Safety of Plastic Food Packaging: The Challenges about Non-Intentionally Added Substances (NIAS) Discovery, Identification and Risk Assessment

Abstract

:1. Introduction

2. Plastic food Packaging and Legislation

3. Migration of Substances from Packaging to the Food

- the contact surface size, since the more extensive the contact surface between packaging and food, the higher the migration rate [24];

- the nature of the migrant, since the more volatile and the lower the molecular weight, the greater the migration rate (also the vapor pressure, water solubility, octanol solubility and polarity) [44];

- FCM material type (e.g., impermeable, permeable, porous materials) [45];

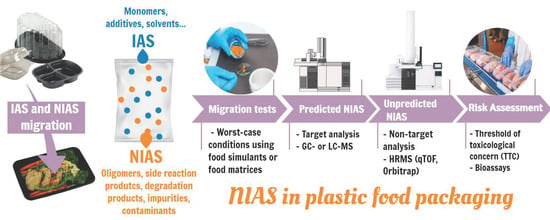

4. NIAS in Plastic Food Packaging

- Search component 1 (SC1) was a population search: “food packaging” OR “food contact article” OR “food contact material” OR “packaging, food” OR “food containers” OR “plastic packaging materials” OR “multilayer food packaging” OR “multilayer packaging materials” OR “recycled plastic packaging” OR “acrylic adhesives” OR “recycled expanded polystyrene containers” OR “polyester-polyurethane” OR “food packaging polymer” OR “biodegradable food packaging” OR “nylons” OR “polyethylenes” OR “polypropylenes” OR “polystyrenes” OR “polyurethanes” OR “polyolefins” OR “acrylic adhesives” OR “recycled expanded polystyrene containers” OR “polyester-polyurethane” OR “polyvinyls” OR “polyesters” OR “polyethylene terephthalates” OR “polyhydroxy ethyl methacrylate” OR “silicones” OR “elastomers” OR “polyvinyl chloride” OR “silicone elastomers”.

- Search component 2 (SC2) was an intervention search: “non-intentionally added substances” OR “non-intentionally added compound” OR “NIAS” OR “breakdown products” OR “impurities” OR “side products” OR “neo-formed compounds” OR “degradation of polymers” OR “degradation of compounds” OR “degradation products” OR “non-volatile migrants” OR “volatile compounds” OR “non-volatile compounds” OR “volatile organic compound” OR “polymer additives” OR “oligomers” OR “additives” OR “plastic additives” OR “additive”.

- Because the ScienceDirect database only allows the use of a maximum of thirteen keywords in the search string, for this base it was used the following search components:

- SC1: (“food packaging” OR “food contact article” OR “food contact material” OR “plastic packaging materials”).

- SC2: (“non-intentionally added substances” OR “non-intentionally added compound” OR “NIAS” OR “additives”). Table 1 presents published works that identified NIAS on different food plastic packaging, the techniques used in each work and the migration tests applied. Despite all efforts, there is much to discover and to do in this area. Below are the leading examples of possible NIAS formation, shown in Figure 3.

4.1. Oligomers

4.2. By-Products Compounds or Side Products

4.3. Breakdown Products or Degradation Products

4.4. Impurities in the Raw Materials

4.5. Contaminants

5. The Challenges of the NIAS Assessment

5.1. NIAS Identification: How to Start?

- although information about the substance’s identity as used and its impurities is necessary, more focus on the migration potential from finished materials and articles is needed. Substances used to manufacture FCM may disappear, and it may be mainly reaction products that turn up in the migrates;

- it is necessary to describe the chemical and the physical properties of a substance that are the determinants for its potential to persist or react in the final FCM and food and migration. The needed information includes: the volatility and thermal/chemical stability of the substances used as well as their impurities; the octanol-water partition coefficient (log Po/w) and the solubility of the migrating substances in solvents of different polarity and food and food simulants; their stability in food simulants and food hydrolysis in the gastrointestinal tract; possible chemical interactions with the food, leading to the generation of reaction products with or from the food;

- information about the level of use, the function of the substance and the manufacturing process conditions are needed for assessing the quantities, types, and nature of potentially migrating substances. Depending on the details of information accessible, such as the nature of the plastics produced using the substance, the food characteristic the plastic materials intended to contact, and whether the FCM is intended for single or repeat use applications, a more or less refined exposure estimate may be derived.

5.1.1. NIAS Extraction

5.1.2. Target Analysis for Predict NIAS

5.1.3. Non-Target Analysis for Unpredicted NIAS

6. The NIAS Risk Assessment Challenge

6.1. Strategies to Hazard Characterisation of NIAS

6.1.1. Bioassays

6.1.2. Threshold of Toxicological Concern (TTC)

7. Alternatives to Plastics: Biopolymers and Bioplastics

8. Conclusions

- it is estimated that most of the food contact material contain NIAS and most of the substances that migrate from plastic food packaging are unknown;

- several studies determining NIAS were carried out in polyurethane adhesives (PU), polyethylene terephthalate (PET), polyester coatings, polypropylene materials (PP), multilayers materials, plastic films, polyvinyl chloride (PVC), recycled materials, high-density polyethylene (HDPE) and low-density polyethylene (LDPE);

- breakdown products are almost the primary source of NIAS in plastic FCMs, most of the degradation products from antioxidants; following by side reaction products and oligomers;

- substances used to manufacture FCM may disappear, and it may be mainly reaction products that turn up in the migrates;

- the NIAS assessment in plastics FCMs is usually made by migration tests under worst-case conditions using food simulants (Tenax, organic solvents, water) and simulating the temperature and time of exposure;

- targeted analytical methods for the analysis of predicted NIAS are applied using GC-MS based methods for volatile NIAS and GC-MS and LC-MS based methods for semi- and non-volatile NIAS;

- non-targeted or screening methods to analyze unknown NIAS in plastic FCMs is mainly done using GC and LC techniques combined with QTOF mass spectrometry;

- for all concepts, better information transfer through the whole value chain would mainly facilitate the identification of unknown compounds since the entire supply chain has responsibility;

- NIAS could be present in the materials in deficient concentrations and still be a risk;

- in terms of risk assessment and prioritization for NIAS, the threshold of toxicological concern (TTC) concept is the most applied tool, by comparing the semi-quantitative concentration of the chemical compound with the estimated exposure limit;

- the combination of bioassays with sensitive analytical techniques seems to be an efficient way of identifying NIAS and their hazard to human exposure; mutagenicity based on the Ames test (genotoxicity testing), together with analytical chemistry and information on packaging manufacture, could allow the application of the Cramer class III TTC to prioritize unknown NIAS;

- oligomers up to a molar weight of 1000 Da seems to be relevant under the assumption of human gastrointestinal absorption, and this cut-off should be re-evaluated by legislation;

- currently, there is an absence of industry-wide harmonized methodology on dealing with NIAS;

- for commonly investigated IAS, there is often risk assessment data available for prior research or via accredited methods, but for the more elusive NIAS, there is rarely relevant data;

- there are only a few references outside Europe and the United States regarding NIAS in food contact materials, although other territories closely follow Europe and the United States legislation;

- the guidelines need to be urgently updated;

- biopolymers/bioplastics are currently being developed as an attempt to replace conventional plastics; however, few studies on the safety of these materials and migration of compounds to food have been carried out and published in the literature;

- the migration of NIAS from biopolymers/bioplastics reported in some studies emphasize the need to evaluate these alternative materials for hazardous compounds and NIAS and establish legislation for these specific new materials.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nerin, C.; Alfaro, P.; Aznar, M.; Domeño, C. The challenge of identifying non-intentionally added substances from food packaging materials: A review. Anal. Chim. Acta 2013, 775, 14–24. [Google Scholar] [CrossRef] [PubMed]

- Leeman, W.; Krul, L. Non-intentionally added substances in food contact materials: How to ensure consumer safety. Curr. Opin. Food Sci. 2015, 6, 33–37. [Google Scholar] [CrossRef]

- Bignardi, C.; Cavazza, A.; Laganà, C.; Salvadeo, P.; Corradini, C. Release of non-intentionally added substances (NIAS) from food contact polycarbonate: Effect of ageing. Food Control. 2017, 71, 329–335. [Google Scholar] [CrossRef]

- Martínez-Bueno, M.J.; Gómez Ramos, M.J.; Bauer, A.; Fernández-Alba, A.R. An overview of non-targeted screening strategies based on high resolution accurate mass spectrometry for the identification of migrants coming from plastic food packaging materials. TrAC Trends Anal. Chem. 2019, 110, 191–203. [Google Scholar] [CrossRef]

- Wrona, M.; Nerín, C. Analytical Approaches for Analysis of Safety of Modern Food Packaging: A Review. Molecules 2020, 25, 752. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.S.; Lee, Y.J.; Koo, Y.J.; Pack, E.C.; Lim, K.M.; Choi, D.W. Migration of monomers, plastic additives, and non-intentionally added substances from food utensils made of melamine–formaldehyde resin following ultraviolet sterilization. Food Control. 2021, 107981. [Google Scholar] [CrossRef]

- Koster, S.; Bani-Estivals, M.H.; Bonuomo, M.; Bradley, E.; Chagnon, M.C.; García, M.L.; Godts, F.; Gude, T.; Helling, R.; Paseiro-Losada, P.; et al. Guidance on Best Practices on the Risk Assessment of Non-Intentionally Added Substances (Nias) in Food Contact Materials and Articles; CABI: Wallingford, UK, 2015. [Google Scholar]

- EFSA; WHO. European Food Safety Authority and World Health Organization Review of the Threshold of Toxicological Concern (TTC) approach and development of new TTC decision tree. EFSA Support. Publ. 2016, 13, 1006E. [Google Scholar]

- Peters, R.J.B.; Groeneveld, I.; Sanchez, P.L.; Gebbink, W.; Gersen, A.; de Nijs, M.; van Leeuwen, S.P.J. Review of analytical approaches for the identification of non-intentionally added substances in paper and board food contact materials. Trends Food Sci. Technol. 2019, 85, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Gao, X.; Liu, B.; Lin, Q.; Xia, Y. Identification of chemicals in a polyvinyl chloride/polyethylene multilayer film by ultra-high-performance liquid chromatography/quadrupole time-of-flight mass spectrometry and their migration into solution. J. Chromatogr. A 2020, 1625, 461274. [Google Scholar] [CrossRef]

- U.S. FDA CFR—Code of Federal Regulations Title 21. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=174.5 (accessed on 25 May 2021).

- Karmaus, A.L.; Osborn, R.; Krishan, M. Scientific advances and challenges in safety evaluation of food packaging materials: Workshop proceedings. Regul. Toxicol. Pharmacol. 2018, 98, 80–87. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Fernando, A.L. Nanoparticles in food packaging: Biodegradability and potential migration to food—A review. Food Packag. Shelf Life 2016, 8, 63–70. [Google Scholar] [CrossRef]

- Yates, J.; Deeney, M.; Rolker, H.B.; White, H.; Kalamatianou, S.; Kadiyala, S. A systematic scoping review of environmental, food security and health impacts of food system plastics. Nat. Food 2021, 2, 80–87. [Google Scholar] [CrossRef]

- Ong, H.-T.; Samsudin, H.; Soto-Valdez, H. Migration of endocrine-disrupting chemicals into food from plastic packaging materials: An overview of chemical risk assessment, techniques to monitor migration, and international regulations. Crit. Rev. Food Sci. Nutr. 2020, 1–23. [Google Scholar] [CrossRef]

- Rodrigues, M.O.; Abrantes, N.; Gonçalves, F.J.M.; Nogueira, H.; Marques, J.C.; Gonçalves, A.M.M. Impacts of plastic products used in daily life on the environment and human health: What is known? Environ. Toxicol. Pharmacol. 2019, 72, 103239. [Google Scholar] [CrossRef] [PubMed]

- Galotto, M.J.; Torres, A.; Guarda, A.; Moraga, N.; Romero, J. Experimental and theoretical study of LDPE versus different concentrations of Irganox 1076 and different thickness. Food Res. Int. 2011, 44, 566–574. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef]

- Groh, K.J.; Backhaus, T.; Carney-Almroth, B.; Geueke, B.; Inostroza, P.A.; Lennquist, A.; Leslie, H.A.; Maffini, M.; Slunge, D.; Trasande, L.; et al. Overview of known plastic packaging-associated chemicals and their hazards. Sci. Total Environ. 2019, 651, 3253–3268. [Google Scholar] [CrossRef] [PubMed]

- Geueke, B.; Wagner, C.C.; Muncke, J. Food contact substances and chemicals of concern: A comparison of inventories. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2014, 31, 1438–1450. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EU) No 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come Into contact With Food. Off. J. Eur. Union. 2011, 12, 1–89. [Google Scholar]

- Boucher, J. Mercosur Positive List for FCM Plastic Additives. 2019. Available online: https://www.foodpackagingforum.org/news/mercosur-positive-list-for-fcm-plastic-additives (accessed on 24 June 2021).

- Muncke, J.; Backhaus, T.; Geueke, B.; Maffini, M.V.; Martin, O.V.; Myers, J.P.; Soto, A.M.; Trasande, L.; Trier, X.; Scheringer, M. Scientific Challenges in the Risk Assessment of Food Contact Materials. Environ. Health Perspect. 2017, 125, 95001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhunia, K.; Sablani, S.S.; Tang, J.; Rasco, B. Migration of Chemical Compounds from Packaging Polymers during Microwave, Conventional Heat Treatment, and Storage. Compr. Rev. Food Sci. Food Saf. 2013, 12, 523–545. [Google Scholar] [CrossRef]

- Ubeda, S.; Aznar, M.; Rosenmai, A.K.; Vinggaard, A.M.; Nerín, C. Migration studies and toxicity evaluation of cyclic polyesters oligomers from food packaging adhesives. Food Chem. 2020, 311, 125918. [Google Scholar] [CrossRef]

- Mistura, L.; Sette, S.; O’Mahony, C.; Engel, K.-H.; Mehegan, J.; Leclercq, C. Modelling framework for assessment of dietary exposure to added flavouring substances within the FACET (Flavours, Additives, and Food Contact Material Exposure Task) project. Food Chem. Toxicol. 2013, 58, 236–241. [Google Scholar] [CrossRef]

- Grob, K.; Biedermann, M.; Scherbaum, E.; Roth, M.; Rieger, K. Food contamination with organic materials in perspective: Packaging materials as the largest and least controlled source? A view focusing on the European situation. Crit. Rev. Food Sci. Nutr. 2006, 46, 529–535. [Google Scholar] [CrossRef] [PubMed]

- Hoppe, M.; Fornari, R.; de Voogt, P.; Franz, R. Migration of oligomers from PET: Determination of diffusion coefficients and comparison of experimental versus modelled migration. Food Addit. Contam. Part A 2017, 34, 1251–1260. [Google Scholar] [CrossRef] [PubMed]

- Eckardt, M.; Hetzel, L.; Brenz, F.; Simat, T.J. Release and migration of cyclic polyester oligomers from bisphenol A non-intent polyester–phenol-coatings into food simulants and infant food—A comprehensive study. Food Addit. Contam. Part A 2020, 37, 681–703. [Google Scholar] [CrossRef] [PubMed]

- Fasano, E.; Bono-Blay, F.; Cirillo, T.; Montuori, P.; Lacorte, S. Migration of phthalates, alkylphenols, bisphenol A and di(2-ethylhexyl)adipate from food packaging. Food Control. 2012, 27, 132–138. [Google Scholar] [CrossRef] [Green Version]

- Whitt, M.; Brown, W.; Danes, J.E.; Vorst, K.L. Migration of heavy metals from recycled polyethylene terephthalate during storage and microwave heating. J. Plast. Film Sheeting 2016, 32, 189–207. [Google Scholar] [CrossRef]

- Clemente, I.; Aznar, M.; Nerín, C.; Bosetti, O. Migration from printing inks in multilayer food packaging materials by GC-MS analysis and pattern recognition with chemometrics. Food Addit. Contam. Part A 2016, 33, 703–714. [Google Scholar] [CrossRef] [PubMed]

- Isella, F.; Canellas, E.; Bosetti, O.; Nerin, C. Migration of non intentionally added substances from adhesives by UPLC-Q-TOF/MS and the role of EVOH to avoid migration in multilayer packaging materials. J. Mass Spectrom. 2013, 48, 430–437. [Google Scholar] [CrossRef]

- Song, X.-C.; Wrona, M.; Nerin, C.; Lin, Q.-B.; Zhong, H.-N. Volatile non-intentionally added substances (NIAS) identified in recycled expanded polystyrene containers and their migration into food simulants. Food Packag. Shelf Life 2019, 20, 100318. [Google Scholar] [CrossRef]

- Helmroth, I.E.; Bekhuis, H.A.M.; Linssen, J.P.H.; Dekker, M. Direct measurement of additive migration from low-density polyethylene as a function of space and time. J. Appl. Polym. Sci. 2002, 86, 3185–3190. [Google Scholar] [CrossRef]

- Lee, D.S.; Yam, K.L.; Piergiovanni, L. Food Packaging Science and Technology; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Alberto Lopes, J.; Tsochatzis, E.D.; Karasek, L.; Hoekstra, E.J.; Emons, H. Analysis of PBT and PET cyclic oligomers in extracts of coffee capsules and food simulants by a HPLC-UV/FLD method. Food Chem. 2021, 345, 128739. [Google Scholar] [CrossRef] [PubMed]

- Committee, E.S.; More, S.J.; Bampidis, V.; Benford, D.; Bragard, C.; Halldorsson, T.I.; Hernández-Jerez, A.F.; Hougaard Bennekou, S.; Koutsoumanis, K.P.; Machera, K.; et al. Guidance on the use of the Threshold of Toxicological Concern approach in food safety assessment. EFSA J. 2019, 17, e05708. [Google Scholar]

- Eckardt, M.; Kubicova, M.; Simat, T.J. Universal response quantification approach using a Corona Charged Aerosol Detector (CAD)—Application on linear and cyclic oligomers extractable from polycondensate plastics polyesters, polyamides and polyarylsulfones. J. Chromatogr. A 2018, 1572, 187–202. [Google Scholar] [CrossRef] [PubMed]

- Nelson, C.P.; Patton, G.W.; Arvidson, K.; Lee, H.; Twaroski, M.L. Assessing the toxicity of polymeric food-contact substances. Food Chem. Toxicol. 2011, 49, 1877–1897. [Google Scholar] [CrossRef] [PubMed]

- Muncke, J.; Myers, J.P.; Scheringer, M.; Porta, M. Food packaging and migration of food contact materials: Will epidemiologists rise to the neotoxic challenge? J. Epidemiol. Community Health 2014, 68, 592–594. [Google Scholar] [CrossRef] [Green Version]

- Arvanitoyannis, I.S.; Kotsanopoulos, K.V. Migration Phenomenon in Food Packaging. Food–Package Interactions, Mechanisms, Types of Migrants, Testing and Relative Legislation—A Review. Food Bioprocess Technol. 2014, 7, 21–36. [Google Scholar] [CrossRef]

- Fang, X.; Vitrac, O. Predicting diffusion coefficients of chemicals in and through packaging materials. Crit. Rev. Food Sci. Nutr. 2017, 57, 275–312. [Google Scholar] [CrossRef]

- Xue, M.; Chai, X.-S.; Li, X.; Chen, R. Migration of organic contaminants into dry powdered food in paper packaging materials and the influencing factors. J. Food Eng. 2019, 262, 75–82. [Google Scholar] [CrossRef]

- Nerín, C.; Aznar, M.; Carrizo, D. Food contamination during food process. Trends Food Sci. Technol. 2016, 48, 63–68. [Google Scholar] [CrossRef]

- Tehrany, E.A.T.; Desobry, S. Partition coefficients in food/packaging systems: A review. Food Addit. Contam. 2004, 21, 1186–1202. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Bosnea, L. Migration of substances from food packaging materials to foods. Crit. Rev. Food Sci. Nutr. 2004, 44, 63–76. [Google Scholar] [CrossRef]

- Begley, T.H.; Biles, J.E.; Cunningham, C.; Piringer, O. Migration of a UV stabilizer from polyethylene terephthalate (PET) into food simulants. Food Addit. Contam. 2004, 21, 1007–1014. [Google Scholar] [CrossRef] [PubMed]

- Ferrara, G.; Bertoldo, M.; Scoponi, M.; Ciardelli, F. Diffusion coefficient and activation energy of Irganox 1010 in poly(propylene-co-ethylene) copolymers. Polym. Degrad. Stab. 2001, 73, 411–416. [Google Scholar] [CrossRef]

- Chung, D.; Papadakis, S.E.; Yam, K.L. Simple models for assessing migration from food-packaging films. Food Addit. Contam. 2002, 19, 611–617. [Google Scholar] [CrossRef]

- O’Brien, A.; Cooper, L. Polymer additive migration to foods—A direct comparison of experimental data and values calculated from migration models for polypropylene. Food Addit. Contam. 2001, 18, 343–355. [Google Scholar] [CrossRef] [PubMed]

- Brandsch, J.; Mercea, P.; Rüter, M.; Tosa, V.; Piringer, O. Migration modelling as a tool for quality assurance of food packaging. Food Addit. Contam. 2002, 19 (Suppl. S1), 29–41. [Google Scholar] [CrossRef]

- Begley, T.; Castle, L.; Feigenbaum, A.; Franz, R.; Hinrichs, K.; Lickly, T.; Mercea, P.; Milana, M.; O’Brien, A.; Rebre, S.; et al. Evaluation of migration models that might be used in support of regulations for food-contact plastics. Food Addit. Contam. 2005, 22, 73–90. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bott, J.; Störmer, A.; Franz, R. A model study into the migration potential of nanoparticles from plastics nanocomposites for food contact. Food Packag. Shelf Life 2014, 2, 73–80. [Google Scholar] [CrossRef]

- Gavriil, G.; Kanavouras, A.; Coutelieris, F.A. Food-packaging migration models: A critical discussion. Crit. Rev. Food Sci. Nutr. 2018, 58, 2262–2272. [Google Scholar] [CrossRef]

- Oldring, P.K.T.; O’Mahony, C.; Dixon, J.; Vints, M.; Mehegan, J.; Dequatre, C.; Castle, L. Development of a new modelling tool (FACET) to assess exposure to chemical migrants from food packaging. Food Addit. Contam. Part A 2014, 31, 444–465. [Google Scholar] [CrossRef] [PubMed]

- Katiyar, V. Sustainable Polymers for Food Packaging; De Gruyter: Berlin, Germany, 2020. [Google Scholar]

- Genualdi, S.; Nyman, P.; Begley, T. Updated evaluation of the migration of styrene monomer and oligomers from polystyrene food contact materials to foods and food simulants. Food Addit. Contam. Part A 2014, 31, 723–733. [Google Scholar] [CrossRef]

- Vera, P.; Canellas, E.; Barknowitz, G.; Goshawk, J.; Nerín, C. Ion-Mobility Quadrupole Time-of-Flight Mass Spectrometry: A Novel Technique Applied to Migration of Nonintentionally Added Substances from Polyethylene Films Intended for Use as Food Packaging. Anal. Chem. 2019, 91, 12741–12751. [Google Scholar] [CrossRef] [PubMed]

- Paseiro-Cerrato, R.; MacMahon, S.; Ridge, C.D.; Noonan, G.O.; Begley, T.H. Identification of unknown compounds from polyester cans coatings that may potentially migrate into food or food simulants. J. Chromatogr. A 2016, 1444, 106–113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Groh, K.J.; Geueke, B.; Martin, O.; Maffini, M.; Muncke, J. Overview of intentionally used food contact chemicals and their hazards. Environ. Int. 2021, 150, 106225. [Google Scholar] [CrossRef]

- Grob, K. Work plans to get out of the deadlock for the safety assurance of migration from food contact materials? A proposal. Food Control. 2014, 46, 312–318. [Google Scholar] [CrossRef]

- Driffield, M.; Garcia-Lopez, M.; Christy, J.; Lloyd, A.S.; Tarbin, J.A.; Hough, P.; Bradley, E.L.; Oldring, P.K.T. The determination of monomers and oligomers from polyester-based can coatings into foodstuffs over extended storage periods. Food Addit. Contam. Part A 2018, 35, 1200–1213. [Google Scholar] [CrossRef]

- Pietropaolo, E.; Albenga, R.; Gosetti, F.; Toson, V.; Koster, S.; Marin-Kuan, M.; Veyrand, J.; Patin, A.; Schilter, B.; Pistone, A.; et al. Synthesis, identification and quantification of oligomers from polyester coatings for metal packaging. J. Chromatogr. A 2018, 1578, 15–27. [Google Scholar] [CrossRef]

- Ubeda, S.; Aznar, M.; Nerín, C. Determination of oligomers in virgin and recycled polyethylene terephthalate (PET) samples by UPLC-MS-QTOF. Anal. Bioanal. Chem. 2018, 410, 2377–2384. [Google Scholar] [CrossRef]

- Bauer, A.; Jesús, F.; Gómez Ramos, M.J.; Lozano, A.; Fernández-Alba, A.R. Identification of unexpected chemical contaminants in baby food coming from plastic packaging migration by high resolution accurate mass spectrometry. Food Chem. 2019, 295, 274–288. [Google Scholar] [CrossRef]

- Felix, J.S.; Isella, F.; Bosetti, O.; Nerin, C. Analytical tools for identification of non-intentionally added substances (NIAS) coming from polyurethane adhesives in multilayer packaging materials and their migration into food simulants. Anal. Bioanal. Chem. 2012, 403, 2869–2882. [Google Scholar] [CrossRef]

- Canellas, E.; Vera, P.; Nerín, C. Ion mobility quadrupole time-of-flight mass spectrometry for the identification of non-intentionally added substances in UV varnishes applied on food contact materials. A safety by design study. Talanta 2019, 205, 120103. [Google Scholar] [CrossRef] [PubMed]

- Pezo, D.; Fedeli, M.; Bosetti, O.; Nerín, C. Aromatic amines from polyurethane adhesives in food packaging: The challenge of identification and pattern recognition using Quadrupole-Time of Flight-Mass SpectrometryE. Anal. Chim. Acta 2012, 756, 49–59. [Google Scholar] [CrossRef]

- Yan, Y.; Hu, C.-Y.; Wang, Z.-W.; Jiang, Z.-W. Degradation of Irgafos 168 and migration of its degradation products from PP-R composite films. Packag. Technol. Sci. 2018, 31, 679–688. [Google Scholar] [CrossRef]

- Vera, P.; Canellas, E.; Nerín, C. Identification of non volatile migrant compounds and NIAS in polypropylene films used as food packaging characterized by UPLC-MS/QTOF. Talanta 2018, 188, 750–762. [Google Scholar] [CrossRef] [PubMed]

- Vera, P.; Canellas, E.; Nerín, C. Identification of non-volatile compounds and their migration from hot melt adhesives used in food packaging materials characterized by ultra-performance liquid chromatography coupled to quadrupole time-of-flight mass spectrometry. Anal. Bioanal. Chem. 2013, 405, 4747–4754. [Google Scholar] [CrossRef] [PubMed]

- Kassouf, A.; Maalouly, J.; Chebib, H.; Rutledge, D.N.; Ducruet, V. Chemometric tools to highlight non-intentionally added substances (NIAS) in polyethylene terephthalate (PET). Talanta 2013, 115, 928–937. [Google Scholar] [CrossRef]

- Riquet, A.M.; Breysse, C.; Dahbi, L.; Loriot, C.; Severin, I.; Chagnon, M.C. The consequences of physical post-treatments (microwave and electron-beam) on food/packaging interactions: A physicochemical and toxicological approach. Food Chem. 2016, 199, 59–69. [Google Scholar] [CrossRef] [Green Version]

- Garcia Ibarra, V.; de Quiros, A.R.; Paseiro Losada, P.; Sendon, R. Non-target analysis of intentionally and non intentionally added substances from plastic packaging materials and their migration into food simulants. Food Packag. Shelf Life 2019, 21, 100325. [Google Scholar] [CrossRef]

- Garcia Ibarra, V.; de Quiros, A.R.; Paseiro Losada, P.; Sendon, R. Identification of intentionally and non-intentionally added substances in plastic packaging materials and their migration into food products. Anal. Bioanal. Chem. 2018, 410, 3789–3803. [Google Scholar] [CrossRef]

- Carrero-Carralero, C.; Escobar-Arnanz, J.; Ros, M.; Jiménez-Falcao, S.; Sanz, M.L.; Ramos, L. An untargeted evaluation of the volatile and semi-volatile compounds migrating into food simulants from polypropylene food containers by comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometry. Talanta 2019, 195, 800–806. [Google Scholar] [CrossRef] [PubMed]

- Lestido Cardama, A.; Sendón, R.; Bustos, J.; Santillana, M.I.; Paseiro Losada, P.; Rodríguez Bernaldo de Quirós, A. GC-MS Screening for the Identification of Potential Migrants Present in Polymeric Coatings of Food Cans. Polymers 2019, 11, 2086. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Horodytska, O.; Cabanes, A.; Fullana, A. Non-intentionally added substances (NIAS) in recycled plastics. Chemosphere 2020, 251, 126373. [Google Scholar] [CrossRef] [PubMed]

- Rajbux, C.; Pereira, J.; do Céu Selbourne, M.; Costa-Pinto, A.R.; Poças, F. Assessment of baby Bibs. GC-MS screening, migration into saliva and insight of toxicity with QSAR tools. Food Control. 2020, 109, 106951. [Google Scholar] [CrossRef]

- Tsochatzis, E.D.; Gika, H.; Theodoridis, G. Development and validation of a fast gas chromatography mass spectrometry method for the quantification of selected non-intentionally added substances and polystyrene/polyurethane oligomers in liquid food simulants. Anal. Chim. Acta 2020, 1130, 49–59. [Google Scholar] [CrossRef]

- Carrizo, D.; Maccagnan, A.; Felix, J.S.; Nerin, C.; Bosetti, O. The Barrier Effect of EVOH versus 1,4,7-Triaxocyclotridecane-8,13-Dione, a Non-intentionally Added Compound from Polyurethane Adhesives in Multilayer Food Packaging. Packag. Technol. Sci. 2015, 28, 1039–1046. [Google Scholar] [CrossRef]

- Vaclavikova, M.; Paseiro-Cerrato, R.; Vaclavik, L.; Noonan, G.O.; De Vries, J.; Begley, T.H. Target and non-target analysis of migrants from PVC-coated cans using UHPLC-Q-Orbitrap MS: Evaluation of long-term migration testing. Food Addit. Contam. Part A 2016, 33, 352–363. [Google Scholar] [CrossRef]

- Martinez-Bueno, M.J.; Hernando, M.D.; Ucles, S.; Rajski, L.; Cimmino, S.; Fernandez-Alba, A.R. Identification of non-intentionally added substances in food packaging nano films by gas and liquid chromatography coupled to orbitrap mass spectrometry. Talanta 2017, 172, 68–77. [Google Scholar] [CrossRef]

- Úbeda, S.; Aznar, M.; Vera, P.; Nerín, C.; Henríquez, L.; Taborda, L.; Restrepo, C. Overall and specific migration from multilayer high barrier food contact materials—Kinetic study of cyclic polyester oligomers migration. Food Addit. Contam. Part A 2017, 34, 1784–1794. [Google Scholar] [CrossRef]

- Aznar, M.; Rodriguez-Lafuente, A.; Alfaro, P.; Nerin, C. UPLC-Q-TOF-MS analysis of non-volatile migrants from new active packaging materials. Anal. Bioanal. Chem. 2012, 404, 1945–1957. [Google Scholar] [CrossRef]

- Aznar, M.; Gómez-Estaca, J.; Vélez, D.; Devesa, V.; Nerín, C. Migrants determination and bioaccessibility study of ethyl lauroyl arginate (LAE) from a LAE based antimicrobial food packaging material. Food Chem. Toxicol. 2013, 56, 363–370. [Google Scholar] [CrossRef]

- Aznar, M.; Domeno, C.; Nerin, C.; Bosetti, O. Set-off of non volatile compounds from printing inks in food packaging materials and the role of lacquers to avoid migration. Dye Pigment 2015, 114, 85–92. [Google Scholar] [CrossRef]

- Helling, R.; Seifried, P.; Fritzsche, D.; Simat, T.J. Characterisation and migration properties of silicone materials during typical long-term commercial and household use applications: A combined case study. Food Addit. Contam. Part A 2012, 29, 1489–1500. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.W.; Hu, C.; Tong, L.H.; Lei, Z.X.; Lin, Q.-B. Migration test and safety assessment of polyurethane adhesives used for food-contact laminated films. Food Packag. Shelf Life 2020, 23, 100449. [Google Scholar] [CrossRef]

- Panseri, S.; Chiesa, L.M.; Zecconi, A.; Soncini, G.; De Noni, I. Determination of Volatile Organic Compounds (VOCs) from wrapping films and wrapped PDO Italian cheeses by using HS-SPME and GC/MS. Molecules 2014, 19, 8707–8724. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aznar, M.; Alfaro, P.; Nerin, C.; Kabir, A.; Furton, K.G. Fabric phase sorptive extraction: An innovative sample preparation approach applied to the analysis of specific migration from food packaging. Anal. Chim. Acta 2016, 936, 97–107. [Google Scholar] [CrossRef]

- Kuki, Á.; Nagy, L.; Nagy, T.; Zsuga, M.; Kéki, S. Screening of additives and other chemicals in polyurethanes by direct analysis in real time mass spectrometry (DART-MS). Anal. Bioanal. Chem. 2017, 409, 6149–6162. [Google Scholar] [CrossRef]

- Bignardi, C.; Cavazza, A.; Corradini, C.; Salvadeo, P. Targeted and untargeted data-dependent experiments for characterization of polycarbonate food-contact plastics by ultra high performance chromatography coupled to quadrupole orbitrap tandem mass spectrometry. J. Chromatogr. A 2014, 1372C, 133–144. [Google Scholar] [CrossRef]

- Galmán Graíño, S.; Sendón, R.; López Hernández, J.; Rodríguez-Bernaldo de Quirós, A.; Graíño, S.G.; Sendón, R.; Hernández, J.L.; de Quirós, A.R.-B. GC-MS screening analysis for the identification of potential migrants in plastic and paper-based candy wrappers. Polymers 2018, 10, 802. [Google Scholar] [CrossRef] [Green Version]

- Omer, E.; Bichon, E.; Hutinet, S.; Royer, A.-L.; Monteau, F.; Germon, H.; Hill, P.; Remaud, G.; Dervilly-Pinel, G.; Cariou, R.; et al. Toward the characterisation of non-intentionally added substances migrating from polyester-polyurethane lacquers by comprehensive gas chromatography-mass spectrometry technologies. J. Chromatogr. A 2019, 1601, 327–334. [Google Scholar] [CrossRef] [PubMed]

- Brenz, F.; Linke, S.; Simat, T. Linear and cyclic oligomers in polybutylene terephthalate for food contact materials. Food Addit. Contam. Part A 2018, 35, 583–598. [Google Scholar] [CrossRef] [PubMed]

- Gómez Ramos, M.J.; Lozano, A.; Fernández-Alba, A.R. High-resolution mass spectrometry with data independent acquisition for the comprehensive non-targeted analysis of migrating chemicals coming from multilayer plastic packaging materials used for fruit purée and juice. Talanta 2019, 191, 180–192. [Google Scholar] [CrossRef] [PubMed]

- Portesi, C.; Visentin, D.; Durbiano, F.; Abete, M.C.; Rizzi, M.; Maurino, V.; Rossi, A.M. Development of a rapid micro-Raman spectroscopy approach for detection of NIAS in LDPE pellets and extruded films for food packaging applications. Polym. Test. 2019, 80, 106098. [Google Scholar] [CrossRef]

- Canellas, E.; Vera, P.; Nerín, C. Migration assessment and the “threshold of toxicological concern” applied to the safe design of an acrylic adhesive for food-contact laminates. Food Addit. Contam. Part A 2017, 34, 1721–1729. [Google Scholar] [CrossRef]

- Habchi, B.; Kassouf, A.; Padellec, Y.; Rathahao-Paris, E.; Alves, S.; Rutledge, D.N.; Maalouly, J.; Ducruet, V. An untargeted evaluation of food contact materials by flow injection analysis-mass spectrometry (FIA-MS) combined with independent components analysis (ICA). Anal. Chim. Acta 2018, 1022, 81–88. [Google Scholar] [CrossRef] [PubMed]

- Salafranca, J.; Clemente, I.; Isella, F.; Nerín, C.; Bosetti, O. Influence of oxygen and long term storage on the profile of volatile compounds released from polymeric multilayer food contact materials sterilized by gamma irradiation. Anal. Chim. Acta 2015, 878, 118–130. [Google Scholar] [CrossRef]

- Paseiro-Cerrato, R.; DeJager, L.; Begley, T.H. Assessment of the Impact of Accelerated Migration Testing for Coated Food Cans Using Food Simulants. Molecules 2019, 24, 3123. [Google Scholar] [CrossRef] [Green Version]

- Bartsch, N.; Girard, M.; Wilde, A.; Bruhn, T.; Kappenstein, O.; Vieth, B.; Hutzler, C.; Luch, A. Thermal Stability of Polymer Additives: Comparison of Decomposition Models Including Oxidative Pyrolysis. J. Vinyl. Addit. Technol. 2019, 25, E12–E27. [Google Scholar] [CrossRef]

- Hoppe, M.; de Voogt, P.; Franz, R. Identification and quantification of oligomers as potential migrants in plastics food contact materials with a focus in polycondensates—A review. Trends Food Sci. Technol. 2016, 50, 118–130. [Google Scholar] [CrossRef]

- EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids (CEF). Scientific Opinion on the safety assessment of the substance, furan-2, 5-dicarboxylic acid, CAS No 3238-40-2, for use in food contact materials. EFSA J. 2014, 12, 3866. [Google Scholar]

- Gelbke, H.-P.; Banton, M.; Block, C.; Dawkins, G.; Leibold, E.; Pemberton, M.; Sakoda, A.; Yasukawa, A. Oligomers of styrene are not endocrine disruptors. Crit. Rev. Toxicol. 2018, 48, 471–499. [Google Scholar] [CrossRef] [PubMed]

- Paseiro-Cerrato, R.; Noonan, G.O.; Begley, T.H. Evaluation of Long-Term Migration Testing from Can Coatings into Food Simulants: Polyester Coatings. J. Agric. Food Chem. 2016, 64, 2377–2385. [Google Scholar] [CrossRef] [PubMed]

- Campanella, G.; Ghaani, M.; Quetti, G.; Farris, S. On the origin of primary aromatic amines in food packaging materials. Trends Food Sci. Technol. 2015, 46, 137–143. [Google Scholar] [CrossRef] [Green Version]

- Wrona, M.; Nerin, C. CHAPTER 7 Risk Assessment of Plastic Packaging for Food Applications. In Food Contact Materials Analysis: Mass Spectrometry Techniques; The Royal Society of Chemistry: London, UK, 2019; pp. 163–191. ISBN 978-1-78801-124-2. [Google Scholar]

- McCombie, G.; Hötzer, K.; Daniel, J.; Biedermann, M.; Eicher, A.; Grob, K. Compliance work for polyolefins in food contact: Results of an official control campaign. Food Control. 2016, 59, 793–800. [Google Scholar] [CrossRef]

- Canellas, E.; Aznar, M.; Nerin, C.; Mercea, P. Partition and diffusion of volatile compounds from acrylic adhesives used for food packaging multilayers manufacturing. J. Mater. Chem. 2010, 20, 5100–5109. [Google Scholar] [CrossRef]

- Biedermann, M.; Grob, K. Polyadipates used as plasticizers in food contact: Fraction below 1000 Da determined by size exclusion chromatography with evaporative light scattering detection and segmental response linearization or UV detection. J. Sep. Sci. 2006, 29, 114–122. [Google Scholar] [CrossRef]

- Groh, K.J.; Muncke, J. In Vitro Toxicity Testing of Food Contact Materials: State-of-the-Art and Future Challenges. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1123–1150. [Google Scholar] [CrossRef] [Green Version]

- Sanchis, Y.; Yusà, V.; Coscollà, C. Analytical strategies for organic food packaging contaminants. J. Chromatogr. A 2017, 1490, 22–46. [Google Scholar] [CrossRef]

- Yusà, V.; López, A.; Dualde, P.; Pardo, O.; Fochi, I.; Pineda, A.; Coscolla, C. Analysis of unknowns in recycled LDPE plastic by LC-Orbitrap Tribrid HRMS using MS3 with an intelligent data acquisition mode. Microchem. J. 2020, 158, 105256. [Google Scholar] [CrossRef]

- Aznar, M.; Alfaro, P.; Nerín, C.; Jones, E.; Riches, E. Progress in mass spectrometry for the analysis of set-off phenomena in plastic food packaging materials. J. Chromatogr. A 2016, 1453, 124–133. [Google Scholar] [CrossRef]

- Hakkarainen, M.; Karlsson, S. Gas Chromatography in Analysis of Polymers and Rubbers. In Encyclopedia of Analytical Chemistry; American Cancer Society: Atlanta, GA, USA, 2006; ISBN 9780470027318. [Google Scholar]

- Peñalver, R.; Arroyo-Manzanares, N.; Campillo, N.; Viñas, P. Targeted and untargeted gas chromatography-mass spectrometry analysis of honey samples for determination of migrants from plastic packages. Food Chem. 2021, 334, 127547. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Yuan, J. Identification and quantification of unknown antioxidants in plastic materials by ultrasonic extraction and ultra-performance liquid chromatography coupled with quadrupole time-of-flight mass spectrometry. Eur. J. Mass Spectrom. 2016, 22, 19–29. [Google Scholar] [CrossRef] [PubMed]

- Canellas, E.; Vera, P.; Domeno, C.; Alfaro, A.P.; Nerin, C. Atmospheric pressure gas chromatography coupled to quadrupole-time of flight mass spectrometry as a powerful tool for identification of non intentionally added substances in acrylic adhesives used in food packaging materials. J. Chromatogr. A 2012, 1235, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Omer, E.; Cariou, R.; Remaud, G.; Guitton, Y.; Germon, H.; Hill, P.; Dervilly-Pinel, G.; Le Bizec, B. Elucidation of non-intentionally added substances migrating from polyester-polyurethane lacquers using automated LC-HRMS data processing. Anal. Bioanal. Chem. 2018, 410, 5391–5403. [Google Scholar] [CrossRef]

- Canellas, E.; Vera, P.; Nerin, C. UPLC-ESI-Q-TOF-MSE and GC-MS identification and quantification of non-intentionally added substances coming from biodegradable food packaging. Anal. Bioanal. Chem. 2015, 407, 6781–6790. [Google Scholar] [CrossRef] [PubMed]

- Špánik, I.; Machyňáková, A. Recent applications of gas chromatography with high-resolution mass spectrometry. J. Sep. Sci. 2018, 41, 163–179. [Google Scholar] [CrossRef]

- Hernández, F.; Portolés, T.; Pitarch, E.; López, F.J. Gas chromatography coupled to high-resolution time-of-flight mass spectrometry to analyze trace-level organic compounds in the environment, food safety and toxicology. TrAC Trends Anal. Chem. 2011, 30, 388–400. [Google Scholar] [CrossRef]

- Hoppe, M.; De Voogt, P.; Franz, R. Oligomers in polyethylene furanoate—Identification and quantification approach via LC-UV LC-MS response ratio. Food Addit. Contam. Part A 2018, 35, 2244–2255. [Google Scholar] [CrossRef]

- Wang, B.; Dong, X.-S.; Wang, Z.; Wang, Y.-F.; Hou, Z.-Y. MEMS-Based Ionization Gas Sensors for VOCs with Array of Nanostructured Silicon Needles. ACS Sens. 2020, 5, 994–1001. [Google Scholar] [CrossRef]

- Liao, W.; Draper, W.M.; Perera, S.K. Identification of Unknowns in Atmospheric Pressure Ionization Mass Spectrometry Using a Mass to Structure Search Engine. Anal. Chem. 2008, 80, 7765–7777. [Google Scholar] [CrossRef] [PubMed]

- Osorio, J.; Dreolin, N.; Aznar, M.; Nerín, C.; Hancock, P. Determination of volatile non intentionally added substances coming from a starch-based biopolymer intended for food contact by different gas chromatography-mass spectrometry approaches. J. Chromatogr. A 2019, 1599, 215–222. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pieke, E.N.; Granby, K.; Teste, B.; Smedsgaard, J.; Rivière, G. Prioritization before risk assessment: The viability of uncertain data on food contact materials. Regul. Toxicol. Pharmacol. 2018, 97, 134–143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Severin, I.; Souton, E.; Dahbi, L.; Chagnon, M.C. Use of bioassays to assess hazard of food contact material extracts: State of the art. Food Chem. Toxicol. 2017, 105, 429–447. [Google Scholar] [CrossRef] [PubMed]

- Schilter, B.; Burnett, K.; Eskes, C.; Geurts, L.; Jacquet, M.; Kirchnawy, C.; Oldring, P.; Pieper, G.; Pinter, E.; Tacker, M.; et al. Value and limitation of in vitro bioassays to support the application of the threshold of toxicological concern to prioritise unidentified chemicals in food contact materials. Food Addit. Contam. Part. A 2019, 36, 1903–1936. [Google Scholar] [CrossRef] [PubMed]

- Groh, K.J.; Geueke, B.; Muncke, J. Food contact materials and gut health: Implications for toxicity assessment and relevance of high molecular weight migrants. Food Chem. Toxicol. 2017, 109, 1–18. [Google Scholar] [CrossRef]

- Koster, S.; Rennen, M.; Leeman, W.; Houben, G.; Muilwijk, B.; van Acker, F.; Krul, L. A novel safety assessment strategy for non-intentionally added substances (NIAS) in carton food contact materials. Food Addit. Contam. Part. A 2014, 31, 422–443. [Google Scholar] [CrossRef]

- Veyrand, J.; Marin-Kuan, M.; Bezencon, C.; Frank, N.; Guérin, V.; Koster, S.; Latado, H.; Mollergues, J.; Patin, A.; Piguet, D.; et al. Integrating bioassays and analytical chemistry as an improved approach to support safety assessment of food contact materials. Food Addit. Contam. Part. A 2017, 34, 1807–1816. [Google Scholar] [CrossRef]

- Gelbke, H.-P.; Banton, M.; Block, C.; Dawkins, G.; Eisert, R.; Leibold, E.; Pemberton, M.; Puijk, I.M.; Sakoda, A.; Yasukawa, A. Risk assessment for migration of styrene oligomers into food from polystyrene food containers. Food Chem. Toxicol. 2019, 124, 151–167. [Google Scholar] [CrossRef]

- Eckardt, M.; Schneider, J.; Simat, T.J. In vitro intestinal digestibility of cyclic aromatic polyester oligomers from polyethylene terephthalate (PET) and polybutylene terephthalate (PBT). Food Addit. Contam. Part A 2019, 36, 1882–1894. [Google Scholar] [CrossRef]

- Mertens, B.; Van Hoeck, E.; Blaude, M.-N.; Simon, C.; Onghena, M.; Vandermarken, T.; Van Langenhove, K.; Demaegdt, H.; Vandermeiren, K.; Covaci, A.; et al. Evaluation of the potential health risks of substances migrating from polycarbonate replacement baby bottles. Food Chem. Toxicol. 2016, 97, 108–119. [Google Scholar] [CrossRef]

- Koster, S.; Boobis, A.R.; Cubberley, R.; Hollnagel, H.M.; Richling, E.; Wildemann, T.; Würtzen, G.; Galli, C.L. Application of the TTC concept to unknown substances found in analysis of foods. Food Chem. Toxicol. 2011, 49, 1643–1660. [Google Scholar] [CrossRef] [PubMed]

- Kroes, R.; Renwick, A.G.; Cheeseman, M.; Kleiner, J.; Mangelsdorf, I.; Piersma, A.; Schilter, B.; Schlatter, J.; van Schothorst, F.; Vos, J.G.; et al. Structure-based thresholds of toxicological concern (TTC): Guidance for application to substances present at low levels in the diet. Food Chem. Toxicol. 2004, 42, 65–83. [Google Scholar] [CrossRef] [PubMed]

- Herrman, J.L.; Younes, M. Background to the ADI/TDI/PTWI. Regul. Toxicol. Pharmacol. 1999, 30, S109–S113. [Google Scholar] [CrossRef]

- Tang, X.Z.; Kumar, P.; Alavi, S.; Sandeep, K.P. Recent Advances in Biopolymers and Biopolymer-Based Nanocomposites for Food Packaging Materials. Crit. Rev. Food Sci. Nutr. 2012, 52, 426–442. [Google Scholar] [CrossRef] [PubMed]

- Grujić, R.; Vujadinović, D.; Savanović, D. Biopolymers as Food Packaging Materials. In Advances in Applications of Industrial Biomaterials; Pellicer, E., Nikolic, D., Sort, J., Baró, M., Zivic, F., Grujovic, N., Grujic, R., Pelemis, S., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 139–160. ISBN 978-3-319-62767-0. [Google Scholar]

- Dintcheva, N.T.; Infurna, G.; Baiamonte, M.; D’Anna, F. Natural Compounds as Sustainable Additives for Biopolymers. Polymers 2020, 12, 732. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zimmermann, L.; Dombrowski, A.; Völker, C.; Wagner, M. Are bioplastics and plant-based materials safer than conventional plastics? In vitro toxicity and chemical composition. Environ. Int. 2020, 145, 106066. [Google Scholar] [CrossRef]

- Polman, E.M.N.; Gruter, G.-J.M.; Parsons, J.R.; Tietema, A. Comparison of the aerobic biodegradation of biopolymers and the corresponding bioplastics: A review. Sci. Total Environ. 2021, 753, 141953. [Google Scholar] [CrossRef]

- Simona, J.; Dani, D.; Petr, S.; Marcela, N.; Jakub, T.; Bohuslava, T. Edible Films from Carrageenan/Orange Essential Oil/Trehalose—Structure, Optical Properties, and Antimicrobial Activity. Polymers 2021, 13, 332. [Google Scholar] [CrossRef]

- Wicochea-Rodríguez, J.D.; Chalier, P.; Ruiz, T.; Gastaldi, E. Active Food Packaging Based on Biopolymers and Aroma Compounds: How to Design and Control the Release. Front. Chem. 2019, 7, 398. [Google Scholar] [CrossRef]

- Asensio, E.; Montañés, L.; Nerín, C. Migration of volatile compounds from natural biomaterials and their safety evaluation as food contact materials. Food Chem. Toxicol. 2020, 142, 111457. [Google Scholar] [CrossRef]

- Aznar, M.; Ubeda, S.; Dreolin, N.; Nerín, C. Determination of non-volatile components of a biodegradable food packaging material based on polyester and polylactic acid (PLA) and its migration to food simulants. J. Chromatogr. A 2019, 1583, 1–8. [Google Scholar] [CrossRef]

- Gavril, G.-L.; Wrona, M.; Bertella, A.; Świeca, M.; Râpă, M.; Salafranca, J.; Nerín, C. Influence of medicinal and aromatic plants into risk assessment of a new bioactive packaging based on polylactic acid (PLA). Food Chem. Toxicol. 2019, 132, 110662. [Google Scholar] [CrossRef] [PubMed]

- Osorio, J.; Aznar, M.; Nerín, C.; Birse, N.; Elliott, C.; Chevallier, O. Ambient mass spectrometry as a tool for a rapid and simultaneous determination of migrants coming from a bamboo-based biopolymer packaging. J. Hazard. Mater. 2020, 398, 122891. [Google Scholar] [CrossRef] [PubMed]

- Ubeda, S.; Aznar, M.; Alfaro, P.; Nerín, C. Migration of oligomers from a food contact biopolymer based on polylactic acid (PLA) and polyester. Anal. Bioanal. Chem. 2019, 411, 3521–3532. [Google Scholar] [CrossRef] [PubMed]

| Food Contact Material | NIAS | Method/Technique | Migration Tests | Reference |

|---|---|---|---|---|

| Polyvinyl chloride PVC/polyethylene-PE multilayer film | Antioxidants derivatives: Triester analog of 1010; Plasticizers (contain glycerol): 1-oleoyl-3-linoleoyl-rac-glycerol; Slip agents (with an amide end group): Tetracosenamide, Docosanamide, Icosanamide; Others: 2-(2-hydroxyethyl-hexadecylamino)ethyl palmitate, Bis(2-ethylhexyl) 2,2′-disulfanediyldiacetate | UPLC-QTOF/MS | Stainless-steel migration cell, water, 40% ethanol or 95% ethanol | [10] |

| Multilayer plastic materials (the combination of aluminium (Al), polyethylene terephthalate (PET), polyamide (PA), polypropylene (PP) and polyethylene (PE) | Cyclic esters (AA-DEG and AA-DEG-IPA-DEG) | UPLC-MS-QTOF and UHPLC-MS-QqQ | Ultrapure water, ethanol 10% and 95% ethanol | [25] |

| Polyethylene terephthalate (PET) | Cyclic oligomers | LC-MS | 50% ethanol at 80 °C | [28] |

| Polyester resins, tin plate sheets coated with polyester–phenolic lacquers and corresponding press-twist-closures (equipped with plasticized polyvinyl chloride [PVC] sealings) | Polyester oligomers (cyclic oligomers, dimers, trimers and tetramers) | HPLC–DAD, HPLC–DAD/MS, GC-MS, GC–MSD and RP-HPLC–DAD/MS | Mashed infant food and two types of homemade carrot puree, Acetonitrile, 50% Etanol, 20% Etanol | [29] |

| Rigid thermoformed containers and films made with Recycled polyethylene terephthalate-RPET | Chromium, nickel | CP-AES | Distilled water, 5% citric acid | [31] |

| Multilayer food packaging materials | Printing unknown ink compounds | GC-MS | Tenax, isooctane and etoh 95% and etoh 50% | [32] |

| Polyurethane adhesive | 1,4,7-trioxacyclotridecane-8,13-dione; 1,6-dioxacyclododecane-7,12-dione dimer; 1,4-dioxacyclotridecane-5,13-dione; 1,4,14,19-tetraoxacyclopent acosene-5,13,20,25-tetra one and 1,4-dioxacyclotridecane-5,13-dione; by-product of the curing reaction: 1,1-(Methanediyldibenzene-4,1-diyl)bis[3-(2-hydroxyethyl)urea]; 4-(7-acetoxy-5-methoxy-8,8-dimethyl-2-oxo-7,8-dihydro-2H,6H-pyrano[3,2-g]chromen-3-yl)-1,3-phenylene diace-tate; Bis[2-(diethylamino)ethyl] 4,4′-[(2-methyl-1,3propanediyl)bis(oxycarbonylimino)] dibenzoate and Bis[2-(diethylamino)ethyl]4,4′-[1,5-p entanediylbis(oxycarbonylim ino)] dibenzoate; unknown compounds | UPLC–Q-TOF/MS | Tenax | [33] |

| Expanded polystyrene (EPS) (recycled material) | Styrene dimmers are observed, like cis-1,2-diphenylcyclobutane, 2,4-diphenyl-1-butene, trans-1,2-diphenylcyclobutane and 1-phenyltetralin. These compounds were reported as by-products during styrene polymerization or material processing | HS-SPME-GC–MS | 10% (v/v) ethanol and 3%(w/v) acetic acid | [34] |

| Polyethylene-PE, low-density polyethylene-LDPE and HIGH-density polyethylene-HDPE | Dibutyl amine, N,N-bis(2-hydroxyethyl)alkylamines (impurity reaction or breakdown products), N,N-bis(2-hydroxyethyl) dodecylamine, tributylphosphine, tridodecylamine, Methyl (Ralox 35), ethyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propanoate (breakdown of Irganox 1010 or Irganox 1076), Benzenepropanoic acid, 3,5-bis(1,1-dimethylethyl)-4-hydroxy-, 1,1′-[2,2-bis(hydroxymethyl)-1,3-propanediyl] ester and benzenepropanoic acid, 3,5-bis(1,1-dimethylethyl)-4-hydroxy-, 1,1′-[2-[[3-[3,5-bis(1,1-dimethylethyl)-4-hydroxyphenyl]-1-oxopropoxy]methyl]-2-(hydroxymethyl)-1,3-propanediyl] ester (degradation of Irganox 1010), alkylamides N,N′-1,2-ethanediylbis-(breakdown or impurity products of the additive octadecanamide, N,N′-1,2-ethanediylbis), Irgafos 168 OXO (oxo-derivative of Irgafos 168), 11-eicosenamide (derived from oleamide) | UPLC IMS QTOF | Ethanol 95%, ethanol 50%, Tenax, ethanol 10% and acetic acid 3% | [59] |

| Empty cans with lids coated with polyester resins | Oligomers | GC–MS, HPLC-DAD/MS, UHPLC-HRMS and DART-HRMS | -- | [60] |

| Polyester coatings based on NAH | Oligomers | LC-MS/MS and LC-TOF-MS | Acetonitrile, Water, 10% Aqueous ethanol (v/v), 50% Aqueous ethanol (v/v) and diverse foodstuffs | [63] |

| Polyester can coating extracts | Linear and cyclic oligomers derived from the incomplete polymerization of polyester monomers, phthalic acids and diols | HPLC-MS, HPLC-ESI MS and HPLC-HRMS/MS | 95/5 etoh/water (v/v-%) solution for 4 h at 60 °C and 50/50 etoh/water (v/v-%) solution for 10 days at 60 °C | [64] |

| Virgin and recycled Polyethylene terephthalate-PET pellets | Cyclic and linear oligomers: TPA-EG, (TPA-EG)2 + H2O, (TPA-EG)2, (TPA-EG)3 + H20, (TPA-EG)3, (TPA-EG)4, and (TPA-EG)5, TPA2-EG-DEG + H2O, TPA2-EG-DEG, TPA3-EG2-DEG + H2O, TPA3-EG2-DEG, and TPA4-EG3-DEG, (TPA-DEG)2 and TPA4-EG2-DEG2 | UPLC-MS-QTOF | Ethanol 10% v/v) and simulant B (acetic acid 3% w/v) as aqueous simulants and ethanol 95% v/v as a fat simulant | [65] |

| Baby food squeezes with multilayer materials (Polyethylene terephthalate-PET/aluminium-Al/polyethylene-PE) | Polyester oligomers, 29 cyclic and six linear oligomers. ε-caprolactam was tentatively identified as a heterogenic polyester oligomer combined with AA, DEG, PA and NPG; BHET and diethyl 5-(2-((2,4,5-trimethoxybenzoyl)oxy)acetamido)isophthalate, methoxyeugenol and Bis(2-methoxyethyl) sebacate | UHPLC-ESI-QTOF MS | Baby food: mixture of fruit purées (apple, banana, pear), fruit jelly, chocolate custard, acetic acid 3% (w/v) and ethanol 20% (v/v) | [66] |

| Polyurethane adhesives in multilayer packaging materials | Silane unknown compounds; degradation of antioxidants Irgafos and Irganox (2,6-Di-tert-butylbenzoquinone; isomer 2,5-di-tert-butylbenzoquinone; 7,9-Di-tert-butyl-1-oxaspiro(4,5)deca-6,9-diene-2,8-dione; benzenepropanoic acid, 3,5-bis(1,1-dimethylethyl)-4-hydroxy-methyl), by-product of the polyester-based urethane 91,6-Dioxacyclododecane-7,12-dione); cyclic adipate; unknown nitrogen-compounds; unknown phenolic compounds; 1,4,7-Trioxacyclotridecane-8,13-dione | HS-SPME-GC-MS | Tenax; isooctane | [67] |

| UV-curable varnishes over polypropylene | 2-propenoic acid,1,1′-[2-[[3-[2,2-bis[[(1-oxo-2-propen-1-yl)oxy]methyl]butoxy]-1-oxopropoxy]methyl]-2-ethyl-1,3-propanediyl] ester is considered a NIAS, as it is a reaction product coming from the monomer TMPTA, 11-diethyl-7-oxo-4,6,10,12-tetraoxopentadecane-3,13-diyl diacrylate | GC-MS/Q and UHPLC-IMS/QTOF | Ethanol 95% (v/v) and Migracell® migration cells | [68] |

| Polyethylene terephthalate (PET), oriented polyamide (OPA), cast polypropylene (CPP), polyethylene (PE) and PE/ethyl vinyl alcohol PE(EVOH) | Primary aromatic amines-PAAs (1,8-diazacyclotetradecane-2,9-dione; caprolactam; 1,8,15-triazacycloheneicosane-2,9,16-trione; 1,3-bis(isocyanatomethyl)-cyclohexane, 1-cyanodecane and 1,4-bis(isocyanatomethyl)-cyclohexane; l-leucyl-l-leucyl-l-leucine; 1,4,7,18,21-pentaoxa-11,14,25,28-tetraazacyclohentriacontane (9CI); l-leucine; l-leucyl-l-leucyl-l-leucyl-l-leucyl-; butanediamide; N4-hydroxy-N1-[(1S)-2-methyl-1-(1-pyrrolidinylcarbonyl)propyl]-2-pentyl-, (2R)-; triethylamine, naphtylethylenediamine; 1,8,15,22-tetraazacyclooctacosane-2,9,16,23-tetrone; urea; N-cyclohexyl, urea, N-cyclohexy-N′-methyl and 1-(cyclohexycarbonyl)piperazine); Dimethyl phthalate | UHPLC–Q-TOF/MSE | 3% (w/v) acetic acid | [69] |

| Polypropylene random copolymer composite films | Irgafos 168 and its two degradation products, 2,4-di-tert-butylphenol (DP1) and tris (2,4-di-tert-butylphenyl) phosphate (DP2) | GC-MS | Isooctane | [70] |

| Polypropylene (PP) | Degradation products derived from phenolic antioxidants, impurity/reaction product/breakdown product of the additives, Family 1: Family formed with the reference structure; was formed by the compounds that had a similar structure constituted by a group 3,5-di-tert-butyl-4-hydroxyphenyl; Family 2: With glycerol molecule (glyceryl monostearate, glyceryl palmitate and glyceryl dihexadecanoate, an ester of an acid chain bonded to a glycerol molecule); Family 3: Dihydroxy alquilamines (amine bonded to two ethanol molecules and also an alkyl hydrocarbon chain); Family 4: ceramide and dihydroceramide (a family of waxy lipid molecules which are composed of sphingosine (an 18 carbon amino alcohol with an unsaturated hydrocarbon chain) and a fatty acid); Family 5: amides bonded by ethylene (degradation products from a lubricant losing C2H4); Other compounds (amides come from the impurities or degradation products from erucamide and oleamide widely used as slip agents) | UPLC-MS-QTOF | Ethanol 95% and 10%, acetic acid 3% and Tenax | [71] |

| Hot melt adhesives (Ethylene-vinyl acetate-EVA and amorphous polyolefin APAO enriched in propene) | Degradation of Irganox 1010: 3,5-di-tert-butyl-4-hydroxybenzaldehyde | UPLC-ESI-MS/QTOF | Tenax | [72] |

| Polyethylene terephthalate (PET) pellets | The degradation product of the antioxidants Irgafos 168 and Irganox 1010: 2,4-bis(1,1-dimethyl ethyl) phenol; 2-methyl-1,3-dioxolane; linear aldehydes; residual monomers: ethylene glycol (EG); thermal degradation products: toluene, ethylbenzene and xylene; phthalates (DEP, DIBP) | HS-SPME/GC-MS | -- | [73] |

| Polypropylene (PP) films | Degradation products from Irgafos 168, Tinuvin 326 and Irganox 1076 | HPLC-DAD and GC-FID–MS | Distilled water/ethanol—50/50 v/v | [74] |

| Plastic films (with and without printing ink) including PE: polyethene. PET: polyethylene terephthalate. PA: Polyamide. PP: Polypropylene. EVA: Ethylene-vinyl acetate. | 2,4-di-tert-butylphenol and 2,6-di-tert-butyl-1,4-benzoquinone. 2,4-di-tert-butylphenol is a degradation product of Irgafos 168 while 2,6-di-tert-butyl-1,4-benzoquinone is a degradation product of antioxidants such as Irganox 1010, Irgafos 168 and Irganox PS 802 | purge and trap (P&T) coupled to GC–MS | Isooctane and Tenax | [75] |

| Polypropylene (PP) | 2,4-di-tert-butylphenol (degradation product of Irgafos 168 and Irganox® 1010), tert-butyl-1-oxaspiro(4,5)deca-6-9-diene-2,8-dione (a by-product of the antioxidant Irganox 1010) and 2,6-di-tert-butyl-1,4-benzoquinone, a degradation product of antioxidants such as Irganox 1010, Irgafos 168 and Irganox PS 802 | GC-MS | -- | [76] |

| Polypropylene food storage containers | Degradation products: 2,4-di-tert-butylphenol and tris(2,4-di-tert-buthylphenyl)phosphate, methyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate, a compound identified as product of degradation of Irganox 1076 and/or Irganox 1010; 2,6-di-tert-butylbenzoquinone (isooctane fraction) and 7,9-di-tert-butyl-1-oxaspiro(4,5)deca-6,9-diene-2,8-dione; different compounds have been identified as metabolites of bis-(2-ethylhexyl) phthalate (e.g., 2-ethylhexanoic acid, 2-ethylhexanol, phthalic acid, mono-2-ethylhexyl phthalate), and consequently suggested as possible degradation products of this phthalate; by-product Benzothiazole; degradation products N,N-bis-(2-hydroxyethyl)alkyl amine | GC × GC−ToF MS | 3% (w/v) acetic acid, 10% (v/v) ethanol, and isooctane | [77] |

| Can coatings | Diisobutyl phthalate (DIBP), Degradation products formed from antioxidants (1,3-di-tert-butylbenzene and 2,4-di-tert-butylphenol degradation products from antioxidants Irgafos 168 or Irganox 1076, 2,6-di-tert-butyl-1,4-benzoquinone degradation products from antioxidants Irgafos 168 and Irganox 1010, 7,9-di-tert-butyl-1-oxaspiro(4,5)deca-6,9-diene-2,8-dione, a degradation product of Irganox 1010. | GC-MS and LC-MS/MS | -- | [78] |

| Recycled pellets obtained from post-consumer low-density polyethylene (PC-LDPE) and high-density polyethylene (PC-HPDE) | Polymer degradation products: octanal and nonanal (aldehydes); 3-decanone, 2-undecanone, 2,2,4,4,6,8,8-heptamethylnonanone and 3-dodecanone (ketones); hexane (others); Additives degradation products: 3,5-di-tert-butyl-4-hydroxybenzaldehyde (aldehyde); 2,6-di-tert-butyl-1,4-benzoquinone and 3,5-di-tert-butyl-4-hydroxyacetophenone (ketones); methyl tetradecanoate, ethyl tetradecanoate and ethyl palmitate(esters); 7,9-di-tert-butyl-1-oxaspiro (4,5)deca-6,9-diene-2,8-dione (others); Contaminants from external sources: methyl lactate, hexyl acetate and dimethyl butanedioate, α-methylionone, 3-(4-Isopropylphenyl)-2-methylpropionaldehyde, α-amylcinnamaldehyde, (phenylmethylene)octanal and dipropylene glycol amog others (cosmetic ingredients); alkylbenzenes (breakdown products produced by the degradation of alkylbenzene sulfonates); contamination related to food: the lactones, 5-methylfurfural, furfural and methyl hexanoate (can derive from food flavors as well as from cosmetics ingredients); furfuryl alcohol, methyl pyruvate and 2-acetyl pyridine (food flavors), methyl-2-ethylhexanoate, acetic acid, propanoic acid, pyridine and dimethyl trisulfide (rotten food products), 2,6-diisopropylnaphthalene (paper labels). | GC/MS and HS-SPME-GC/MS | -- | [79] |

| Plastic baby bibs (polyethylene vinyl acetate-PEVA, polyamide-PA and polyethylene-PE) | Azocine, octahydro-1-nitroso-(Possible NIAS from printing ink); 1,6-Dioxacyclododecane-7,12-dione (NIAS from polyurethane adhesive); 1-Propene-1,2,3-tricarboxylic acid, tributyl ester (Tributyl aconitate) | GC-MS | Artificial saliva | [80] |

| Polystyrene-PS cups and multilayer films | Styrene monomer and oligomers; polyester urethane-based oligomers (PU) cyclic oligomers: α-methylstyrene; 1,1-diphenyl-ethylene; 2,4-diphenyl-1-butene; trans-1,2-diphenycyclobutane; 2,4,6-triphenyl-1-hexene; | GC-MS | 10% v/v ethanol in water and 50% v/v ethanol in water | [81] |

| Polyurethane adhesives | 1,4,7-trioxacyclotridecane-8,13-dione, a lactone | UPLC-TQMS and UPLC-QTOF-MS | Tenax and 3% acetic acid | [82] |

| Polyvinylchloride (PVC)-coated cans | 6-(4-methylphenyl)-1,2,4,5-tetrazin-3-amine and BGA (6-phenyl-1,3,5-triazine-2,4-diamine) | UHPLC-HRMS | Water and 3% acetic acid | [83] |

| Monolayer film with polylactic acid (PLA), polylimonene (PL) and zinc oxide nanoparticles (ZnO NPs) | Tripropylene glycol diacrylate; 10-Heneicosene; α-Tocopherol acetate; N, N-Diethyldodecanamide; N-[(9Z)-9-Octadecen-1-yl]acetamide; 1-Palmitoylglycerol and Glycerol stearate | ICP-MS, GC–Q-Orbitrap-MS and LC–Q-Orbitrap-MS | 10% ethanol, 3% acetic acid | [84] |

| Flexible multilayer materials point by polyurethane (PU) layers | Polyamide oligomers; Anhydride of monomethyl succinate, 3,5-di-tert-butyl-4-hydroxybenzaldehyde; Erythritol monopalmitate; PU oligomers (cyclic esters made up of phthalic acid (PA); diethylene glycol (DEG) in combination 1:1 (PA-DEG) or 2:2 (PA-DEG-PA-DEG0); adipic acid (AA) or phthalic acid (PA); and diols such as diethylene glycol (DEG), neopentyl glycol (NPG), dipropylene glycol (DPG), dihydroxyalkyl ethers (dHAE), ethylene glycol (EG), propylene glycol (PG), butylene glycol (BD) or hexanediol (HD). | UPLC MS–QTOF | Ethanol 10% v/v, acetic acid 3% w/v, and ethanol 95% v/v | [85] |

| Active packaging: Polypropylene (PP); PP + green tea; PP/poly (ethylene-co-vinyl alcohol) EVOH; PP/EVOH + oregano; PP/EVOH + citral; EVOH; Polyethylene terephthalate-PET/EVOH + citral; PET/EVOH + cinnamon; PP/EVOH/PP; PP/EVOH + oregano | Degradation of active compounds; impurities from the raw materials; additives used in the manufacture of the active polymer (citral thermal reaction products; oxidation product of citral; decomposition product of adipates used as plasticizers; impurity/reaction product/breakdown product for the additives used in the manufacture of PE materials; xanthenone derivates) | UPLC-QTOF-MS | Ethanol 10%; ethanol 95% | [86] |

| Polyethylene terephthalate (PET) film with an acrylic resin | Ethyl lauroyl arginate (LAE) impurities: N2-Dodecanoyl-L-arginine (LAS) | UPLC–MS(QTOF) | Ethanol 10%; ethanol 95%; sliced fresh chicken breasts | [87] |

| Multilayer materials | 1,4,7-trioxacyclotridecane-8,13-dione, and diethylene glycol (DEG) [AA-DEG]. | LC-HRMS | Ethanol 95% and Tenax | [88] |

| Silicone moulds and teats | Side reactions in the polymerization (cyclic and linear polydimethylsiloxanes; oligomeric dimethyl siloxanes) | H-NMR and GC-MS | Pizza | [89] |

| Polyurethane adhesives commonly used for food-contact laminated films | No NIAS detected. | GC–MS | Isooctane | [90] |

| Polyvinylchloride (PVC)—and polyethylene (PE)—based cling-films | 2-ethyl hexanoic acid (2-EHA), triacetin | Solid-Phase Micro-Extraction and GC/MS | PDO Italian cheeses during cold storage under light or dark | [91] |

| Oriented polypropylene (OPP) and polyethylene terephthalate (PET) with printing inks | Printing unknown ink compounds | UPLC-QTOF-MS | Ethanol (95%) and Tenax | [92] |

| Polyurethanes (PURs) | Pyridine (NIAS, solvent); Dimethylacetamide (NIAS, solvent); 1,4-Dioxane (NIAS, reaction medium); Aniline NIAS, precursor, o-Toluidine NIAS, degradation product, Diaminotoluene NIAS, intermediate, o-Anisidine NIAS, intermediate, 1,4,7-trioxacyclotridecane-8,13-dione, Myristamide NIAS, contaminant, Palmitamide NIAS, contaminant, Oleamide NIAS, contaminant, Stearamide NIAS, contaminant. | GC-MS and DART-MS | -- | [93] |

| Polycarbonate (PC) | Oligomers; PC-degradation products | UHPLC–ESI Q-orbitrap | -- | [94] |

| Candy wrappers based on plastic and paper materials | 2,6-Di-tert-butyl-4-methylene-2,5-cyclohexadienone, a degradation product of BHT, Diethyl maleate, Triacetin, Propanoic acid, 2-methyl-, 3-Hydroxy-2,4,4-trimethylpentyl ester, Diethyl phthalate, Diisobutyl phthalate, 7,9-Di-tert-butyl-1-oxaspiro(4,5)deca-6-9-diene-2,8-dione, Heneicosane, Tributyl aconitate, Docosane, Tricosane, Tetracosane, Pentacosane, Hexacosane, Heptacosane, Octocosane, Squalene, n-Nonacosane, Glycerol tricaprylate | GC-MS | -- | [95] |

| Polyester-polyurethane lacquers | Impurities or degradation products of IPDI trimer IPDI and DPMDI, two cyclic oligoesters, 2EG + 2TPA and 2NPG + 2oPA | GC-(EI)qMS, GC-(EI)Orbitrap, GC-(APCI)TOFHRMS and GC(×GC)-(EI)TOFLRMS | -- | [96] |

| Polybutylene terephthalate (PBT) | Cyclic oligomers from dimer to pentamer containing TPA and BD, cyclic oligomers, linear oligomers, dehydration products | HPLC-DAD/ESI-MS | -- | [97] |

| Multilayer plastic materials (polyethylene (PE) and low-density polyethylene (LDPE) plus nylon) | Four cyclic oligomers of caprolactam (dimer, trimer, tetramer, and pentamer); by-products-cyclic ester oligomers made of the monomers adipic acid (AA), phthalic acid (PA), diethylene glycol (DEG), monoethylene glycol (MEG) and neopentilglycol (NPG); Nylon cyclic dimer, Caprolactam Cyclic Trimer, AA-DEG, Caprolactam Cyclic Tetramer, Caprolactam Cyclic Pentamer, PA-DEG, Cyclic ester made up of Phthalic acid and diethylene glycol in combination 1:2, AA-MEG-AA-MEG, AA-MEG-AA-DEG, AA-DEG-AA-DEG, PA-MEG-AA-DEG, PA-DEG-PA-DEG, PA-DEG-AA-NPG, AA-BD, AA-BD-AA-BD, AA-DEG + H2O, AA-DEG-PA-DEG + H2O, 3,6,9,12,15-pentaoxabicyclo(15.3.1)henicosa-1(21),17,19-triene-2,16-dione, 1,6-dioxacyclodecane-7,12-dione, 1,6-dioxacyclodecane-7,12-dione, 1,6,13,18-tetraoxacyclotetracosane-2,5,14,17-tetrone | LC-HRAMS and LC-ESI-Q-TOF-MS | 3% acetic acid in water (w/v) and 20% of ethanol in water (v/v) | [98] |

| Low-Density Polyethylene (LDPE) films | Calcite (CaCO3), calcium sulphate (CaSO4), polystyrene (PS) and titanium dioxide (TiO2), Ca and Ti | Raman spectroscopy and ICP-MS | -- | [99] |

| Water-based acrylic adhesive | 2-(12-(methacryloyloxy) dodecyl)malonic acid | GC-MS and UPLC-QTOF | Poly(2,6-diphenyl-p-phenylene oxide) (Tenax®) | [100] |

| High and low-density polyethylene(HDPE and LDPE) | Phthalic anhydride, phthalic acid, di-butyl phthalate (DBP) and bis(2-ethylhexyl) phthalate (DEHP) | FIA-MS, LTQ-Orbitrap | -- | [101] |

| Multilayer materials with barrier properties | Acids (nonanoic acid), Alcohols (2-nonen-1-ol), Aldehydes (5-hydroxymethylfurfural), Aldehydes (5-hydroxymethylfurfural), Alkanes (n-dodecane), Alkenes (1-undecene), Antioxidants (2,6-di-tert-butyl-4-methylphenol), Aromatics (1,3-di-tert-butyl-benzene), Cyclics (n-propyl-cyclohexane), Esters (ethyl hydrogen sebacate), Ethers (1,1′-oxybis-octane), Ketones (2-undecanone), Oxidation Products (2,6-di-tert-butyl-1,4-benzoquinone) | SPME–GC–MS | -- | [102] |

| Polyester Coatings | Oligomers | HPLC-DAD/CAD, HPLC-MS and HPLC-MS/MS | Water, 3% acetic acid, 10% ethanol, 50% ethanol, and isooctane | [103] |

| Low-density polyethylen-LDPE and polyamide-PA added of NBBS, α-MSD, Irganox 1081, Irganox 1222, Santonox; LDPE 2/PA 6 2: Nonox A, Neozon D, Antioxidant 2246, Tinuvin P, TOTM | Degradation products of TOTM, including DEHP, isophthalate bis(2-ethylhexyl)benzene-1,3-dicarboxylate (DOIP); decomposition product of NBBS was N-ethyl-N-methylbenzenesulfonamide; The formation of the cyclic saturated isomer (1,1,3-trimethyl-3-phenyl-2H-indene) is triggered by thermal impact, and so is the rearrangement of the carbon double bond to form isomer 2,4-diphenyl-4-methyl-2(E)-pentene). Decomposition product 2,3-dimethyl-3-phenylbutan-2-yl)benzene is formed by combining two cumyl radicals during pyrolysis of the pure additive and pyrolysis of LDPE entailing α-MSD. The degradation product of Neozon D and Nonox A identified in oxidative pyrolysis of the pure analyte was 10-methyl-benz[a]acridine; degradation products of Antioxidant 2246, Santonox, Irganox 1222/1081 and Tinuvin P: o-cresol, m-cresol or p-cresol, 2-tert-butyl-4-methylphenol and 2-tert-butyl-4,6-dimethylphenol, 3,5-di-tert-butyl-4-hydroxybenzaldehyde | Pyr-GC–MS and GC-EI-MS/MS | -- | [104] |

| Food Contact Material | NIAS | Method/Technique | Reference |

|---|---|---|---|

| Polycarbonate (PC) | Oligomers | UHPLC–ESI Q-orbitrap | [94] |

| Polyester Coatings | Oligomers | HPLC-DAD/CAD, HPLC-MS and HPLC-MS/MS | [60] |

| Polyester coatings based on NAH | Oligomers | LC-MS/MS and LC-TOF-MS | [63] |

| Polyester can coating extracts | Linear and cyclic oligomers derived from the incomplete polymerization of polyester monomers, phthalic acids and diols | HPLC-MS, HPLC-ESI MS and HPLC-HRMS/MS | [64] |

| Empty cans with lids coated with polyester resins | Oligomers | GC–MS, HPLC-DAD/MS, UHPLC-HRMS and DART-HRMS | [60] |

| Polyester resins, tin plate sheets coated with polyester–phenolic lacquers and corresponding press-twist-closures (equipped with plasticized polyvinyl chloride (PVC) sealings) | Polyester oligomers (cyclic oligomers, dimers, trimers and tetramers) | HPLC–DAD, HPLC–DAD/MS, GC-MS, GC–MSD and RP-HPLC–DAD/MS | [29] |

| Flexible multilayer materials point by polyurethane (PU) layers | Polyamide oligomers, PU oligomers (cyclic esters made up of phthalic acid (PA) | UPLC MS–QTOF | [85] |

| Polyethylene terephthalate (PET) | Cyclic oligomers | LC-MS | [28] |

| Virgin and recycled Polyethylene terephthalate-PET pellets | Cyclic and linear oligomers: TPA-EG, (TPA-EG)2 + H2O, (TPA-EG)2, (TPA-EG)3 + H20, (TPA-EG)3, (TPA-EG)4, and (TPA-EG)5, TPA2-EG-DEG + H2O, TPA2-EG-DEG, TPA3-EG2-DEG + H2O, TPA3-EG2-DEG, and TPA4-EG3-DEG, (TPA-DEG)2 and TPA4-EG2-DEG2 | UPLC-MS-QTOF | [65] |

| Baby food squeezes with multilayer materials (Polyethylene terephthalate-PET/aluminium-Al/polyethylene-PE) | Polyester oligomers, 29 cyclic and six linear oligomers. ε-caprolactam was tentatively identified as a heterogenic polyester oligomer combined with AA, DEG, PA and NPG; BHET and diethyl 5-(2-((2,4,5-trimethoxybenzoyl)oxy)acetamido)isophthalate, methoxyeugenol and Bis(2-methoxyethyl) sebacate | UHPLC-ESI-QTOF MS | [66] |

| Polybutylene terephthalate (PBT) | Cyclic oligomers from dimer to pentamer containing TPA and BD, cyclic oligomers, linear oligomers, dehydration products | HPLC-DAD/ESI-MS | [97] |

| Multilayer plastic materials (polyethylene (PE) and low-density polyethylene (LDPE) plus nylon | Four cyclic oligomers of caprolactam (dimer, trimer, tetramer, and pentamer); by-products-cyclic ester oligomers made of the monomers adipic acid (AA), phthalic acid (PA), diethylene glycol (DEG), monoethylene glycol (MEG) and neopentilglycol (NPG); Nylon cyclic dimer, Caprolactam Cyclic Trimer, AA-DEG, Caprolactam Cyclic Tetramer, Caprolactam Cyclic Pentamer, PA-DEG, Cyclic ester made up of Phthalic acid and diethylene glycol in combination 1:2, AA-MEG-AA-MEG, AA-MEG-AA-DEG, AA-DEG-AA-DEG, PA-MEG-AA-DEG, PA-DEG-PA-DEG, PA-DEG-AA-NPG, AA-BD, AA-BD-AA-BD, AA-DEG + H2O, AA-DEG-PA-DEG + H2O, 3,6,9,12,15-pentaoxabicyclo(15.3.1)henicosa-1(21),17,19-triene-2,16-dione, 1,6-dioxacyclodecane-7,12-dione, 1,6-dioxacyclodecane-7,12-dione, 1,6,13,18-tetraoxacyclotetracosane-2,5,14,17-tetrone | LC-HRAMS and LC-ESI-Q-TOF-MS | [98] |

| Polystyrene-PS cups and multilayer films | Styrene monomer and oligomers; polyester urethane-based oligomers (PU) cyclic oligomers: α-methylstyrene; 1,1-diphenyl-ethylene; 2,4-diphenyl-1-butene; trans-1,2-diphenycyclobutane; 2,4,6-triphenyl-1-hexene; | GC-MS | [81] |

| Food Contact Material | NIAS | Method/Technique | Reference |

|---|---|---|---|

| Active packaging: Polypropylene (PP); PP + green tea; PP/poly (ethylene-co-vinyl alcohol) EVOH; PP/EVOH + oregano; PP/EVOH + citral; EVOH; Polyethylene terephthalate-PET/EVOH + citral; PET/EVOH + cinnamon; PP/EVOH/PP; PP/EVOH + oregano | Degradation of active compounds; impurities from the raw materials; additives used in the manufacture of the active polymer (citral thermal reaction products; oxidation product of citral; decomposition product of adipates used as plasticizers; impurity/reaction product/breakdown product for the additives used in the manufacture of PE materials; xanthenone derivates) | UPLC-QTOF-MS | [86] |

| Polyurethane adhesives in multilayer packaging materials | By-product of the polyester-based urethane 91,6-Dioxacyclododecane-7,12-dione); cyclic adipate; unknown nitrogen-compounds; unknown phenolic compounds; 1,4,7-Trioxacyclotridecane-8,13-dione | HS-SPME-GC-MS | [67] |

| Polyethylene terephthalate (PET), oriented polyamide (OPA), cast polypropylene (CPP), polyethylene (PE) and PE/ethyl vinyl alcohol PE(EVOH) | Primary aromatic amines-PAAs (1,8-diazacyclotetradecane-2,9-dione; caprolactam; 1,8,15-triazacycloheneicosane-2,9,16-trione; 1,3-bis(isocyanatomethyl)-cyclohexane, 1-cyanodecane and 1,4-bis(isocyanatomethyl)-cyclohexane; l-leucyl-l-leucyl-l-leucine; 1,4,7,18,21-pentaoxa-11,14,25,28-tetraazacyclohentriacontane (9CI); l-leucine; l-leucyl-l-leucyl-l-leucyl-l-leucyl-; butanediamide; N4-hydroxy-N1-[(1S)-2-methyl-1-(1-pyrrolidinylcarbonyl)propyl]-2-pentyl-, (2R)-; triethylamine, naphtylethylenediamine; 1,8,15,22-tetraazacyclooctacosane-2,9,16,23-tetrone; urea; N-cyclohexyl, urea, N-cyclohexy-N′-methyl and 1-(cyclohexycarbonyl)piperazine); Dimethyl phthalate | UHPLC–Q-TOF/MSE | [69] |

| Silicone moulds and teats | Side reactions in the polymerization (cyclic and linear polydimethylsiloxanes; oligomeric dimethyl siloxanes) | H-NMR and GC-MS | [89] |

| Multilayer plastic materials (polyethylene (PE) and low-density polyethylene (LDPE) plus nylon | By-products-cyclic ester oligomers made of the monomers adipic acid (AA), phthalic acid (PA), diethylene glycol (DEG), monoethylene glycol (MEG) and neopentilglycol (NPG) | LC-HRAMS and LC-ESI-Q-TOF-MS | [98] |

| Polypropylene food storage containers | By-product Benzothiazole | GC × GC−ToF MS | [77] |

| UV-curable varnishes over polypropylene | 2-propenoic acid,1,1′-[2-[[3-[2,2-bis[[(1-oxo-2-propen-1-yl)oxy]methyl]butoxy]-1-oxopropoxy]methyl]-2-ethyl-1,3-propanediyl] ester is considered a NIAS, as it is a reaction product coming from the monomer TMPTA, 11-diethyl-7-oxo-4,6,10,12-tetraoxopentadecane-3,13-diyl diacrylate | GC-MS/Q and UHPLC-IMS/QTOF | [68] |

| Food Contact Material | NIAS | Method/Technique | Reference |

|---|---|---|---|

| Active packaging: Polypropylene (PP); PP + green tea; PP/poly (ethylene-co-vinyl alcohol) EVOH; PP/EVOH + oregano; PP/EVOH + citral; EVOH; Polyethylene terephthalate-PET/EVOH + citral; PET/EVOH + cinnamon; PP/EVOH/PP; PP/EVOH + oregano | Degradation of active compounds; impurities from the raw materials; additives used in the manufacture of the active polymer (citral thermal reaction products; oxidation product of citral; decomposition product of adipates used as plasticizers; impurity/reaction product/breakdown product for the additives used in the manufacture of PE materials; xanthenone derivates) | UPLC-QTOF-MS | [86] |

| Polyurethane adhesives in multilayer packaging materials | Silane unknown compounds; degradation of antioxidants Irgafos and Irganox (2,6-Di-tert-butylbenzoquinone; isomer 2,5-di-tert-butylbenzoquinone; 7,9-Di-tert-butyl-1-oxaspiro(4,5)deca-6,9-diene-2,8-dione; benzenepropanoic acid, 3,5-bis(1,1-dimethylethyl)-4-hydroxy-methyl) | HS-SPME-GC-MS | [67] |

| Hot melt adhesives (Ethylene-vinyl acetate-EVA and amorphous polyolefin APAO enriched in propene) | Degradation of Irganox 1010: 3,5-di-tert-butyl-4-hydroxybenzaldehyde | UPLC-ESI-MS/QTOF | [72] |

| Polyethylene terephthalate-PET pellets | The degradation product of the antioxidants Irgafos 168 and Irganox 1010: 2,4-bis(1,1-dimethyl ethyl) phenol; 2-methyl-1,3-dioxolane; linear aldehydes; residual monomers: ethylene glycol (EG); thermal degradation products: toluene, ethylbenzene and xylene; phthalates (DEP, DIBP) | HS-SPME/GC-MS | [73] |

| Polycarbonate (PC) | Oligomers; PC-degradation products | UHPLC–ESI Q-orbitrap | [94] |

| Polypropylene (PP) films | Degradation products from Irgafos 168, Tinuvin 326 and Irganox 1076 | HPLC-DAD and GC-FID–MS | [74] |

| Candy wrappers based on plastic and paper materials | 2,6-Di-tert-butyl-4-methylene-2,5-cyclohexadienone, a degradation product of BHT, Diethyl maleate, Triacetin, Propanoic acid, 2-methyl-, 3-Hydroxy-2,4,4-trimethylpentyl ester, Diethyl phthalate, Diisobutyl phthalate, 7,9-Di-tert-butyl-1-oxaspiro(4,5)deca-6-9-diene-2,8-dione, Heneicosane, Tributyl aconitate, Docosane, Tricosane, Tetracosane, Pentacosane, Hexacosane, Heptacosane, Octocosane, Squalene, n-Nonacosane, Glycerol tricaprylate | GC-MS | [95] |