1. Introduction

The manufacturing of technical parts from a digital model is an effective way of producing complex geometries [

1,

2]. As reported by [

1], AM is developed to conceptualise models for products but quickly to process materials. Zai et al. [

2] also reported that AM is an advanced manufacturing process for the fabrication of 3D functional components with a limited dependence on tooling and fixture. Despite the large amount of time needed to manufacture a single part by additive manufacturing (AM) technologies compared to traditional processes such as injection moulding or extrusion [

3], AM is still an attractive method [

3,

4,

5]. Indeed, the fabrication cycle for AM requires only a CAD model instead of preparing, adapting, or producing a new tool. As described by Baumers et al. [

3], AM has, in that sense, a huge economic impact on the manufacturing sector because of the reduced tooling costs. According to Berman [

5], this reduction in cost can be also attributed to automation, which allows AM be autonomous, not requiring constant attention from the operators during the production cycle. The economic impact has been covering a large number of industries, but as reported in the review paper by Mousa et al. [

4], key sectors such as aerospace, automotive, medical industries, and electronics are sharing most of the AM focus. In terms of the fabrication cycle, once the CAD model is prepared, a series of tool paths is the only intermediate step to transform the virtual sketch into a real part [

6,

7,

8]. As explained in the paper by Pandey [

6], the series of tool paths requires slicing the CAD model into a series of thin layers. The thickness of these layers determines the balance between the surface finish and the building time. According to Hague et al. [

7], the outcome of the slicing procedure results in critical factors such as surface finish, resolution, and accuracy that engineers need to constantly adapt to allow AM to be a viable manufacturing technology. This is why early contributions such as the one on stereolithography by Jamison et al. [

8] tackled the deviation errors in design tessellation, which is the basic procedure for converting the 3D design into a set of triangular patches.

Waiving the obligation for tooling means also increasing the offer for personalised products that AM is able to fulfil [

5]. There is no doubt that several industries clearly understood this potential by directing a substantial investment towards AM-based products [

9,

10,

11,

12,

13]. The review paper by Sing et al. [

9] shows that the leading market for AM-based products is consumer products and electronics, with up to 21% of the total market shares. The automatic and medical sectors come in the second and third positions, respectively. In the automotive industry, for instance, the market needs lighter, safer, and cost-effective products with as short a lead time as possible, which are the main value drivers for AM according to Giffi et al. [

10]. In the aerospace sector, safety concerns with regards to the reliability of 3D printed parts is still a challenge, but some leading projects using AM processes to manufacture parts have been granted substantial funding, such as to produce air-cooling ducts, plastic interior parts, leading-edge blades, and even entire spacecraft structures [

11]. In the medical sector, Peltola et al. [

12] pointed out the advantage of the overall conventional AM route for biocompatible parts for customising implants or engineered body parts from medical scans of patients. A huge segment of the market is dedicated to AM technologies, such as tissue engineering for bone and cartilage repair applications. For civil engineering applications, Krimi et al. [

13] demonstrated that design flexibility versus the production rate is still a challenging balance for AM to compete with standard routes in construction such as prefabrication or casting on site. The growing interest in AM technologies comes with some aspirations to solve the problems of part inaccuracy and finishing state [

14,

15,

16], to improve the productivity [

9], and to gain in performance [

17,

18]. For instance, Zhou et al. [

14] applied surface response and ANOVA analysis to optimise the process parameters in stereolithography technology to achieve optimal dimensional accuracy and build time. Most of the performance limitations come from mechanical anisotropy and the loss in strength and stiffness driven by the presence of the particular arrangement of defects. For instance, Dawoud et al. [

18] compared the rendering of FDM (fused deposition modelling) with injection moulding and showed that ABS specimens manufactured using injection moulding exhibited the highest mechanical performance. Hague et al. [

7] compared the mechanical performance of specimens printed using stereolithography and the laser sintering process under different building orientations. The study concluded on different trends with respect to the processing route. Although stereolithography based specimens exhibited isotropic properties, the laser sintering process generated more anisotropic parts. Puebla et al. [

17] showed, however, that stereolithography may generate anisotropic behaviour, especially if the part orientation is combined with different aging trends. Huang et al. [

15] studied the shape shrinkage responsible for design dimension inaccuracy and developed a methodology for anticipating geometric errors. Depending on the complexity of the designs, geometrical inaccuracy can also be related to the presence of support material needed for printing overhangs. Thus, attempts have been made to decrease the influence of support material as suggested by Paul et al. [

16] by using an algorithmic approach to minimise the flatness and cylindricity errors.

There is, generally, no balance between AM technologies with regards to their sensitivity to process-induced defects. For instance, fused deposition modelling (FDM) is known to produce two-dimensional discontinuities because the process is based on the laying down of 1D continuous features, i.e., the filaments. In 3D space, this obviously generates a particular arrangement of three-dimensional porosities. As a result, the part contains a well-ordered porosity network evidenced by several imaging techniques such as X-ray micro-tomography [

19]. The origin of mechanical anisotropy, and especially the lack of performance in the building direction, results from this process-induced porosity. In the case of stereolithography, the laser drawing leaves no material discontinuity within the plane, and the liquid state of the resin used in such technology ensures the continuity of the material both in the plane of deposition and along the building direction [

20]. This means that stereolithography has better mechanical rendering compared to FDM but has some limitations, especially in producing parts with closed porosities [

20]. In addition, stereolithography requires the feedstock material to be photo-sensitive and generates more operating costs. These factors narrow down the spectrum of applications for this type of technology.

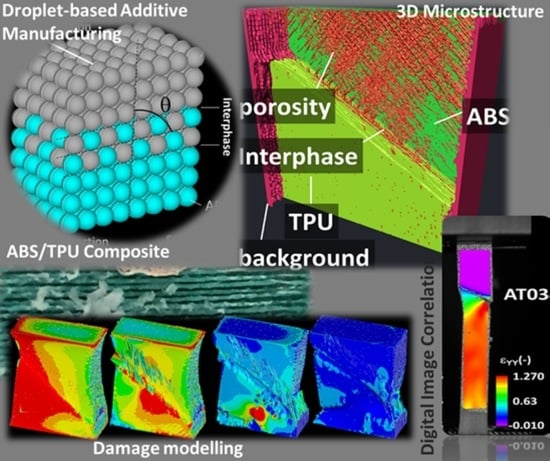

In this study, the effect of process-induced defects in droplet-based additive manufacturing is investigated with respect to the tensile performance of a polymeric composite. This technology naturally produces 3D discontinuities related to the successive laying down of individual droplets. In a printed composite structure, the material discontinuity may exhibit a complex trend that this study intends to quantify. For instance, in a two-phase composite, defects created in each phase are not the same as those dependent on the thermal behaviour of the intrinsic phases during the laying down. However, close to the interface, both phases are expected to contribute to the defects created by material discontinuity. In particular, this study combines a 3D imaging tool based on X-ray micro-tomography, finite element computation, and testing experiments to reveal the nature, magnitude, and extent of the process-generated defects as well as the interfacial effect on the mechanical response. The materials considered for this study are acrylonitrile butadiene styrene (ABS) and thermoplastic polyurethane (TPU). ABS material is usually used for applications where chock resistance, dimensional stability, and electric insulation are required. It is, for instance, widely used in consumer products, communication equipment, automotive parts, and home appliances. TPU, on the other hand, is known for its elasticity and resistance to abrasion, and has common use as ABS in the automotive, appliance, construction, and recreation industries. The combination of the tough and elastic properties in a single material is needed in some applications like in the automotive industry to allow damping under cycle loading while maintaining a sufficient mechanical resistance. Thus, this study focuses on understanding how the composite made of ABS and TPU can be used without degrading the performance of the two phases. This can be done by looking at the interface bounding when using bi-material parts in the context of a droplet 3D printing technique. Indeed, 3D printing technologies allow more degrees of freedom to adapt the quality of the interface as in the droplet-based technology to achieve adaptable designs with the ability to combine different materials.

In fact, the overmoulding process can be considered the conventional counterpart of AM for the design of composite structures [

21]. Although substantial progress has been made in the area of multi-material injection moulding, the complexity of the designs brought on by the growing need for light-weight and high-performance composites limits the use of the overmoulding process to simplified designs. Another critical issue addressed in many papers related to the overmoulding technique is the quality of the interface [

22], where in these conventional processes, there is a limited leverage to adjust the interface properties by directly playing on the process deposition. This context allows the droplet-based technology to be a step ahead in providing leverage both at the material side by selecting the appropriate material combination and at the process side by locally adjusting the interface properties.

This approach is considered in this study to demonstrate the leverage on the design that can help improve the bonding between ABS and TPU. Composites exhibit strong or weak interface properties depending on the nature of chemical bond generated at the interface. In the present study, both the thickness and orientation of this interface are varied to quantify the quality of ABS/TPU interface properties on the composite tensile behaviour.

2. Experimental Layout

The two polymeric materials ABS and TPU were used to manufacture regular samples with the dimensions 70 mm × 10 mm × 4 mm. In the three-dimensional space attached to the CAD model of the sample, the following conventions were used for each axis (

Figure 1): X—width direction, Y—longitudinal direction, and Z—thickness or building direction.

The in-plane (X–Y) surface denotes the plane normal to the building direction and containing the two largest dimensions of the sample (length and width). The two materials were provided by BASF GmbH, Berlin, Germany, under the trade names of Terluran GP35 Green and Elastollan EC78A15. The two polymers had similar densities (1.18 g/cm3 for TPU and 1.04 g/cm3 for ABS) and close values of Poisson ratios (0.419 for TPU and 0.394 for ABS), but a large difference in Young’s moduli (527 MPa for TPU and 2300 MPa for ABS).

3D printing was performed using the Arburg Plastics Freeformer from Arburg, Germany (

Figure 1b). Droplet deposition was performed at a rate of 80 mm/s and with a 100% infill (duration per print was 35 min.). The slice thickness was adjusted to 0.21 mm, assuming a shape factor for the droplet of 1.04. Two extrusion heads of 150 µm in diameter each were used to print the ABS/TPU composite material following the logic explained in

Figure 1. The interface orientation with respect to the loading direction is labelled by the angle θ. Both horizontal (θ = 90°) and inclined (θ = 60°) interfaces were considered in the study. The number of droplets (n) that spilled over the interface was adjusted to one or two intertwining droplets. As suggested in

Figure 1, the laying down of the droplets was performed along the thickness of the composite sample. There were four different situations, named AT01 through AT04, that were tested to reveal the interfacial behaviour of the ABS/TPU composite. The interphase covered a finite thickness of 0.21 mm or 0.42 mm, depending on the printing conditions. The droplet arrangement in

Figure 1 was secured by an external frame to provide more strength to the sample.

X-ray micro-tomography was used to obtain the 3D arrangement of the droplets after printing. The imaging setup based on UltraTom X-ray µ-CT from Rx-Solutions (Chavanod, France) equipment and sample views are shown in

Figure 2.

The central part of the ABS/TPU specimens including the interface zone was imaged with typical ROI volumes in the range of 10 mm × 10 mm × 4 mm and 14 mm × 11 mm × 5 mm. The imaging conditions were as follows: voltage = 60 kV, current intensity = 70 µA, resolution = 1920 × 1536 pixels, and voxel size between 8.36 µm and 10.92 µm.

The construction of the 3D tomograms based on 1440 radiographic 2D images per sample was performed using the filtered back-projection technique using the X-Act software environment from Rx-Solutions (Chavanod, France). The acquisition time was about 23 min per sample. The number of voxels per tomogram was in the interval of 0.55–0.84 billon voxels.

Image analysis was considered to process the 3D images and isolate all features of interest, including the ABS and TPU phases, the interface region, and the process-induced porosity. ImageJ free software from NIH (version 1.8.0_172, Bethesda, MD, USA) was used with typical operators such as 2D/3D labelling, dilation, erosion, particle analysis, thresholding, flooding, wrapping, and image calculators. Porosity content was derived from segmented images, where the porosity phase appeared in binary images as black voxels (

) and white voxels (

) were assigned to either the ABS or TPU phase. Further processing treatment was done to avoid counting the surrounding external area and to distinguish between the porosity levels in each phase.

where

gi is the grey level of voxel

i from the domain ∏, where the porosity level was measured.

Tensile experiments were performed on Lloyd universal testing equipment from Lloyd Instruments Ltd. (Sussex UK), (maximum load capacity of 10 kN). The displacement rate was fixed to 5 mm/min for a gage length in the range of 41–42 mm. From the tensile experiments, both engineering strain and stress were derived (

Figure 3c) and the Young’s modulus was measured from the initial slope of the stress–strain curves.

Tensile loading was simultaneously conducted with digital image correlation instrumentation using equipment provided by Correlated Solutions (Irmo, SC, USA). Optical recording was performed with a resolution of 2000 × 2000 pixels (where the size of one pixel was 166 µm) and constant illumination conditions to allow the exploitation of the produced sequences of grey level images with the VIC-2D software. The acquisition frequency was adjusted to 5 frames per second (fps) and the subset size was limited to 2.5 mm and stepped by 0.8 mm. The accuracy of the measurement was as small as 10 microstrains, which is well below the strain levels achieved upon loading.

Figure 3 shows the experimental setup and ruptured samples covered with a layer of speckles needed for the image correlation process.

3. Modelling Technique

Two main models are explored in this section. The first one is a macroscopic model based on the geometry of the printed sample. The meshing of the paralepipedic sample was preformed using a reasonable number of 3D-8node structural elements (13,400 elements). Each node is capable of translations in the X-, Y-, and Z-directions. In addition, interface elements were added as 3D-8node cohesive zone elements. The model size was thus increased to 48,762 degrees of freedom (dof). Both ABS and TPU phases were considered as isotropic elastic materials, fully defined by the Young’s moduli and Poisson ratios introduced earlier. In addition, a cohesive model was implemented [

23]. According to this model, the work

at the interface can be written as

where

T is the traction at the interface, δ is the interfacial separation, and

ds is a surface normal to the interface.

The interfacial separation and the traction can be expressed as a function of the normal and tangential components as follows:

where

and

are the normal and tangential separations, respectively;

and

are the normal and tangential components of the traction, respectively; and

and

are unit vectors in tangential and normal directions, respectively.

An exponential function of the cohesive zone model was adopted according to the surface potential

φ as follows:

where

and

are the maximum normal and tangential separations, respectively, and

is the maximum normal traction. These were the three interfacial parameters to be identified based on the experiments.

Image-based finite element (FE) computation was considered to predict the tensile performance of the ABS/TPU printed samples. The grey-level information contained in the tomograms was converted into a material model. The computational domain corresponded to the central part of the specimen imaged with the dimensions given above. The computational model was thus based on a voxel-to-cubic-element conversion under the simulation environment Ansys Mechanical (Canonsburg, PA, USA). Cuboid elements defined by eight nodes and with three degrees of freedom each (structural displacements in the X-, Y-, and Z-directions) were used to mesh the printed microstructure. The meshing was conducted on a regular basis, which means that the model size was linearly proportional to the resolution of the embedded 3D images. Preliminary tests conducted on a high-performance computer (dual processor E-5 3Ghz equipped with 1Tbytes of RAM) showed that decreasing the original resolution of the tomograms by a factor of between 6.67 and 8.42 was required to achieve the largest possible models on the available resources. This limit corresponded to a maximum model size of between 153 and 257 million degrees of freedom, depending on the resolution of the tomograms. The element size varied between 18 µm and 22 µm. In addition, nine other intermediate meshes were used to check the sensitivity of the computations with regards to the resolution lowering. The largest element size varied for these cases between 145 µm and 218 µm, depending on the printing conditions. Four different grey levels were associated with four different phases, namely, ABS, TPU, interphase, and porosity. The elasticity constants for the first two phases were the ones introduced in the experimental section. Material properties for the interphase layer were identified from the experiments. The first load increment was used to identify the Young’s modulus of the composite for all conditions. While the loading was increased, a damage model was implemented based on a stress intensity criterion. For the elements that reached the maximum stress intensity, their associated Young’s modulus was changed to the ground value. The load was increased up to the rupture point corresponding to a residual reaction force. The number of damaged elements with respect to the total number of elements that could be possibly damaged scaled the damage variable. The damage kinetics were plotted by monitoring the damage variable as a function of the iteration level, which refers to the number of load levels.

For both macroscopic and microscopic models, displacement constrain conditions were used to simulate the tensile loading as follows:

and

Where , , and are translations or structural displacements in the X-, Y-, and Z-directions, respectively; is the sample length or the largest dimension of the microstructure; is a positive amount, and t is the iteration level.

The elasticity problems were solved using a preconditioned conjugate gradient solver with a typical computation duration of less than 5 min for the macroscopic model and between 229 and 346 min for the largest models based on X-ray micro-tomography images. The PCG error tolerance was adjusted to 10−8, which is the recommended value for elasticity problems.