An Overview of the Measurement of Permeability of Composite Reinforcements

Abstract

:1. Introduction

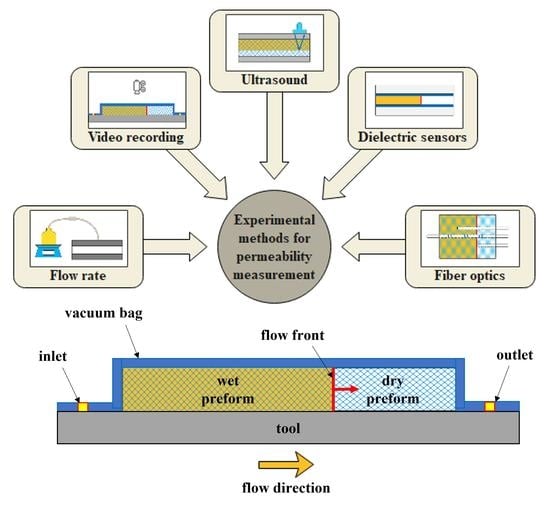

2. Permeability

3. Measurement Methods

3.1. Methods Based on Flow Rate Measurement

3.2. Methods Based on Video Recording

3.3. Methods Based on Ultrasonic Wave Propagation

3.3.1. Ultrasonic Methods Based on Longitudinal Waves

3.3.2. Ultrasonic Methods Based on Lamb Waves

3.4. Methods Based on Dielectric Sensors

3.4.1. Methods Based on Capacitive Sensors

3.4.2. Methods Based on Resistive Sensors

3.5. Methods Based on Fiber Optic Sensors

3.6. Numerical Methods for Permeability Prediction Based on X-ray Microtomography

4. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fleischer, J.; Teti, R.; Lanza, G.; Mativenga, P.; Möhring, H.C.; Caggiano, A. Composite Materials Parts Manufacturing. CIRP Ann. 2018, 67, 603–626. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent Progress of Reinforcement Materials: A Comprehensive Overview of Composite Materials. J. Mater. Res. Technol. 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- McIlhagger, A.; Archer, E.; McIlhagger, R. Manufacturing Processes for Composite Materials and Components for Aerospace Applications. In Polymer Composites in the Aerospace Industry; Woodhead Publishing: Cambridge, UK, 2020; pp. 59–81. [Google Scholar] [CrossRef]

- Hindersmann, A. Confusion about Infusion: An Overview of Infusion Processes. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105583. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef]

- Konstantopoulos, S.; Hueber, C.; Antoniadis, I.; Summerscales, J.; Schledjewski, R. Liquid Composite Molding Reproducibility in Real-World Production of Fiber Reinforced Polymeric Composites: A Review of Challenges and Solutions. Polym. Compos. Sci. 2019, 5, 85–99. [Google Scholar] [CrossRef]

- Arbter, R.; Beraud, J.M.; Binetruy, C.; Bizet, L.; Bréard, J.; Comas-Cardona, S.; Demaria, C.; Endruweit, A.; Ermanni, P.; Gommer, F.; et al. Experimental Determination of the Permeability of Textiles: A Benchmark Exercise. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1157–1168. [Google Scholar] [CrossRef]

- Vernet, N.; Ruiz, E.; Advani, S.; Alms, J.B.; Aubert, M.; Barburski, M.; Barari, B.; Beraud, J.M.; Berg, D.C.; Correia, N.; et al. Experimental Determination of the Permeability of Engineering Textiles: Benchmark II. Compos. Part A Appl. Sci. Manuf. 2014, 61, 172–184. [Google Scholar] [CrossRef] [Green Version]

- May, D.; Aktas, A.; Advani, S.G.; Berg, D.C.; Endruweit, A.; Fauster, E.; Lomov, S.V.; Long, A.; Mitschang, P.; Abaimov, S.; et al. In-Plane Permeability Characterization of Engineering Textiles Based on Radial Flow Experiments: A Benchmark Exercise. Compos. Part A Appl. Sci. Manuf. 2019, 121, 100–114. [Google Scholar] [CrossRef]

- Yong, A.X.H.; Aktas, A.; May, D.; Endruweit, A.; Advani, S.; Hubert, P.; Abaimov, S.G.; Abliz, D.; Akhatov, I.; Ali, M.A.; et al. Out-of-Plane Permeability Measurement for Reinforcement Textiles: A Benchmark Exercise. Compos. Part A Appl. Sci. Manuf. 2021, 148, 106480. [Google Scholar] [CrossRef]

- Park, C.H.; Krawczak, P. Unsaturated and Saturated Permeabilities of Fiber Reinforcement: Critics and Suggestions. Front. Mater. 2015, 2, 38. [Google Scholar] [CrossRef] [Green Version]

- Alms, J.B.; Correia, N.; Advani, S.G.; Ruiz, E.; Gonçalves, C.T. Experimental Procedures to Run Longitudinal Injections to Measure Unsaturated Permeability of LCM Reinforcements. FCPM Collab. 2010, 1. [Google Scholar]

- Moldex3D | Plastic Injection Molding Simulation Software. Available online: https://www.moldex3d.com/ (accessed on 6 November 2022).

- PAM-RTM. Available online: https://www.esi.com.au/software/pamrtm/ (accessed on 6 November 2022).

- Moldflow | Plastic Injection & Compression Molding Software | Autodesk. Available online: https://www.autodesk.com/products/moldflow/overview (accessed on 6 November 2022).

- RTM-Worx Applications—RTM, VARTM, CVI, VIP and SCRIMP—Polyworx. Available online: https://www.polyworx.com/apz/ (accessed on 6 November 2022).

- COMSOL—Software for Multiphysics Simulation. Available online: https://www.comsol.com/ (accessed on 6 November 2022).

- Ansys Fluent | Fluid Simulation Software. Available online: https://www.ansys.com/products/fluids/ansys-fluent (accessed on 6 November 2022).

- OpenFOAM. Available online: https://www.openfoam.com/ (accessed on 6 November 2022).

- Grössing, H.; Stadlmajer, N.; Fauster, E.; Fleischmann, M.; Schledjewski, R. Flow Front Advancement during Composite Processing: Predictions from Numerical Filling Simulation Tools in Comparison with Real-World Experiments. Polym. Compos. 2016, 37, 2782–2793. [Google Scholar] [CrossRef]

- Seuffert, J.; Kärger, L.; Henning, F. Simulating Mold Filling in Compression Resin Transfer Molding (CRTM) Using a Three-Dimensional Finite-Volume Formulation. J. Compos. Sci. 2018, 2, 23. [Google Scholar] [CrossRef] [Green Version]

- Yang, B.; Huang, W.; Causse, P.; Béguin, C.; Wang, J.; Trochu, F. On the Design of Test Molds Based on Unidirectional Saturated Flows to Measure Transverse Permeability in Liquid Composite Molding. Polym. Compos. 2022, 43, 2234–2251. [Google Scholar] [CrossRef]

- Ali, M.A.; Umer, R.; Khan, K.A.; Bickerton, S.; Cantwell, W.J. Non-Destructive Evaluation of through-Thickness Permeability in 3D Woven Fabrics for Composite Fan Blade Applications. Aerosp. Sci. Technol. 2018, 82–83, 520–533. [Google Scholar] [CrossRef]

- Ali, M.A.; Umer, R.; Khan, K.A.; Cantwell, W.J. Application of X-ray Computed Tomography for the Virtual Permeability Prediction of Fiber Reinforcements for Liquid Composite Molding Processes: A Review. Compos. Sci. Technol. 2019, 184, 107828. [Google Scholar] [CrossRef]

- Scopus—Document Search | Signed in. Available online: https://0-www-scopus-com.brum.beds.ac.uk/search/form.uri?display=basic#basic (accessed on 14 November 2022).

- Naik, N.K.; Sirisha, M.; Inani, A. Permeability Characterization of Polymer Matrix Composites by RTM/VARTM. Prog. Aerosp. Sci. 2014, 65, 22–40. [Google Scholar] [CrossRef]

- Pantaloni, D.; Bourmaud, A.; Baley, C.; Clifford, M.J.; Ramage, M.H.; Shah, D.U. A Review of Permeability and Flow Simulation for Liquid Composite Moulding of Plant Fibre Composites. Materials 2020, 13, 4811. [Google Scholar] [CrossRef]

- Michaud, V. A Review of Non-Saturated Resin Flow in Liquid Composite Moulding Processes. Transp. Porous Media 2016, 115, 581–601. [Google Scholar] [CrossRef]

- Karaki, M.; Younes, R.; Trochu, F.; Lafon, P. Progress in Experimental and Theoretical Evaluation Methods for Textile Permeability. J. Compos. Sci. 2019, 3, 73. [Google Scholar] [CrossRef]

- Sharma, S.; Siginer, D.A. Permeability Measurement Methods in Porous Media of Fiber Reinforced Composites. Appl. Mech. Rev. 2010, 63, 47. [Google Scholar] [CrossRef]

- Darcy, H. Les Fontaines Publiques de La Ville de Dijon: Exposition et Application Des Principes à Suivre et Des Formules à Employer Dans Les Questions de Distribution d’eau: Ouvrage Terminé Par Un Appendice Relatif Aux Fournitures d’eau de Plusieurs Villes, Au Filtrage Des Eaux et à La Fabrication Des Tuyaux de Fonte, de Plomb, de Tôle et de Bitume; Dalmont, V., Ed.; Librairie des Corps Impériaux des Ponts et Chaussées et des Mines: Paris, France, 1856; Volume 2. [Google Scholar]

- Weitzenböck, J.R.; Shenoi, R.A.; Wilson, P.A. Measurement of Principal Permeability with the Channel Flow Experiment. Polym. Compos. 1999, 20, 321–335. [Google Scholar] [CrossRef]

- Demaría, C.; Ruiz, E.; Trochu, F. In-Plane Anisotropic Permeability Characterization of Deformed Woven Fabrics by Unidirectional Injection. Part I: Experimental Results. Polym. Compos. 2007, 28, 797–811. [Google Scholar] [CrossRef]

- Di Fratta, C.; Koutsoukis, G.; Klunker, F.; Trochu, F.; Ermanni, P. Characterization of Anisotropic Permeability from Flow Front Angle Measurements. Polym. Compos. 2016, 37, 2037–2052. [Google Scholar] [CrossRef]

- Zhou, F.; Kuentzer, N.; Simacek, P.; Advani, S.G.; Walsh, S. Analytic Characterization of the Permeability of Dual-Scale Fibrous Porous Media. Compos. Sci. Technol. 2006, 66, 2795–2803. [Google Scholar] [CrossRef]

- Gourichon, B.; Binetruy, C.; Krawczak, P. Experimental Investigation of High Fiber Tow Count Fabric Unsaturation during RTM. Compos. Sci. Technol. 2006, 66, 976–982. [Google Scholar] [CrossRef]

- Labat, L.; Bréard, J.; Pillut-Lesavre, S.; Bouquet, G. Void Fraction Prevision in LCM Parts. Eur. Phys. J. Appl. Phys. 2001, 16, 157–164. [Google Scholar] [CrossRef]

- Ruiz, E.; Achim, V.; Soukane, S.; Trochu, F.; Bréard, J. Optimization of Injection Flow Rate to Minimize Micro/Macro-Voids Formation in Resin Transfer Molded Composites. Compos. Sci. Technol. 2006, 66, 475–486. [Google Scholar] [CrossRef]

- Patel, N.; Rohatgi, V.; Lee, L.J. Micro Scale Flow Behavior and Void Formation Mechanism during Impregnation through a Unidirectional Stitched Fiberglass Mat. Polym. Eng. Sci. 1995, 35, 837–851. [Google Scholar] [CrossRef]

- Alotaibi, H.; Jabbari, M.; Abeykoon, C.; Soutis, C. Numerical Investigation of Multi-Scale Characteristics of Single and Multi-Layered Woven Structures. Appl. Compos. Mater. 2022, 29, 405–421. [Google Scholar] [CrossRef]

- Hangi, M.; Wheeler, V.; Lipiński, W. Numerical Determination of Permeability and Forchheimer Coefficient in Dual-Scale Porous Media. Int. Commun. Heat Mass Transf. 2021, 122, 105089. [Google Scholar] [CrossRef]

- Godbole, M.G.; Gururaja, S.; Joshi, M.; Advani, S. Semi-Analytical Formulation of Effective Permeability of a Dual Scale Unidirectional Fabric. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106630. [Google Scholar] [CrossRef]

- He, X.; Liu, Y.; Wu, W. A General and Efficient Approach for the Dual-Scale Infiltration Flow Balancing in In Situ Injection Molding of Continuous Fiber Reinforced Thermoplastic Composites. Polymers 2021, 13, 2689. [Google Scholar] [CrossRef]

- Ali, M.A.; Khan, K.A.; Umer, R. An Electric Circuit Analogy-Based Homogenization Approach for Predicting the Effective Permeability of Complex Dual-Scale Porous Media. Mater. Today Commun. 2021, 28, 102565. [Google Scholar] [CrossRef]

- He, Y.; Li, Y.; Hao, X.; Zhou, J.; Liu, S. Micro-Flow Sensor for Continuous Resin Fluidity Monitoring between Fibers. Sens. Actuators B Chem. 2019, 282, 177–186. [Google Scholar] [CrossRef]

- De Parseval, Y.; Pillai, K.M.; Advani, S.G. A Simple Model for the Variation of Permeability Due to Partial Saturation in Dual Scale Porous Media. Transp. Porous Media 1997, 27, 243–264. [Google Scholar] [CrossRef]

- Bréard, J.; Henzel, Y.; Trochu, F.; Gauvin, R. Analysis of Dynamic Flows through Porous Media. Part I: Comparison between Saturated and Unsaturated Flows in Fibrous Reinforcements. Polym. Compos. 2003, 24, 391–408. [Google Scholar] [CrossRef]

- García, J.A.; Gascón, L.; Chinesta, F.; Ruiz, E.; Trochu, F. An Efficient Solver of the Saturation Equation in Liquid Composite Molding Processes. Int. J. Mater. Form. 2010, 3, 1295–1302. [Google Scholar] [CrossRef] [Green Version]

- Terekhov, I.V.; Chistyakov, E.M. Binders Used for the Manufacturing of Composite Materials by Liquid Composite Molding. Polymers 2022, 14, 87. [Google Scholar] [CrossRef]

- Aziz, A.R.; Ali, M.A.; Zeng, X.; Umer, R.; Schubel, P.; Cantwell, W.J. Transverse Permeability of Dry Fiber Preforms Manufactured by Automated Fiber Placement. Compos. Sci. Technol. 2017, 152, 57–67. [Google Scholar] [CrossRef]

- Rimmel, O.; May, D.; Mitschang, P. Impact of Stitching on Permeability and Mechanical Properties of Preforms Manufactured by Dry Fiber Placement. Polym. Compos. 2019, 40, 1631–1642. [Google Scholar] [CrossRef]

- Lionetto, F.; Montagna, F.; Maffezzoli, A. Out-Of-Plane Permeability Evaluation of Carbon Fiber Preforms by Ultrasonic Wave Propagation. Materials 2020, 13, 2684. [Google Scholar] [CrossRef] [PubMed]

- Kabachi, M.A.; Danzi, M.; Arreguin, S.; Ermanni, P. Experimental Study on the Influence of Cyclic Compaction on the Fiber-Bed Permeability, Quasi-Static and Dynamic Compaction Responses. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105559. [Google Scholar] [CrossRef]

- Caglar, B.; Orgéas, L.; Rolland du Roscoat, S.; Sozer, E.M.; Michaud, V. Permeability of Textile Fabrics with Spherical Inclusions. Compos. Part A Appl. Sci. Manuf. 2017, 99, 1–14. [Google Scholar] [CrossRef]

- Hermann, T.; Schelte, A.; Henke, T.; Kelly, P.A.; Bickerton, S. Non-Destructive Injectability Measurements for Fibre Preforms and Semi-Finished Textiles. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106018. [Google Scholar] [CrossRef]

- Abdoli, H.; Hermann, T.; Bickerton, S. A Novel, Fast and Clean 3D Permeability Measurement Method for Multi-Layer Textiles and Fabrics. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107167. [Google Scholar] [CrossRef]

- Lionetto, F.; Moscatello, A.; Totaro, G.; Raffone, M.; Maffezzoli, A. Experimental and Numerical Study of Vacuum Resin Infusion of Stiffened Carbon Fiber Reinforced Panels. Materials 2020, 13, 4800. [Google Scholar] [CrossRef]

- Trevino, L.; Rupel, K.; Young, W.B.; Liou, M.J.; Lee, L.J. Analysis of Resin Injection Molding in Molds with Preplaced Fiber Mats. I: Permeability and Compressibility Measurements. Polym. Compos. 1991, 12, 20–29. [Google Scholar] [CrossRef]

- Da Silva, A.A.X.; Souza, J.A.; Manes, A.; Amico, S.C. In-Plane Permeability and Mechanical Properties of R-Glass/Aramid Hybrid Composites. J. Mater. Eng. Perform. 2020, 29, 4484–4492. [Google Scholar] [CrossRef]

- De Oliveira, D.M.; de Carvalho Benini, K.C.C.; Monticeli, F.M.I.; Schukraft, J.P.; de Bomfim, A.S.C.; Cioffi, M.O.H.; Voorwald, H.J.C. Permeability of Untreated and Atmospheric Plasma Treated Coconut Fiber Mats. Mater. Res. Express 2019, 6, 095323. [Google Scholar] [CrossRef]

- Zhu, Y.; Cai, J.; Qin, Y.; Liu, D.; Yan, C.; Zhang, H. Effects of Liquid Absorption and Swelling on the Permeability of Natural Fiber Fabrics in Liquid Composite Moulding. Polym. Compos. 2017, 38, 996–1004. [Google Scholar] [CrossRef]

- Kabachi, M.A.; Stettler, L.; Arreguin, S.; Ermanni, P. Concurrent Characterization of Through-Thickness Permeability and Compaction of Fiber Reinforcements. Compos. Part A Appl. Sci. Manuf. 2021, 141. [Google Scholar] [CrossRef]

- Almazán-Lázaro, J.A.; López-Alba, E.; Díaz-Garrido, F.A. Applied Computer Vision for Composite Material Manufacturing by Optimizing the Impregnation Velocity: An Experimental Approach. J. Manuf. Process. 2022, 74, 52–62. [Google Scholar] [CrossRef]

- Jeong, J.M.; Eum, S.; On, S.Y.; Kageyama, K.; Murayama, H.; Uzawa, K.; Kim, S.S. In-Situ Resin Flow Monitoring in VaRTM Process by Using Optical Frequency Domain Reflectometry and Long-Gauge FBG Sensors. Compos. Struct. 2022, 282, 115034. [Google Scholar] [CrossRef]

- Rubino, F.; Tucci, F.; Esperto, V.; Carlone, P. Filling Time Reduction in Liquid Composite Molding Processes. J. Compos. Sci. 2022, 6, 222. [Google Scholar] [CrossRef]

- Dai, H.; Thostenson, E.T. Scalable and Multifunctional Carbon Nanotube-Based Textile as Distributed Sensors for Flow and Cure Monitoring. Carbon 2020, 164, 28–41. [Google Scholar] [CrossRef]

- Sánchez del Río, J.; Pascual-González, C.; Martínez, V.; Jiménez, J.L.; González, C. 3D-Printed Resistive Carbon-Fiber-Reinforced Sensors for Monitoring the Resin Frontal Flow during Composite Manufacturing. Sens. Actuators A Phys. 2021, 317, 112422. [Google Scholar] [CrossRef]

- Changchun, W.; Guanghui, B.; Yang, W.; Boming, Z.; Lijian, P. Permeability Tests of Fiber Fabrics in the Vacuum Assisted Resin Transfer Molding Process. Appl. Compos. Mater. 2015, 22, 363–375. [Google Scholar] [CrossRef]

- Pouchias, A.; Cunningham, P.R.; Stein, J.; Kazilas, M. Development of a Flexible Dielectric Sensor for Flow Monitoring of the Liquid Resin Infusion Process. Sensors 2019, 19, 5292. [Google Scholar] [CrossRef] [Green Version]

- Buchmann, C.; Filsinger, J.; Ladstätter, E. Investigation of Electrical Time Domain Reflectometry for Infusion and Cure Monitoring in Combination with Electrically Conductive Fibers and Tooling Materials. Compos. B Eng. 2016, 94, 389–398. [Google Scholar] [CrossRef]

- Kot, P.; Muradov, M.; Gkantou, M.; Kamaris, G.S.; Hashim, K.; Yeboah, D. Recent Advancements in Non-Destructive Testing Techniques for Structural Health Monitoring. Appl. Sci. 2021, 11, 2750. [Google Scholar] [CrossRef]

- Liu, H.L.; Tu, X.C.; Lee, J.O.; Kim, H.B.; Hwang, W.R. Visualization of Resin Impregnation through Opaque Reinforcement Textiles during the Vacuum-Assisted Resin Transfer Molding Process Using Ultrasound. J. Compos. Mater. 2013, 48, 1113–1120. [Google Scholar] [CrossRef]

- Liebers, N.; Bertling, D. Reducing NDT Effort by Coupled Monitoring and Simulation of Liquid Composite Molding Processes. In Proceedings of the 11th International Symposium on NDT in Aerospace, Paris, France, 13–15 November 2019. [Google Scholar]

- Stöven, T.; Weyrauch, F.; Mitschang, P.; Neitzel, M. Continuous Monitoring of Three-Dimensional Resin Flow through a Fibre Preform. Compos. Part. A Appl. Sci. Manuf. 2003, 34, 475–480. [Google Scholar] [CrossRef]

- Konstantopoulos, S.; Grössing, H.; Hergan, P.; Weninger, M.; Schledjewski, R. Determination of the Unsaturated Through-Thickness Permeability of Fibrous Preforms Based on Flow Front Detection by Ultrasound. Polym. Compos. 2018, 39, 360–367. [Google Scholar] [CrossRef]

- Becker, D.; Grössing, H.; Konstantopoulos, S.; Fauster, E.; Mitschang, P.; Schledjewski, R. An Evaluation of the Reproducibility of Ultrasonic Sensor-Based out-of-Plane Permeability Measurements: A Benchmarking Study. Polym. Compos. Sci. 2016, 2, 34–45. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Cui, X.; Liang, Z.; Qing, X.; Yan, W. Monitoring of Three-Dimensional Resin Flow Front Using Hybrid Piezoelectric-Fiber Sensor Network in a Liquid Composite Molding Process. Compos. Sci. Technol. 2022, 229, 109712. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Zhu, J.; Wang, Y.; Qing, X. Monitoring of Resin Flow Front and Degree of Cure in Vacuum-Assisted Resin Infusion Process Using Multifunctional Piezoelectric Sensor Network. Polym. Compos. 2021, 42, 113–125. [Google Scholar] [CrossRef]

- Liu, X.; Yu, Y.; Li, J.; Zhu, J.; Wang, Y.; Qing, X. Leaky Lamb Wave–Based Resin Impregnation Monitoring with Noninvasive and Integrated Piezoelectric Sensor Network. Measurement 2022, 189, 110480. [Google Scholar] [CrossRef]

- Qi, W.; Chiu, T.-H.; Kao, Y.-K.; Yao, Y.; Chen, Y.-H.; Yang, H.; Wang, C.-C.; Hsu, C.-H.; Chang, R.-Y. Sensor Fusion for Simultaneous Estimation of In-Plane Permeability and Porosity of Fiber Reinforcement in Resin Transfer Molding. Polymers 2022, 14, 2652. [Google Scholar] [CrossRef]

- Goncharenko, A.V.; Lozovski, V.Z.; Venger, E.F. Lichtenecker’s Equation: Applicability and Limitations. Opt. Commun. 2000, 174, 19–32. [Google Scholar] [CrossRef]

- Grössing, H.; Becker, D.; Kaufmann, S.; Schledjewski, R.; Mitschang, P. An Evaluation of the Reproducibility of Capacitive Sensor Based In-Plane Permeability Measurements: A Benchmarking Study. Express Polym. Lett. 2015, 9, 129–142. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, Y.; Lu, S.; Wang, X.; Ma, C.; Ma, K. In Situ Monitoring of Sandwich Structure in Liquid Composite Molding Process Using Multifunctional MXene/Carbon Nanotube Sensors. Polym. Compos. 2022, 43, 2252–2263. [Google Scholar] [CrossRef]

- Wan, Y.; Hu, W.; Yang, L.; Wang, Z.; Tan, J.; Liu, Y.; Wang, F.; Yang, B. In-Situ Monitoring of Glass Fiber/Epoxy Composites by the Embedded Multi-Walled Carbon Nanotube Coated Glass Fiber Sensor: From Fabrication to Application. Polym. Compos. 2022, 43, 4210–4222. [Google Scholar] [CrossRef]

- Khan, T.; Ali, M.A.; Irfan, M.S.; Khan, K.A.; Liao, K.; Umer, R. Resin Infusion Process Monitoring Using Graphene Coated Glass Fabric Sensors and Infusible Thermoplastic and Thermoset Matrices. Polym. Compos. 2022, 43, 2924–2940. [Google Scholar] [CrossRef]

- Ali, M.A.; Umer, R.; Khan, K.A.; Samad, Y.A.; Liao, K.; Cantwell, W. Graphene Coated Piezo-Resistive Fabrics for Liquid Composite Molding Process Monitoring. Compos. Sci. Technol. 2017, 148, 106–114. [Google Scholar] [CrossRef]

- Luo, S.; Wang, G.; Wang, Y.; Xu, Y.; Luo, Y. Carbon Nanomaterials Enabled Fiber Sensors: A Structure-Oriented Strategy for Highly Sensitive and Versatile in Situ Monitoring of Composite Curing Process. Compos. B Eng. 2019, 166, 645–652. [Google Scholar] [CrossRef]

- Irfan, M.S.; Khan, T.; Hussain, T.; Liao, K.; Umer, R. Carbon Coated Piezoresistive Fiber Sensors: From Process Monitoring to Structural Health Monitoring of Composites—A Review. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106236. [Google Scholar] [CrossRef]

- Tifkitsis, K.I.; Skordos, A.A. A Novel Dielectric Sensor for Process Monitoring of Carbon Fibre Composites Manufacture. Compos. Part A Appl. Sci. Manuf. 2019, 123, 180–189. [Google Scholar] [CrossRef]

- Tifkitsis, K.I.; Skordos, A.A. Real Time Uncertainty Estimation in Filling Stage of Resin Transfer Molding Process. Polym. Compos. 2020, 41, 5387–5402. [Google Scholar] [CrossRef]

- Ahn, S.H.; Lee, W.I.; Springer, G.S. Measurement of the Three-Dimensional Permeability of Fiber Preforms Using Embedded Fiber Optic Sensors. J. Compos. Mater. 1995, 29, 714–733. [Google Scholar] [CrossRef]

- Bernstein, J.R.; Wagner, J.W. Fiber Optic Sensors for Use in Monitoring Flow Front in Vacuum Resin Transfer Molding Processes. Rev. Sci. Instrum. 1997, 68, 2156. [Google Scholar] [CrossRef]

- Novo, C. Progression Monitoring of the Flow Front in RTM Process Using Fibre Bragg Grating Sensors. In Proceedings of the Fourteenth International Conference on Optical Fiber Sensors, Venice, Italy, 9 November 2000; Mignani, A.G., Lefèvre, H.C., Eds.; SPIE: Venice, Italy, 2000; p. 148. [Google Scholar]

- Vacher, S.; Molimard, J.; Gagnaire, H.; Vautrin, A. A Fresnel’s Reflection Optical Fiber Sensor for Thermoset Polymer Cure Monitoring. Polym. Polym. Compos. 2004, 12, 269–276. [Google Scholar] [CrossRef]

- Othonos, A. Fiber Bragg Gratings. Rev. Sci. Instrum. 1997, 68, 4309. [Google Scholar] [CrossRef]

- Chehura, E.; James, S.W.; Staines, S.; Groenendijk, C.; Cartie, D.; Portet, S.; Hugon, M.; Tatam, R.P. Production Process Monitoring and Post-Production Strain Measurement on a Full-Size Carbon-Fibre Composite Aircraft Tail Cone Assembly Using Embedded Optical Fibre Sensors. Meas. Sci. Technol. 2020, 31, 105204. [Google Scholar] [CrossRef]

- Marrazzo, V.R.; Laudati, A.; Vitale, M.; Fienga, F.; Iagulli, G.; Raffone, M.; Cusano, A.; Giordano, M.; Cutolo, A.; Breglio, G. Liquid Resin Infusion Process Validation through Fiber Optic Sensor Technology. Sensors 2022, 22, 508. [Google Scholar] [CrossRef]

- Wang, P.; Molimard, J.; Drapier, S.; Vautrin, A.; Minni, J.C. Monitoring the Resin Infusion Manufacturing Process under Industrial Environment Using Distributed Sensors. J. Compos. Mater. 2011, 46, 691–706. [Google Scholar] [CrossRef] [Green Version]

- Kozeny, J. Uber Kapillare Leitung Des Wassersim Boden Stizurgsberichte. Proc. Class I 1927, 136, 271–306. [Google Scholar]

- Carman, P.C. Fluid Flow through Granular Beds. Trans. Inst. Chem. Eng. 1937, 15, 150–166. [Google Scholar] [CrossRef]

- Carman, P.C. Flow of Gases through Porous Media; Butterworths: London, UK, 1956. [Google Scholar]

- Gebart, B.R. Permeability of Unidirectional Reinforcements for RTM. J. Compos. Mater. 1992, 26, 1100–1133. [Google Scholar] [CrossRef]

- Berdichevsky, A.L.; Cai, Z. Preform Permeability Predictions by Self-Consistent Method and Finite Element Simulation. Polym. Compos. 1993, 14, 132–143. [Google Scholar] [CrossRef]

- Garcea, S.C.; Wang, Y.; Withers, P.J. X-ray Computed Tomography of Polymer Composites. Compos. Sci. Technol. 2018, 156, 305–319. [Google Scholar] [CrossRef]

- Lionetto, F.; Montagna, F.; Natali, D.; de Pascalis, F.; Nacucchi, M.; Caretto, F.; Maffezzoli, A. Correlation between Elastic Properties and Morphology in Short Fiber Composites by X-ray Computed Micro-Tomography. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106169. [Google Scholar] [CrossRef]

- De Pascalis, F.; Lionetto, F.; Maffezzoli, A.; Nacucchi, M. A General Approach to Calculate the Stiffness Tensor of Short-Fiber Composites Using the Fabric Tensor Determined by X-ray Computed Tomography. Polym. Compos. 2023, 1–15. [Google Scholar] [CrossRef]

- Yousaf, Z.; Withers, P.J.; Potluri, P. Compaction, Nesting and Image Based Permeability Analysis of Multi-Layer Dry Preforms by Computed Tomography (CT). Compos. Struct. 2021, 263, 113676. [Google Scholar] [CrossRef]

- Ali, M.A.; Umer, R.; Khan, K.A.; Cantwell, W.J. XCT-Scan Assisted Flow Path Analysis and Permeability Prediction of a 3D Woven Fabric. Compos. B Eng. 2019, 176, 107320. [Google Scholar] [CrossRef]

- Zeng, X.; Brown, L.P.; Endruweit, A.; Matveev, M.; Long, A.C. Geometrical Modelling of 3D Woven Reinforcements for Polymer Composites: Prediction of Fabric Permeability and Composite Mechanical Properties. Compos. Part A Appl. Sci. Manuf. 2014, 56, 150–160. [Google Scholar] [CrossRef]

- Ali, M.A.; Umer, R.; Khan, K.A.; Cantwell, W.J. In-Plane Virtual Permeability Characterization of 3D Woven Fabrics Using a Hybrid Experimental and Numerical Approach. Compos. Sci. Technol. 2019, 173, 99–109. [Google Scholar] [CrossRef]

- Ghafour, T.A.; Balbinot, C.; Audry, N.; Martoïa, F.; Orgéas, L.; Dumont, P.J.J.; Vroman, P.; Boller, E. Permeability of Flax Fibre Mats: Numerical and Theoretical Prediction from 3D X-ray Microtomography Images. Compos. Part A Appl. Sci. Manuf. 2021, 151, 106644. [Google Scholar] [CrossRef]

- Syerko, E.; Schmidt, T.; May, D.; Binetruy, C.; Advani, S.G.; Lomov, S.; Silva, L.; Abaimov, S.; Aissa, N.; Akhatov, I.; et al. Benchmark Exercise on Image-Based Permeability Determination of Engineering Textiles: Microscale Predictions. Compos. Part A Appl. Sci. Manuf. 2023, 167, 107397. [Google Scholar] [CrossRef]

- Tuncol, G.; Danisman, M.; Kaynar, A.; Sozer, E.M. Constraints on Monitoring Resin Flow in the Resin Transfer Molding (RTM) Process by Using Thermocouple Sensors. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1363–1386. [Google Scholar] [CrossRef]

- Danisman, M.; Tuncol, G.; Kaynar, A.; Sozer, E.M. Monitoring of Resin Flow in the Resin Transfer Molding (RTM) Process Using Point-Voltage Sensors. Compos. Sci. Technol. 2007, 67, 367–379. [Google Scholar] [CrossRef]

- Di Fratta, C.; Koutsoukis, G.; Klunker, F.; Ermanni, P. Fast Method to Monitor the Flow Front and Control Injection Parameters in Resin Transfer Molding Using Pressure Sensors. J. Compos. Mater. 2016, 50, 2941–2957. [Google Scholar] [CrossRef]

- Di Fratta, C.; Klunker, F.; Ermanni, P. A Methodology for Flow-Front Estimation in LCM Processes Based on Pressure Sensors. Compos. Part A Appl. Sci. Manuf. 2013, 47, 1–11. [Google Scholar] [CrossRef]

| Method | Measured Permeability | Advantages | Drawbacks |

|---|---|---|---|

| Flow Rate Measurement | saturated; in-plane and out-of-plane | simplicity, low cost, suitable for all materials, non-destructiveness (gaseous test fluid) | fluid compressibility for gaseous test fluid |

| Video Recording | unsaturated; in-plane and out-of-plane | simplicity (in-plane), low cost, suitable for all materials | only for superficial monitoring, transparent mold required |

| Ultrasonic Wave Propagation | unsaturated; in-plane and out-of-plane | non-invasiveness, low cost, suitable for all materials | complexity, limited resolution (longitudinal waves) |

| Dielectric Sensors | unsaturated; in-plane and out-of-plane | low cost, non-invasiveness, integrability (resistive nanosensors) | not suitable for conductive materials (separating layer required) |

| Fiber Optic Sensors | unsaturated; in-plane and out-of-plane | immunity to electromagnetic interference | invasiveness, signal loss due to fiber bending |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dei Sommi, A.; Lionetto, F.; Maffezzoli, A. An Overview of the Measurement of Permeability of Composite Reinforcements. Polymers 2023, 15, 728. https://0-doi-org.brum.beds.ac.uk/10.3390/polym15030728

Dei Sommi A, Lionetto F, Maffezzoli A. An Overview of the Measurement of Permeability of Composite Reinforcements. Polymers. 2023; 15(3):728. https://0-doi-org.brum.beds.ac.uk/10.3390/polym15030728

Chicago/Turabian StyleDei Sommi, Andrea, Francesca Lionetto, and Alfonso Maffezzoli. 2023. "An Overview of the Measurement of Permeability of Composite Reinforcements" Polymers 15, no. 3: 728. https://0-doi-org.brum.beds.ac.uk/10.3390/polym15030728