reubroycharoen, P.; Hao, X.; Xu, G.; Abudula, A.; Guan, G. Nanocellulose: Extraction and application. Carbon Resour. Convers. 2018, 1, 32–43. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Naceur Belgacem, M.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crop. Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Trache, D.; Hussin, M.H.; Haafiz, M.M.; Thakur, V.K. Recent progress in cellulose nanocrystals: Sources and production. Nanoscale 2017, 9, 1763–1786. [Google Scholar] [CrossRef] [PubMed]

- George, J.; Sabapathi, S. Cellulose nanocrystals: Synthesis, functional properties, and applications. Nanotechnol. Sci. Appl. 2015, 8, 45. [Google Scholar] [CrossRef]

- Azizi Samir, M.A.S.; Alloin, F.; Dufresne, A. Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 2005, 6, 612–626. [Google Scholar] [CrossRef]

- Mariano, M.; El Kissi, N.; Dufresne, A. Cellulose nanocrystals and related nanocomposites: Review of some properties and challenges. J. Polym. Sci. Pol. Phys. 2014, 52, 791–806. [Google Scholar] [CrossRef]

- Campano, C.; Balea, A.; Blanco, A.; Negro, C. Enhancement of the fermentation process and properties of bacterial cellulose: A review. Cellulose 2016, 23, 57–91. [Google Scholar] [CrossRef]

- Jonoobi, M.; Mathew, A.P.; Oksman, K. Producing low-cost cellulose nanofiber from sludge as new source of raw materials. Ind. Crop. Prod. 2012, 40, 232–238. [Google Scholar] [CrossRef]

- Jonoobi, M.; Oladi, R.; Davoudpour, Y.; Oksman, K.; Dufresne, A.; Hamzeh, Y.; Davoodi, R. Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: A review. Cellulose 2015, 22, 935–969. [Google Scholar] [CrossRef]

- Chin, K.M.; Sung Ting, S.; Ong, H.L.; Omar, M. Surface functionalized nanocellulose as a veritable inclusionary material in contemporary bioinspired applications: A review. J. Appl. Polym. Sci. 2018, 135, 46065. [Google Scholar] [CrossRef]

- Shatkin, J.A.; Wegner, T.H.; Bilek, E.M.; Cowie, J. Market projections of cellulose nanomaterial-enabled products—Part 1: Applications. Tappi J. 2014, 13, 9–16. [Google Scholar]

- Cowie, J.; Bilek, E.M.; Wegner, T.H.; Shatkin, J.A. Market projections of cellulose nanomaterial-enabled products—Part 2: Volume estimates. Tappi J. 2014, 13, 57–69. [Google Scholar]

- Charreau, H.; L Foresti, M.; Vázquez, A. Nanocellulose patents trends: A comprehensive review on patents on cellulose nanocrystals, microfibrillated and bacterial cellulose. Recent Pat. Nanotechnol. 2013, 7, 56–80. [Google Scholar] [CrossRef]

- Kim, J.H.; Shim, B.S.; Kim, H.S.; Lee, Y.J.; Min, S.K.; Jang, D.; Abas, Z.; Kim, J. Review of nanocellulose for sustainable future materials. Int. J. Precis. Eng. Manuf. Green Technol. 2015, 2, 197–213. [Google Scholar] [CrossRef]

- Boufi, S.; González, I.; Delgado-Aguilar, M.; Tarrès, Q.; Pèlach, M.À.; Mutje, P. Nanofibrillated cellulose as an additive in papermaking process: A review. Carbohyd. Polym. 2016, 154, 151–166. [Google Scholar] [CrossRef]

- Li, F.; Mascheroni, E.; Piergiovanni, L. The potential of nanocellulose in the packaging field: A review. Packag. Technol. Sci. 2015, 28, 475–508. [Google Scholar] [CrossRef]

- Mahfoudhi, N.; Boufi, S. Nanocellulose as a novel nanostructured adsorbent for environmental remediation: A review. Cellulose 2017, 24, 1171–1197. [Google Scholar] [CrossRef]

- Carpenter, A.W.; de Lannoy, C.F.; Wiesner, M.R. Cellulose nanomaterials in water treatment technologies. Environ. Sci. Technol. 2015, 49, 5277–5287. [Google Scholar] [CrossRef]

- Brodin, F.W.; Gregersen, O.W.; Syverud, K. Cellulose nanofibrils: Challenges and possibilities as a paper additive or coating material—A review. Nord. Pulp Pap. Res. J. 2014, 29, 156–166. [Google Scholar] [CrossRef]

- Vilarinho, F.; Sanches Silva, A.; Vaz, M.F.; Farinha, J.P. Nanocellulose in green food packaging. Crit. Rev. Food Sci. Nutr. 2018, 58, 1526–1537. [Google Scholar] [CrossRef]

- Balea, A.; Blanco, A.; Monte, M.C.; Merayo, N.; Negro, C. Effect of bleached eucalyptus and pine cellulose nanofibers on the physico-mechanical properties of cartonboard. Bioresources 2016, 11, 8123–8138. [Google Scholar] [CrossRef]

- Balea, A.; Blanco, A.; Merayo, N.; Negro, C. Effect of nanofibrillated cellulose to reduce linting on high filler-loaded recycled papers. Appita J. 2016, 69, 148–156. [Google Scholar]

- Gomez, C.; Serpa, A.; Velasquez-Cock, J.; Ganan, P.; Castro, C.; Velez, L.; Zuluaga, R. Vegetable nanocellulose in food science: A review. Food Hydrocoll. 2016, 57, 178–186. [Google Scholar] [CrossRef]

- Lin, N.; Dufresne, A. Nanocellulose in biomedicine: Current status and future prospect. Eur. Polym. J. 2014, 59, 302–325. [Google Scholar] [CrossRef]

- Sanchez-Salvador, J.L.; Balea, A.; Monte, M.C.; Blanco, A.; Negro, C. Pickering emulsions containing cellulose microfibers produced by mechanical treatments as stabilizer in the food industry. Appl. Sci. 2019, 9, 359. [Google Scholar] [CrossRef]

- Dai, L.; Cheng, T.; Duan, C.; Zhao, W.; Zhang, W.; Zou, X.; Aspler, J.; Ni, Y. 3D printing using plant-derived cellulose and its derivatives: A review. Carbohyd. Polym. 2018, 203, 71–86. [Google Scholar] [CrossRef]

- Du, X.; Zhang, Z.; Liu, W.; Deng, Y.L. Nanocellulose-based conductive materials and their emerging applications in energy devices—A review. Nano Energy 2017, 35, 299–320. [Google Scholar] [CrossRef]

- Hoeng, F.; Denneulin, A.; Bras, J. Use of nanocellulose in printed electronics: A review. Nanoscale 2016, 8, 13131–13154. [Google Scholar] [CrossRef]

- Li, Y.; Yu, S.; Chen, P.; Rojas, R.; Hajian, A.; Berglund, L. Cellulose nanofibers enable paraffin encapsulation and the formation of stable thermal regulation nanocomposites. Nano Energy 2017, 34, 541–548. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Rojas, O.J.; Lucia, L.A.; Sain, M. Cellulosic nanocomposites: A review. Bioresources 2008, 3, 929–980. [Google Scholar]

- Ching, Y.C.; Ali, M.E.; Abdullah, L.C.; Choo, K.W.; Kuan, Y.C.; Julaihi, S.J.; Chuah, C.H.; Liou, N.-S. Rheological properties of cellulose nanocrystal-embedded polymer composites: A review. Cellulose 2016, 23, 1011–1030. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Dufresne, A.; Aranguren, M.; Marcovich, N.E.; Capadona, J.R.; Rowan, S.J.; Weder, C.; Thielemans, W.; Roman, M.; Renneckar, S.; et al. Review: Current international research into cellulose nanofibres and nanocomposites. J. Mater. Sci. 2010, 45, 1–33. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Mariano, M.; Huang, J.; Lin, N.; Ahmad, I.; Dufresne, A.; Thomas, S. Recent developments on nanocellulose reinforced polymer nanocomposites: A review. Polymer 2017, 132, 368–393. [Google Scholar] [CrossRef]

- Lee, K.Y.; Aitomaki, Y.; Berglund, L.A.; Oksman, K.; Bismarck, A. On the use of nanocellulose as reinforcement in polymer matrix composites. Compos. Sci. Technol. 2014, 105, 15–27. [Google Scholar] [CrossRef]

- Oksman, K.; Aitomaki, Y.; Mathew, A.P.; Siqueira, G.; Zhou, Q.; Butylina, S.; Tanpichai, S.; Zhou, X.J.; Hooshmand, S. Review of the recent developments in cellulose nanocomposite processing. Compos. Part A Appl. Sci. Manuf. 2016, 83, 2–18. [Google Scholar] [CrossRef]

- Negro, C.; Garcia-Ochoa, F.; Tanguy, P.; Ferreira, G.; Thibault, J.; Yamamoto, S.; Gani, R. Barcelona declaration–10th world congress of chemical engineering, 1–5 october 2017. Chem. Eng. Res. Des. 2018, 129, A1–A2. [Google Scholar] [CrossRef]

- Chinga-Carrasco, G.; Averianova, N.; Gibadullin, M.; Petrov, V.; Leirset, I.; Syverud, K. Micro-structural characterisation of homogeneous and layered MFC nano-composites. Micron 2013, 44, 331–338. [Google Scholar] [CrossRef]

- Jonoobi, M.; Harun, J.; Mathew, A.P.; Oksman, K. Mechanical properties of cellulose nanofiber (CNF) reinforced polylactic acid (PLA) prepared by twin screw extrusion. Compos. Sci. Technol. 2010, 70, 1742–1747. [Google Scholar] [CrossRef]

- Osong, S.H.; Norgren, S.; Engstrand, P. Processing of wood-based microfibrillated cellulose, and applications relating to papermaking: A review. Cellulose 2016, 23, 93–123. [Google Scholar] [CrossRef]

- Dufresne, A. Cellulose nanomaterials as green nanoreinforcements for polymer nanocomposites. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2017, 376, 20170040. [Google Scholar] [CrossRef]

- Siqueira, G.; Bras, J.; Dufresne, A. Cellulosic bionanocomposites: A review of preparation, properties and applications. Polymers 2010, 2, 728–765. [Google Scholar] [CrossRef]

- Balea, A.; Merayo, N.; Fuente, E.; Delgado-Aguilar, M.; Mutje, P.; Blanco, A.; Negro, C. Valorization of corn stalk by the production of cellulose nanofibers to improve recycled paper properties. Bioresources 2016, 11, 3416–3431. [Google Scholar] [CrossRef]

- Fu, T.; Moon, R.J.; Zavattieri, P.; Youngblood, J.; Weiss, W.J. Cellulose nanomaterials. In Cellulose-Reinforced Nanofibre Composites, 1st ed.; Jawaid, M., Boufi, S., Khalil, A.H.P.S., Eds.; Elsevier: Duxford, UK, 2017; pp. 455–482. [Google Scholar]

- Parveen, S.; Rana, S.; Fangueiro, R. Macro-and nanodimensional plant fiber reinforcements for cementitious composites. In Sustainable and Nonconventional Construction Materials Using Inorganic Bonded Fiber Composites, 1st ed.; Savastano, H., Jr., Fiorelli, F., Dos Santos, S.F., Eds.; Elsevier: Duxford, UK, 2017; pp. 343–382. [Google Scholar]

- Claramunt, J.; Ardanuy, M.; Fernandez-Carrasco, L.J. Wet/dry cycling durability of cement mortar composites reinforced with micro-and nanoscale cellulose pulps. BioResources 2015, 10, 3045–3055. [Google Scholar] [CrossRef]

- Ardanuy Raso, M.; Claramunt Blanes, J.; Arévalo Peces, R.; Parés Sabatés, F.; Aracri, E.; Vidal Lluciá, T. Nanofibrillated cellulose (NFC) as a potential reinforcement for high performance cement mortar composites. BioResources 2012, 7, 3883–3894. [Google Scholar]

- Peters, S.; Rushing, T.; Landis, E.; Cummins, T. Nanocellulose and microcellulose fibers for concrete. Transp. Res. Rec. 2010, 25–28. [Google Scholar] [CrossRef]

- Ardanuy, M.; Clarmunt, J.; Toledo Filho, R.D. Evaluation of durability to wet/dry cycling of cement mortar composites reinforced with nanofibrillated cellulose. In Brittle Matrix Composites 10; Brandt Glinicki, M.A., Olek, J., Leung, C.K.Y., Eds.; Elsevier: Duxford, UK, 2013; pp. 33–41. [Google Scholar]

- Claramunt Blanes, J.; Ardanuy Raso, M.; Arévalo Peces, R.; Parés Sabatés, F.; Tolêdo Filho, R.D. Mechanical performance of ductile cement mortar composites reinforced with nanofibrilated cellulose. In Strain Hardening Cementitious Composites (SHCC2-Rio); Proceedings of the 2nd International RILEM Conference, Río de Janeiro, Brazil, 12–14 December; Toledo Filho, R.D., Silva, F.A., Koenders, E.A.B., Fairbairn, E.M.R., Eds.; RILEM Publications: Paris, France, 2011; pp. 131–138. [Google Scholar]

- Cengiz, A.; Kaya, M.; Bayramgil, N.P. Flexural stress enhancement of concrete by incorporation of algal cellulose nanofibers. Constr. Build. Mater. 2017, 149, 289–295. [Google Scholar] [CrossRef]

- Mejdoub, R.; Hammi, H.; Sunol, J.J.; Khitouni, M.; M’Nif, A.; Boufi, S. Nanofibrillated cellulose as nanoreinforcement in portland cement: Thermal, mechanical and microstructural properties. J. Compos. Mater. 2017, 51, 2491–2503. [Google Scholar] [CrossRef]

- El Bakkari, M.; Bindiganavile, V.; Goncalves, J.; Boluk, Y. Preparation of cellulose nanofibers by tempo-oxidation of bleached chemi-thermomechanical pulp for cement applications. Carbohyd. Polym. 2019, 203, 238–245. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Omran, A.F.; Tagnit-Hamou, A. Influence of cellulose filaments on cement paste and concrete. J. Mater. Civ. Eng. 2018, 30, 04018109. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K.; Sain, M. Properties of nanofibre reinforced cement composites. Constr. Build. Mater. 2014, 63, 119–124. [Google Scholar] [CrossRef]

- Soares Fonseca, C.; Ferreira da Silva, T.; Silva, M.F.; Rodrigues de Campos Oliveira, I.; Farinassi Mendes, R.; Gherardi Hein, P.R.; Marin Mendes, L.; Denzin Tonoli, G.H. Micro/nanofibrilas celulósicas de eucalyptus em fibrocimentos extrudados. CERNE 2016, 22, 59–68. [Google Scholar] [CrossRef]

- da Costa Correia, V.; Santos, S.F.; Teixeira, R.S.; Junior, H.S. Nanofibrillated cellulose and cellulosic pulp for reinforcement of the extruded cement based materials. Constr. Build. Mater. 2018, 160, 376–384. [Google Scholar] [CrossRef]

- Nilsson, J.; Sargenius, P. Effect of Microfibrillar Cellulose on Concrete Equivalent Mortar Fresh and Hardened Properties; KTH: Stockholm, Sweden, 2011. [Google Scholar]

- Mohamed, M.; Ghorbel, E.; Wardeh, G. Valorization of micro-cellulose fibers in self-compacting concrete. Constr. Build. Mater. 2010, 24, 2473–2480. [Google Scholar] [CrossRef]

- Cao, Y.; Zavaterri, P.; Youngblood, J.; Moon, R.; Weiss, J. The influence of cellulose nanocrystal additions on the performance of cement paste. Cem. Concr. Compos. 2015, 56, 73–83. [Google Scholar] [CrossRef]

- Cao, Y.; Tian, N.; Bahr, D.; Zavattieri, P.D.; Youngblood, J.; Moon, R.J.; Weiss, J. The influence of cellulose nanocrystals on the microstructure of cement paste. Cem. Concr. Compos. 2016, 74, 164–173. [Google Scholar] [CrossRef]

- Cao, Y.; Zavattieri, P.; Youngblood, J.; Moon, R.; Weiss, J. The relationship between cellulose nanocrystal dispersion and strength. Constr. Build. Mater. 2016, 119, 71–79. [Google Scholar] [CrossRef]

- Vazquez, A.; Piqué, T.M.; Hoyos, C.G.; Escobar, M.M. Study of kinetic, structure and properties evaluation of organically modified montmorillonites and micro nanocellulose added to cement paste. In Proceedings of the ASME 2012 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012; American Society of Mechanical Engineers: New York, NY, USA; pp. 829–833. [Google Scholar]

- Alshaghel, A.; Parveen, S.; Rana, S.; Fangueiro, R. Effect of multiscale reinforcement on the mechanical properties and microstructure of microcrystalline cellulose-carbon nanotube reinforced cementitious composites. Compos. Part B Eng. 2018, 149, 122–134. [Google Scholar] [CrossRef]

- Anju, T.; Ramamurthy, K.; Dhamodharan, R. Surface modified microcrystalline cellulose from cotton as a potential mineral admixture in cement mortar composite. Cem. Concr. Compos. 2016, 74, 147–153. [Google Scholar] [CrossRef]

- Hoyos, C.G.; Cristia, E.; Vázquez, A. Effect of cellulose microcrystalline particles on properties of cement based composites. Mater. Des. 2013, 51, 810–818. [Google Scholar] [CrossRef]

- Shuzhen, L.; Ning, C.; Zhonghua, P.; Yanhua, P.; Huang, T. Preparation and properties of bacterial cellulose reinforced cement composites. China Powder Sci. Technol. 2011, 17, 57–60. [Google Scholar]

- Mohammadkazemi, F.; Aguiar, R.; Cordeiro, N. Improvement of bagasse fiber–cement composites by addition of bacterial nanocellulose: An inverse gas chromatography study. Cellulose 2017, 24, 1803–1814. [Google Scholar] [CrossRef]

- Mohammadkazemi, F.; Doosthoseini, K.; Ganjian, E.; Azin, M. Manufacturing of bacterial nano-cellulose reinforced fiber—Cement composites. Constr. Build. Mater. 2015, 101, 958–964. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; dos Santos, S.F.; Joaquim, A.P.; Savastano, H., Jr. Effect of accelerated carbonation on cementitious roofing tiles reinforced with lignocellulosic fibre. Constr. Build. Mater. 2010, 24, 193–201. [Google Scholar] [CrossRef]

- De Lhoneux, B.; Alderweireldt, L.; Boersma, A.; Bordin, R.; Saenen, W.; Heyden, L.; Verleene, D. Selected issues of fibre-cement sustainability: Wood pulp refining energy and accelerated ageing of fibres and composites. In Proceedings of the IIBCC 11th International Inorganic-Bonded Fiber Composites Conference, Madrid, Spain, 5–8 November 2011. [Google Scholar]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Banthia, N.; Bindiganavile, V.; Azhari, F.; Zanotti, C. Curling control in concrete slabs using fiber reinforcement. J. Test. Eval. 2014, 42, 390–397. [Google Scholar] [CrossRef]

- Stephenson, K.M. Characterizing the Behavior and Properties of Nano Cellulose Reinforced Ultra High Performance Concrete; University of Maine: Orono, ME, USA, 2011. [Google Scholar]

- Dai, H.; Jiao, L.; Zhu, Y.; Pi, C. Nanometer Cellulose Fibre Reinforced Cement-Based Material. Patent Publication No. CN105174768A, 23 December 2015. [Google Scholar]

- Ferrara, L.; Ferreira, S.R.; della Torre, M.; Krelani, V.; de Silva, F.A.; Toledo Filho, R.D. Effect of cellulose nanopulp on autogenous and drying shrinkage of cement based composites. In Nanotechnology in Construction; Konstantin Sobolev, K., Shah, S.P., Eds.; Springer: Basel, Switzerland, 2015; pp. 325–330. [Google Scholar]

- Knill, C.J.; Kennedy, J.F. Degradation of cellulose under alkaline conditions. Carbohyd. Polym. 2003, 51, 281–300. [Google Scholar] [CrossRef]

- Mezencevova, A.; Garas, V.; Nanko, H.; Kurtis, K.E. Influence of thermomechanical pulp fiber compositions on internal curing of cementitious materials. J. Mater. Civ. Eng. 2011, 24, 970–975. [Google Scholar] [CrossRef]

- Wu, L.; Farzadnia, N.; Shi, C.; Zhang, Z.; Wang, H. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Tolêdo Filho, R.D. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Hakalahti, M.; Salminen, A.; Seppälä, J.; Tammelin, T.; Hänninen, T. Effect of interfibrillar PVA bridging on water stability and mechanical properties of TEMPO/NaClO2 oxidized cellulosic nanofibril films. Carbohyd. Polym. 2015, 126, 78–82. [Google Scholar] [CrossRef] [PubMed]

- Reid, M.S.; Villalobos, M.; Cranston, E.D. The role of hydrogen bonding in non-ionic polymer adsorption to cellulose nanocrystals and silica colloids. Curr. Opin. Colloid Interface Sci. 2017, 29, 76–82. [Google Scholar] [CrossRef]

- Changsarn, S.; Mendez, J.D.; Shanmuganathan, K.; Foster, E.J.; Weder, C.; Supaphol, P. Biologically inspired hierarchical design of nanocomposites based on poly (ethylene oxide) and cellulose nanofibers. Macromol. Rapid Commun. 2011, 32, 1367–1372. [Google Scholar] [CrossRef] [PubMed]

- Isogai, A.; Saito, T.; Fukuzumi, H. TEMPO-oxidized cellulose nanofibers. Nanoscale 2011, 3, 71–85. [Google Scholar] [CrossRef] [PubMed]

- Tanpichai, S. A comparative study of nanofibrillated cellulose and microcrystalline cellulose as reinforcements in all-cellulose composites. J. Met. Mater. Miner. 2018, 28. [Google Scholar]

- Campano, C.; Merayo, N.; Balea, A.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P.; Negro, C.; Blanco, Á. Mechanical and chemical dispersion of nanocelluloses to improve their reinforcing effect on recycled paper. Cellulose 2018, 25, 269–280. [Google Scholar] [CrossRef]

- Pourchez, J.; Grosseau, P.; Ruot, B. Changes in c3s hydration in the presence of cellulose ethers. Cem. Concr. Res. 2010, 40, 179–188. [Google Scholar] [CrossRef]

- Pourchez, J.; Govin, A.; Grosseau, P.; Guyonnet, R.; Guilhot, B.; Ruot, B. Alkaline stability of cellulose ethers and impact of their degradation products on cement hydration. Cem. Concr. Res. 2006, 36, 1252–1256. [Google Scholar] [CrossRef]

- Peschard, A.; Govin, A.; Grosseau, P.; Guilhot, B.; Guyonnet, R. Effect of polysaccharides on the hydration of cement paste at early ages. Cem. Concr. Res. 2004, 34, 2153–2158. [Google Scholar] [CrossRef]

- Peschard, A.; Govin, A.; Pourchez, J.A.E.; Fredon, E.; Bertrand, L.; Maximilien, S.; Guilhot, B. Effect of polysaccharides on the hydration of cement suspension. J. Eur. Ceram. Soc. 2006, 26, 1439–1445. [Google Scholar] [CrossRef]

- Johnson, R.K.; Zink-Sharp, A.; Glasser, W.G. Preparation and characterization of hydrophobic derivatives of TEMPO-oxidized nanocelluloses. Cellulose 2011, 18, 1599–1609. [Google Scholar] [CrossRef]

- Agopyan, V.; Savastano, H., Jr.; John, V.; Cincotto, M. Developments on vegetable fibre–cement based materials in São Paulo, Brazil: An overview. Cem. Concr. Compos. 2005, 27, 527–536. [Google Scholar] [CrossRef]

- Negro, C.; Blanco, A.; San Pío, I.; Tijero, J. Methodology for flocculant selection in fibre–cement manufacture. Cem. Concr. Compos. 2006, 28, 90–96. [Google Scholar] [CrossRef]

- Negro, C.; Sánchez, L.M.; Fuente, E.; Blanco, Á.; Tijero, J. Polyacrylamide induced flocculation of a cement suspension. Chem. Eng. Sci. 2006, 61, 2522–2532. [Google Scholar] [CrossRef]

- Negro, C.; Blanco, A.; Fuente, E.; Sánchez, L.M.; Tijero, J. Influence of flocculant molecular weight and anionic charge on flocculation behaviour and on the manufacture of fibre cement composites by the Hatschek process. Cem. Concr. Res. 2005, 35, 2095–2103. [Google Scholar] [CrossRef]

- Negro, C.; Fuente, E.; Sánchez, L.M.; Blanco, Á.; Tijero, J. Evaluation of an alternative flocculation system for manufacture of fiber–cement composites. Ind. Eng. Chem. Res. 2006, 45, 6672–6678. [Google Scholar] [CrossRef]

- Negro, C.; Blanco, A.; Fuente, E.; Sánchez, L.; Tijero, J. Evaluation of a flocculation dual system as a novel alternative for fiber-cement manufacture: Effect on product strength. Chem. Eng. Process. 2008, 47, 755–760. [Google Scholar] [CrossRef]

- Tonoli, G.; Rodrigues Filho, U.; Savastano, H., Jr.; Bras, J.; Belgacem, M.; Lahr, F.R. Cellulose modified fibres in cement based composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2046–2053. [Google Scholar] [CrossRef]

- Korhonen, M.H.J.; Laine, J. Flocculation and retention of fillers with nanocelluloses. Nord. Pulp Pap. Res. J. 2014, 29, 119–128. [Google Scholar] [CrossRef]

- Diab, M.; Curtil, D.; El-shinnawy, N.; Hassan, M.L.; Zeid, I.F.; Mauret, E. Biobased polymers and cationic microfibrillated cellulose as retention and drainage aids in papermaking: Comparison between softwood and bagasse pulps. Ind. Crop. Prod. 2015, 72, 34–45. [Google Scholar] [CrossRef]

- Brockman, A.C.; Hubbe, M.A. Charge reversal system with cationized cellulose nanocrystals to promote dewatering of a cellulosic fiber suspension. Cellulose 2017, 24, 4821–4830. [Google Scholar] [CrossRef]

- Sun, X.; Danumah, C.; Liu, Y.; Boluk, Y. Flocculation of bacteria by depletion interactions due to rod-shaped cellulose nanocrystals. Chem. Eng. J. 2012, 198, 476–481. [Google Scholar] [CrossRef]

- Suopajärvi, T.; Liimatainen, H.; Hormi, O.; Niinimäki, J. Coagulation–flocculation treatment of municipal wastewater based on anionized nanocelluloses. Chem. Eng. J. 2013, 231, 59–67. [Google Scholar] [CrossRef]

- Suopajärvi, T.; Koivuranta, E.; Liimatainen, H.; Niinimäki, J. Flocculation of municipal wastewaters with anionic nanocelluloses: Influence of nanocellulose characteristics on floc morphology and strength. J. Environ. Chem. Eng. 2014, 2, 2005–2012. [Google Scholar] [CrossRef]

- Yu, H.-Y.; Zhang, D.-Z.; Lu, F.-F.; Yao, J. New approach for single-step extraction of carboxylated cellulose nanocrystals for their use as adsorbents and flocculants. ACS Sustain. Chem. Eng. 2016, 4, 2632–2643. [Google Scholar] [CrossRef]

- Yu, S.I.; Min, S.K.; Shin, H.S. Nanocellulose size regulates microalgal flocculation and lipid metabolism. Sci. Rep. UK 2016, 6, 35684. [Google Scholar] [CrossRef]

- Sanchez-Salvador, J.; Balea, A.; Monte, M.; Blanco, A.; Negro, C. Study of the reaction mechanism to produce nanocellulose-graft-chitosan polymer. Nanomaterials 2018, 8, 883. [Google Scholar] [CrossRef]

- Balea, A.; Monte, M.C.; Negro, C.; Blanco, A. Application of cellulose nanofibers to remove water-based flexographic inks from wastewaters. Environ. Sci. Pollut. Res. 2017, 24, 5049–5059. [Google Scholar] [CrossRef]

- Voisin, H.; Bergström, L.; Liu, P.; Mathew, A. Nanocellulose-based materials for water purification. Nanomaterials 2017, 7, 57. [Google Scholar] [CrossRef]

- Liang, H.; Hu, X. A quick review of the applications of nano crystalline cellulose in wastewater treatment. J. Bioresour. Bioprod. 2016, 1, 199–204. [Google Scholar]

- Shak, K.P.Y.; Pang, Y.L.; Mah, S.K. Nanocellulose: Recent advances and its prospects in environmental remediation. Beilstein J. Nanotechnol. 2018, 9, 2479–2498. [Google Scholar] [CrossRef]

- Sehaqui, H.; Mautner, A.; de Larraya, U.P.; Pfenninger, N.; Tingaut, P.; Zimmermann, T. Cationic cellulose nanofibers from waste pulp residues and their nitrate, fluoride, sulphate and phosphate adsorption properties. Carbohyd. Polym. 2016, 135, 334–340. [Google Scholar] [CrossRef] [PubMed]

- Hohenthal, C.; Ovaskainen, M.; Bussini, D.; Sadocco, P.; Pajula, T.; Lehtinen, H.; Kautto, J.; Salmenkivi, K. Final assessment of nano enhanced new products. In SUNPAP (Scale-up Nanoparticles in Modern Papermaking), Oct.31, 2012. CTT Technical Research Center of Finland, InnovHub-SSCCP, Poyry Management Consulting Oy. Funded by European Community’s 7th Frame Work Programme under Grant Agreement n° 228802; VTT Technical Research Centre of Finland: Espoo, Findland, 2012. [Google Scholar]

- De Figueirêdo, M.C.B.; de Freitas Rosa, M.; Ugaya, C.M.L.; de Souza, M.d.S.M.; da Silva Braid, A.C.C.; de Melo, L.F.L. Life cycle assessment of cellulose nanowhiskers. J. Clean. Prod. 2012, 35, 130–139. [Google Scholar] [CrossRef]

- Hervy, M.; Evangelisti, S.; Lettieri, P.; Lee, K.-Y. Life cycle assessment of nanocellulose-reinforced advanced fibre composites. Compos. Sci. Technol. 2015, 118, 154–162. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. Predicting the environmental impact of a future nanocellulose production at industrial scale: Application of the life cycle assessment scale-up framework. J. Clean. Prod. 2018, 174, 283–295. [Google Scholar] [CrossRef]

- Li, Q.Q.; McGinnis, S.; Sydnor, C.; Wong, A.; Renneckar, S. Nanocellulose life cycle assessment. ACS Sustain. Chem. Eng. 2013, 1, 919–928. [Google Scholar] [CrossRef]

- Nanocellulose Investment and Pricing Guide 2019; Future Markets, Inc.: Dublin, Ireland, 2019.

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

- Merayo, N.; Balea, A.; de la Fuente, E.; Blanco, Á.; Negro, C. Interactions between cellulose nanofibers and retention systems in flocculation of recycled fibers. Cellulose 2017, 24, 677–692. [Google Scholar] [CrossRef]

- Merayo, N.; Balea, A.; de la Fuente, E.; Blanco, Á.; Negro, C. Synergies between cellulose nanofibers and retention additives to improve recycled paper properties and the drainage process. Cellulose 2017, 24, 2987–3000. [Google Scholar] [CrossRef]

- Alonso, A.; Negro, C.; Blanco, A.; San Pío, I. Application of advanced data treatment to predict paper properties. Math. Comput. Model. Dyn. Syst. 2009, 15, 453–462. [Google Scholar] [CrossRef]

- Blanco, A.; Negro, C.; Hooimeijer, A.; Tijero, J. Polymer optimization in paper mills by means of a particle size analyser: An alternative to zeta potential measurements. Appita J. 1996, 49, 113–116. [Google Scholar]

- Rasteiro, M.; Garcia, F.; Ferreira, P.; Blanco, A.; Negro, C.; Antunes, E. Evaluation of flocs resistance and reflocculation capacity using the lds technique. Powder Technol. 2008, 183, 231–238. [Google Scholar] [CrossRef]

- Lopez-Exposito, P.; Negro, C.; Blanco, A. Direct estimation of microalgal flocs fractal dimension through laser reflectance and machine learning. Algal Res. 2019, 37, 240–247. [Google Scholar] [CrossRef]

- Tonoli, G.; Savastano, H., Jr.; Fuente, E.; Negro, C.; Blanco, A.; Lahr, F.R. Eucalyptus pulp fibres as alternative reinforcement to engineered cement-based composites. Ind. Crop. Prod. 2010, 31, 225–232. [Google Scholar] [CrossRef]

| NC Type | Source NC | NC Dose (wt.%) | Cementitious Material | Effect on Mechanical Properties | Other Effects | Ref. |

|---|---|---|---|---|---|---|

| Cellulose nanofibers (CNFs) | ||||||

| High intensity refining process in a Valley Beater Refining time: 6 h d = 25–250 nm | Sisal (Agave sisalana) | 3.3 | Cement mortar - Type I cement - Sand - Ratio (C:S:W) = 1:1:0.67 | ΔMOE (%) = 70.83 * ΔMOR (%) = 35.92 * ΔFracture Energy (%) = −52.96 * | [71] | |

| 4 | Cement mortar - Type I cement - Silica Fume - Sand - Ratio (C:Si:S) = 0.9:0.1:1 - Ratio (W:C) = 0.6 | ΔMOE (%) = 30.77 * ΔMOR (%) ≈ 5 * ΔFracture Energy (J) ≈ −83.33 * | [73] | |||

| 2 | Fiber cement - Type I cement - Silica Fume - Cellulose fibers (2 wt.%) - Sand - Ratio (C:Si:S) = 0.9:0.1:1 - Ratio (W:C) = 0.7 | ΔMOE (%) = 50 * ΔMOR (%) ≈ −5 * ΔFracture Energy (%) ≈ −46.67 * | [73] | |||

| 8 | Cement mortar - Type I cement - Silica Fume - Sand - Ratio (C:Si:S) = 0.9:0.1:1 - Ratio (W:C) = 0.56 | ΔMOE (%) = 55.55 * ΔMOR (%) = 37.07 * ΔFracture Energy (%) = −90.55 * | [70] | |||

| 2–6 | Fiber cement - Type I cement - Silica Fume - Cellulose fibers (2–6 wt.%) - Sand - Ratio (C:Si:S) = 0.9:0.1:1 - Ratio (W:C) = 0.56–0.69 | ΔMOE (%) = 27.78–113.89 * ΔMOR (%) = 3.45–23.27 * ΔFracture Energy (%) = −51.32–(−83.88) * | [70] | |||

| 3.4 | Cement mortar - Type I cement - Silica fume - Sand coarse - Ratio (C:Si:S) = 0.7:0.3:1 - Ratio (W:C) = 0.84 | ΔMOE (%) = 10.17 * ΔMOR (%) = 1.55 * ΔFracture Energy (%) = −81.90 * | [74] | |||

| 3.3 | Cement mortar - Type I cement - Silica fume - Sand fine - Ratio (C:Si:S) = 0.7:0.3:1 - Ratio (W:C) = 0.89 | ΔMOE (%) = 60.71 * ΔMOR (%) = 6.06 * ΔFracture Energy (%) = 6.45 * | [74] | |||

| Bleaching (NaClO) Deproteinization (NaOH) and removing of oil and pigments (CHCl3) Demineralization (HCl) d = 37–55 nm | Waste algae (Cladophora sp.) | 0.1–1.0 | Cement mortar - Portland cement - Sand - Ratio (C:S:W) = 1:4:1 | ΔMOE (%) = 3.62–169.68 (adding 0.1 and 1.00 wt.% CNF, respectively) | [75] | |

| Commercial supplied by Sigma-Aldrich, CAS: 9004-34-6 d < 35 nm | Cotton | 0.1–1.0 | Cement mortar - Portland cement - Sand - Ratio (C:S:W) = 1:4:1 | ΔMOE (%) = −37.10–(−36.20) (adding 0.1 and 1.00 wt.% CNF, respectively) | [75] | |

| TEMPO oxidation and fibrillation L = 0.6–1.7 µm d = 20–100 nm COOH = 1850 µmol/g | Bleached hardwood pulp | 0–0.4 | Cement mortar - Type I cement - Ratio (W:C) = 0.5 | ΔCompression strength (%) = 20 ΔFlexural strength (%) = 15 Both with the optimal dose of CNF (0.15 wt.%) | The porosity notably decreased with the increasing dose of CNF | [74] |

| TEMPO oxidation and fibrillation at 600 bar at 1.5% to obtain a gel (5–6 cycles) L = 1–2 µm d = 5–10 nm COOH = 500 µmol/g, | Bleached Eucalyptus Kraft | 0–0.5 | Cement mortar - Type I cement 32.5 N EN197-1:2000 - Ratio (W:C) = 0.26 | ΔCompression strength (%) = 43 | ΔHardening (%) = 66 ΔConductivity (%) = 36 ΔPorosity (%) = −36 | [76] |

| - TEMPO oxidation and grinding at 1 wt.% - COOH = 1130 µmol/g, | Bleached Eucalyptus chemithermomechanical pulp | 0–1.2 | Cement mortar - Portland Type II cement C3A < 8% - Ratio (W:C) = 0.485 | ΔYield stress (%) = 94 (0.2 wt.% CNF) ΔPlastic viscosity (%) = 25 (0.2 wt.% CNF) Reduced bleeding and leaching ΔCrack area (%) = 27 (0.8 wt.% of CNF) | [77] | |

| - Cellulose filaments (CFs): Commercial supplied by Kruger Biomaterials Mechanical fibrillation L = 100–2000 µm d = 20–200 nm | Wood | 0–0.2 | Cement mortar - General used cement (GU) - Fly ash (FA) - Ratio (GU:FA:W) = 1:0.33:0.5 | ΔCompression strength (%) = −20 ΔFlexural strength (%) = 38 (with 0.2 wt.% CF) | ΔSlump (%) = −61 (with 0.2 wt.% CF) ΔPlastic viscosity (%) = 41 ΔAutogeneous shrinkage (%) = −43 | [78] |

| 0–0.2 | Self-consolidating concrete - General used cement (GU) - Sand (S) - Coarse aggregate (CA) - Superplasticizer (SP) - Ratio (GU:S:CA:SP:W) = 1:0.33:0.5:2:2.15 | ΔCompression strength = 16% ΔFlexural strength = 28% ΔEnergy absorption = 96% with 0.2 wt.% CF | ΔSlump (%) = −50 (with 0.2 wt.% CF) ΔPlastic viscosity (%) = 113 ΔYield stress (%) = 794 | [78] | ||

| Disc grinding method Grinding cycles: 15 L = 1–2.5 µm d = 20–200 nm | Bleached softwood pulp | 0–0.4 | Limestone based cement - Ratio (W:C) = 0.5 - Superplasticizer (1.6 wt.% on cement) | ΔFlexural strength = 106% ΔEnergy absorption = 186% with 0.1 wt.% of CNF | ΔHardening (%) = 10 | [79] |

| Super Masscolloider method Grinding cycles: 35 d (55%) = 40 nm, Mean d = 50 nm | Bleached Eucalyptus Kraft | 0, 0.5, 1 | Extruded cement Cement plus limestone | ΔMOE and ΔMOR insignificant changes Δabsorbed Energy (%) = −72 (with 1wt.% CNF) | ΔPorosity (%) = 95 (with 1 wt.% CNF) ΔWater absorption ability (%) = 80 (with 1 wt.% CNF) | [80] |

| Grinding method Grinding cycles: 10 L > 1 µm mean d = 16.2 nm | Unbleached bamboo organosolv | 1 | Fiber cement - Type I cement - Limestone filler - Unbleached bamboo organosolv pulp (9 wt.%) - Ratio (C:Li) = 3:1 - Ratio (W:C) = 0.57 | ΔMOE (%) = 5.20 * ΔMOR (%) = 34.46 * ΔFracture Energy (%) = 6.86 * ΔFracture toughness (%) = 12.74 * | Significant effects were not observed on density and porosity | [81] |

| Chemical and mechanical pretreatment Homogenization | Pine Kraft | 0.14, 0.27, 0.41 | Cement mortar - Portland-limestone cement (CEM II/A-LL 42.5R) - Sand - Superplasticizer - Anti-washout admixture - Ratio (W:C) = 0.6 - Ratio (C:S:W) = 1:1.07:0.6 | ΔMOR (%) = 4.93–18.64 ΔCompressive Strength (%) = 3.96–4.56 | ΔMini-slump flow (%) = −14.54–(−24.73) ΔYield stress (%) = 100–142.10 ΔPlastic viscosity (%) = −40–200 | [82] |

| Only chemical treatment L = 1.1. mm Mean d = 45 µm L/d = 24.4 Density = 30 kg/m3 | Recycled cartonboard | 0.045 | Cement mortar - CEM I CALCIA cement 52.5 N - Sand (0.125–4 mm) - Filler (F): calcium carbonate - Superplasticizer: modified polycarboxylate -Ratio (W:C) = 0.48 -Ratio (C:S:F) = 1:2.6:0.37 | ΔMOR (%) = 4.35 ΔCompressive Strength (%) = 10 | ΔWater porosity (%) = 12.5 | [83] |

| 5.7 | Cement concrete - CEM I CALCIA cement 52.5 N 2 - Sand (0.125–4 mm) plus Gravel (G) (4–16 mm) - Filler (F): calcium carbonate - Superplasticizer: modified polycarboxylate -Ratio (W:C) = 0.48 -Ratio (C:S+G:F) = 1:4.65:0.37 | ΔCompressive Strength (%) = 25 | ΔMercury intrusion porosimetry (%) = −7.25 ΔPermeability (%) = −25 | [83] | ||

| Microcellulose Sigmacell 101 Nanocellulose in gel at 3% | unknown | 1, 3, 5 | Reactive powder concrete - Sand - Silica flour - Silica fume - Superplasticizer 1.6% on cement -Ratio (C:S:Sflour:Sfume:) = 1:0.98:0.28:0.39 -Ratio (W:C) = 0.22–0.35 | ΔMOE and ΔMOR insignificant changes with 1% of micro or nanocellulose ΔFracture Energy (%) = 24 * with 2 wt.% of mixture micro-nanocellulose ΔFracture Energy (%) = 50 * with 3 wt.% of microcellulose | [72] | |

| Cellulose micro and nanocrystals (MCCs and CNCs) | ||||||

| - CNC Produced via sulfuric acid hydrolysis 0.814 wt.% surface sulfate content Freeze-dried powder | Eucalyptus | 0–0.77 | Cement paste - Type V cement - Ratio (W:C) = 0.35 | ΔMOR (%) = 20 with 0.10 wt.% of CNC (max improvement) | ΔYield stress (%) = from −67.2 (with 0.02% of CNC) to 1137 (with 1.5 wt.% of CNC) ΔCumulative heat (%) = 16 with 0.77 wt.% of CNC (at an age of 200 h) ΔPorosity (%) = −16% ΔDegree of hydration (%) = 20 with 0.77 wt.% of CNC | [84] |

| CNC Produced via sulfuric acid hydrolysis 0.814 wt.% surface sulfate content Dispersed in water by sonication | Eucalyptus | 0–0.77 | Cement paste - Type V cement - Ratio (W:C) = 0.35 | ΔMOR (%) = 23 with 0.10 wt.% of CNC, but 30 with 0.5 wt.% of CNC | ΔPorosity (%) = −16% | [85,86] |

| Commercial MCC, Sigma Aldrich | Cotton | 0, 3 | Cement mortar - Portland cement - Ratio (W:C) = 0.45 | ΔCompressive strength (%) = −12 ΔFlexural strength (%) = −25 | ΔCritical yield stress (%) = 155 | [87] |

| MCC (Avicel® PH101) plus Carbon nanotubes (CNTs) L = 2–260 µm mean d = 49.1 µm (MCC) L = 10–30 µm d (inner) = 2–5 nm; d (outer) < 8 nm (CNTs) | Cotton linters | 0.2 (+ 0.1 wt.% CNTs) | Cement mortar -Portland cement (CEM I 42.5R) -Sand (NP-EN 196-1) - 1.5 wt.% Plutonic F-127 surfactant to dispersed MCC plus CNTs in water - 0.75 wt.% defoamer (tri-butyl phosphate (TBP)) to suppress the foam formation -Ratio (W:C) = 0.5 -Ratio (C:S:W) = 1:3:0.5 | ΔMOR (%) = 2.9 ΔMOE (%) = 24.1 ΔFracture Energy (%) = 16.1 ΔCompressive Strength (%) = 16.98 | ΔDry bulk density (%) = 8.24 ΔPore diameter = −40.51 ΔPorosity = 32.38 | [88] |

| 0.5 (+ 0.3 wt.% CNTs) | Cement mortar -Portland cement (CEM I 42.5R) -Sand (NP-EN 196-1) - 1.0 wt.% CTAB surfactant to dispersed MCC plus CNTs in water - 1.0 wt.% defoamer (TBP) to suppress the foam formation -Ratio (W:C) = 0.5 -Ratio (C:S:W) = 1:3:0.5 | ΔMOR (%) = 12.3 ΔMOE (%) = 12.7 ΔFracture Energy (%) = 85.2 ΔCompressive Strength (%) = 16.26 | ΔDry bulk density (%) = 4.49 ΔPore diameter = −36.08 ΔPorosity = 22.86 | [88] | ||

| MCC Sulphuric acid solution L = 75–400 µm L > 150 µm, for about 40% of MCC; d = 10–30 µm Maximum weight loss temperature (°C) = 300 | Cotton linters | 2.5 | Cement mortar - Portland cement - Sand - Ratio (W:C) = 0.45 - Ratio (C:S) = 1:3 | ΔMOR (%) = 50 ΔCompressive Strength (%) = −21.45 | [89] | |

| 2.5 | Cement mortar - Portland cement - Sand -Superplasticizer: polycarboxylate ether (1 wt.% of cement) - Ratio (W:C) = 0.4 - Ratio (C:S:W) = 1:2.5:0.4 | ΔMOR (%) = 16 ΔCompressive Strength (%) = −9.47 | [89] | |||

| Tetraethyl orthosilicate (TEOS) surface-modified MCC Sulphuric acid solution TEOS as silane agent L = 75–400 µm L > 150 µm, for about 40% of MCC; d = 10–30 µm Maximum weight loss temperature (°C) = 360 | Cotton linters | 2.5 | Cement mortar - Portland cement - Sand - Ratio (W:C) = 0.45 - Ratio (C:S) = 1:3 | ΔMOR (%) = 94 ΔCompressive Strength (%) = 45 | [89] | |

| Cement mortar - Portland cement - Sand -Superplasticizer: polycarboxylate ether (1 wt.% of cement) -Ratio (W:C) = 0.4 -Ratio (C:S) = 1:3 | ΔMOR (%) = 59 ΔCompressive Strength (%) = 57 | [89] | ||||

| Commercial MCC (Sigma Aldrich) Bulk density = 0.459 g/mL | - | 3 | Cement mortar - Portland Low Alkali CP40 cement - Sand -Ratio (W:C) = 0.45 -Ratio (C:S) = 1:2.7 | ΔMOR (%) = −26.31 ΔCompressive Strength (%) = −13.46 | ΔDensity (%) = −2.16 ΔDiameter (mini-slump test)(%) = −17.65 ΔYield stress (mini-slump test) (%) = 160 ΔGlobal heat transference coefficient (%) = −24 ΔTemperature adiabatic max (%) = −5.28 | [90] |

| Bacterial cellulose (BC) | ||||||

| 0.02 | Cement mortar | ΔMOR (%) = 20 ** ΔCompressive strength (%) = 8 ** | Accelerated production of calcium silicate hydrate (CSH) | [91] | ||

| Zetasizer (75 nm) crystallinity (DXR) = 65% BC was used for coating bagasse fibers before mixing | Gluconacetobacter xylinus cultured in Hestrin–Schramm medium | 0, 3 | Fiber cement - Portland Type II - 5% CaCl2 - Unbleached bagasse fibers (6 wt.%) -Polycarboxilated superplasticizer | ΔMOE (%) = 38 ** ΔMOR (%) = 68 ** ΔInternal Bonding strength (%) = 50 ** ΔFracture toughness (%) = 70 ** | Decreased fiber mineralization Increased durability Decreased porosity Great increase in the surface basicity | [92,93] |

| Zetasizer (75 nm) crystallinity (DXR) = 65% Freeze-dried powder | Gluconacetobacter xylinus cultured in Hestrin–Schramm medium | 0, 3 | Fiber cement - Portland Type II - 5% CaCl2 - Unbleached bagasse fibers (6 wt.%) -Polycarboxilated superplasticizer | ΔMOE (%) = 11 ** ΔMOR (%) = 47 ** ΔInternal Bonding strength (%) = 10 ** ΔFracture toughness (%) = 60 ** | Decreased fiber mineralization, surface porosity, and surface roughness | [92,93] |

| Zetasizer (75 nm) crystallinity (DXR) = 65% BC dispersed in water forming a gel | Gluconacetobacter xylinus cultured in Hestrin–Schramm medium | 0, 3 | Fiber cement - Portland Type II - 5% CaCl2 - Unbleached bagasse fibers (6 wt.%) -Polycarboxilated superplasticizer | ΔMOE (%) = 33 ** ΔMOR (%) = 58 ** ΔInternal Bonding strength (%) = 30 ** ΔFracture toughness (%) = 40 ** | Decreased fiber mineralization Increased durability Decreased porosity, surface basicity, and roughness Increased the organic compounds on the surface | [92,93] |

| Refining | NC | |

|---|---|---|

| Production requirements | High energy demands | High energy demand and/or chemical reactives |

| Type and properties of cellulose fibers produced | Cellulose fibers with internal and external fibrillation Production of fines | Nano- or microcellulose fibers No fines production |

| Medium specific surface area | Very high specific surface area | |

| Macroscale dimensions | Nanoscale dimensions | |

| Length reduction (cutting) | Length and diameter reduction | |

| Formation of hydrogen bridges | High tendency to form hydrogen bridges | |

| Increases swelling ability | Very high swelling ability, gel formation | |

| Chemical modification | Easy (after refining) | Even during production, many different possibilities for chemical modification |

| Cracks prevention | Macrocracks | Microcracks |

| Interactions | Increasing the capacity of the cellulose fibers to bond with cement matrix | Highly reactive with the cellulose fibers and the cement matrix, coating the cellulose fibers |

| Mechanical properties | Improves mechanical properties and network strength | Highly improved mechanical properties in combination with the cellulose fibers |

| Durability | Increases durability, reducing strength losses by increasing interaction with the matrix | Increases durability: preventing lumen mineralization, increasing interaction with the matrix, decreasing porosity |

| Drainage | Decrease in the drainage rate | It likely decreases the drainage rate; however, there are no studies on that in C-FCCs |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balea, A.; Fuente, E.; Blanco, A.; Negro, C. Nanocelluloses: Natural-Based Materials for Fiber-Reinforced Cement Composites. A Critical Review. Polymers 2019, 11, 518. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11030518

Balea A, Fuente E, Blanco A, Negro C. Nanocelluloses: Natural-Based Materials for Fiber-Reinforced Cement Composites. A Critical Review. Polymers. 2019; 11(3):518. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11030518

Chicago/Turabian StyleBalea, Ana, Elena Fuente, Angeles Blanco, and Carlos Negro. 2019. "Nanocelluloses: Natural-Based Materials for Fiber-Reinforced Cement Composites. A Critical Review" Polymers 11, no. 3: 518. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11030518