1. Introduction

In an effluent treatment station (ETS), wastewater is usually treated by physical routes such as flotation and sedimentation, chemical pathways such as flocculation, and by biological processes such as microbial treatment [

1]. According to Ji et al. [

2], anaerobic biological treatment is a preferred option for the treatment of wastewater with pharmaceutical products, considering its advantages, including withstanding high organic loads, lower sludge production, and lower operating costs than conventional activated sludge process.

After effluent treatment, the sludge obtained and organic residue decanted both during and at the end of the process should be treated. Generally, three types of sludge are produced: primary, secondary, and tertiary. Sludge can undergo processes of densification, stabilization, conditioning, dehydration or dewatering, purification, and final disposal. Generally, sludge is destined for landfills; however, there are several studies reporting the use of sludge as a potential source of biofertilizer for agricultural systems as well as biofuel production. This is a recurring concern of industries, with respect to achieving environmental sustainability. Liu et al. [

3], for example, optimized biogas production through the anaerobic co-digestion of sludge with low organic content and food residues.

Sludge produced in an ETS contains nutrients, especially nitrogen, phosphorus, and carbon, and, in smaller amounts, potassium, calcium, magnesium, organic matter, heavy metals, pathogens, and other elements from tributaries. These may pose health risks and environment hazards if they are not properly monitored and controlled [

4]. The concentration of substances from pharmaceutical residues varies among regions and their properties significantly affect treatment performance [

5].

The need for characterization prior to treatment has been increasingly carried by ETSs. Laboreaux, in the city of Itabira, Minas Gerais, Brazil, showed that pressurized filtered sludge, if subjected to drying to improve heat output, can be used as a fuel to supply consumers in the region, replacing coal or firewood [

6]. Another study characterized the physicochemical properties of oily residues from sanitation, and only from this study was it proposed that the use of these residues may serve as a substrate for the production of biofuels [

7].

It is imperative to carry out studies on the composition and characterization of solid waste in order to propose appropriate treatment, minimizing environmental impacts, and to optimize the resources in ETS equipment. The characteristics of sludge directly affect the processes of treatment and final disposal; therefore, understanding of its characteristics is fundamental to defining residue management [

8].

Knowledge of the effluent generated by an industry is essential to the determination of treatment processes performed by the ETS that aims to accord with legislation, in order to dispose of it safely into the environment and ecosystem, as well as to reuse it, guaranteeing environmental sustainability.

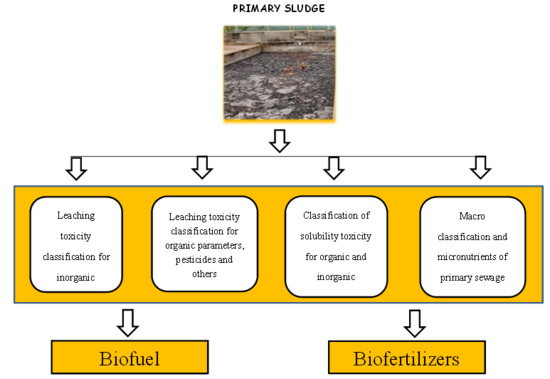

The objective of this work was to characterize the physicochemical properties of primary sludge of a pharmaceutical industry ETS, classifying it in terms of its potential risks according to current legislation, as well as its final disposal.

3. Results and Discussion

After descriptive analysis of the data, we obtained mean values of TS (25.05%), TFS (7.52%), and TVS (17.40%). The largest fraction of TS was represented by TVS, indicating a high biodegradable fraction of this residue. This result was compatible with that of Oliveira et al. [

7], who performed chemical physical characterization of oily residues from sanitation waste and observed that the largest fraction of total solids was represented by volatile solids. Cucina et al. [

11], when evaluating the risks and benefits associated with the agricultural use of three different organic fertilizers derived from a pharmaceutical manufacturing effluent, found values of 14.30% and 8.80% for total solids and volatile solids, respectively.

In relation to the moisture content of the sludge, a value of 74.95% was found. In a study carried out by Silva [

12], when evaluating the characteristics of sludge produced at the Brasília Norte Sewage Treatment Plant (Brasília - DF), there was a moisture content of 83%. Moisture variation correlated with environmental factors. In December, February, and March, this occurred on the day of collection and over the subsequent days, as opposed to the meteorological situation in January when there was no precipitation [

13].

Regarding COD, the mean value obtained was 267.333 mg L

−1. This value was higher when compared to COD measurements reported in the literature. According to some studies, COD values from effluents of the pharmaceutical industry vary between 4.410 and 40.000 mg L

−1 [

14,

15]. The high value observed for sewage sludge can be explained by the high concentration of organic material that is dumped in the effluent of the pharmaceutical industry, requiring a large amount of oxygen to oxidize and stabilize this organic material.

Table 1,

Table 2 and

Table 3 display the results of the leaching toxicity analyses, including the amounts of heavy metals and pesticides in the waste that is indispensable for evaluation for agricultural use, in addition to the evaluation of the risk heavy metals pose to the environment.

According to the results presented in

Table 1, the concentration of inorganic compounds in the leached residue agrees with the established limits. Therefore, the primary sludge from pharmaceutical industry effluents cannot be considered toxic in terms of this parameter.

Table 2 shows that the concentration of organic compounds (pesticides) agree with the established limits. Therefore, primary sludge from pharmaceutical industry effluents can not be considered toxic with respect to this parameter.

According to the results presented in

Table 3, the concentration of organic compounds (other organic) also agrees with the established limits. Therefore, the primary sludge from pharmaceutical industry effluents cannot be considered toxic with respect to this parameter.

According to Turki et al. [

16], cited by Rigobello et al. [

17], the organic compounds that are present in the residues can leach into groundwater and surface water and, because of the difficulty of their removal by conventional methods such as coagulation, sedimentation, flocculation, and filtration, they can be found in water intended for human consumption. These same authors, Turki et al. [

16], studying landfill leachate samples before and after treatment with Fenton reagent, identified aromatic acids (1,2-diphenylcyclobutane, 4-phenyl cyclohexane, and 1,2-benzenedicarboxylic acid), phenolic compounds (2,4-bisphenol, 4-methyl phenol), aliphatic acid and ester (bis(2-methoxyethyl)ester), phthalate ester - alcohols (2-chlorocyclohexanol and cholestanol), and polyaromatic hydrocarbons (anthracene and naphthalene). All of the aforementioned compounds are considered mutagenic or carcinogenic [

18], except for cholestanol, a natural sterol that may be associated with natural sources of organic matter of terrigenous or marine origin [

19].

Although the evaluation of organic pollutants in sludge from wastewater treatment plants is a practice already established in some countries [

20], there have been no studies related to the identification of these compounds in primary sludge of effluents from the pharmaceutical industry in Brazil.

Table 4 and

Table 5 display the results of the solubility toxicity analyses, including heavy metals and pesticides in waste, the understanding of which is indispensable for agricultural purposes, in addition to the fact that heavy metals pose a risk to the environment.

Within the classification of solubility toxicity for inorganic parameters (

Table 4), the primary sludge of effluents from the pharmaceutical industry presented levels of chloride and sodium above the maximum limits allowed.

According to Lakhdar et al. [

21], organic matter controls the effects of salt on soils. Therefore, high levels of chloride and sodium (

Table 4) in the sludge would be controlled by the high content of organic matter, indicated by the high volatile solids content and the COD that are indirect measures of the organic matter content of the substrate.

According to Daliakopoulos et al. [

22], cited by Cucina et al. [

11], the content thereof should be highlighted when organic fertilizers of pharmaceutical origin are applied to soils to avoid salination and/or negative effects, for example, the structure of the soil, colloidal dispersion, or inhibition of plant growth.

According to the results presented in

Table 5, within the classification of toxicity by solubilization for organic parameters, the primary sludge of pharmaceutical industry effluents presented levels within the maximum allowed limits.

Table 6 shows the results for the analysis of macro- and micronutrients that are indispensable for disposal of soil residues.

Sewage sludge is a source of important nutrients. According to Teixeira et al. [

24], cited by Botero et al. [

25], in the flocculation and decantation stage, a residue rich in organic matter, micro- and macronutrients is generated. Its use can reduce the environmental impact associated with inadequate disposal of such waste.

According to Correia [

26], the percentage of carbon present in the dry mass of sewage sludge ranges from 18% to 50%. The value of 25.2% (

Table 6) found for the sludge accords with already recorded data. In addition, we observed that the concentrations of copper, molybdenum, nickel, and selenium were below the maximum allowed values [

23]. On the other hand, the concentrations found for other compounds (macro- and micronutrients) disagreed with established values, and there should be no absence of these elements [

23].

The use of sewage sludge for agricultural use is regulated by law as prescribed by resolution number 375/2006 of the National Council for the Environment in CONAMA [

23], establishing criteria and procedures for agricultural use of sewage sludge generated in sewage treatment plants. The Technical Report on Solid Waste Classification of the Brazilian Association of Technical Standards ABNT NBR 10004 establishes a classification for solid wastes [

27], divided into two classes that can be classified as Class I, considered to be hazardous, and Class II, considered to be non-hazardous. The second classification is further divided into inert (B) and non-inert (A).

ETS sludge from the pharmaceutical industry, according to the ABNT NBR 10004 [

27] Solid Waste Classification Technical Report, is classified as Class II A (non-hazardous, non-inert). It is also neither corrosive nor reactive [

27]. The toxicity evaluated by the parameters analyzed, namely, leaching toxicity classification—inorganic parameters, leaching toxicity classification—organic parameters (pesticides), leaching toxicity classification—organic parameters (other organic), classification of toxicity by solubilization—inorganic parameters (chromatography), and classification of toxicity by solubilization—organic parameters (chromatography), presented results according to specifications [

27].

According to Cieslik et al. [

8], one of the methods of stabilization of sewage sludge is anaerobic biodigestion with biogas production. The products of this process can be used in agriculture and in the generation of energy, contributing to the sustainable development of small and large facilities. Anaerobic biodigestion (degradation of biodegradable organic matter by microorganisms in the absence of oxygen gas) is a common effective method for the stabilization of sludge, concomitant with the production of biogas. The various methods of performing anaerobic biodigestion should be challenged to optimize the achievement of the desired product [

28]. The generation of energy from biogas must take into account certain criteria to reach maximum efficiency, including the raw materials and energy demands (input) [

29].

Matteo et al. [

30] achieved satisfactory results, studying environmentally sustainable solutions, including biogas production and energy conversion. Based on the results presented here, it can be inferred that the treatment of sewage sludge is a promising alternative for the production of biofertilizer and biofuels.