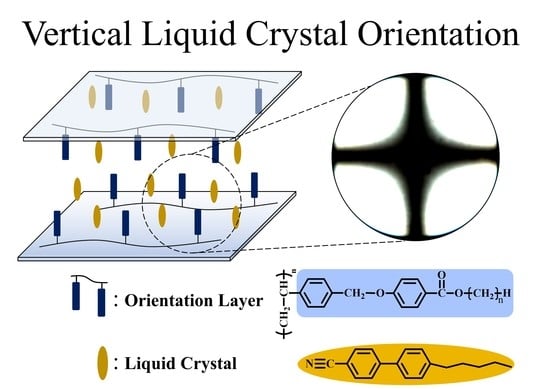

Vertical Orientation of Liquid Crystal on Polystyrene Substituted with n-Alkylbenzoate-p-oxymethyl Pendant Group as a Liquid Crystal Precursor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of n-alkylbenzoate-p-oxymethyl Modified Polystyrene

2.3. Film Preparation and LC Cell Assembly

2.4. Instrumentation

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Demus, D.; Goodby, J.; Gray, G.W.; Spiess, H.-W.; Vill, V. Handbook of Liquid Crystals, 1st ed.; Wiley-VCH: Weinheim, Germany, 1998; pp. 44–63. [Google Scholar]

- Yoon, D.K.; Deb, R.; Chen, D.; Körblova, E.; Shao, R.; Ishikawa, K.; Rao, N.V.S.; Walba, D.M.; Smalyukh, I.I.; Clark, N.A. Organization of the polarization splay modulated smectic liquid crystal phase by topographic confinement. Proc. Natl. Acad. Sci. USA 2010, 107, 21311–21315. [Google Scholar] [CrossRef] [Green Version]

- Cha, Y.J.; Gim, M.-J.; Ahn, H.; Shin, T.J.; Jeong, J.; Yoon, D.K. Orthogonal Liquid Crystal Alignment Layer: Templating Speed-Dependent Orientation of Chromonic Liquid Crystals. ACS Appl. Mater. Interfaces 2017, 9, 18355–18361. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, Y.H.; Jeong, H.S.; Srinivasarao, M.; Hudson, S.D.; Jung, H.-T. Thermally responsive microlens arrays fabricated with the use of defect arrays in a smectic liquid crystal. RSC Adv. 2012, 2, 6729–6732. [Google Scholar] [CrossRef]

- Scharf, T. Polarized Light in Liquid Crystals and Polymers; John Wiley & Sons: Hoboken, NJ, USA, 2006; pp. 103–141. [Google Scholar]

- Hamley, I.W. Introduction to Soft Matter: Polymers, Colloids, Amphiphiles, and Liquid Crystals, 1st ed.; John Wiley & Sons: West Sussex, UK, 2000; pp. 267–311. [Google Scholar]

- Khoo, C.H.; Simoni, F. Physics of Liquid Crystalline Materials, 1st ed.; Gordon & Breach Publishers: Philadelphia, PA, USA, 1991; pp. 3–29. [Google Scholar]

- de Gennes, P.G. The Physics of Liquid Crystals, 1st ed.; Oxford University Press: Oxford, UK, 1974; pp. 1–18, 23–50. [Google Scholar]

- Chandrasekhar, S. Liquid Crystals, 1st ed.; Cambridge University Press: Cambridge, UK, 2010; pp. 1–84. [Google Scholar]

- O’Neill, M.; Kelly, S.M. Photoinduced surface alignment for liquid crystal displays. J. Phys. D Appl. Phys. 2000, 33, R67–R84. [Google Scholar] [CrossRef]

- Chaudhari, P.; Lacey, J.; Doyle, J.; Galligan, E.; Lien, S.-C.A.; Callegari, A.; Hougham, G.; Lang, N.D.; Andry, P.S.; John, R.; et al. Atomic-beam alignment of inorganic materials for liquid-crystal displays. Nat. Cell Biol. 2001, 411, 56–59. [Google Scholar] [CrossRef] [PubMed]

- Ishihara, S.; Mizusaki, M. Alignment control technology of liquid crystal molecules. J. Soc. Inf. Disp. 2020, 28, 44–74. [Google Scholar] [CrossRef]

- Kawatsuki, N.; Matsuyoshi, K.; Hayashi, M.; Takatsuka, A.H.; Yamamoto, T. Photoreaction of Photo-cross-linkable Methacrylate Polymer Films Comprising 2-Cinnamoyloxyethoxybiphenyl Side Group by Linearly Polarized Ultraviolet Light and Liquid Crystal Alignment on the Resultant Films. Chem. Mater. 2000, 12, 1549–1555. [Google Scholar] [CrossRef]

- Rempel, T.D.; Gandy, R.F.; Wootton, A.J. Density fluctuation effects on electron cyclotron emission correlation measurements in optically gray plasmas. Rev. Sci. Instrum. 1994, 65, 2044–2048. [Google Scholar] [CrossRef]

- van Aerle, N.A.J.M.; Tol, A.J.W. Molecular Orientation in Rubbed Polyimide Alignment Layers Used for Liquid-Crystal Displays. Macromolecules 1994, 27, 6520–6526. [Google Scholar] [CrossRef]

- Park, H.-G.; Lee, J.-J.; Dong, K.-Y.; Oh, B.-Y.; Kim, Y.-H.; Jeong, H.-Y.; Ju, B.-K.; Seo, D.-S. Homeotropic alignment of liquid crystals on a nano-patterned polyimide surface using nanoimprint lithography. Soft Matter 2011, 7, 5610–5614. [Google Scholar] [CrossRef]

- Kang, D.-H.; Kim, S.-H.; Kim, B.-Y.; Kim, J.-Y.; Ok, C.-H.; Kim, Y.-H.; Han, J.-W.; Hwang, J.-Y.; Oh, B.-Y.; Han, J.-M.; et al. Liquid Crystal Alignment Effects for Nematic Liquid Crystal on Homeotropic Polyimide Surface Using New Ion-Beam Source. Jpn. J. Appl. Phys. 2007, 46, 6601–6603. [Google Scholar] [CrossRef]

- Chae, B.; Lee, S.W.; Ree, M.; Jung, A.Y.M.; Kim, S.B. Photoreaction and Molecular Reorientation in a Nanoscaled Film of Poly(methyl 4-(methacryloyloxy)cinnamate) Studied by Two-Dimensional FTIR and UV Correlation Spectroscopy. Langmuir 2003, 19, 687–695. [Google Scholar] [CrossRef]

- Kim, J.B.; Kim, K.C.; Ahn, H.J.; Hwang, B.H.; Hyun, D.C.; Baik, H.K. Variable liquid crystal pretilt angles on various compositions of alignment layers. Appl. Phys. Lett. 2007, 90, 43515. [Google Scholar] [CrossRef]

- Ishihara, S.; Wakemoto, H.; Nakazima, K.; Matsuo, Y. The effect of rubbed polymer films on the liquid crystal alignment. Liq. Cryst. 1989, 4, 669–675. [Google Scholar] [CrossRef]

- Stöhr, J.; Samant, M. Liquid crystal alignment by rubbed polymer surfaces: A microscopic bond orientation model. J. Electron Spectrosc. Relat. Phenom. 1999, 98–99, 189–207. [Google Scholar] [CrossRef]

- Ghosh, M.K.; Mittal, K.L. Polyimides: Fundamentals and Applications; Marcel Dekker: New York, NY, USA, 1996. [Google Scholar]

- Feller, M.B.; Chen, W.; Shen, Y.R. Investigation of surface-induced alignment of liquid-crystal molecules by optical second-harmonic generation. Phys. Rev. A 1991, 43, 6778–6792. [Google Scholar] [CrossRef] [PubMed]

- Weiss, K.; Wöll, C.; Böhm, E.; Fiebranz, B.; Forstmann, G.; Peng, B.; Scheumann, V.; Johannsmann, D. Molecular Orientation at Rubbed Polyimide Surfaces Determined with X-ray Absorption Spectroscopy: Relevance for Liquid Crystal Alignment. Macromolecules 1998, 31, 1930–1936. [Google Scholar] [CrossRef]

- Hahm, S.G.; Lee, T.J.; Chang, T.; Jung, J.C.; Zin, W.-C.; Ree, M. Unusual Alignment of Liquid Crystals on Rubbed Films of Polyimides with Fluorenyl Side Groups. Macromolecules 2006, 39, 5385–5392. [Google Scholar] [CrossRef]

- Lee, J.K.; Lee, S.J.; Jung, J.C.; Zin, W.-C.; Chang, T.; Ree, M. Synthesis, characterization and liquid crystal-aligning properties of new poly{3-[4-(n-alkyloxy)phenyloxy]pyromellitimide}s. Polym. Adv. Technol. 2006, 17, 444–452. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, H.Y.; Park, I.C.; Rho, B.G.; Park, J.S.; Park, H.S.; Lee, C.H. Rubbing-free, vertically aligned nematic liquid crystal display controlled by in-plane field. Appl. Phys. Lett. 1997, 71, 2851–2853. [Google Scholar] [CrossRef]

- Bechtold, I.; De Santo, M.P.; Bonvent, J.J.; Oliveira, E.A.; Barberi, R.; Rasing, T. Rubbing-induced charge domains observed by electrostatic force microscopy: Effect on liquid crystal alignment. Liq. Cryst. 2003, 30, 591–598. [Google Scholar] [CrossRef]

- Kim, J.-H.; Acharya, B.R.; Kumar, S.; Ha, K.R. A method for liquid crystal alignment using in situ ultraviolet exposure during imidization of polyimide. Appl. Phys. Lett. 1998, 73, 3372–3374. [Google Scholar] [CrossRef]

- Chigrinov, V.G.; Kozenkov, V.M.; Kwok, H. Photoalignment of Liquid Crystalline Materials: Physics and Applications, 1st ed.; John Wiley & Sons: West Sussex, UK, 2008; pp. 69–93, 101–131. [Google Scholar]

- Natansohn, A.; Rochon, P. Photoinduced Motions in Azo-Containing Polymers. Chem. Rev. 2002, 102, 4139–4176. [Google Scholar] [CrossRef]

- Seki, T.; Nagano, S.; Hara, M. Versatility of photoalignment techniques: From nematics to a wide range of functional materials. Polymer 2013, 54, 6053–6072. [Google Scholar] [CrossRef] [Green Version]

- Takatoh, K.; Hasegawa, M.; Koden, M.; Itoh, N.; Hasegawa, R.; Sakamoto, M. Alignment Technology and Applications of Liquid Crystal Devices; Taylor & Francis: New York, NY, USA, 2005; pp. 99–137. [Google Scholar]

- Okazaki, M.; Kawata, K.; Nishikawa, H.; Negoro, M. Polymerizable discoticnematic triphenylene derivatives and their application to an optically anisotropic film. Polym. Adv. Technol. 2000, 11, 398–403. [Google Scholar] [CrossRef]

- Bahadur, B. Liquid Crystal Displays. Mol. Cryst. Liq. Cryst. 1984, 109, 3–93. [Google Scholar] [CrossRef]

- Oh-E, M.; Kondo, K. Electro-optical characteristics and switching behavior of the in-plane switching mode. Appl. Phys. Lett. 1995, 67, 3895–3897. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, H.Y. Electro-optic characteristics and switching principle of a nematic liquid crystal cell controlled by fringe-field switching. Appl. Phys. Lett. 1998, 73, 2881–2883. [Google Scholar] [CrossRef]

- Takeda, A.; Kataoka, S.; Sasaki, T.; Chida, H.; Tsuda, H.; Ohmuro, K.; Sasabayashi, T.; Koike, Y.; Okamoto, K. 41.1: A Super-High Image Quality Multi-Domain Vertical Alignment LCD by New Rubbing-Less Technology. SID Symp. Dig. Tech. Pap. 1998, 29, 1077–1080. [Google Scholar] [CrossRef]

- Jeong, E.; Lim, Y.J.; Rhee, J.M.; Lee, S.H.; Lee, G.-D.; Park, K.H.; Choi, H.C. Viewing angle switching of vertical alignment liquid crystal displays by controlling birefringence of homogenously aligned liquid crystal layer. Appl. Phys. Lett. 2007, 90, 051116. [Google Scholar] [CrossRef]

- Lee, J.H.; Oh, K.; Kim, H.S.; Wu, S.-T. Novel Surface-Stabilized Vertical Alignment Mode for Fast-Response Liquid Crystal Display. J. Disp. Technol. 2012, 8, 296–298. [Google Scholar] [CrossRef]

- Kwok, H.-S.; Naemura, S.; Ong, H.L. Progress in Liquid Crystal Science and Technology; World Scientific: Hackensack, NJ, USA, 2012; pp. 293–319. [Google Scholar]

- Popov, P.; Mann, E.K.; Jákli, A. Thermotropic liquid crystal films for biosensors and beyond. J. Mater. Chem. B 2017, 5, 5061–5078. [Google Scholar] [CrossRef] [PubMed]

- Collings, P.J.; Goodby, J.W. Introduction to Liquid Crystals; CRC Press: Boca Raton, FL, USA, 2019; pp. 29–84. [Google Scholar]

- Ye, L.; Zhao, C.; Feng, Y.; Gu, B.; Cui, Y.; Lu, Y. Study on the Polarization of Random Lasers from Dye-Doped Nematic Liquid Crystals. Nanoscale Res. Lett. 2017, 12, 27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stöhr, J.; Samant, M.G.; Cossy-Favre, A.; Díaz, J.; Momoi, Y.; Odahara, A.S.; Nagata, T. Microscopic Origin of Liquid Crystal Alignment on Rubbed Polymer Surfaces. Macromolecules 1998, 31, 1942–1946. [Google Scholar] [CrossRef]

- Xia, C.; Zhou, D.; Su, Y.; Zhou, G.; Yao, L.; Sun, W.; Liu, Y. A liquid-crystal-based immunosensor for the detection of cardiac troponin I. Analyst 2020, 145, 4569–4575. [Google Scholar] [CrossRef] [PubMed]

- Sivaranjini, B.; Mangaiyarkarasi, R.; Ganesh, V.; Umadevi, S. Vertical Alignment of Liquid Crystals Over a Functionalized Flexible Substrate. Sci. Rep. 2018, 8, 8891. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.-S.; Jeng, S.-C. Liquid crystal alignment by polyhedral oligomeric silsesquioxane (POSS)–polyimide nanocomposites. Opt. Mater. 2013, 35, 1418–1421. [Google Scholar] [CrossRef]

- Creagh, L.T.; Kmetz, A.R. Mechanism of Surface Alignment in Nematic Liquid Crystals. Mol. Cryst. Liq. Cryst. 1973, 24, 59–68. [Google Scholar] [CrossRef]

- Hwang, S.-J.; Jeng, S.-C.; Yang, C.-Y.; Kuo, C.-W.; Liao, C.-C. Characteristics of nanoparticle-doped homeotropic liquid crystal devices. J. Phys. D: Appl. Phys. 2008, 42, 025102. [Google Scholar] [CrossRef]

- Liaw, D.-J.; Wang, K.-L.; Huang, Y.-C.; Lee, K.-R.; Lai, J.-Y.; Ha, C.-S. Advanced polyimide materials: Syntheses, physical properties and applications. Prog. Polym. Sci. 2012, 37, 907–974. [Google Scholar] [CrossRef]

- Wu, W.-Y.; Wang, C.-C.; Fuh, A.Y.-G. Controlling pre-tilt angles of liquid crystal using mixed polyimide alignment layer. Opt. Express 2008, 16, 17131–17137. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, J.; Wang, K.; Fan, L.; Yang, S. Synthesis and characterization of novel fluorinated polyimides derived from 4,4′-[2,2,2-trifluoro-1-(3,5-ditrifluoromethylphenyl)ethylidene]diphthalic anhydride and aromatic diamines. Polymer 2006, 47, 1443–1450. [Google Scholar] [CrossRef]

- Ju, C.; Park, C.; Kim, T.; Kang, H. Vertical alignment of liquid crystals on plant-based vanillin derivative-substituted polystyrene films. RSC Adv. 2019, 9, 14188–14193. [Google Scholar] [CrossRef] [Green Version]

- Ju, C.; Kim, T.; Kang, H. Renewable, Eugenol—Modified Polystyrene Layer for Liquid Crystal Orientation. Polymer 2018, 10, 201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kang, H.; Choi, Y.-S.; Hong, H.; Ko, T.; Kang, D.; Lee, J.-C. Vertical alignment of liquid crystals on polymer films containing renewable cardanol moieties. Eur. Polym. J. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Ju, C.; Kim, T.; Kang, H. Liquid crystal alignment behaviors on capsaicin substituted polystyrene films. RSC Adv. 2017, 7, 41376–41383. [Google Scholar] [CrossRef] [Green Version]

- Hanemann, T.; Haase, W.; Svoboda, I.; Fuess, H. Crystal structure of 4′-pentyl-4-cyanobiphenyl (5CB). Liq. Cryst. 1995, 19, 699–702. [Google Scholar] [CrossRef]

- Bogi, A.; Faetti, S. Elastic, dielectric and optical constants of 4’-pentyl-4-cyanobiphenyl. Liq. Cryst. 2001, 28, 729–739. [Google Scholar] [CrossRef]

- Maze, C. Determination of Nematic Liquid Crystal Elastic and Dielectric Properties from the Shape of a Capacitance-Voltage Curve. Mol. Cryst. Liq. Cryst. 1978, 48, 273–287. [Google Scholar] [CrossRef]

- Schell, K.T.; Porter, R.S. Dielectric Studies of Highly Polar Nematic Liquid Crystals and Their Mixtures. Mol. Cryst. Liq. Cryst. Inc. Nonlinear Opt. 1990, 188, 97–103. [Google Scholar] [CrossRef]

- Neamnark, A.; Suwantong, O.; Bahadur, K.C.R.; Hsu, C.Y.M.; Supaphol, P.; Uludag, H. Aliphatic Lipid Substitution on 2 kDa Polyethylenimine Improves Plasmid Delivery and Transgene Expression. Mol. Pharm. 2009, 6, 1798–1815. [Google Scholar] [CrossRef]

- Kang, H.; Park, J.S.; Kang, D.; Lee, J.-C. 2-Naphthoxymethyl-Substituted Polystyrenes for Homeotropic Liquid-Crystal Alignment Layers. Macromol. Chem. Phys. 2008, 209, 1900–1908. [Google Scholar] [CrossRef]

- Kang, H.; Kang, D.; Lee, J.-C. Liquid crystal alignment property of polystyrene derivatives containing dual photoreactive side groups. Polymer 2009, 50, 2104–2112. [Google Scholar] [CrossRef]

- Zhang, T.; Lang, Q.; Zeng, L.; Li, T.; Wei, M.; Liu, A. Substituent effect on the oxidation peak potentials of phenol derivatives at ordered mesoporous carbons modified electrode and its application in determination of acidity coefficients (pKa). Electrochim. Acta 2014, 115, 283–289. [Google Scholar] [CrossRef]

- Hayes, N.V.; Branch, G.E.K. The Acidic Dissociation Constants of Phenoxyacetic Acid and its Derivatives. J. Am. Chem. Soc. 1943, 65, 1555–1564. [Google Scholar] [CrossRef]

- Rempp, P.; Lutz, P.; Masson, P.; Franta, E. Macromonomers—A new class of polymeric intermediates in macromolecular synthesis. I—synthesis and characterization. Die Makromol. Chem. 1984, 8, 3–15. [Google Scholar] [CrossRef]

- Holzgrabe, U. Quantitative NMR spectroscopy in pharmaceutical applications. Prog. Nucl. Magn. Reson. Spectrosc. 2010, 57, 229–240. [Google Scholar] [CrossRef] [PubMed]

- Fowles, J.; Boatman, R.; Bootman, J.; Lewis, C.; Morgott, D.; Rushton, E.; Van Rooij, J.; Banton, M. A review of the toxicological and environmental hazards and risks of tetrahydrofuran. Crit. Rev. Toxicol. 2013, 43, 811–828. [Google Scholar] [CrossRef]

- Royall, P.G.; Craig, D.Q.M.; Doherty, C. Characterisation of the glass transition of an amorphous drug using modulated DSC. Pharm. Res. 1998, 15, 1117–1121. [Google Scholar] [CrossRef]

- Hutchinson, J. Determination of the glass transition temperature: Methods correlation and structural heterogeneity. J. Therm. Anal. 2009, 98, 579–589. [Google Scholar] [CrossRef] [Green Version]

- Hayes, R.A. The relationship between glass temperature, molar cohesion, and polymer structure. J. Appl. Polym. Sci. 1961, 5, 318–321. [Google Scholar] [CrossRef]

- Senta, R.; Leo, M. Glass transitions of the poly-(n-alkyl methacrylates). J. Phys. Chem. 1957, 61, 985–991. [Google Scholar]

- Kahn, F.; Taylor, G.; Schonhorn, H. Surface-produced alignment of liquid crystals. Proc. IEEE 1973, 61, 823–828. [Google Scholar] [CrossRef]

- Kim, S.I.; Ree, M.; Shin, T.J.; Jung, J.C. Synthesis of new aromatic polyimides with various side chains containing a biphenyl mesogen unit and their abilities to control liquid-crystal alignments on the rubbed surface. J. Polym. Sci. Part A Polym. Chem. 1999, 37, 2909–2921. [Google Scholar] [CrossRef]

- Myrvold, B.O. Odd-even effects in the alignment of ferroelectric liquid crystals. Liq. Cryst. 1989, 5, 1139–1147. [Google Scholar] [CrossRef]

- Seo, D.-S.; Kobayashi, S.; Nishikawa, M.; Yabe, Y. A Study of High Pretilt Angle Generation in Nematic Liquid Crystal (5CB) on Rubbed Polythiophene Surfaces with Alkyl Chain Lengths. Jpn. J. Appl. Phys. 1996, 35, 3531–3532. [Google Scholar] [CrossRef]

- Schwartz, J.J.; Mendoza, A.; Wattanatorn, N.; Zhao, Y.; Nguyen, V.T.; Spokoyny, A.M.; Mirkin, C.A.; Baše, T.; Weiss, P. Surface Dipole Control of Liquid Crystal Alignment. J. Am. Chem. Soc. 2016, 138, 5957–5967. [Google Scholar] [CrossRef] [Green Version]

- Bouchiat, M.; Langevin-Cruchon, D. Molecular order at the free surface of a nematic liquid crystal from light reflectivity measurements. Phys. Lett. A 1971, 34, 331–332. [Google Scholar] [CrossRef]

- Haller, I. Alignment and wetting properties of nematic liquids. Appl. Phys. Lett. 1974, 24, 349. [Google Scholar] [CrossRef]

- Shafrin, E.G.; Zisman, W.A. Constitutive relations in the wetting of low energy surfaces and the theory of the retraction method of prepar-ing monolayers. J. Phys. Chem. 1960, 64, 519–524. [Google Scholar] [CrossRef]

- Birdi, K.S. Surface Chemistry Essentials; CRC Press: Boca Raton, FL, USA, 2013; pp. 137–161. [Google Scholar]

- Adamson, A.W.; Gast, A.P. Physical Chemistry of Surfaces, 6th ed.; John Wiley & Sons: New York, NY, USA, 1997; pp. 347–378. [Google Scholar]

| Polymer Designation | Feed Ratio of n-alkyl-p-hydroxybenzoate (mol%) | Degree of Substitution (mol%, ±10%) | Tg (°C) |

|---|---|---|---|

| P2BO20 | 20 | 20 | 110.6 |

| P2BO40 | 40 | 40 | 89.2 |

| P2BO60 | 60 | 60 | 74.4 |

| P2BO80 | 80 | 80 | 71.9 |

| P2BO | 150 | 100 | 70.3 |

| P4BO | 150 | 100 | 43.9 |

| P6BO | 150 | 100 | 28.5 |

| P8BO | 150 | 100 | 19.5 |

| Polymer Designation | Water Contact Angle (°) a | Vertical LC Aligning Ability b |

|---|---|---|

| P2BO20 | 81 | X |

| P2BO40 | 86 | O |

| P2BO60 | 87 | O |

| P2BO80 | 89 | O |

| P2BO | 90 | O |

| P4BO | 91 | O |

| P6BO | 92 | O |

| P8BO | 93 | O |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seo, K.; Kang, H. Vertical Orientation of Liquid Crystal on Polystyrene Substituted with n-Alkylbenzoate-p-oxymethyl Pendant Group as a Liquid Crystal Precursor. Polymers 2021, 13, 2058. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13132058

Seo K, Kang H. Vertical Orientation of Liquid Crystal on Polystyrene Substituted with n-Alkylbenzoate-p-oxymethyl Pendant Group as a Liquid Crystal Precursor. Polymers. 2021; 13(13):2058. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13132058

Chicago/Turabian StyleSeo, Kyutae, and Hyo Kang. 2021. "Vertical Orientation of Liquid Crystal on Polystyrene Substituted with n-Alkylbenzoate-p-oxymethyl Pendant Group as a Liquid Crystal Precursor" Polymers 13, no. 13: 2058. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13132058