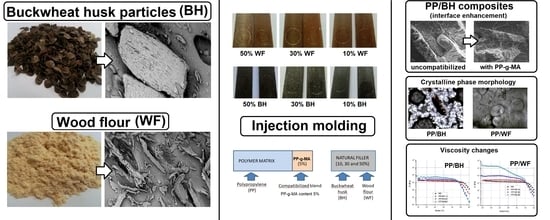

Injection Molding of Highly Filled Polypropylene-based Biocomposites. Buckwheat Husk and Wood Flour Filler: A Comparison of Agricultural and Wood Industry Waste Utilization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Material Characterization

3. Results and Discussion

3.1. Mechanical Properties—Static Tests and Impact Resistance

3.2. Thermo-Mechanical Properties—DMTA Analysis

3.3. Nucleation of the Crystalline Phase and Analysis of Spherulites Growth Kinetics—DSC Analysis, POM Observations

3.4. Morphological Analysis—BH and WF Composites Structure Comparison

3.5. Rheological Behavior—Influence of Filler Concentration and Compatibilization Method

3.6. Chemical Structure Evaluation—FTIR Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thakur, V.K.; Thakur, M.K. Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Parija, S.; Nayak, S.K.; Tripathy, S.S. Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Compos. Sci. Technol. 2003, 63, 1377–1385. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-Fibre-Reinforced polymer composites in automotive applications. J. Miner. Met. Mater. Soc. 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Rueda, M.M.; Fulchiron, R.; Martin, G.; Cassagnau, P. Rheology of polypropylene filled with short-glass fibers: From low to concentrated filled composites. Eur. Polym. J. 2017, 93, 167–181. [Google Scholar] [CrossRef]

- Kráčalík, M.; Pospíšil, L.; Šlouf, M.; Mikešová, J.; Sikora, A.; Šimoník, J.; Fortelný, I. Effect of glass fibers on rheology, thermal and mechanical properties of recycled PET. Polym. Compos. 2008, 29, 915–921. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.P. Effects of processing method and fiber size on the structure and properties of wood-plastic composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 80–85. [Google Scholar] [CrossRef]

- Rytlewski, P.; Stepczyńska, M.; Moraczewski, K.; Malinowski, R. Mechanical properties and biodegradability of flax fiber-reinforced composite of polylactide and polycaprolactone. Polymers 2018, 63, 603–610. [Google Scholar] [CrossRef]

- Kijenski, J.; Kijenska, M.; Osawaru, O. Plant fibers as alternatives to mineral fillers in thermoplastic composites—Ford’s vision or Al Gore’s? Polimery 2016, 61, 467–473. [Google Scholar] [CrossRef]

- Doumbia, A.S.; Castro, M.; Jouannet, D.; Kervoëlen, A.; Falher, T.; Cauret, L.; Bourmaud, A. Flax/Polypropylene composites for lightened structures: Multiscale analysis of process and fibre parameters. Mater. Des. 2015, 87, 331–341. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Injection molded wheat straw and corn stem filled polypropylene composites. J. Polym. Environ. 2006, 14, 265–272. [Google Scholar] [CrossRef]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Polylactide-Based renewable green composites from agricultural residues and their hybrids. Biomacromolecules 2010, 11, 1654–1660. [Google Scholar] [CrossRef]

- Salasinska, K.; Osica, A.; Ryszkowska, J. The use of tree leaves as reinforcement in composites with recycled pe-hd matrix. Polimery 2012, 57, 646–655. [Google Scholar] [CrossRef]

- Kar, J.; Rout, A.K.; Sutar, A.K. Physical, mechanical, and erosion characterization of palm leaf stalk fiber reinforced epoxy composites filled with palm leaf stem stalk (PLSS) powder. BioResources 2018, 13, 7212–7231. [Google Scholar] [CrossRef]

- Salasinska, K.; Polka, M.; Gloc, M.; Ryszkowska, J. Natural fiber composites: The effect of the kind and content of filler on the dimensional and fire stability of polyolefin-based composites. Polimery 2016, 61, 255–265. [Google Scholar] [CrossRef]

- Salasinska, K.; Ryszkowska, J. Natural fibre composites from polyethylene waste and hazelnut shell: Dimensional stability, physical, mechanical and thermal properties. Compos. Interfaces 2012, 19, 321–332. [Google Scholar] [CrossRef]

- Barczewski, M.; Matykiewicz, D.; Krygier, A.; Andrzejewski, J.; Skórczewska, K. Characterization of poly(lactic acid) biocomposites filled with chestnut shell waste. J. Mater. Cycles Waste Manag. 2018, 20, 1–11. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O. Rheological and processing properties of poly(lactic acid) composites filled with ground chestnut shell. Polymers 2018, 42, 267–274. [Google Scholar]

- Zieleniewska, M.; Szczepkowski, L.; Krzyżowska, M.; Leszczyński, M.K.; Ryszkowska, J. Rigid polyurethane foam composites with vegetable filler for application in the cosmetics industry. Polymers 2016, 61, 807–814. [Google Scholar] [CrossRef]

- Güngör, A.; Akbay, I.K.; Özdemir, T. Waste walnut shell as an alternative bio-based filler for the EPDM: Mechanical, thermal, and kinetic studies. J. Mater. Cycles Waste Manag. 2018, 21, 145–155. [Google Scholar] [CrossRef]

- Nanda, M.R.; Misra, M.; Mohanty, A.K. Mechanical performance of soy-hull-reinforced bioplastic green composites: A comparison with polypropylene composites. Macromol. Mater. Eng. 2012, 297, 184–194. [Google Scholar] [CrossRef]

- Chen, R.S.; Ahmad, S. Mechanical performance and flame retardancy of rice husk/organoclay-reinforced blend of recycled plastics. Mater. Chem. Phys. 2017, 198, 57–65. [Google Scholar] [CrossRef]

- Sabbatini, A.; Lanari, S.; Santulli, C.; Pettinari, C. Use of almond shells and rice husk as fillers of poly(methyl methacrylate) (PMMA) composites. Materials 2017, 10, 872. [Google Scholar] [CrossRef] [PubMed]

- Kwon, H.; Sunthornvarabhas, J.; Park, J.; Lee, J.; Kim, H.; Piyachomkwan, K.; Sriroth, K.; Cho, D. Tensile properties of kenaf fiber and corn husk flour reinforced poly(lactic acid) hybrid bio-composites: Role of aspect ratio of natural fibers. Compos. Part B Eng. 2014, 56, 232–237. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Gendy, A.; Kamel, S. Evaluation of corn husk fibers reinforced recycled low density polyethylene composites. Mater. Chem. Phys. 2015, 152, 26–33. [Google Scholar] [CrossRef]

- Iyer, K.A.; Torkelson, J.M. Novel, synergistic composites of polypropylene and rice husk ash: Sustainable resource hybrids prepared by solid-state shear pulverization. Polym. Compos. 2013, 34, 1211–1221. [Google Scholar] [CrossRef]

- Sarangi, M.; Nayak, P.; Tiwari, T.N. Effect of temperature on nano-crystalline silica and carbon composites obtained from rice-husk ash. Compos. Part B Eng. 2011, 42, 1994–1998. [Google Scholar] [CrossRef]

- Flauzino Neto, W.P.; Mariano, M.; da Silva, I.S.V.; Silvério, H.A.; Putaux, J.L.; Otaguro, H.; Pasquini, D.; Dufresne, A. Mechanical properties of natural rubber nanocomposites reinforced with high aspect ratio cellulose nanocrystals isolated from soy hulls. Carbohydr. Polym. 2016, 153, 143–152. [Google Scholar] [CrossRef]

- Jonoobi, M.; Oladi, R.; Davoudpour, Y.; Oksman, K.; Dufresne, A.; Hamzeh, Y.; Davoodi, R. Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: A review. Cellulose 2015, 22, 935–969. [Google Scholar] [CrossRef]

- Purkait, B.S.; Ray, D.; Sengupta, S.; Kar, T.; Mohanty, A.; Misra, M. Isolation of cellulose nanoparticles from sesame husk. Ind. Eng. Chem. Res. 2011, 50, 871–876. [Google Scholar] [CrossRef]

- Quosai, P.; Anstey, A.; Mohanty, A.K.; Misra, M. Characterization of biocarbon generated by high- and low-temperature pyrolysis of soy hulls and coffee chaff: For polymer composite applications. R. Soc. Open Sci. 2018, 5, 171970. [Google Scholar] [CrossRef]

- Zhang, Q.; Yi, W.; Li, Z.; Wang, L.; Cai, H. Mechanical properties of rice husk biochar reinforced high density polyethylene composites. Polymers 2018, 10, 286. [Google Scholar] [CrossRef]

- Kumari, R.; Ito, H.; Takatani, M.; Uchiyama, M.; Okamoto, T. Fundamental studies on wood/cellulose-plastic composites: Effects of composition and cellulose dimension on the properties of cellulose/PP composite. J. Wood Sci. 2007, 53, 470–480. [Google Scholar] [CrossRef]

- Gao, H.; Xie, Y.; Ou, R.; Wang, Q. Grafting effects of polypropylene/polyethylene blends with maleic anhydride on the properties of the resulting wood-plastic composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 150–157. [Google Scholar] [CrossRef]

- Yang, T.H.; Leu, S.Y.; Yang, T.H.; Lo, S.F. Optimized material composition to improve the physical and mechanical properties of extruded wood-plastic composites (WPCs). Constr. Build. Mater. 2012, 29, 120–127. [Google Scholar]

- Wilczynski, K.; Buziak, K.; Bartnik, M. Study on the flow of wood-plastic composites in the single-screw extrusion process. Polimery 2016, 61, 195–201. [Google Scholar] [CrossRef]

- Wilczynski, K.J.; Nastaj, A.; Buziak, K. Modeling of starve-fed single screw extrusion of wood-polymer composites. Polimery 2018, 63, 542–548. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Law, S.; Sain, M. Enhancement of processability of rice husk filled high-density polyethylene composite profiles. J. Thermoplast. Compos. Mater. 2005, 18, 445–458. [Google Scholar] [CrossRef]

- Gozdecki, C.; Zajchowski, S.; Kociszewski, M.; Wilczyński, A.; Mirowski, J. Effect of wood particle size on mechanical properties of industrial wood particle-polyethylene composites. Polimery 2011, 56, 375–380. [Google Scholar] [CrossRef]

- Crespo, J.E.; Sanchez, L.; Parres, F.; López, J. Mechanical and morphological characterization of PVC plastisol composites with almond husk fillers. Polym. Compos. 2007, 28, 71–77. [Google Scholar] [CrossRef]

- Mousa, A.; Heinrich, G. Thermoplastic composites based on renewable natural resources: Unplasticized PVC/olive husk. Int. J. Polym. Mater. 2010, 59, 843–853. [Google Scholar] [CrossRef]

- Gozdecki, C.; Wilczyński, A.; Kociszewski, M.; Zajchowski, S. Properties of wood–plastic composites made of milled particleboard and polypropylene. Eur. J. Wood Wood Prod. 2015, 73, 87–95. [Google Scholar] [CrossRef] [Green Version]

- Gozdecki, C.; Wilczyński, A.; Kociszewski, M.; Tomaszewska, J.; Zajchowski, S. Mechanical properties of wood-polypropylene composites with industrial wood particles of different sizes. Wood Fiber Sci. 2012, 44, 14–21. [Google Scholar]

- Rahman, M.R.; Islam, M.N.; Huque, M.M.; Hamdan, S.; Ahmed, A.S. Effect of chemical treatment on rice husk (RH) reinforced polyethylene (PE) composites. BioResources 2010, 5, 854–869. [Google Scholar]

- Guo, R.; Azaiez, J.; Bellehumeur, C. Rheology of fiber filled polymer melts: Role of fiber-fiber interactions and polymer-fiber coupling. Polym. Eng. Sci. 2005, 45, 385–399. [Google Scholar] [CrossRef]

- Rueda, M.M.; Auscher, M.C.; Fulchiron, R.; Périé, T.; Martin, G.; Sonntag, P.; Cassagnau, P. Rheology and applications of highly filled polymers: A review of current understanding. Prog. Polym. Sci. 2017, 66, 22–53. [Google Scholar] [CrossRef]

- Naghmouchi, I.; Espinach, F.X.; Mutjé, P.; Boufi, S. Polypropylene composites based on lignocellulosic fillers: How the filler morphology affects the composite properties. Mater. Des. 2015, 65, 454–461. [Google Scholar] [CrossRef]

- Naghmouchi, I.; Mutjé, P.; Boufi, S. Olive stones flour as reinforcement in polypropylene composites: A step forward in the valorization of the solid waste from the olive oil industry. Ind. Crops Prod. 2014, 72, 183–191. [Google Scholar] [CrossRef]

- Gozdecki, C.; Wilczyński, A. Effect of wood flour type on tensile properties of wood-polymer composites. Ann. Warsaw Univ. Life Sci. SGGW. For. Wood Technol. 2015, 91, 65–69. [Google Scholar]

- Gwon, J.G.; Lee, S.Y.; Chun, S.J.; Doh, G.H.; Kim, J.H. Effects of chemical treatments of hybrid fillers on the physical and thermal properties of wood plastic composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1491–1497. [Google Scholar] [CrossRef]

- Frącz, W.; Janowski, G. Analysis of fiber orientation in the wood-polymer composites (WPC) on selected examples. Adv. Sci. Technol. Res. J. 2017, 11, 122–129. [Google Scholar] [CrossRef]

- Ahmed, A.K.; Atiqullah, M.; Pradhan, D.R.; Al-Harthi, M.A. Crystallization and melting behavior of i-PP: A perspective from Flory’s thermodynamic equilibrium theory and DSC experiment. RSC Adv. 2017, 7, 42491–42504. [Google Scholar] [CrossRef] [Green Version]

- Ndiaye, D.; Matuana, L.M.; Morlat-Therias, S.; Vidal, L.; Tidjani, A.; Gardette, J.-L. Thermal and mechanical properties of polypropylene/wood-flour composites. J. Appl. Polym. Sci. 2011, 119, 3321–3328. [Google Scholar] [CrossRef]

- Zemnukhova, L.A.; Shkorina, E.D.; Fedorishcheva, G.A. Composition of inorganic components of buckwheat husk and straw. Russ. J. Appl. Chem. 2005, 78, 324–328. [Google Scholar] [CrossRef]

- Zemnukhova, L.A.; Kolzunova, L.G.; Shkorina, E.D. Extractive substances formed from buckwheat grain production waste. Russ. J. Appl. Chem. 2007, 80, 1007–1011. [Google Scholar] [CrossRef]

- Joffre, T.; Miettinen, A.; Wernersson, E.L.G.; Isaksson, P.; Gamstedt, E.K. Effects of defects on the tensile strength of short-fibre composite materials. Mech. Mater. 2014, 75, 125–134. [Google Scholar] [CrossRef] [Green Version]

- Keskin, H.; Kucuktuvek, M.; Guru, M. The potential of poppy (Papaver somniferum Linnaeus) husk for manufacturing wood-based particleboards. Constr. Build. Mater. 2015, 95, 224–231. [Google Scholar] [CrossRef]

- Doan, T.T.L.; Brodowsky, H.M.; Mäder, E. Polyolefine composites reinforced by rice husk and saw dust. In Composites from Renewable and Sustainable Materials; InTech: London, UK, 2016; pp. 1–24. [Google Scholar]

- Weng, W.; Costa, M.; Aldén, M.; Li, Z. Single particle ignition and combustion of pulverized pine wood, wheat straw, rice husk and grape pomace. Proc. Combust. Inst. 2018, 37, 1–9. [Google Scholar] [CrossRef]

- Malchev, P.G.; Norder, B.; Picken, S.J.; Gotsis, A.D. The strain dependence of the dynamic moduli of short fiber reinforced thermoplastic blends. J. Rheol. 2007, 51, 235. [Google Scholar] [CrossRef]

- Sykacek, E.; Hrabalova, M.; Frech, H.; Mundigler, N. Extrusion of five biopolymers reinforced with increasing wood flour concentration on a production machine, injection moulding and mechanical performance. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1272–1282. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J.; Santana, R.M.C. Structural differences between wood species: Evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. J. Appl. Polym. Sci. 2012, 126, E337–E344. [Google Scholar] [CrossRef]

| Sample | Matrix [wt %] | Filler [wt %] | Density * [g/cm3] | Void Content ** [%] | ||

|---|---|---|---|---|---|---|

| iPP | PP-g-MA | Buckwheat Husk (BH) | Wood Flour(WF) | |||

| Unmodified Samples | ||||||

| PP | 100 | - | - | - | 0.895 | - |

| PP/WF10 | 90 | - | - | 10 | 0.919 | 1.37 |

| PP/WF30 | 70 | - | - | 30 | 0.987 | 2.61 |

| PP/WF50 | 50 | - | - | 50 | 1.075 | 3.36 |

| PP/BH10 | 90 | - | 10 | - | 0.918 | 1.36 |

| PP/BH30 | 70 | - | 30 | - | 0.969 | 4.50 |

| PP/BH50 | 50 | - | 50 | - | 1.035 | 6.98 |

| Maleic Anhydride Modified Composites (PP/PP-g-MA = 95%/5%) | ||||||

| PP/WF10(MA) | 85.5 | 4.5 | - | 10 | 0.916 | 1.47 |

| PP/WF30(MA) | 66.5 | 3.5 | - | 30 | 0.984 | 2.24 |

| PP/WF50(MA) | 47.5 | 2.5 | - | 50 | 1.062 | 3.27 |

| PP/BH10(MA) | 85.5 | 4.5 | 10 | - | 0.921 | 0.88 |

| PP/BH30(MA) | 66.5 | 3.5 | 30 | - | 0.976 | 3.02 |

| PP/BH50(MA) | 47.5 | 2.5 | 50 | - | 1.094 | 0.45 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrzejewski, J.; Barczewski, M.; Szostak, M. Injection Molding of Highly Filled Polypropylene-based Biocomposites. Buckwheat Husk and Wood Flour Filler: A Comparison of Agricultural and Wood Industry Waste Utilization. Polymers 2019, 11, 1881. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11111881

Andrzejewski J, Barczewski M, Szostak M. Injection Molding of Highly Filled Polypropylene-based Biocomposites. Buckwheat Husk and Wood Flour Filler: A Comparison of Agricultural and Wood Industry Waste Utilization. Polymers. 2019; 11(11):1881. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11111881

Chicago/Turabian StyleAndrzejewski, Jacek, Mateusz Barczewski, and Marek Szostak. 2019. "Injection Molding of Highly Filled Polypropylene-based Biocomposites. Buckwheat Husk and Wood Flour Filler: A Comparison of Agricultural and Wood Industry Waste Utilization" Polymers 11, no. 11: 1881. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11111881