Design of Web-to-Web Spacing for the Reduced Pressure Drop and Effective Depth Filtration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

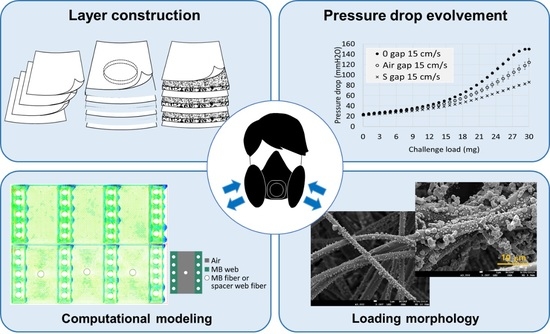

2.2. Preparation of Multi-Layer Construction

2.3. Filtration Performance

2.4. Morphological Characterization

2.5. Modeling and Simulation

3. Results and Discussions

3.1. Effect of Layer Construction on Filtration Performance

3.2. Depth Filtration and Loading Capacity

3.3. Morphological Characterization

3.4. Modeling and Simulation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Harrison, R.M.; Hester, R.E.; Querol, X. Airborne Particulate Matter: Sources, Atmospheric Processes and Health, 1st ed.; Royal Society of Chemistry: Cambridge, Canbrudgesgurem, England, 2016. [Google Scholar]

- Schauer, J.J.; Rogge, W.F.; Hildemann, L.M.; Mazurek, M.A.; Cass, G.R.; Simoneit, B.R. Source apportionment of airborne particulate matter using organic compounds as tracers. Atmos. Environ. 1996, 30, 3837–3855. [Google Scholar] [CrossRef]

- Harrison, R.M.; Yin, J. Particulate matter in the atmosphere: which particle properties are important for its effects on health? Sci. Total Environ. 2000, 249, 85–101. [Google Scholar] [CrossRef]

- Nel, A. Air pollution-related illness: effects of particles. Science 2005, 308, 804–806. [Google Scholar] [CrossRef] [PubMed]

- Ailshire, J.A.; Crimmins, E.M. Fine particulate matter air pollution and cognitive function among older US adults. Am. J. Epidemiol. 2014, 180, 359–366. [Google Scholar] [CrossRef] [PubMed]

- Pope, C.A.; Burnett, R.T.; Thun, M.J.; Calle, E.E.; Krewski, D.; Ito, K.; Thurston, G.D. Lung cancer, cardiopulmonary mortality, and long-term exposure to fine particulate air pollution. J. Am. Med. Assoc. 2002, 287, 1132–1141. [Google Scholar] [CrossRef] [PubMed]

- Anderson, J.O.; Thundiyil, J.G.; Stolbach, A. Clearing the air: a review of the effects of particulate matter air pollution on human health. J. Med. Toxicol. 2012, 8, 166–175. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Qu, C.; Zhang, J.; Talpur, S.A.; Ding, Y.; Xing, X.; Qi, S. Polycyclic aromatic hydrocarbons (PAHs) in agricultural soils from Ningde, China: levels, sources, and human health risk assessment. Environ. Geochem. Hlth. 2019, 41, 907–919. [Google Scholar] [CrossRef]

- Kim, K.H.; Jahan, S.A.; Kabir, E.; Brown, R.J. A review of airborne polycyclic aromatic hydrocarbons (PAHs) and their human health effects. Environ. Int. 2013, 60, 71–80. [Google Scholar] [CrossRef]

- Chen, S.C.; Liao, C.M. Health risk assessment on human exposed to environmental polycyclic aromatic hydrocarbons pollution sources. Sci. Total Environ. 2006, 366, 112–123. [Google Scholar] [CrossRef]

- Jung, S.; An, J.; Na, H.; Kim, J. Surface energy of filtration media influencing the filtration performance against solid particles, oily aerosol, and bacterial aerosol. Polymers 2019, 11, 935. [Google Scholar] [CrossRef]

- Tang, M.; Chen, S.C.; Chang, D.Q.; Xie, X.; Sun, J.; Pui, D.Y.H. Filtration efficiency and loading characteristics of PM2.5 through composite filter media consisting of commercial HVAC electret media and nanofiber layer. Sep. Purif. Technol. 2018, 198, 137–145. [Google Scholar] [CrossRef]

- Podgórski, A.; Bałazy, A.; Gradoń, L. Application of nanofibers to improve the filtration efficiency of the most penetrating aerosol particles in fibrous filters. Chem. Eng. Sci. 2006, 61, 6804–6815. [Google Scholar] [CrossRef]

- Liu, C.; Hsu, P.C.; Lee, H.W.; Ye, M.; Zheng, G.; Liu, N.; Li, W.; Cui, Y. Transparent air filter for high-efficiency PM 2.5 capture. Nat. Commun. 2015, 6, 6205. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Shim, W.S.; Kim, J. Design of ultra-fine nonwovens via electrospinning of Nylon 6: Spinning parameters and filtration efficiency. Mater. Des. 2009, 30, 3659–3666. [Google Scholar] [CrossRef]

- Lee, Y.C.; Wadsworth, L.C. Structure and filtration properties of melt blown polypropylene webs. Polym. Eng. Sci. 1990, 30, 1413–1419. [Google Scholar] [CrossRef]

- Barhate, R.S.; Ramakrishna, S. Nanofibrous filtering media: filtration problems and solutions from tiny materials. J. Membr. Sci. 2007, 296, 1–8. [Google Scholar] [CrossRef]

- Stafford, R.G.; Ettinger, H.J. Filter efficiency as a function of particle size and velocity. Atmos. Environ. 1972, 6, 353–362. [Google Scholar] [CrossRef]

- Hinds, W.C. Aerosol technology: properties, behavior, and measurement of airborne particles, 2nd ed.; John Wiley & Sons: Hoboken, New Jersey, USA, 1999. [Google Scholar]

- Novick, V.; Monson, P.; Ellison, P. The effect of solid particle mass loading on the pressure drop of HEPA filters. J. Aerosol. Sci. 1992, 23, 657–665. [Google Scholar] [CrossRef]

- Thomas, D.; Penicot, P.; Contal, P.; Leclerc, D.; Vendel, J. Clogging of fibrous filters by solid aerosol particles experimental and modelling study. Chem. Eng. Sci. 2001, 56, 3549–3561. [Google Scholar] [CrossRef]

- Frising, T.; Gujisaite, V.; Thomas, D.; Callé, S.; Bémer, D.; Contal, P.; Leclerc, D. Filtration of solid and liquid aerosol mixtures: pressure drop evolution and influence of solid/liquid ratio. Filtr. Separat. 2004, 41, 37–39. [Google Scholar] [CrossRef]

- Wang, J.; Kim, S.C.; Pui, D.Y.H. Investigation of the figure of merit for filters with a single nanofiber layer on a substrate. J. Aerosol Sci. 2008, 39, 323–334. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Zuo, F.; Yin, X.; Yu, J.; Ding, B.A. Controlled design of ripple-like polyamide-6 nanofiber/nets membrane for high-efficiency air filter. Small 2017, 13, 1603151. [Google Scholar] [CrossRef] [PubMed]

- Thakur, R.; Das, D.; Das, A. Optimization of charge storage in corona-charged fibrous electrets. J. Text. I. 2014, 105, 676–684. [Google Scholar] [CrossRef]

- Thakur, R.; Das, D.; Das, A.A. Combined taguchi and response surface approach to improve electret charge in corona-charged fibrous electrets. Fiber. Polym. 2016, 17, 1790–1800. [Google Scholar] [CrossRef]

- Nifuku, M.; Zhou, Y.; Kisiel, A.; Kobayashi, T.; Katoh, H. Charging characteristics for electret filter materials. J. Electrostat. 2001, 51, 200–205. [Google Scholar] [CrossRef]

- Xiao, H.; Song, Y.; Chen, G. Correlation between charge decay and solvent effect for melt-blown polypropylene electret filter fabrics. J. Electrostat. 2014, 72, 311–314. [Google Scholar] [CrossRef]

- Roh, S.; Kim, S.; Kim, J. Facile functionalization via plasma-enhanced chemical vapor deposition for the effective filtration of oily aerosol. Polymers 2019, 11, 1490. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Zhang, X.; Huang, C.; Jin, X. Design of electret polypropylene melt blown air filtration material containing nucleating agent for effective PM2. 5 capture. RSC Adv. 2018, 8, 7932–7941. [Google Scholar] [CrossRef]

- Eninger, R.M.; Honda, T.; Adhikari, A.; Heinonen-Tanski, H.; Reponen, T.; Grinshpun, S.A. Filter performance of N99 and N95 facepiece respirators against viruses and ultrafine particles. Ann. Occup. Hyg. 2008, 52, 385–396. [Google Scholar]

- Cho, H.W.; Yoon, C.S.; Lee, J.H.; Lee, S.J.; Viner, A.; Johnson, E.W. Comparison of pressure drop and filtration efficiency of particulate respirators using welding fumes and sodium chloride. Ann. Occup. Hyg. 2011, 55, 666–680. [Google Scholar]

- Baig, A.S.; Knapp, C.; Eagan, A.E.; Radonovich Jr, L.J. Health care workers’ views about respirator use and features that should be included in the next generation of respirators. J. Infect. Control 2010, 38, 18–25. [Google Scholar] [CrossRef]

- Locatelli, S.M.; Lavela, S.L.; Gosch, M. Health care workers’ reported discomfort while wearing filtering face-piece respirators. Workplace Health Saf. 2014, 62, 362–368. [Google Scholar] [CrossRef] [PubMed]

- Rebmann, T.; Carrico, R.; Wang, J. Physiologic and other effects and compliance with long-term respirator use among medical intensive care unit nurses. Am. J. Infect. Control 2013, 41, 1218–1223. [Google Scholar] [CrossRef]

- Zaatari, M.; Novoselac, A.; Siegel, J. The relationship between filter pressure drop, indoor air quality, and energy consumption in rooftop HVAC units. Buld. Environ. 2014, 73, 151–161. [Google Scholar] [CrossRef]

- Jones, J.G. The physiological cost of wearing a disposable respirator. Am. Ind. Hyg. Assoc. J. 1991, 52, 219–225. [Google Scholar] [CrossRef] [PubMed]

- Raven, P.B.; Bradley, O.; Rohm, Y.D.; Mcclure, F.L.; Skaggs, B. Physiological response to “pressure-demand” respirator wear. Am. Ind. Hyg. Assoc. J. 1982, 43, 773–781. [Google Scholar] [CrossRef] [PubMed]

- Wilson, J.R.; Raven, P.B.; Morgan, W.P.; Zinkgraf, S.A.; Garmon, R.G.; Jackson, A.W. Effects of pressure-demand respirator wear on physiological and perceptual variables during progressive exercise to maximal levels. Am. Ind. Hyg. Assoc. J. 1989, 50, 85–94. [Google Scholar] [CrossRef]

- Nassif, N. Impacts of air filters on energy consumption in typical HVAC systems. ASHRAE Trans. 2012, 118, 74. [Google Scholar]

- Wang, Z.; Pan, Z. Preparation of hierarchical structured nano-sized/porous poly (lactic acid) composite fibrous membranes for air filtration. Appl. Surf. Sci. 2015, 356, 1168–1179. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.; Zhang, H.; Zheng, L.; Huang, C.; Wu, H.; Wang, R.; Jin, X. Low resistance bicomponent spunbond materials for fresh air filtration with ultra-high dust holding capacity. RSC Adv. 2017, 7, 43879–43887. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Wang, S.; Yin, X.; Yu, J.; Ding, B. Slip-effect functional air filter for efficient purification of PM 2.5. Sci. Rep. 2016, 6, 35472. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Li, Y.; Hua, T.; Jiang, P.; Yin, X.; Yu, J.; Ding, B. Low-resistance dual-purpose air filter releasing negative ions and effectively capturing PM2. 5. ACS Appl. Mater. Interfaces 2017, 9, 12054–12063. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Li, Q.; Young, T.M.; Harper, D.P.; Wang, S. A novel method for fabricating an electrospun poly (vinyl alcohol)/cellulose nanocrystals composite nanofibrous filter with low air resistance for high-efficiency filtration of particulate matter. ACS Sustainable Chem. Environ. 2019, 7, 8706–8714. [Google Scholar] [CrossRef]

- Gao, H.; Yang, Y.; Akampumuza, O.; Hou, J.; Zhang, H.; Qin, X. A low filtration resistance three-dimensional composite membrane fabricated via free surface electrospinning for effective PM 2.5 capture. Envrion. Sci. Nano 2017, 4, 864–875. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, S.; Zhao, X.; Yu, J.; Ding, B. Sandwich structured polyamide-6/polyacrylonitrile nanonets/bead-on-string composite membrane for effective air filtration. Sep. Purif. Technol. 2015, 152, 14–22. [Google Scholar] [CrossRef]

- Zhang, Q.; Welch, J.; Park, H.; Wu, C.Y.; Sigmund, W.; Marijnissen, J.C. Improvement in nanofiber filtration by multiple thin layers of nanofiber mats. J. Aerosol Sci. 2010, 41, 230–236. [Google Scholar] [CrossRef]

- Onur, A.; Ng, A.; Batchelor, W.; Garnier, G. Multi-layer filters: adsorption and filtration mechanisms for improved separation. Front. Chem. 2018, 6, 417. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Yin, X.; Yu, J.; Ding, B. Electret polyvinylidene fluoride nanofibers hybridized by polytetrafluoroethylene nanoparticles for high-efficiency air filtration. ACS Appl. Mater. Interfaces 2016, 8, 23985–23994. [Google Scholar] [CrossRef]

| Meltblown Filter Web (MB) | Spacer Web (S) | |

|---|---|---|

| Material | Polypropylene | Polyethylene terephthalate |

| Basis weight (g/m2) | 34 (±3, n = 5) | 76 (±5, n = 5) |

| Thickness (mm) | 0.28 (±0.03, n = 5) | 5.5 (±0.2, n = 5) |

| Solidity (unitless) | 0.133 | 0.010 |

| Porosity (%) | 86.7 | 99.0 |

| Mean fiber diameter (μm) | 2.6 (±1.1, n = 20) | 35.0 (±4.3, n = 20) |

| 0 mm Gap | Air Gap (5 mm) | Spacer Web (5.5 mm) | |||||

|---|---|---|---|---|---|---|---|

| Face velocity (cm/s) | 15 | 20 | 15 | 20 | 15 | 20 | |

| No. MB layers | 1-Layer (control) | O | O | - | - | - | - |

| 2-Layer | O | O | O | O | O | O | |

| 4-Layer | O | O | O | O | O | O | |

| Facevel. | Constr. | In. pn (%) | Max. pn (%) | In. dP (mm H2O) | dP at max. pn (mm H2O) | Challenge Load at max. pn (mg) | Challenge at 50 mmH2O (mg) | dP at 20 mg Challenge (mm H2O) |

|---|---|---|---|---|---|---|---|---|

| 15 cm/s | 1L-MB | 3.62 | 11.77 | 6.9 | 13.5 | 5.2 | 17.0 | 69.2 |

| 2L-0 gap | 0.12 | 0.83 | 12.1 | 24.0 | 9.8 | 18.6 | 57.7 | |

| 2L-air gap | 0.14 | 0.95 | 11.9 | 23.9 | 9.8 | 18.8 | 55.4 | |

| 2L-S gap | 0.14 | 0.89 | 11.8 | 24.0 | 9.8 | 17.9 | 64.0 | |

| 4L-0 gap | ≤0.01 | ≤0.01 | 24.2 | N.D. | N.D. | 14.7 | 76.9 | |

| 4L-air gap | ≤0.01 | ≤0.01 | 22.7 | N.D. | N.D. | 16.6 | 63.4 | |

| 4L-S gap | ≤0.01 | ≤0.01 | 22.0 | N.D. | N.D. | 19.5 | 51.9 | |

| 20 cm/s | 1L-MB | 5.2 | 13.77 | 9.1 | 16.8 | 3.71 | 11.6 | 88.2 |

| 2L-0 gap | 0.3 | 1.11 | 17.6 | 31.3 | 7.2 | 13.0 | 99.7 | |

| 2L-air gap | 0.2 | 0.71 | 17.5 | 29.4 | 7.2 | 13.4 | 79.1 | |

| 2L-S gap | 0.3 | 1.01 | 17.5 | 31.6 | 7.2 | 12.1 | 112.9 | |

| 4L-0 gap | ≤0.01 | ≤0.01 | 34.1 | N.D. | N.D. | 8.1 | 118.0 | |

| 4L-air gap | ≤0.01 | ≤0.01 | 33.2 | N.D. | N.D. | 8.9 | 92.2 | |

| 4L-S gap | ≤0.01 | ≤0.01 | 30.4 | N.D. | N.D. | 13.5 | 67.2 |

| Gap | 0 mm Gap | Air Gap | S Gap | |||

|---|---|---|---|---|---|---|

| Layer Tested | Mass Loaded (mg) | % Load Share (%) | Mass Loaded (mg) | % Load Share (%) | Mass Loaded (mg) | % Load Share (%) |

| 1st layer MB | 29.3 (±0.6) | 97.8 (±1.9) | 28.3 (±1.2) | 96.6 (±0.1) | 25.7 (±0.6) | 85.6 (±1.9) |

| 2nd layer MB | 0.7 (±0.6) | 2.2 (±1.9) | 1.3 (±0.6) | 4.5 (±1.9) | 2.7 (±0) | 8.9 (±1.9) |

| 3rd layer MB | - | - | - | - | 1 (±0) | 3.3 (±0) |

| 4th layer MB | - | - | - | - | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roh, S.; Park, K.; Kim, J. Design of Web-to-Web Spacing for the Reduced Pressure Drop and Effective Depth Filtration. Polymers 2019, 11, 1822. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11111822

Roh S, Park K, Kim J. Design of Web-to-Web Spacing for the Reduced Pressure Drop and Effective Depth Filtration. Polymers. 2019; 11(11):1822. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11111822

Chicago/Turabian StyleRoh, Sanghyun, Kangsoo Park, and Jooyoun Kim. 2019. "Design of Web-to-Web Spacing for the Reduced Pressure Drop and Effective Depth Filtration" Polymers 11, no. 11: 1822. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11111822