1. Introduction

Although cellular materials have been used in different engineering applications over the years [

1], additive manufacturing (AM) opens up new opportunities for their design and development. While in conventional cellular materials cell size can only be partially controlled, AM offers control over cell size and shape, shape and size of struts, topology of the structure, and many other features [

2]. These features provide new opportunities for the design and fabrication of biomedical devices, such as tissue scaffolds [

3,

4,

5,

6], artificial high porosity structures with complex geometries designed to support tissue growth, for instance bone [

3,

7]. AM lattices could be used for that purpose, but there is a need for characterizing their accuracy and mechanical performance to fully assess their suitability for the manufacturing of scaffolds [

3]. Extensive mechanical experiments and modeling are necessary due to the unique behaviors of the different designs [

8].

Recently, special attention has been given to the development of design and optimization methods for lattice structures [

9,

10,

11,

12,

13], most of them based on analytical or numerical methods. However, while analytical and numerical models of lattice structures could be used to assess their mechanical behavior, they usually do not consider local geometrical irregularities, an unavoidable consequence of the manufacturing process [

14]. Furthermore, it does not provide information regarding the manufacturability of lattice structures via additive manufacturing. The quality of the lattice structure, including dimensional accuracy, surface quality, residual stresses, microstructure, and overall variability does influence its performance [

14,

15].

Lattices are also considered an excellent alternative for producing lightweight, strong parts using AM [

16]. There has been some interest in assessing the capabilities and limits of AM for printing lattice structures, i.e., cellular materials, although in a non-methodical fashion. Mueller et al. [

17] identified some restrictions of the laser sintering process, similar to those reported for general AM: overhangs should not exceed 45° and only open cell structures are possible, so the non-molten metal powder could be removed. However, limitations such as the minimum cell size, thickness of walls/struts, or cell geometry were not evaluated.

Zhou [

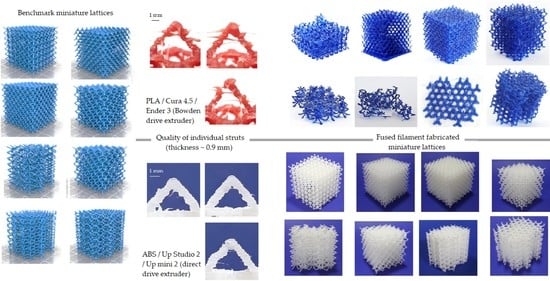

18] reported on the manufacturability of selected miniature lattice structures using different technologies that included fused filament fabrication (FFF), selective laser sintering (SLS), stereolithography (SLA) and direct light processing (DLP), evidencing that FFF does not have an adequate resolution to print microstructures, in opposition to SLS and DLP printers. In FFF, broken struts and uneven thickness were evident. Minimal strut thickness ranged from 0.2 in SL and DLP to 2 mm in FFF. The periodic lattice structures were modeled using the software nTopology (nTopology Inc., New York, USA). Neither dimensions nor geometric features of the tested lattices were reported, although the STL files of the models are available online [

19].

FFF could seem inadequate when compared to stereolithography and selective laser sintering technologies for the production of 3D miniature lattice structures, as the process has limited accuracy, manufacturing of overhangs require support for struts above a certain threshold of length/angle, and the removal of supports could be cumbersome. However, the feedstock is safer and easier to handle, and does not require additional post-processing. Furthermore, in special cases, such as in zero gravity manufacturing, FFF is a proven technology [

20]. Given the shortcomings of FFF and the availability of alternate AM methods, just a small number of experimental studies have been carried out using FFF.

Other researchers have reported the manufacturing of miniature polymer lattice structures, but information regarding manufacturability or manufacturing restrictions has been sparse. Al Rifaie et al. [

21] studied the compression behavior of 3D printed polymer lattice structures. Four variants of the cubic cell (cell size 5 mm and strut thickness 1 mm) were manufactured and tested. Support material was used in some cases, depending on complexity, which was removed in post-processing using a heated chemical bath. Karamooz Ravari et al. [

22] fabricated and tested the mechanical properties of a polymer lattice structure. The unit cell was a body-centered cube, with a nominal diameter of struts of 1.5 mm. Some benchmarks were carried out to assess the capabilities of the available AM machine, but results were not reported. More recently, Rossiter et al. [

23] evaluated the compressive behavior of truncated octahedron lattice structure (cell size 12–16 mm) manufactured using nylon through the process of FFF. Gautam et al. [

24] evaluated the compressive performance of Kagome truss unit cells of acrylonitrile butadiene styrene (ABS) of 35 mm height fabricated by FFF, considering the effect of build orientation and surface quality on its compressive response and energy absorption capacity. Habib et al. [

25] compared the performance of octagonal lattices (cell size 10 mm) built by multi-jet fusion (MJF) and FFF, reporting that the MJF fabricated samples had better properties than the FFF samples. Manufacturing of polymer lattice structures by other AM methods has also been reported, including stereolithography [

26,

27], multi-jet fusion [

28], and laser sintering [

29,

30], but little information is reported regarding manufacturability. Stereolithography and LS are capable of producing small features (strut/wall thickness 0.4–0.6 mm) while values reported for multi-jet fusion are larger (cell size 10 mm; strut diameter > 1.13 mm). Cell forms were limited, and overhang angles were constrained.

An extended summary of research carried out, such as experimental tests and numerical modeling of lattice structures fabricated by AM processes was presented by Dong et al. [

25]. Nevertheless, information regarding the capability of FFF to produce miniature cellular structures—or the influence of printing parameters on their quality—is still unresolved. Hence, the limits of the FFF process for building miniature lattice structures of polymeric materials must be explored. The greatest challenge is achieving the quality of the lattice structure, which includes dimensional accuracy, surface quality, residual stresses, material microstructure, trace impurities, and hence variability in material and structural performance.

Previous research has explored the overall capabilities and limitations of various AM methods to produce typical geometrical features. Stratasys [

31], offers general design guidelines for material extrusion 3D printing, addressing some limitations such as minimum wall thickness and hole size, as well as the effect of contraction on accuracy.

Adam and Zimmer [

32] tested the capabilities of FFF by defining standard features that included elementary geometrical shapes (e.g., cylinders), joints of basic elements, and arrangements of many basic elements, which led to the formulation of general design rules developed for selective laser sintering (SLS), laser melting and FFF.

Schäfer [

33] analyzed the restrictions of FFF, which included minimum radii of curvature, wall thickness, hole size, and maximum overhang, among others. Additionally, the influence of layer thickness and printing orientation on precision and surface quality were described. Schäfer proposed FFF design guidelines that considered the restrictions of the process. Considering the typical features of lattice structures, the most relevant guidelines are summarized in

Table 1. Although these guidelines were proposed considering the design of large parts, whether they are also applicable to miniature lattice structures is still unclear.

In the present work, we explore the manufacturing of 3D miniature polymer lattice structures using fused filament fabrication, specifically for lattices with cell size and strut diameter close to the smallest dimension possible.

5. Conclusions

Miniature 3D open cell lattice structures could be manufactured by FFF without using support material, using complex unit cell geometries not limited to the classic cubic-type cell arrangements. The 3D printed miniature lattice structures were capable of supporting compressive loads, even when overall quality and accuracy were not optimal. While thickness and orientation of the struts were identified as important parameters to assess the manufacturability of miniature lattice structures, hardware setup is considered a critical factor.

In conventional Bowden extruder printers, general design guidelines should be observed: strut diameter should not be smaller than 1 mm, and there are limits of length for both vertical and inclined struts depending on overhang angle: the steeper the angle, the shorter the strut. In vertical struts, the length-to-diameter ratio should not exceed the recommended value. On the other hand, although manufacturing restrictions could be circumvented using a direct drive extruder, there are hard limits to the FFF process.

Further research is required to characterize the properties of the eight lattices and the influence of geometric parameters on their mechanical behavior. There is potential for the development of cellular metals based on polymer lattice structures, as the printed structures could be used as patterns for investment casting or electro-deposition techniques [

49,

50]; FFF could also directly produce cellular metals through the material extrusion additive manufacturing (FFF), debinding, and sintering route [

51]. Even if printing errors cannot be completely avoided when 3D printing lattice structures, the process could offer some advantages when compared to other available methods.

The validity of the results could be expanded to other feedstock materials, such as polycarbonate and possibly polyetheretherketone (PEEK). PEEK, a semi-crystalline thermoplastic with excellent biocompatibility and mechanical properties that could be printed using FFF processes [

52,

53,

54], could be of special interest, as it would enable its use in applications such as orthopedic implants.

Further study of the hardware setup of printers, for instance, the type of extruder (direct vs. Bowden) or the use of smaller nozzle diameters (0.2 mm) when printing miniature geometric features is recommended, as the literature dealing with both topics is scarce.

Finally, accuracy assessments of the printed lattices—although not widely available—could be used in the future to compare the performance of different AM processes. For instance, 3D tomography could be used to reconstruct the geometry of printed lattice and generate a digital image of the real structure, which can be compared with the original STL model [

14,

55].