Effect of Formation Route on the Mechanical Properties of the Polyethersulfone Composites Reinforced with Glass Fibers

Abstract

:1. Introduction

2. Materials and Methods

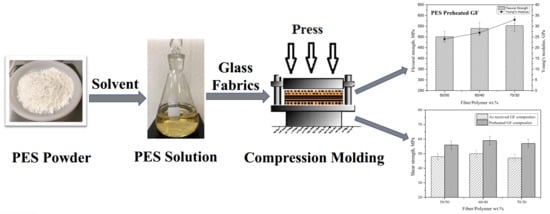

Preparation of PES Composites

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gupta, M.K.; Srivastava, R.K. Mechanical properties of hybrid fibers-reinforced polymer composite: A review. Polym. Plast. Technol. Eng. 2016, 55, 626–642. [Google Scholar] [CrossRef]

- Kumar, V.V.; Balaganesan, G.; Lee, J.K.Y.; Neisiany, R.E.; Surendran, S.; Ramakrishna, S. A review of recent advances in nanoengineered polymer composites. Polymers 2019, 11, 644. [Google Scholar] [CrossRef] [PubMed]

- Dikshit, V.; Bhudolia, S.K.; Joshi, S.C. Multiscale polymer composites: A review of the interlaminar fracture toughness improvement. Fibers 2017, 5, 38. [Google Scholar] [CrossRef]

- Munirathnamma, L.M.; Ravikumar, H.B. Microstructural characterization of short glass fibre reinforced polyethersulfone composites: A positron lifetime study. J. Appl. Polym. Sci. 2016, 133, 43647. [Google Scholar] [CrossRef]

- Sen Du, S.; Li, F.; Xiao, H.M.; Li, Y.Q.; Hu, N.; Fu, S.Y. Tensile and flexural properties of graphene oxide coated-short glass fiber reinforced polyethersulfone composites. Compos. Part B Eng. 2016, 99, 407–415. [Google Scholar]

- Caixeta, R.W.; Guiraldo, R.D.; Berger, S.B.; Kaneshima, E.N.; Faria Júnior, E.M.; Drumond, A.C.; Gonini Júnior, A.; Lopes, M.B. Influence of glass-fiber reinforcement on the flexural strength of different resin composites. Appl. Adhes. Sci. 2015, 3, 24. [Google Scholar] [CrossRef] [Green Version]

- Jing, M.; Che, J.; Xu, S.; Liu, Z.; Fu, Q. The effect of surface modification of glass fiber on the performance of poly (lactic acid) composites: Graphene oxide vs. silane coupling agents. Appl. Surf. Sci. 2018, 435, 1046–1056. [Google Scholar] [CrossRef]

- Thomason, J.L. The influence of fibre length, diameter and concentration on the modulus of glass fibre reinforced polyamide 6, 6. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1732–1738. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Sergi, C.; Seghini, M.C.; Cozzarini, L.; Graupner, N. Effect of basalt fibre hybridisation and sizing removal on mechanical and thermal properties of hemp fibre reinforced HDPE composites. Compos. Struct. 2018, 188, 394–406. [Google Scholar] [CrossRef] [Green Version]

- Nassir, N.A.; Birch, R.S.; Cantwell, W.J.; Wang, Q.Y.; Liu, L.Q.; Guan, Z.W. The perforation resistance of glass fibre reinforced PEKK composites. Polym. Test. 2018, 72, 423–431. [Google Scholar] [CrossRef]

- Yang, L.; Thomason, J.L. Interface strength in glass fibre-polypropylene measured using the fibre pull-out and microbond methods. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1077–1083. [Google Scholar] [CrossRef]

- Cech, V.; Prikryl, R.; Balkova, R.; Grycova, A.; Vanek, J. Plasma surface treatment and modification of glass fibers. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1367–1372. [Google Scholar] [CrossRef]

- Zhang, S.; Caprani, C.; Heidarpour, A. Influence of fibre orientation on pultruded GFRP material properties. Compos. Struct. 2018, 204, 368–377. [Google Scholar] [CrossRef]

- Larson, B.K.; Drzal, L.T. Glass fibre sizing/matrix interphase formation in liquid composite moulding: Effects on fibre/matrix adhesion and mechanical properties. Composites 1994, 25, 711–721. [Google Scholar] [CrossRef]

- Zheng, L.; Jian, X. Enhanced continuous glass fibre-reinforced poly (phthalazinone ether sulfone ketone) composites by blending polyetherimide and polyethersulfone. Polym. Polym. Compos. 2011, 19, 445–450. [Google Scholar] [CrossRef]

- Boufaida, Z.; Farge, L.; André, S.; Meshaka, Y. Influence of the fiber/matrix strength on the mechanical properties of a glass fiber/thermoplastic-matrix plain weave fabric composite. Compos. Part A Appl. Sci. Manuf. 2015, 75, 28–38. [Google Scholar] [CrossRef]

- Feih, S.; Wei, J.; Kingshott, P.; Sørensen, B.F. The influence of fibre sizing on the strength and fracture toughness of glass fibre composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 245–255. [Google Scholar] [CrossRef]

- Zhong, Y.; Cheng, M.; Zhang, X.; Hu, H.; Cao, D.; Li, S. Hygrothermal durability of glass and carbon fiber reinforced composites–A comparative study. Compos. Struct. 2018, 211, 134–143. [Google Scholar] [CrossRef]

- Jafari, A.; Ashrafi, H.; Bazli, M.; Ozbakkaloglu, T. Effect of thermal cycles on mechanical response of pultruded glass fiber reinforced polymer profiles of different geometries. Compos. Struct. 2019, 223, 110959. [Google Scholar] [CrossRef]

- Lee, N.; Jang, J. The effect of fibre content on the mechanical properties of glass fibre mat/polypropylene composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 815–822. [Google Scholar] [CrossRef]

- Bajerova, M.; Krejcova, K.; Rabiskova, M.; Gajdziok, J.; Masteikova, R. Oxycellulose: Significant characteristics in relation to its pharmaceutical and medical applications. Adv. Polym. Technol. 2009, 28, 199–208. [Google Scholar]

- Thomason, J.L.; Vlug, M.A.; Schipper, G.; Krikor, H.G.L.T. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: Part 3. Strength and strain at failure. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1075–1084. [Google Scholar] [CrossRef]

- Thomason, J.L.; Schoolenberg, G.E. An investigation of glass fibre/polypropylene interface strength and its effect on composite properties. Composites 1994, 25, 197–203. [Google Scholar] [CrossRef]

- Nygård, P.; Gustafson, C.G. Interface and impregnation relevant tests for continuous glass fibre-polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2003, 34, 995–1006. [Google Scholar] [CrossRef]

- Wongpajan, R.; Mathurosemontri, S.; Takematsu, R.; Xu, H.Y.; Uawongsuwan, P.; Thumsorn, S.; Hamada, H. Interfacial Shear Strength of Glass Fiber Reinforced Polymer Composites by the Modified Rule of Mixture and Kelly-Tyson Model. Energy Procedia 2016, 89, 328–334. [Google Scholar] [CrossRef] [Green Version]

- Harinath, P.N.V.; Radadia, N.; Bramhe, S.; Surendran, D.; Sabane, V.; Singh, A.; Kim, T.N.; Sharbidre, R.; Cheol, B.J.; Peters, L.; et al. Analysis of microstructural, thermal and mechanical properties of unidirectional glass fiber fabrics exhibiting sizing migration. Compos. Part B Eng. 2019, 164, 570–575. [Google Scholar] [CrossRef]

- Yang, L.; Thomason, J.L.; Zhu, W. The influence of thermo-oxidative degradation on the measured interface strength of glass fibre-polypropylene. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1293–1300. [Google Scholar] [CrossRef]

- Palmese, G.R.; Andersen, O.A.; Karbhari, V.M. Effect of glass fiber sizing on the cure kinetics of vinyl-ester resins. Compos. Part A Appl. Sci. Manuf. 1999, 30, 11–18. [Google Scholar] [CrossRef]

- Petersen, H.; Kusano, Y.; Brøndsted, P.; Almdal, K. Preliminary characterization of glass fiber sizing. Proc. 34th Risø Int. Symp. Mater. Sci. 2013, 34, 333–340. [Google Scholar]

- Laura, D.M.; Keskkula, H.; Barlow, J.W.; Paul, D.R. Effect of glass fiber surface chemistry on the mechanical properties of glass fiber reinforced, rubber-toughened nylon 6. Polymer 2002, 43, 4673–4687. [Google Scholar] [CrossRef]

- Thomason, J.L.; Nagel, U.; Yang, L.; Bryce, D. A study of the thermal degradation of glass fibre sizings at composite processing temperatures. Compos. Part A Appl. Sci. Manuf. 2019, 121, 56–63. [Google Scholar] [CrossRef] [Green Version]

- Thomason, J.L.; Dwight, D.W. Use of XPS for characterization of glass fibre coatings. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1401–1413. [Google Scholar] [CrossRef]

- Qin, Y.J.; Xu, Y.H.; Zhang, L.Y.; Zheng, G.Q.; Yan, X.R.; Dai, K.; Liu, C.T.; Shen, C.Y.; Guo, Z.H. Interfacial interaction enhancement by shear-induced β-cylindrite in isotactic polypropylene/glass fiber composites. Polymer 2016, 100, 111–118. [Google Scholar] [CrossRef]

- Dey, M.; Deitzel, J.M.; Gillespie, J.W.; Schweiger, S. Influence of sizing formulations on glass/epoxy interphase properties. Compos. Part A Appl. Sci. Manuf. 2014, 63, 59–67. [Google Scholar] [CrossRef]

- Li, F.; Liu, Y.; Qu, C.B.; Xiao, H.M.; Hua, Y.; Sui, G.X.; Fu, S.Y. Enhanced mechanical properties of short carbon fiber reinforced polyethersulfone composites by graphene oxide coating. Polymer 2015, 59, 155–165. [Google Scholar] [CrossRef]

- Kim, N.; Kim, D.Y.; Kim, Y.J.; Jeong, K.U. Enhanced thermomechanical properties of long and short glass fiber-reinforced polyamide 6,6/polypropylene mixtures by tuning the processing procedures. J. Mater. Sci. 2014, 49, 6333–6342. [Google Scholar] [CrossRef]

- Sheng, Y.; Wen, B.; Li, X.; Hu, X. Effect of surface treatment on the mechanical properties of BF/PLA composite. Fuhe Cailiao Xuebao/Acta Mater. Compos. Sin. 2012, 29, 6. [Google Scholar]

- Feih, S.; Boiocchi, E.; Mathys, G.; Mathys, Z.; Gibson, A.G.; Mouritz, A.P. Mechanical properties of thermally-treated and recycled glass fibres. Compos. Part B Eng. 2011, 42, 350–358. [Google Scholar] [CrossRef] [Green Version]

- Manikandan, V.; Winowlin Jappes, J.T.; Suresh Kumar, S.M.; Amuthakkannan, P. Investigation of the effect of surface modifications on the mechanical properties of basalt fibre reinforced polymer composites. Compos. Part B Eng. 2012, 43, 812–818. [Google Scholar] [CrossRef]

- Thomason, J.L.; Yang, L.; Meier, R. The properties of glass fibres after conditioning at composite recycling temperatures. Compos. Part A Appl. Sci. Manuf. 2014, 61, 201–208. [Google Scholar] [CrossRef] [Green Version]

- Karger-Kocsis, J.; Mahmood, H.; Pegoretti, A. Recent advances in fiber/matrix interphase engineering for polymer composites. Prog. Mater. Sci. 2015, 73, 1–43. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, D.; Jin, X.; Wang, C.; Wang, D.; Ge, H. Modifying glass fibers with graphene oxide: Towards high-performance polymer composites. Compos. Sci. Technol. 2014, 97, 41–45. [Google Scholar] [CrossRef]

- Cech, V.; Palesch, E.; Lukes, J. The glass fiber-polymer matrix interface/interphase characterized by nanoscale imaging techniques. Compos. Sci. Technol. 2013, 83, 22–26. [Google Scholar] [CrossRef]

- Zhou, X.; Lin, Q.; Dai, G. Studies on mechanical properties of discontinuous glass fiber/continuous glass mat/polypropylene composite. Polym. Polym. Compos. 2002, 10, 299–306. [Google Scholar] [CrossRef]

| Fiber/Polymer | 50/50 | 60/40 | 70/30 | |||

|---|---|---|---|---|---|---|

| Property | Flexural Strength, MPa | Young′s Modulus, GPa | Flexural Strength, MPa | Young′s Modulus, GPa | Flexural Strength, MPa | Young′s Modulus, GPa |

| As-received GF composites | 417 | 19 | 457 | 22 | 423 | 23 |

| Preheated GF composites | 501 | 24 | 540 | 27 | 553 | 33 |

| Increase, % | 20.1 | 26.3 | 18.2 | 22.7 | 30.7 | 43.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sherif, G.; Chukov, D.; Tcherdyntsev, V.; Torokhov, V. Effect of Formation Route on the Mechanical Properties of the Polyethersulfone Composites Reinforced with Glass Fibers. Polymers 2019, 11, 1364. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11081364

Sherif G, Chukov D, Tcherdyntsev V, Torokhov V. Effect of Formation Route on the Mechanical Properties of the Polyethersulfone Composites Reinforced with Glass Fibers. Polymers. 2019; 11(8):1364. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11081364

Chicago/Turabian StyleSherif, Galal, Dilyus Chukov, Victor Tcherdyntsev, and Valerii Torokhov. 2019. "Effect of Formation Route on the Mechanical Properties of the Polyethersulfone Composites Reinforced with Glass Fibers" Polymers 11, no. 8: 1364. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11081364