Experimental Characterization of Polymer Surfaces Subject to Corona Discharges in Controlled Atmospheres

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Setup

2.3. Material Characterization

2.3.1. Scanning Electron Microscopy (SEM)

2.3.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.3.3. X-ray Photoelectron Spectroscopy (XPS)

3. Results and Discussion

3.1. SEM

3.1.1. Polyethylene

3.1.2. Polypropylene

3.1.3. Polymethyl Methacrylate

3.1.4. Polytetrafluoroethylene

3.2. FTIR

3.2.1. Untreated Polymers

3.2.2. Treated Polymers

3.3. XPS

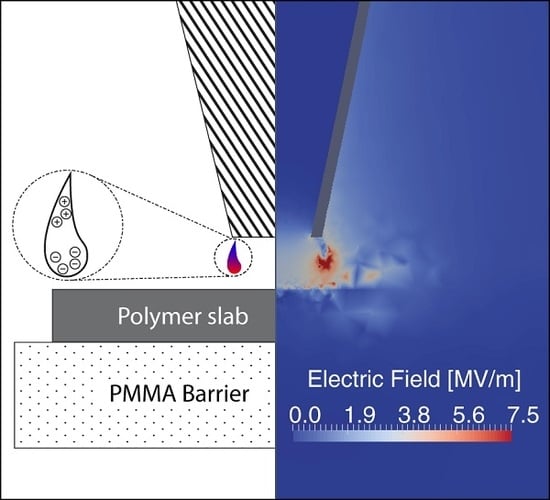

3.4. Modelling of the Corona Discharge

4. Conclusions

- From a structural point of view, both discharges in nitrogen and air atmosphere were able to modify to a large extent the surface of the PE, PP, and PMMA samples. In both atmospheres, polymer surfaces suffered from oxidation contributions since hydroxyl and/or carbonyl functional groups were observed by FTIR and XPS; such modifications closely resemble those obtained by partial discharges in unvented voids embedded in PET [22].

- No functionalities were observed on the PTFE surfaces due to the significant stability of C–F bonds. On the contrary, the modifications introduced by corona discharges over non-fluorinated polymer surfaces are comparable with each other and with those obtained by partial discharge degradation on XLPE and PET [21,22].

- 3D simulation of the system confirmed the availability of oxygen-based species, and in particular of atomic oxygen, in close proximity to the polymer surface. These species are readily active to cause chemical modifications to the material.

- our results are analogous to the modifications observed after the degradation of polyethylene terephthalate due to partial discharges in enclosed voids but using rather different experimental conditions;

- this suggests that the aging of the specimens share a common degradation mechanism from a chemical point of view.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Haji, K.; Zhu, Y.; Otsubo, M.; Honda, C. Surface Modification of Silicone Rubber After Corona Exposure. Plasma Process. Polym. 2007, 4, S1075–S1080. [Google Scholar] [CrossRef]

- Wutzel, H.; Jarvid, M.; Bjuggren, J.M.; Johansson, A.; Englund, V.; Gubanski, S.; Andersson, M.R. Thioxanthone derivatives as stabilizers against electrical breakdown in cross-linked polyethylene for high voltage cable applications. Polym. Degrad. Stab. 2015, 112, 63–69. [Google Scholar] [CrossRef]

- Leon-Garzon, A.R.; Manenti, F.; Dotelli, G.; Villa, A.; Barbieri, L.; Gondola, M. Lumped Mechanism for Polymeric Dielectric Degradation Under High Electrical Fields. Chem. Eng. Trans. 2015, 43, 1711–1716. [Google Scholar] [CrossRef]

- Leon Garzon, A.R.; Dotelli, G.; Villa, A.; Barbieri, L.; Gondola, M.; Cavallotti, C. Thermodynamic Analysis of the Degradation of Polyethylene Subjected to Partial Discharges. Chem. Eng. Sci. 2018, 180, 1–10. [Google Scholar] [CrossRef]

- Villa, A.; Barbieri, L.; Malgesini, R.; Leon-Garzon, A.R. Ignition of discharges in macroscopic isolated voids and first electron availability. J. Appl. Phys. 2019, 125, 043302. [Google Scholar] [CrossRef]

- Montanari, G.C. Notes on theoretical and practical aspects of polymeric insulation aging. IEEE Electr. Insul. Mag. 2013, 29, 34–44. [Google Scholar] [CrossRef]

- Tanaka, T. Internal Partial Discharge and Material Degradation. IEEE Trans. Electr. Insul. 1986, EI-21, 899–905. [Google Scholar] [CrossRef]

- Kao, K.C. Dielectric Phenomena in Solids: With Emphasis on Physical Concepts of Electronic Processes; Elsevier Academic Press: San Diego, CA, USA, 2004. [Google Scholar]

- Novak, J.P.; Bartnikas, R. Ionization and excitation behavior in a microcavity. IEEE Trans. Dielectr. Electr. Insul. 1995, 2, 724–728. [Google Scholar] [CrossRef]

- Vaughan, A.S.; Hosier, I.L.; Dodd, S.J.; Sutton, S.J. On the structure and chemistry of electrical trees in polyethylene. J. Phys. D Appl. Phys. 2006, 39, 962–978. [Google Scholar] [CrossRef]

- Dodd, S.J. A deterministic model for the growth of non-conducting electrical tree structures. J. Phys. D Appl. Phys. 2003, 36, 129–141. [Google Scholar] [CrossRef]

- Hauschild, W.; Lemke, E. High.-Voltage Test. and Measuring Techniques; Springer-Verlag: Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Schwarz, R.; Judendorfer, T.; Muhr, M. Review of partial discharge monitoring techniques used in high voltage equipment. In Proceedings of the 2008 Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP 2008), Quebec, QC, Canada, 26–29 October 2008; pp. 400–403. [Google Scholar]

- Yaacob, M.M.; Alsaedi, M.A.; Rashed, J.R.; Dakhil, A.M.; Atyah, S.F. Review on partial discharge detection techniques related to high voltage power equipment using different sensors. Photonic Sens. 2014, 4, 325–337. [Google Scholar] [CrossRef] [Green Version]

- Lemke, E. A critical review of partial-discharge models. IEEE Electr. Insul. Mag. 2012, 28, 11–16. [Google Scholar] [CrossRef]

- Han, Y.; Song, Y.H. Condition monitoring techniques for electrical equipment-a literature survey. IEEE Trans. Power Deliv. 2003, 18, 4–13. [Google Scholar] [CrossRef]

- Raymond, W.J.K.; Illias, H.A.; Bakar, A.H.A.; Mokhlis, H. Partial discharge classifications: Review of recent progress. Measurement 2015, 68, 164–181. [Google Scholar] [CrossRef] [Green Version]

- Eigner, A.; Rethmeier, K. An overview on the current status of partial discharge measurements on AC high voltage cable accessories. IEEE Electr. Insul. Mag. 2016, 32, 48–55. [Google Scholar] [CrossRef]

- Morshuis, P.H.F.; Smit, J.J. Partial discharges at DC voltage: Their mechanism, detection and analysis. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 328–340. [Google Scholar] [CrossRef]

- Morshuis, P.H. Degradation of Solid Dielectrics due to Internal Partial Discharge: Some thoughts on progress made and where to go now. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 905–913. [Google Scholar] [CrossRef]

- Sekii, Y. Degradation of low-density polyethylene and cross-linked polyethylene by partial discharge. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 116–124. [Google Scholar] [CrossRef]

- Adhikari, D.; Hepburn, D.M.; Stewart, B.G. PD characteristics and degradation in PET insulation with vented and unvented internal voids. Electr. Power Syst. Res. 2013, 100, 65–72. [Google Scholar] [CrossRef]

- Siow, K.S.; Britcher, L.; Kumar, S.; Griesser, H.J. Plasma Methods for the Generation of Chemically Reactive Surfaces for Biomolecule Immobilization and Cell Colonization—A Review. Plasma Process. Polym. 2006, 3, 392–418. [Google Scholar] [CrossRef]

- Grace, J.M.; Gerenser, L.J. Plasma Treatment of Polymers. J. Dispers. Sci. Technol. 2003, 24, 305–341. [Google Scholar] [CrossRef]

- Ren, C.S.; Wang, K.; Nie, Q.Y.; Wang, D.Z.; Guo, S.H. Surface modification of PE film by DBD plasma in air. Appl. Surf. Sci. 2008, 255, 3421–3425. [Google Scholar] [CrossRef]

- Morent, R.; Geyter, N.D.; Leys, C.; Gengembre, L.; Payen, E. Comparison between XPS- and FTIR-analysis of plasma-treated polypropylene film surfaces. Surf. Interface Anal. 2008, 40, 597–600. [Google Scholar] [CrossRef]

- Borcia, G.; Anderson, C.A.; Brown, N.M.D. Dielectric barrier discharge for surface treatment: Application to selected polymers in film and fibre form. Plasma Sources Sci. Technol. 2003, 12, 335–344. [Google Scholar] [CrossRef]

- Borcia, G.; Anderson, C.A.; Brown, N.M.D. The surface oxidation of selected polymers using an atmospheric pressure air dielectric barrier discharge. Part, I. Appl. Surf. Sci. 2004, 221, 203–214. [Google Scholar] [CrossRef]

- Fricke, K.; Steffen, H.; von Woedtke, T.; Schröder, K.; Weltmann, K.-D. High Rate Etching of Polymers by Means of an Atmospheric Pressure Plasma Jet. Plasma Process. Polym. 2011, 8, 51–58. [Google Scholar] [CrossRef]

- Noeske, M.; Degenhardt, J.; Strudthoff, S.; Lommatzsch, U. Plasma jet treatment of five polymers at atmospheric pressure: Surface modifications and the relevance for adhesion. Int. J. Adhes. Adhes. 2004, 24, 171–177. [Google Scholar] [CrossRef]

- Lommatzsch, U.; Pasedag, D.; Baalmann, A.; Ellinghorst, G.; Wagner, H.-E. Atmospheric Pressure Plasma Jet Treatment of Polyethylene Surfaces for Adhesion Improvement. Plasma Process. Polym. 2007, 4, S1041–S1045. [Google Scholar] [CrossRef]

- Šíra, M.; Trunec, D.; Stahel, P.; Buršíková, V.; Navrátil, Z.; Buršík, J. Surface modification of polyethylene and polypropylene in atmospheric pressure glow discharge. J. Phys. D Appl. Phys. 2005, 38, 621–627. [Google Scholar] [CrossRef] [Green Version]

- Pandiyaraj, K.N.; Selvarajan, V.; Deshmukh, R.R.; Gao, C. Modification of surface properties of polypropylene (PP) film using DC glow discharge air plasma. Appl. Surf. Sci. 2009, 255, 3965–3971. [Google Scholar] [CrossRef]

- Malinowski, S.; Herbert, P.A.F.; Rogalski, J.; Jaroszynska-Wolinska, J. Laccase Enzyme Polymerization by Soft Plasma Jet for Durable Bioactive Coatings. Polymers. 2018, 10. [Google Scholar] [CrossRef] [PubMed]

- Malinowski, S.; Jaroszyńska-Wolińska, J.; Herbert, P.A.F. Theoretical insight into plasma deposition of laccase bio-coating formation. J. Mater. Sci. 2019, 54, 10746–10763. [Google Scholar] [CrossRef] [Green Version]

- Malinowski, S.; Wardak, C.; Jaroszynska-Wolinska, J.; Herbert, P.A.F.; Panek, R. Cold Plasma as an Innovative Construction Method of Voltammetric Biosensor Based on Laccase. Sensors 2018, 18. [Google Scholar] [CrossRef] [PubMed]

- Barbieri, L.; Villa, A.; Malgesini, R. A step forward in the characterization of the partial discharge phenomenon and the degradation of insulating materials through nonlinear analysis of time series. IEEE Electr. Insul. Mag. 2012, 28, 14–21. [Google Scholar] [CrossRef]

- Fang, Z.; Liu, Y.; Liu, K.; Shao, T.; Zhang, C. Surface modifications of polymethylmetacrylate films using atmospheric pressure air dielectric barrier discharge plasma. Vacuum 2012, 86, 1305–1312. [Google Scholar] [CrossRef]

- Inagaki, N.; Narushim, K.; Tuchida, N.; Miyazaki, K. Surface characterization of plasma-modified poly(ethylene terephthalate) film surfaces. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 3727–3740. [Google Scholar] [CrossRef]

- Fang, Z.; Hao, L.; Yang, H.; Xie, X.; Qiu, Y.; Edmund, K. Polytetrafluoroethylene surface modification by filamentary and homogeneous dielectric barrier discharges in air. Appl. Surf. Sci. 2009, 255, 7279–7285. [Google Scholar] [CrossRef]

- Sarra-Bournet, C.; Ayotte, G.; Turgeon, S.; Massines, F.; Laroche, G. Effects of Chemical Composition and the Addition of H2 in a N2 Atmospheric Pressure Dielectric Barrier Discharge on Polymer Surface Functionalization. Langmuir 2009, 25, 9432–9440. [Google Scholar] [CrossRef]

- Socrates, G. Infrared and Raman Characteristic Group Frequencies: Tables and Charts; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Wang, S.; Li, J.; Suo, J.; Luo, T. Surface modification of porous poly(tetrafluoraethylene) film by a simple chemical oxidation treatment. Appl. Surf. Sci. 2010, 256, 2293–2298. [Google Scholar] [CrossRef]

- Strobel, M.; Dunatov, C.; Strobel, J.M.; Lyons, C.S.; Perron, S.J.; Morgen, M.C. Low-molecular-weight materials on corona-treated polypropylene. J. Adhes. Sci. Technol. 1989, 3, 321–335. [Google Scholar] [CrossRef]

- Massines, F.; Gouda, G.; Gherardi, N.; Duran, M.; Croquesel, E. The Role of Dielectric Barrier Discharge Atmosphere and Physics on Polypropylene Surface Treatment. Plasmas Polym. 2001, 6, 35–49. [Google Scholar] [CrossRef]

- Földes, E.; Tóth, A.; Kálmán, E.; Fekete, E.; Tomasovszky–Bobák, Á. Surface changes of corona-discharge-treated polyethylene films. J. Appl. Polym. Sci. 2000, 76, 1529–1541. [Google Scholar] [CrossRef]

- Strobel, M.; Jones, V.; Lyons, C.S.; Ulsh, M.; Kushner, M.J.; Dorai, R.; Branch, M.C. A Comparison of Corona-Treated and Flame-Treated Polypropylene Films. Plasmas Polym. 2003, 8, 61–95. [Google Scholar] [CrossRef]

- Chan, C.M.; Ko, T.M.; Hiraoka, H. Polymer surface modification by plasmas and photons. Surf. Sci. Rep. 1996, 24, 1–54. [Google Scholar] [CrossRef]

- Ataeefard, M.; Moradian, S.; Mirabedini, M.; Ebrahimi, M.; Asiaban, S. Surface Properties of Low Density Polyethylene upon Low-Temperature Plasma Treatment with Various Gases. Plasma Chem. Plasma Process. 2008, 28, 377–390. [Google Scholar] [CrossRef]

- Navaneetha Pandiyaraj, K.; Selvarajan, V.; Deshmukh, R.R.; Gao, C. Adhesive properties of polypropylene (PP) and polyethylene terephthalate (PET) film surfaces treated by DC glow discharge plasma. Vacuum 2008, 83, 332–339. [Google Scholar] [CrossRef]

- Cota-Sanchez, G.; Soucy, G.; Huczko, A.; Lange, H. Induction plasma synthesis of fullerenes and nanotubes using carbon black–nickel particles. Carbon 2005, 43, 3153–3166. [Google Scholar] [CrossRef]

- Jiang, J.-H.; Zhu, L.-P.; Li, X.-L.; Xu, Y.-Y.; Zhu, B.-K. Surface modification of PE porous membranes based on the strong adhesion of polydopamine and covalent immobilization of heparin. J. Membr. Sci. 2010, 364, 194–202. [Google Scholar] [CrossRef]

- Wu, Y.J.; Timmons, R.B.; Jen, J.S.; Molock, F.E. Non-fouling surfaces produced by gas phase pulsed plasma polymerization of an ultra low molecular weight ethylene oxide containing monomer. Colloids Surf. B Biointerfaces 2000, 18, 235–248. [Google Scholar] [CrossRef]

- Guimond, S.; Radu, I.; Czeremuszkin, G.; Carlsson, D.J.; Wertheimer, M.R. Biaxially Oriented Polypropylene (BOPP) Surface Modification by Nitrogen Atmospheric Pressure Glow Discharge (APGD) and by Air Corona. Plasmas Polym. 2002, 7, 71–88. [Google Scholar] [CrossRef]

- Lehocký, M.; Drnovská, H.; Lapčíková, B.; Barros-Timmons, A.M.; Trindade, T.; Zembala, M.; Lapčík, L.R. Plasma surface modification of polyethylene. Colloids Surf. A Physicochem. Eng. Asp. 2003, 222, 125–131. [Google Scholar] [CrossRef]

- Arpagaus, C.; Rossi, A.; Rudolf von Rohr, P. Short-time plasma surface modification of HDPE powder in a Plasma Downer Reactor—Process, wettability improvement and ageing effects. Appl. Surf. Sci. 2005, 252, 1581–1595. [Google Scholar] [CrossRef]

- Kim, H.I.; Kim, S.S. Plasma treatment of polypropylene and polysulfone supports for thin film composite reverse osmosis membrane. J. Membr. Sci. 2006, 286, 193–201. [Google Scholar] [CrossRef]

- O’Kell, S.; Henshaw, T.; Farrow, G.; Aindow, M.; Jones, C. Effects of low-power plasma treatment on polyethylene surfaces. Surf. Interface Anal. 1995, 23, 319–327. [Google Scholar] [CrossRef]

- Villa, A.; Barbieri, L.; Gondola, M.; Leon-Garzon, A.R.; Malgesini, R. An efficient algorithm for corona simulation with complex chemical models. J. Comput. Phys. 2017, 337, 233–251. [Google Scholar] [CrossRef]

- Villa, A.; Barbieri, L.; Gondola, M.; Leon-Garzon, A.R.; Malgesini, R. An implicit three-dimensional fractional step method for the simulation of the corona phenomenon. Appl. Math. Comput. 2017, 311, 85–99. [Google Scholar] [CrossRef]

- Villa, A.; Barbieri, L.; Gondola, M.; Leon-Garzon, A.R.; Malgesini, R. Stability of the discretization of the electron avalanche phenomenon. J. Comput. Phys. 2015, 296, 369–381. [Google Scholar] [CrossRef]

- Villa, A.; Barbieri, L.; Gondola, M.; Leon-Garzon, A.R.; Malgesini, R. Mesh dependent stability of discretization of the streamer equations for very high electric fields. Comput. Fluids 2014, 105, 1–7. [Google Scholar] [CrossRef]

- Villa, A.; Barbieri, L.; Marco, G.; Malgesini, R.; Leon-Garzon, A.R. Simulation of the AC corona phenomenon with experimental validation. J. Phys. D Appl. Phys. 2017, 50, 1–14. [Google Scholar] [CrossRef]

- Sakiyama, Y.; Graves, D.B.; Chang, H.W.; Shimizu, T.; Morfill, G.E. Plasma chemistry model of surface microdischarge in humid air and dynamics of reactive neutral species. J. Phys. D Appl. Phys. 2012, 45, 1–19. [Google Scholar] [CrossRef]

- Rabie, M.; Franck, C.M. METHES: A Monte Carlo collision code for the simulation of electron transport in low temperature plasmas. Comput. Phys. Commun. 2016, 203, 268–277. [Google Scholar] [CrossRef] [Green Version]

- Pitchford, L.C.; Alves, L.L.; Bartschat, K.; Biagi, S.F.; Bordage, M.-C.; Bray, I.; Brion, C.E.; Brunger, M.J.; Campbell, L.; Chachereau, A.; et al. LXCat: An Open-Access, Web-Based Platform for Data Needed for Modeling Low Temperature Plasmas. Plasma Process. Polym. 2017, 14, 1600098-n/a. [Google Scholar] [CrossRef]

- Dorai, R.; Kushner, M.J. A model for plasma modification of polypropylene using atmospheric pressure discharges. J. Phys. D Appl. Phys. 2003, 36, 666–685. [Google Scholar] [CrossRef]

- Singh, B.; Sharma, N. Mechanistic implications of plastic degradation. Polym. Degrad. Stab. 2008, 93, 561–584. [Google Scholar] [CrossRef]

- Akishev, Y.; Grushin, M.; Dyatko, N.; Kochetov, I.; Napartovich, A.; Trushkin, N.; Minh Duc, T.; Descours, S. Studies on cold plasma–polymer surface interaction by example of PP- and PET-films. J. Phys. D Appl. Phys. 2008, 41, 1–13. [Google Scholar] [CrossRef]

- Chai, A.M.; Manion, R.E.H.; Levin, D.R.; Burgess, V.L., Jr.; Orkin, W.; Tsang, W.S.; McGivern, J.W.; Hudgens, V.D.; Knyazev, D.B.; Atkinson, E.; et al. NIST Chemical Kinetics Database, NIST Standard Reference Database 17; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015; Volume 20899-8320.

| Polymer | Treatment Atmosphere | Elemental Composition (%) | O/C Ratio | N/C Ratio | ||

|---|---|---|---|---|---|---|

| C 1s | O 1s | N 1s | ||||

| Polyethylene | Untreated | 92.47 | 7.53 | − | 0.08 | − |

| Nitrogen-treated | 86.58 | 10.68 | 2.74 | 0.12 | 0.03 | |

| Air-treated | 83.21 | 16.06 | 0.73 | 0.19 | 0.01 | |

| Polypropylene | Untreated | 93.14 | 6.86 | − | 0.07 | − |

| Nitrogen-treated | 84.96 | 11.24 | 3.79 | 0.13 | 0.04 | |

| Air-treated | 88.47 | 10.62 | 0.91 | 0.12 | 0.01 | |

| Species | Relative Peak Concentration at Pulse (ppm) | |||||

|---|---|---|---|---|---|---|

| 1st (3.85 ms) | 2nd (11.5 ms) | 3rd (14.5 ms) | 4th (22 ms) | 5th (32.5 ms) | 6th (42.5 ms) | |

| O3 | 0.1134 | 3.042 | 2.414 | 3.945 | 1.842 | 3.38 |

| O(3P) | 0.0124 | 0.4374 | 0.0002 | 0.2527 | 0.7235 | 0.786 |

| NO | 0.0132 | 0.2182 | 0.1917 | 0.4287 | 0.1434 | 0.386 |

| O2(a1Δg) | 0.0097 | 0.2842 | 0.2049 | 0.3498 | 0.157 | 0.2784 |

| OH | 0.0068 | 0.0826 | 0.0389 | 0.1528 | 0.0486 | 0.1427 |

| N(4S) | 0.0124 | 0.0483 | 0.014 | 0.2941 | 0.0179 | 0.3227 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leon-Garzon, A.R.; Dotelli, G.; Tommasini, M.; Bianchi, C.L.; Pirola, C.; Villa, A.; Lucotti, A.; Sacchi, B.; Barbieri, L. Experimental Characterization of Polymer Surfaces Subject to Corona Discharges in Controlled Atmospheres. Polymers 2019, 11, 1646. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11101646

Leon-Garzon AR, Dotelli G, Tommasini M, Bianchi CL, Pirola C, Villa A, Lucotti A, Sacchi B, Barbieri L. Experimental Characterization of Polymer Surfaces Subject to Corona Discharges in Controlled Atmospheres. Polymers. 2019; 11(10):1646. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11101646

Chicago/Turabian StyleLeon-Garzon, Andres R., Giovanni Dotelli, Matteo Tommasini, Claudia L. Bianchi, Carlo Pirola, Andrea Villa, Andrea Lucotti, Benedetta Sacchi, and Luca Barbieri. 2019. "Experimental Characterization of Polymer Surfaces Subject to Corona Discharges in Controlled Atmospheres" Polymers 11, no. 10: 1646. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11101646