Electrodeposited Gold Nanostructures for the Enhancement of Electrochromic Properties of PANI–PEDOT Film Deposited on Transparent Electrode

Abstract

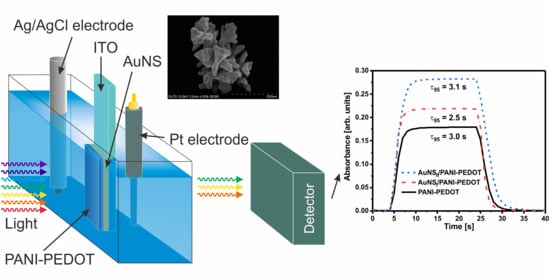

:1. Introduction

2. Experimental

2.1. Materials and Methods

2.2. Pre-Treatment of ITO Electrode

2.3. Electrodeposition of Gold Nanostructures

2.4. Preparation of Polymer Films

2.5. Characterization of AuNS and PANI-PEDOT Films

2.6. Electrochromic Switching

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Spychalska, K.; Zajac, D.; Baluta, S.; Halicka, K.; Cabaj, J. Functional polymers structures for (Bio)sensing application—A review. Polymers 2020, 12, 1154. [Google Scholar] [CrossRef] [PubMed]

- Deshmukh, M.A.; Gicevicius, M.; Ramanaviciene, A.; Shirsat, M.D.; Viter, R.; Ramanavicius, A. Hybrid electrochemical/electrochromic Cu(II) ion sensor prototype based on PANI/ITO-electrode. Sens. Actuators B Chem. 2017, 248, 527–535. [Google Scholar] [CrossRef]

- Popov, A.; Brasiunas, B.; Mikoliunaite, L.; Bagdziunas, G.; Ramanavicius, A.; Ramanaviciene, A. Comparative study of polyaniline (PANI), poly(3,4-ethylenedioxythiophene) (PEDOT) and PANI-PEDOT films electrochemically deposited on transparent indium thin oxide based electrodes. Polymer 2019, 172, 133–141. [Google Scholar] [CrossRef]

- Mantione, D.; del Agua, I.; Sanchez-Sanchez, A.; Mecerreyes, D. Poly(3,4-ethylenedioxythiophene) (PEDOT) derivatives: Innovative conductive polymers for bioelectronics. Polymers 2017, 9, 354. [Google Scholar] [CrossRef]

- Le, T.-H.; Kim, Y.; Yoon, H. Electrical and electrochemical properties of conducting polymers. Polymers 2017, 9, 150. [Google Scholar] [CrossRef]

- Celiesiute, R.; Ramanaviciene, A.; Gicevicius, M.; Ramanavicius, A. Electrochromic sensors based on conducting polymers, metal oxides, and coordination complexes. Crit. Rev. Anal. Chem. 2019, 49, 195–208. [Google Scholar] [CrossRef]

- Wang, H.; Yao, C.-J.; Nie, H.-J.; Yang, L.; Mei, S.; Zhang, Q. Recent progress in integrated functional electrochromic energy storage devices. J. Mater. Chem. C 2020. [Google Scholar] [CrossRef]

- Kraft, A. Electrochromism: A fascinating branch of electrochemistry. ChemTexts 2019, 5, 1. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, Y.; Tang, K.; Song, Y.; Cui, J.; Shu, X.; Wang, Y.; Liu, J.; Wu, Y. In situ growth of PEDOT/graphene oxide nanostructures with enhanced electrochromic performance. RSC Adv. 2018, 8, 13679–13685. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.; Chen, L.; Liu, S.; Sun, C.; Hu, X.; Zhou, S. MoO3@PEDOT coaxial heterostructure nanobelts by in situ polymerization with enhanced electrochromic performance. Mater. Res. Express 2019, 6, 1150h8. [Google Scholar] [CrossRef]

- Li, J.; Levitt, A.; Kurra, N.; Juan, K.; Noriega, N.; Xiao, X.; Wang, X.; Wang, H.; Alshareef, H.N.; Gogotsi, Y. MXene-conducting polymer electrochromic microsupercapacitors. Energy Storage Mater. 2019, 20, 455–461. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, L.; Xu, Y.; Qiu, T.; Zhi, L.; Shi, G. Polyaniline electrochromic devices with transparent graphene electrodes. Electrochim. Acta 2009, 55, 491–497. [Google Scholar] [CrossRef]

- Pacios, R.; Marcilla, R.; Pozo-Gonzalo, C.; Pomposo, J.A.; Grande, H.; Aizpurua, J.; Mecerreyes, D. Combined electrochromic and plasmonic optical responses in conducting polymer/metal nanoparticle films. J. Nanosci. Nanotechnol. 2007, 7, 2938–2941. [Google Scholar] [CrossRef] [PubMed]

- Mikoliunaite, L.; Kubiliute, R.; Popov, A.; Voronovič, J.; Šakirzanovas, S.; Ramanavičiene, A.; Ramanavičius, A. Development of gold nanoparticle-polypyrrole nanocomposites. Chemija 2014, 25, 63–69. [Google Scholar]

- Loguercio, L.F.; Alves, C.C.; Thesing, A.; Ferreira, J. Enhanced electrochromic properties of a polypyrrole-indigo carmine-gold nanoparticles nanocomposite. Phys. Chem. Chem. Phys. 2015, 17, 1234–1240. [Google Scholar] [CrossRef]

- Mumtaz, M.; Ouvrard, B.; Maillaud, L.; Labrugere, C.; Cloutet, E.; Cramail, H.; Delville, M.-H. Hybrid PEDOT-metal nanoparticles—New substitutes for PEDOT:PSS in electrochromic layers—Towards improved performance. Eur. J. Inorg. Chem. 2012, 2012, 5360–5370. [Google Scholar] [CrossRef]

- Xiong, S.; Lan, J.; Yin, S.; Wang, Y.; Kong, Z.; Gong, M.; Wu, B.; Chu, J.; Wang, X.; Zhang, R.; et al. Enhancing the electrochromic properties of polyaniline via coordinate bond tethering the polyaniline with gold colloids. Sol. Energy Mater. Sol. Cells 2018, 177, 134–141. [Google Scholar] [CrossRef]

- König, T.A.F.; Ledin, P.A.; Kerszulis, J.; Mahmoud, M.A.; El-Sayed, M.A.; Reynolds, J.R.; Tsukruk, V.V. Electrically tunable plasmonic behavior of nanocube-polymer nanomaterials induced by a redox-active electrochromic polymer. ACS Nano 2014, 8, 6182–6192. [Google Scholar] [CrossRef]

- Ledin, P.A.; Jeon, J.W.; Geldmeier, J.A.; Ponder, J.F.; Mahmoud, M.A.; El-Sayed, M.; Reynolds, J.R.; Tsukruk, V.V. Design of hybrid electrochromic materials with large electrical modulation of plasmonic resonances. ACS Appl. Mater. Interfaces 2016, 8, 13064–13075. [Google Scholar] [CrossRef]

- Shahabuddin, M.; McDowell, T.; Bonner, C.E.; Noginova, N. Enhancement of electrochromic polymer switching in plasmonic nanostructured environment. ACS Appl. Nano Mater. 2019, 2, 1713–1719. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, S.; Zhou, J.; Ponder, J.F.; Smith, M.J.; Reynolds, J.R.; Tsukruk, V.V. Heterogeneous forward and backward scattering modulation by polymer-infused plasmonic nanohole arrays. J. Mater. Chem. C 2019, 7, 3090–3099. [Google Scholar] [CrossRef]

- Xu, T.; Walter, E.C.; Agrawal, A.; Bohn, C.; Velmurugan, J.; Zhu, W.; Lezec, H.J.; Talin, A.A. High-contrast and fast electrochromic switching enabled by plasmonics. Nat. Commun. 2016, 7, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Niu, M.; Wen, Z.; Hao, X. Recent advances of plasmonic organic solar cells: Photophysical investigations. Polymers 2018, 10, 123. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Terao, K.; Kakita, C.; Nagase, N.; Miyanishi, N.; Suzuki, T.; Takao, H.; Shimokawa, F.; Oohira, F. Evaluation of electrodeposited gold nanostructures for applications in QCM sensing. Anal. Sci. 2012, 28, 291–294. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Shi, G. Electrochemical growth of two-dimensional gold nanostructures on a thin polypyrrole film modified ITO electrode. J. Phys. Chem. B 2005, 109, 23787–23793. [Google Scholar] [CrossRef] [PubMed]

- Yu, F.; Liu, W.; Ke, S.-W.; Kurmoo, M.; Zuo, J.-L.; Zhang, Q. Electrochromic two-dimensional covalent organic framework with a reversible dark-to-transparent switch. Nat. Commun. 2020, 11, 5534. [Google Scholar] [CrossRef]

- Nikolaev, K.; Ermakov, S.; Ermolenko, Y.; Averyaskina, E.; Offenhäusser, A.; Mourzina, Y. A novel bioelectrochemical interface based on in situ synthesis of gold nanostructures on electrode surfaces and surface activation by Meerwein’s salt. A bioelectrochemical sensor for glucose determination. Bioelectrochemistry 2015, 105, 34–43. [Google Scholar] [CrossRef]

- Trasatti, S.; Petrii, O.A. Real surface area measurements in electrochemistry. J. Electroanal. Chem. 1992, 327, 353–376. [Google Scholar] [CrossRef]

- Stojkoski, V.; Kert, M. Design of pH responsive textile as a sensor material for acid rain. Polymers 2020, 12, 2251. [Google Scholar] [CrossRef]

- Shu, H.; Cao, L.; Chang, G.; He, H.; Zhang, Y.; He, Y. Direct electrodeposition of gold nanostructures onto glassy carbon electrodes for non-enzymatic detection of glucose. Electrochim. Acta 2014, 132, 524–532. [Google Scholar] [CrossRef]

- Tran, M.; Mundt, C.; Lan, T.; Padalkar, S. Electrodeposition of gold nanostructures having controlled morphology. J. Nanosci. Nanotechnol. 2017, 18, 3492–3498. [Google Scholar] [CrossRef] [PubMed]

- Oesch, U.; Janata, J. Electrochemical study of gold electrodes with anodic oxide films-I. Formation and reduction behaviour of anodic oxides on gold. Electrochim. Acta 1983, 28, 1237–1246. [Google Scholar] [CrossRef]

- Plowman, B.J.; O’Mullane, A.P.; Bhargava, S.K. The active site behaviour of electrochemically synthesised gold nanomaterials. Faraday Discuss. 2011, 152, 43–62. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hamelin, A. Cyclic voltammetry at gold single-crystal surfaces. Part 1. Behaviour at low-index faces. J. Electroanal. Chem. 1996, 407, 1–11. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, H.; Zhao, G.; Tatsuma, T. Shape-controlled electrodeposition of gold nanostructures. J. Phys. Chem. B 2006, 110, 23478–23481. [Google Scholar] [CrossRef] [PubMed]

- Millstone, J.E.; Park, S.; Shuford, K.L.; Qin, L.; Schatz, G.C.; Mirkin, C.A. Observation of a quadrupole plasmon mode for a colloidal solution of gold nanoprisms. J. Am. Chem. Soc. 2005, 127, 5312–5313. [Google Scholar] [CrossRef]

- Sajanlal, P.R.; Pradeep, T. Growth of anisotropic gold nanostructures on conducting glass surfaces. J. Chem. Sci. 2008, 120, 79–85. [Google Scholar] [CrossRef] [Green Version]

- Goy-López, S.; Castro, E.; Taboada, P.; Mosquera, V. Block copolymer-mediated synthesis of size-tunable gold nanospheres and nanoplates. Langmuir 2008, 24, 13186–13196. [Google Scholar] [CrossRef]

- Yu, K.; Kelly, K.L.; Sakai, N.; Tatsuma, T. Morphologies and surface plasmon resonance properties of monodisperse bumpy gold nanoparticles. Langmuir 2008, 24, 5849–5854. [Google Scholar] [CrossRef]

- Yu, Y.Y.; Chang, S.S.; Lee, C.L.; Wang, C.R.C. Gold nanorods: Electrochemical synthesis and optical properties. J. Phys. Chem. B 1997, 101, 6661–6664. [Google Scholar] [CrossRef]

- Wang, H.; Goodrich, G.P.; Tam, F.; Oubre, C.; Nordlander, P.; Halas, N.J. Controlled texturing modifies the surface topography and plasmonic properties of Au nanoshells. J. Phys. Chem. B 2005, 109, 11083–11087. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Liu, Z.; Du, X.; Ringer, S.P. Electrodeposited PEDOT films on ITO with a flower-like hierarchical structure. Synth. Met. 2010, 160, 1636–1641. [Google Scholar] [CrossRef]

- Mirmohseni, A.; Wallace, G. Preparation and characterization of processable electroactive polyaniline–polyvinyl alcohol composite. Polymer 2003, 44, 3523–3528. [Google Scholar] [CrossRef]

- Chen, W.-C.; Wen, T.-C.; Gopalan, A. Negative capacitance for polyaniline: An analysis via electrochemical impedance spectroscopy. Synth. Met. 2002, 128, 179–189. [Google Scholar] [CrossRef]

- Sakmeche, N.; Aeiyach, S.; Aaron, J.-J.; Jouini, M.; Lacroix, J.C.; Lacaze, P.-C. Improvement of the electrosynthesis and physicochemical properties of poly(3,4-ethylenedioxythiophene) using a sodium dodecyl sulfate micellar aqueous medium. Langmuir 1999, 15, 2566–2574. [Google Scholar] [CrossRef]

- Yue, H.; Kong, L.; Wang, B.; Yuan, Q.; Zhang, Y.; Du, H.; Dong, Y.; Zhao, J. Synthesis and characterization of novel D-A type neutral blue electrochromic polymers containing pyrrole[3-c]pyrrole-1,4-diketone as the acceptor units and the aromatics donor units with different planar structures. Polymers 2019, 11, 2023. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Runnerstrom, E.L.; Llordés, A.; Lounis, S.D.; Milliron, D.J. Nanostructured electrochromic smart windows: Traditional materials and NIR-selective plasmonic nanocrystals. Chem. Commun. 2014, 50, 10555–10572. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Pluchery, O.; Caillard, L.; Lamic-Humblot, A.F.; Casale, S.; Chabal, Y.J.; Salmeron, M. Sensing the charge state of single gold nanoparticles via work function measurements. Nano Lett. 2015, 15, 51–55. [Google Scholar] [CrossRef]

- Pluchery, O.; Zhang, Y.; Benbalagh, R.; Caillard, L.; Gallet, J.J.; Bournel, F.; Lamic-Humblot, A.F.; Salmeron, M.; Chabal, Y.J.; Rochet, F. Static and dynamic electronic characterization of organic monolayers grafted on a silicon surface. Phys. Chem. Chem. Phys. 2016, 18, 3675–3684. [Google Scholar] [CrossRef] [Green Version]

- Park, Y.; Choong, V.; Gao, Y.; Hsieh, B.R.; Tang, C.W. Work function of indium tin oxide transparent conductor measured by photoelectron spectroscopy. Appl. Phys. Lett. 1996, 68, 2699–2701. [Google Scholar] [CrossRef]

- Abdulrazzaq, O.; Bourdo, S.E.; Saini, V.; Watanabe, F.; Barnes, B.; Ghosh, A.; Biris, A.S. Tuning the work function of polyaniline via camphorsulfonic acid: An X-ray photoelectron spectroscopy investigation. RSC Adv. 2015, 5, 33–40. [Google Scholar] [CrossRef]

- Nardes, A.M.; Kemerink, M.; de Kok, M.M.; Vinken, E.; Maturova, K.; Janssen, R.A.J. Conductivity, work function, and environmental stability of PEDOT:PSS thin films treated with sorbitol. Org. Electron. 2008, 9, 727–734. [Google Scholar] [CrossRef]

- Abdellatif, M.H.; Ghosh, S.; Liakos, I.; Scarpellini, A.; Marras, S.; Diaspro, A.; Salerno, M. Effect of nanoscale size and medium on metal work function in oleylamine-capped gold nanocrystals. J. Phys. Chem. Solids 2016, 89, 7–14. [Google Scholar] [CrossRef]

- Roduner, E. Size matters: Why nanomaterials are different. Chem. Soc. Rev. 2006, 35, 583–592. [Google Scholar] [CrossRef]

| Substrate | N | Q [mC cm−2] | Tc/Tb [%] | ΔT [%] | CE [cm2 C−1] |

|---|---|---|---|---|---|

| ITO | 1 | 5.6 | 29.4/20.7 | 8.7 | 21.7 |

| 150 | 2.3 | 28.6/26.0 | 2.6 | 14.3 | |

| ITO/AuNSI | 1 | 4.8 | 24.9/15.9 | 9.0 | 32.8 |

| 150 | 2.5 | 25.1/21.0 | 4.1 | 24.5 | |

| ITO/AuNSII | 1 | 10.0 | 23.8/13.2 | 10.6 | 20.5 |

| 150 | 3.8 | 23.5/18.8 | 4.7 | 14.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popov, A.; Brasiunas, B.; Damaskaite, A.; Plikusiene, I.; Ramanavicius, A.; Ramanaviciene, A. Electrodeposited Gold Nanostructures for the Enhancement of Electrochromic Properties of PANI–PEDOT Film Deposited on Transparent Electrode. Polymers 2020, 12, 2778. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12122778

Popov A, Brasiunas B, Damaskaite A, Plikusiene I, Ramanavicius A, Ramanaviciene A. Electrodeposited Gold Nanostructures for the Enhancement of Electrochromic Properties of PANI–PEDOT Film Deposited on Transparent Electrode. Polymers. 2020; 12(12):2778. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12122778

Chicago/Turabian StylePopov, Anton, Benediktas Brasiunas, Anzelika Damaskaite, Ieva Plikusiene, Arunas Ramanavicius, and Almira Ramanaviciene. 2020. "Electrodeposited Gold Nanostructures for the Enhancement of Electrochromic Properties of PANI–PEDOT Film Deposited on Transparent Electrode" Polymers 12, no. 12: 2778. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12122778