Characterization of Used Lubricant Oil in a Latin-American Medium-Size City and Analysis of Options for Its Regeneration

Abstract

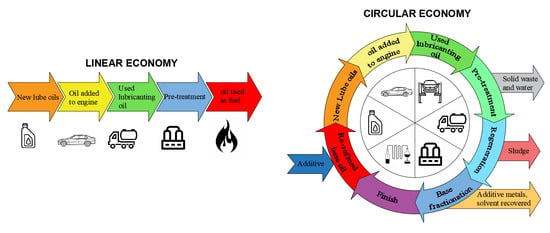

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization of the Used Oil Mixtures

2.3. Statistical Analysis of the Used Oil Properties

2.4. Analysis of Options for Re-Refining Used Oils in Cuenca

3. Results and Discussion

3.1. Physical Characteristics of the Used Oils, and Their Metal Content, in Cuenca

3.2. Influence of Storage Conditions on Used Oil Properties

3.3. Physical Properties of the Used Lubricating Oils in Cuenca and Comparison with the Properties of the Used Oils in Various Countries

3.4. Analysis of Options for Re-Refining Used Oils in Cuenca

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- References Agencia de Regulación y Control Hidrocarburifero [ARCH]. Reglamento Elaboración Aceites, Lubricantes Para Uso de Automotores. Available online: https://www.controlhidrocarburos.gob.ec/wp-content/uploads/MARCO-LEGAL-2016/Registro-Oficial-Suplemento-621-Res.-ARCH-3.pdf (accessed on 12 June 2019).

- Mensah-Brown, H. Re-refining and recycling of used lubricating oil: An option for foreign exchange and natural resource conservation in Ghana. ARPN J. Eng. Appl. Sci. 2015, 10, 797–801. [Google Scholar]

- El-Fadel, M.; Khoury, R. Strategies for vehicle waste-oil management: A case study. Resour. Conserv. Recycl. 2002, 33, 75–91. [Google Scholar] [CrossRef]

- Almeida Streitwieser, D.; Jativa Guzmán, F.; Aguirre Ortega, B. Conversión de aceite lubricante usado de automóviles a Diésel #2. Rev. Digit. VI Congr. Cienc. Tecnol. 2011. Available online: http://repositorio.espe.edu.ec/handle/21000/3483 (accessed on 6 February 2019).

- Fong Silva, W.; Quiñones Bolaños, E.; Tejada Tovar, C. Physical-chemical caracterization of spent engine oils for its recycling Caracterización físico-química de aceites usados de motores para su reciclaje. Prospectiva 2017, 15, 135–144. [Google Scholar] [CrossRef] [Green Version]

- Ministerio del Medio Ambiente [MMA]. Evaluación Económica, Ambiental y Social de la Implementación de la REP en Chile. Available online: https://mma.gob.cl/wp-content/uploads/2015/07/Publicacion-impactos-2012.pdf (accessed on 28 December 2019).

- Botas, J.A.; Moreno, J.; Espada, J.J.; Serrano, D.P.; Dufour, J. Recycling of used lubricating oil: Evaluation of environmental and energy performance by LCA. Resour. Conserv. Recycl. 2017, 125, 315–323. [Google Scholar] [CrossRef]

- Parry, B.J. Oil Recycling. In Kirk-Othmer Encyclopedia of Chemical Technology; Terrapure Environmental: North Vancouver, BC, Canada, 2016; pp. 1–16. ISBN 0471238961. [Google Scholar]

- Martelli-Tristão, J.A.; Valentini-Tristão, V.T.; Frederico, E. O processo de reciclagem do óleo lubrificante. Rev. Ibero-Am. Ciênc. Ambient. 2017, 8, 224–238. [Google Scholar] [CrossRef] [Green Version]

- CONAMA. A Importância da Destinação Correta do Óleo Lubrificante Usado—A Logística Reversa Como Instrumento na Aplicação da Resolução CONAMA No 362/2005. Available online: https://www.linkedin.com/pulse/importância-da-destinação-correta-do-óleo-usado-logística-ramos/ (accessed on 29 November 2019).

- SINDIRREFINO—Processo Industrial/Rerrefino. Available online: https://www.sindirrefino.org.br/institucional/a-instituicao (accessed on 17 December 2020).

- Compañía Industrial Lima S.A. [CILSA]. Protegemos el Medio Ambiente. Available online: https://www.cilsaperu.com/leer.html (accessed on 30 May 2020).

- BIOFACTOR S.A. Available online: http://biofactorsa.com/ (accessed on 30 May 2020).

- Nueva Energía S.A. Available online: https://nuevaenergiasa.com.ar/ (accessed on 30 May 2020).

- Muñoz, E.; Montoya, D.; Muñoz, A. La Re-Refinación: Una Alternativa a la Mano Para la Disposición Adecuada de Aceites usados (1). Available online: http://nuevagaceta.co/inicio/re-refinacion-alternativa-disposicion-adecuada-de-aceites-usados (accessed on 30 May 2020).

- BID. BID Lab Apoya Creación de Primera Planta de Recuperación de Aceite en Centroamérica | IADB. Available online: https://www.iadb.org/es/noticias/bid-lab-apoya-creacion-de-primera-planta-de-recuperacion-de-aceite-en-centroamerica (accessed on 29 November 2019).

- Banco Central del Ecuador [BCE]. Evolución de la Balanza Comercial Enero-Julio/2018. Available online: https://contenido.bce.fin.ec/documentos/Estadisticas/SectorExterno/BalanzaPagos/balanzaComercial/ebc201812.pdf (accessed on 25 January 2019).

- Ministerio del Ambiente y Agua [MAE]. Instructivo para la Gestión Integral de Aceites Lubricantes Usados y Envases Vacíos—Apel. Available online: http://apel.ec/biblioteca/mae-instructivo-para-la-gestion-integral-de-aceites-lubricantes-usados-y-envases-vacios/ (accessed on 30 May 2020).

- Diario el Comercio Convenios en cinco ciudades del Ecuador para Reciclar Aceites Usados. Available online: https://www.elcomercio.com/actualidad/convenios-ciudades-ecuador-reciclar-aceites.html (accessed on 29 November 2019).

- ETAPA. EP—Servicios de Telefonía, Televisión, Internet, Agua Potable, Alcantarillado de Cuenca—Ecuador > Información > Gestión Ambiental > Gestión Ambiental Urbana > Programa de Recolección de Aceites. Available online: https://www.etapa.net.ec/informacion/gestion-ambiental/gestion-ambiental-urbana/programa-de-recoleccion-de-aceites (accessed on 31 March 2020).

- Navarro-Nuñez, W. Estado Situacional del Manejo del Aceite Lubricante Usado en la Ciudad de Ayacucho y Propuesta de Disposición Final. Master’s Thesis, Universidad de Piura, Piura, Perú, 2014. [Google Scholar]

- Pinheiro, C.T.; Ascensão, V.R.; Cardoso, C.M.; Quina, M.J.; Gando-Ferreira, L.M. An overview of waste lubricant oil management system: Physicochemical characterization contribution for its improvement. J. Clean. Prod. 2017, 150, 301–308. [Google Scholar] [CrossRef]

- Jaramillo, D.; Redrován, L.; Urgilés, D. Analisis Técnico de la Vida Útil de un Lubricante de Aceite Mineral, para Motores de Combustion Interna a Gasolina de los Vehículos de Servicios de Taxis en la Ciudad de Cuenca. Bachelor’s Thesis, Universidad Politécnica Salesiana, Cuenca, Ecuador, 2011. [Google Scholar]

- Fundación PRO-AMBIENTE Manejo Ambientalmente Racional de Aceites Lubricantes Usados. Available online: https://es.slideshare.net/JGNathyvidad/aceites-usados-39623939 (accessed on 30 November 2019).

- Peñafiel Chiriboga, S.L. Caracterización del Manejo de Aceites de Desecho de Automóviles e Hidráulicos de Origen Industrial en la Ciudad de Cuenca. Bachelor’s Thesis, Universidad de Cuenca, Cuenca, Ecuador, 2017. [Google Scholar]

- ASTM International Standard. Practice for Calculating Viscosity Index from Kinematic Viscosity; D 2270-04; ASTM International: West Conshohocken, PA, USA, 2009; pp. 1–6. [Google Scholar]

- ASTM International Standard. Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter; D4052-11; ASTM International: West Conshohocken, PA, USA, 2011; pp. 1–8. [Google Scholar]

- ASTM International Standard. Test Method for Acid Number of Petroleum Products by Potentiometric Perchloric Acid Titration; D 2896-03; ASTM International: West Conshohocken, PA, USA, 2003; pp. 1–7. [Google Scholar]

- ASTM International Standard. Test Method for Flash and Fire Points by Cleveland Open Cup Tester; D 92-05; ASTM International: West Conshohocken, PA, USA, 2005; pp. 1–10. [Google Scholar]

- ASTM International Standard. Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 and 100 °C; D 2270-93 (Reapproved 1998); ASTM International: West Conshohocken, PA, USA, 1993; pp. 1–6. [Google Scholar]

- ASTM International Standard. Test Method for Determination of Wear Metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by Rotating Disc Electrode Atomic Emission Spectrometry; D6595-16; ASTM International: West Conshohocken, PA, USA, 2011; pp. 1–6. [Google Scholar]

- De la Fuente Fernandez, S. Análisis de Conglomerados. Available online: https://www.academia.edu/32046069/Análisis_Conglomerados_Santiago_de_la_Fuente_Fernández (accessed on 18 September 2018).

- Hines, W.; Montgomery, D.; Borror, C. Probabilidad y Estadística para Ingeniería, 3rd ed.; Compañía Editorial Continental: Mexico City, Mexico, 2005; ISBN 970240553X. [Google Scholar]

- Widman, R. Interpretando el Reporte de Análisis de Aceite. Available online: http://www.mantenimientomundial.com/notas/w46.pdf (accessed on 6 February 2019).

- Widodo, S.; Ariono, D.; Khoiruddin, K.; Hakim, A.N.; Wenten, I.G. Recent advances in waste lube oils processing technologies. Environ. Prog. Sustain. Energy 2018, 37, 1867–1881. [Google Scholar] [CrossRef]

- Gómez Estrada, Y. Contribución al Desarrollo y Mejora para la Cuantificación de la Degradación en Aceites Lubricantes Usados de MCIA a Través de la Técnica de Espectrometría Infrarroja por Transformada de Fourier (FT-IR). Ph.D. Thesis, Universitat Politècnica de València, Valencia, Spain, 2013. [Google Scholar]

- Terpel Terpel Oiltec 20W-50 Titanio. Available online: https://www.terpel.com/Plantillas/Terpel/Descargables/Lubricantes/TerpelOiltec20W-50Titanio.pdf (accessed on 30 June 2020).

- Noria Corporation. Q & A: ¿Qué es el TBN y qué Indica en el Análisis de Aceite? Noria Latín América. Available online: http://noria.mx/lublearn/q-a-que-es-el-tbn-y-que-indica-en-el-analisis-de-aceite/ (accessed on 30 November 2019).

- Mang, T.; Dresel, W. Lubricants and Lubrication, 2nd ed.; WILEY-VCH: Weinheim, Germany, 2007; ISBN 9783527610341. [Google Scholar]

- Arellano, L. Proyecto Planta de Reciclaje de Aceites Usados por Extracción por Solvente; Asesorías y Proyectos Ribotta: Valparaíso, Chile, 2008. [Google Scholar]

- Amesty, R.; De Turris, A.; Rojas, D.; Hurtado, A.; Medrano, J.; López, Y. Characterization of Oil Lubricant Automotive for Reuse. Redieluz 2015, 5, 43–48. [Google Scholar]

- Villanueva Torres, C. Diseño de una Planta Piloto para Desarrollar Tecnología de Extracción con Solvente para Tratamiento de Aceites Usados. Bachelor’s Thesis, Universidad Nacional de Ingeniería, Lima, Perú, 2005. [Google Scholar]

- Moya Díaz, L. Desde el Aceite Lubricante Usado Hasta su Puesta en el Mercado Tras Su Regeneración. Master’s Thesis, Fundación Escuela de Organización Industrial, Madrid, Spain, 2010. [Google Scholar]

- Abdel-Jabbar, N.M.; Al Zubaidy, E.A.H.; Mehrvar, M. Waste lubricating oil treatment by adsorption process using different adsorbents. World Acad. Sci. Eng. Technol. 2010, 62, 9–12. [Google Scholar]

- Boughton, B.; Horvath, A. Environmental Assessment of Used Oil Management Methods. Environ. Sci. Technol. 2004, 38, 353–358. [Google Scholar] [CrossRef] [Green Version]

- Syrmanova, K.K.; Kovaleva, A.Y.; Kaldybekova, Z.B.; Botabayev, N.Y.; Botashev, Y.T.; Beloborodov, B.Y. Chemistry and recycling technology of used motor oil. Orient. J. Chem. 2017, 33, 3195–3199. [Google Scholar] [CrossRef]

- Owolabi, R.; Amosa, M.K. Some Physico-Chemical and Adsorptive Reclamation Strategies of Spent Automobile Engine Lubricating Oil. J. Eng. Res. 2017, 22, 98–106. [Google Scholar]

- Abdulkareem, A.S.; Afolabi, A.S.; Ahanonu, S.O.; Mokrani, T. Effect of treatment methods on used lubricating oil for recycling purposes. Energy Sources, Part A Recover. Util. Environ. Eff. 2014, 36, 966–973. [Google Scholar] [CrossRef]

- Korchak, B.; Hrynyshyn, O.; Chervinskyy, T.; Polyuzhin, I. Application of vacuum distillation for the used mineral oils recycling. Chem. Chem. Technol. 2018, 12, 365–371. [Google Scholar] [CrossRef]

- Ramadass, K.; Megharaj, M.; Venkateswarlu, K.; Naidu, R. Ecological implications of motor oil pollution: Earthworm survival and soil health. Soil Biol. Biochem. 2015, 85, 72–81. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Słowik, T.; Kuranc, A.; Kamińska, A. Designation of chosen heavy metals in used engine oils using the XRF method. Polish J. Environ. Stud. 2015, 24, 2277–2283. [Google Scholar] [CrossRef]

- Hamawand, I.; Yusaf, T.; Rafat, S. Recycling of waste engine oils using a new washing agent. Energies 2013, 6, 1023–1049. [Google Scholar] [CrossRef]

- Mohammed, R.R.; Ibrahim, I.A.R.; Taha, A.H.; McKay, G. Waste lubricating oil treatment by extraction and adsorption. Chem. Eng. J. 2013, 220, 343–351. [Google Scholar] [CrossRef]

- Muhammad, Q.; Tariq, M.A.; Mazhar, H. Physico-chemical characteristics of Pakistani used engine oils. J. Pet. Technol. Altern. Fuels 2016, 7, 13–17. [Google Scholar] [CrossRef]

- Elkhaleefa, A.M. Waste Engine Oil Characterization and Atmospheric Distillation to Produce Gas Oil. Int. J. Eng. Adv. Technol. 2016, 5, 6–8. [Google Scholar]

- Osman, D.I.; Attia, S.K.; Taman, A.R. Recycling of used engine oil by different solvent. Egypt. J. Pet. 2018, 27, 221–225. [Google Scholar] [CrossRef]

- U.S. Environmenteal Protection Agency (EPA). Used Oil Management Program. Available online: https://archive.epa.gov/wastes/conserve/materials/usedoil/web/html/index.html (accessed on 29 November 2019).

- Speight, J.G.; Exall, D.I. Refining Used Lubricating Oils; CRC Press: Boca Raton, FL, USA; Taylor and Francis: Boca Raton, FL, USA, 2014; ISBN 9781466551497. [Google Scholar]

- Emam, E.A.; Shoaib, A.M. Re-refining of Used Lube Oil, II- by Solvent/Clay and Acid/Clay-Percolation Processes. ARPN J. Sci. Technol. 2012, 2, 1034–1041. [Google Scholar]

- Isah, A.G.; Abdulkadir, M.; Onifade, K.R.; Musa, U.; Garba, M.U.; Bawa, A.A.; Sani, Y. Regeneration of used engine oil. Lect. Notes Eng. Comput. Sci. 2013, 1 LNECS, 5–8. [Google Scholar]

- Stan, C.; Andreescu, C.; Toma, M. Some aspects of the regeneration of used motor oil. Procedia Manuf. 2018, 22, 709–713. [Google Scholar] [CrossRef]

- Salem, S.; Salem, A.; Agha Babaei, A. Preparation and characterization of nano porous bentonite for regeneration of semi-treated waste engine oil: Applied aspects for enhanced recovery. Chem. Eng. J. 2015, 260, 368–376. [Google Scholar] [CrossRef]

- García González, M.T. Regeneración de Aceites Lubricantes Usados Mediante Extracción. Available online: https://dialnet.unirioja.es/servlet/tesis?codigo=105028 (accessed on 30 November 2019).

- Uribe, R. Investigaciones de Materias Primas Minerales No Metálicas en el Ecuador. Rev. Politec. 2015, 36, 34. [Google Scholar] [CrossRef]

- Haro, C.; De La Torre, E.; Aragón, C.; Guevara, A. Regeneración de arcillas de blanqueo empleadas en la decoloración de aceites vegetales comestibles. Rev. EPN 2014, 34, 1–8. [Google Scholar]

- Kupareva, A.; Mäki-Arvela, P.; Murzin, D.Y. Technology for rerefining used lube oils applied in Europe: A review. J. Chem. Technol. Biotechnol. 2013, 88, 1780–1793. [Google Scholar] [CrossRef]

- Maghsoodi, A.I.; Afezalkotob, A.; Ari, I.A.; Maghsoodi, S.I.; Hafezalkotob, A. Selection of waste lubricant oil regenerative technology using entropy-weighted risk-based fuzzy axiomatic design approach. Informatica 2018, 29, 41–74. [Google Scholar] [CrossRef]

- Jafari, A.J.; Hassanpour, M. Analysis and comparison of used lubricants, regenerative technologies in the world. Resour. Conserv. Recycl. 2014, 103, 179–191. [Google Scholar] [CrossRef]

- Nwachukwu, A. Review and assessment of mechanic village potentials for small scale used engine oil recycling business. Afr. J. Environ. Sci. Technol. 2012, 6, 464–475. [Google Scholar] [CrossRef] [Green Version]

- Oladimeji, T.E.; Sonibare, J.A.; Omoleye, J.A.; Emetere, M.E.; Elehinafe, F.B. A review on treatment methods of used lubricating oil. Int. J. Civ. Eng. Technol. 2018, 9, 506–514. [Google Scholar]

- CleanOil Limited—China’s Most Advanced and Cleanest Oil Re-Refiner. Available online: http://www.cleanoil.com.hk/ (accessed on 26 December 2020).

- AEADE SECTOR AUTOMOTOR en Cifras. Available online: http://www.aeade.net/wp-content/uploads/2017/03/Sector-en-cifras_6-Marzo-2017.pdf (accessed on 30 December 2019).

- Ecuador Evolución de la Balanza Comercial Enero—Diciembre/2019. Subgerencia Program. y Regul. Available online: https://contenido.bce.fin.ec/documentos/Estadisticas/SectorExterno/BalanzaPagos/balanzaComercial/ebc202002.pdf (accessed on 16 February 2019).

| Sample Number | Container Material | Top of Tank | Pre-Filtered a | Covered b | Collection Frequency c |

|---|---|---|---|---|---|

| 1 | Directly from vehicle’s engine | no | - | - | |

| 2 | Directly from vehicle’s engine | no | - | - | |

| 3 | Directly from vehicle’s engine | no | - | - | |

| 4 | Metal | Closed | no | yes | monthly |

| 5 | Metal | Closed | no | yes | monthly |

| 6 | Metal | Closed | no | yes | monthly |

| 7 | Metal | Closed | no | yes | monthly |

| 8 | Metal | Closed | no | yes | bimonthly |

| 9 | Metal | Closed | no | yes | bimonthly |

| 10 | Metal | Closed | no | yes | quarterly |

| 11 | Metal | Closed | no | no | monthly |

| 12 | Metal | Closed | yes | no | monthly |

| 13 | Metal | closed | yes | yes | bimonthly |

| 14 | Metal | closed | yes | yes | monthly |

| 15 | Metal | closed | yes | yes | monthly |

| 16 | Metal | open | yes | yes | monthly |

| 17 | Metal | open | no | yes | monthly |

| 18 | HDPE | closed | no | no | monthly |

| 19 | HDPE | closed | no | yes | bimonthly |

| 20 | HDPE | closed | no | yes | quarterly |

| 21 | HDPE | closed | yes | yes | quarterly |

| 22 | HDPE | closed | yes | yes | monthly |

| 23 | HDPE | open | yes | yes | monthly |

| Parameter | A. Instrument | Brand | Model | Serial Number |

|---|---|---|---|---|

| Water content | Distiller | Stanhope Seta | 24415-2 | 1031631 |

| Density at 15 °C | Digital densimeter | Mettler Toledo | Densito 30 PX | LWE13A54 |

| Viscosity index | Thermostatic bath | Petrotest | Visco Bath | 0263125001 |

| Total base number (TBN) | Potentiometer | Metrohm | 916 Ti Touch | 1916001003195 |

| Flashpoint | Equipment to flashpoint | Fisher Tag | Flash Tester | 926 |

| Metal content | Atomic emission spectrometer | Spectroil | M/F-W | 626 |

| Parameter | Unit | Mean | Range a |

|---|---|---|---|

| Water content | %v/v | 0.2 | 0.1–0.3 |

| Density at 15 °C | g/mL | 0.88 | 0.88–0.89 |

| Viscosity index | - | 132.6 | 128.1–137 |

| Total Base number (TBN) | mg KOH/g | 5.8 | 4.8–6.8 |

| Flashpoint | °C | 179.5 | 168–191 |

| Kinematic viscosity at 100 °C | mm2/s | 12.2 | 11–13.4 |

| Al | mg/kg | 8 | 6.1–9.8 |

| Ba | mg/kg | 1.5 | 0.3–2 |

| B | mg/kg | 43 | 24.8–62 |

| Cd | mg/kg | 0.4 | 0.02–0.2 |

| Ca | mg/kg | 1988.7 | 1744.4–2233.1 |

| Cu | mg/kg | 13.4 | 2.8–23.9 |

| Cr | mg/kg | 2.9 | 1.5–4.1 |

| Sn | mg/kg | 9.2 | 0.5–2.9 |

| P | mg/kg | 910.5 | 782.2–1038.7 |

| Fe | mg/kg | 40.6 | 21.3–59.8 |

| Mg | mg/kg | 37.8 | 14.3–61.2 |

| Mn | mg/kg | 3.2 | 2.2–4.2 |

| Mo | mg/kg | 31 | 15.5–46.4 |

| Ni | mg/kg | 1.8 | 1.1–2.6 |

| Ag | mg/kg | 0.7 | 0.1–0.5 |

| Pb | mg/kg | 39.6 | 1.3–25.4 |

| Si | mg/kg | 20.2 | 13.9–26.4 |

| Na | mg/kg | 62.7 | 24–101.4 |

| Ti | mg/kg | 12 | 3.1–15.7 |

| V | mg/kg | 3.3 | 1.7–5 |

| Zn | mg/kg | 781 | 671–890.1 |

| Property | Oils in Cuenca | Typical Range Other Studies | Expected Limits [34] | Tendency with Respect to New Oils | ||

|---|---|---|---|---|---|---|

| This Study | Average New Oils [23] | Ref. [8] | Ref. [35] | |||

| Water content (%v/v) | 0.2 | 0.1 | - | 1.1–13.7 | - | increases |

| Flashpoint (°C) | 178.1 | - | 75–240 | 120–214 | >38 | decreases |

| Density at 15 °C (g/mL) | 0.9 | - | - | - | - | increases |

| Viscosity index | 134.2 | 138.1 | - | 92.5–144 | - | increases |

| TBN (mg KOH/g) | 5.7 | 5.3 | - | 4.1–4.7 | - | decreases |

| Kinematic Viscosity 100 °C (mm2/s) | 11.8 | 16.4 | - | 9.3–14.8 | - | increases |

| Metals content (mg/kg) | ||||||

| Al | 8 | <1 | - | 4–20.3 | <20 | increases |

| Ba | 1.5 | 64.7 | 5–110 | - | - | decreases |

| B | 43 | 10 | - | 30–4100 | - | decreases |

| Cd | 0.4 | - | 0–3.8 | 2–9.4 | <2 | increases |

| Ca | 1988.7 | 1396.6 | 936–1670 | 606–1890 | - | decreases |

| Cu | 13.4 | <1 | - | 7–30 | <30 | increases |

| Cr | 2.9 | <1 | - | 3.2–233 | <10 | increases |

| Sn | 9.2 | <1 | - | 9.7 | <20 | increases |

| P | 910.5 | 802.2 | 494–973 | - | - | decreases |

| Fe | 40.6 | 1.3 | 23–99 | 15–348 | <100 | increases |

| Mg | 37.8 | 12 | 66–120 | 43.5–332 | - | decreases |

| Mn | 3.2 | - | 0.9–18 | - | - | increases |

| Mo | 31 | 97.9 | 24–42 | - | - | decreases |

| Ni | 1.8 | <1 | 0–5.4 | 2 | <10 | increases |

| Ag | 0.7 | <1 | - | - | <3 | increases |

| Pb | 39.6 | <1 | 7–57 | 2–2813 | <30 | increases |

| Si | 20.2 | 4.3 | 29–76 | 11–21.9 | <20 | increases |

| Na | 62.7 | 48.1 | 174–606 | 13–65 | <50 | increases |

| Ti | 12 | <1 | 0–4.9 | - | - | increases |

| V | 3.3 | <1 | 0.2–10 | - | - | increases |

| Zn | 781 | 803.3 | 444-1280 | 54.9–1100 | - | decreases |

| Element (ppm) | This Work | Quito-Ecuador [4] | Chile [40] | Colombia [5] | Venezuela [41] | Perú [42] | Spain [43] | Portugal [22] | UAE [44] | USA [45] | Kazakhstan [46] | Ghana [2] | Nigeria [47] | South Africa [48] | Ukraine [49] | Australia [50] | Poland [51] | Iraq [52] | Iraq [53] | Pakistan [54] | Saudi Arabia [55] | Egypt [56] | Mean |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | 8 | - | - | 17 | - | 375 | - | - | 4 | - | 57.9 | - | - | 20.1 | - | 64 | - | - | - | - | - | - | 89.7 |

| Ba | 1.5 | - | - | - | 113 | 9 | 297 | - | <1 | 2.9 | - | - | - | - | - | - | - | - | - | - | - | - | 84.6 |

| B | 43 | - | - | - | - | - | - | - | 3 | - | - | - | - | - | - | - | - | - | - | - | - | - | 3 |

| Cd | 0.4 | - | 0.1 | - | - | - | - | - | <1 | 1.7 | - | - | - | - | - | 0.04 | - | 1 | - | - | - | - | 0.8 |

| Ca | 1988.7 | - | - | 285.3 | 190 | 1250 | 4.5 | 1805 | 1667 | - | 171.9 | 606.5 | - | - | 1445.7 | - | - | - | - | - | - | - | 825.1 |

| Cu | 13.4 | - | 9.7 | 14.3 | 16 | 15 | 29 | - | 7 | 36 | 37.9 | 21.3 | - | - | 74.1 | 7 | 18 | 4.6 | - | - | - | - | 22.3 |

| Cr | 2.9 | - | 5 | - | <1 | - | - | - | 4 | 3.3 | 18.3 | - | 1.3 | - | 52.6 | 0.2 | 1.4 | 1.5 | - | - | - | - | 8.9 |

| Sn | 9.2 | - | 5 | - | - | - | - | - | <1 | - | - | - | - | - | - | - | - | 1.6 | - | - | - | - | 2.5 |

| P | 910.5 | - | - | 18.4 | - | 1550 | 931 | 739 | 632 | - | - | - | - | - | 2797.1 | 485 | - | - | - | - | - | - | 1021.8 |

| Fe | 40.6 | - | - | - | 46 | 240 | 205 | 212 | 15 | - | - | 89.5 | - | 21.3 | 696.4 | 41 | 53.5 | 72 | - | - | - | - | 153.8 |

| Mg | 37.8 | - | - | - | 1.5 | - | 309 | - | 38 | - | 436.1 | - | - | - | 549.8 | 24 | - | 81 | - | - | - | - | 205.6 |

| Mn | 3.2 | - | - | - | - | - | - | - | 1 | - | - | - | 5.3 | - | 8.8 | 1 | 1.8 | 1.5 | - | - | - | - | 3.2 |

| Mo | 31 | - | - | - | - | - | - | - | 7 | - | - | - | - | - | 48.15 | - | 462.9 | - | - | - | - | - | 172.7 |

| Ni | 1.8 | - | 1.4 | - | - | - | - | 5 | <1 | 1.5 | - | 2 | 0.8 | - | 5.8 | 0.2 | 0.4 | - | - | - | - | - | 2 |

| Ag | 0.7 | - | - | - | - | - | - | - | <1 | - | - | - | - | - | - | - | - | - | - | - | - | - | <1 |

| Pb | 39.6 | - | 15.5 | 45.4 | |||||||||||||||||||

| Si | 20.2 | - | - | 2.3 | - | - | - | - | 11 | - | - | - | - | - | 140 | - | - | - | - | - | - | - | 51.1 |

| Na | 62.7 | - | - | 216.8 | 43.5 | - | 118 | - | 20 | - | - | 9.5 | - | - | - | - | - | - | - | - | - | - | 73.3 |

| Ti | 12 | - | - | - | - | - | - | - | 2 | - | - | - | - | - | - | - | - | - | - | - | - | - | 2 |

| V | 3.3 | - | 2 | - | - | - | - | - | <1 | - | - | - | - | - | - | - | - | - | - | - | - | - | 1.5 |

| Zn | 781 | - | 340 | 825.5 | 651 | 1025 | 1 | 1000 | 780 | 1152 | 403 | - | - | - | 4361 | 254 | 1106.7 | 1280 | - | - | - | - | 1013.8 |

| Water content | 0.2 | 0.4 | 10 | 0.5 | 0.6 | 5.1 | - | - | 0.8 | - | 0.03 | - | - | 11.5 | 0.2 | - | - | 0.9 | 1.5 | - | - | 0.3 | 2.7 |

| Density at 15 °C | 0.9 | - | - | 0.9 | - | - | - | - | 0.9 | - | 0.9 | - | 0.9 | 0.9 | 0.9 | - | - | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 |

| Viscosity index | 134.2 | 122 | - | - | - | 115 | - | 103.1 | - | - | - | - | - | 25.5 | 110 | - | - | 89.1 | - | 110.6 | 80 | 115.1 | 96.7 |

| Base number (TBN) | 5.7 | 18.6 | - | - | - | - | 1.7 | - | 4.1 | - | - | - | - | - | 3.5 | - | - | 0.1 | 5.8 | 4.6 | 13.5 | - | 6.5 |

| Flashpoint | 178.1 | 90.8 | - | - | 182.2 | - | 348 | - | 152 | - | 190 | - | 135 | 125 | 511 | - | - | 158 | 178 | 183 | 101 | 128 | 190.9 |

| Kinematic viscosity at 100 °C | 11.8 | 29.8 | 55 | 81.1 | - | 17 | - | 7.8 | - | - | 9.5 | - | - | 6.5 | 13.9 | - | - | 13.5 | -12 | 15.5 | 14.1 | 12.93 | 22.2 |

| Technology | Country and Reference | |

|---|---|---|

| Pre-Treatment | Filtration, centrifugation, decantation, and sedimentation | South Africa [48], Egypt [59] |

| Distillation | ||

| Filtration | Egypt [56] | |

| Sedimentation, magnetization, heating, and agitation | Nigeria [60] | |

| Sedimentation | UAE [44] | |

| Regeneration | Acid treatment | Romania [61], Iran [62], Nigeria [47], Colombia [5] |

| Caustic treatment | Ghana [2] | |

| Activated carbon/clay treatment | South Africa [48] | |

| Distillation/clay | ||

| Acid clay treatment | ||

| Irradiation and ultrasonic adsorption | Kazakhstan [46] | |

| Solvent extraction | Egypt [56], Iraq [53], Portugal [22], Egypt [59], Nigeria [60], Spain [43], UAE [44] | |

| Fractionation of the Bases | Vacuum distillation | Ukraine [49], Egypt [56], Iraq [53], Ghana [2], UAE [44] |

| Atmospheric and vacuum distillations. | Spain [43] | |

| Finishing | Adsorption, neutralization, sedimentation, and filtration. | Romania [61], Nigeria [47] |

| Filtration and heating | South Africa [48] | |

| Filtration | Colombia [5] | |

| Adsorption | Kazakhstan [46], Egypt [56], Iraq [53], Nigeria [60], Iran [62], UAE [44] |

| Re-Refining Method | Process | Advantages | Disadvantages |

|---|---|---|---|

| Acid–clay [68,69] | Dehydration: removal of impurities, water, antifreeze, and solvents by preliminary distillation at low temperature. Vacuum distillation. Sulfuric acid: reverse reaction with oxygen, sulfur, and nitrogen to form sludge. Additional refining to eliminate paraffinic and naphthenic hydrocarbons. Adsorption with clay to reduce odor and dark color. | Proven technology. Low production cost. Simple and straightforward process. Does not require qualified operators. Adequate for small capacities. Low capital investment, profitable for small-scale plants. Low energy consumption. Produces good quality base oils. | Generates polluting waste. Causes corrosion of equipment. Low yield due to loss of oil in mud and clay. Not compatible with pollution control regulations. Technology is prohibited in many countries |

| Activated clay [68,69] | Dehydration. Vacuum distillation with conventional vacuum column. Adsorption with activated clay at 120 °C for 2 h. Filtered. | No acid is required. Simple process. Suitable for small capacity plants. Produces good quality base oils. | High consumption of clay. Low performance. Inconsistent quality. Environmental problems to eliminate large amounts of spent clay. Depends on a particular type of clay that may not be readily available |

| Thin film evaporation (TFE) [59,68] | Dehydration. Evaporation of thin-film (via vacuum distillation). Process involves the removal of volatile materials and the separation of the high boiling distillate from residues containing heavy metals. Two options: (a) hydraulic finishing to remove chlorine, nitrogen, oxygen, and sulfur compounds or (b) adsorption with clay to remove impurities (e.g., heavy metals and decomposition products) | Suitable for high capacity plants The thin-film evaporator is capable of operating under high vacuum and is usually used for high value products It does not cause contamination. Produces very good quality base oils | Operates at high temperature and high vacuum. The plant must have high capacity to be economically viable. High energy consumption |

| Solvent extraction [67,68,70] | Dehydration. Removal of impurities by mixing solvents that do not include sulfuric acid, the solvent produces insoluble and suspended substances (e.g., asphalt, metal compounds, and resin). The sludge removed as non-hazardous waste. Vacuum distillation with conventional vacuum column. Adsorption with clay to reduce odor and dark color. | The solvent is recyclable. Does not cause contamination. Functional recovery of base oils. Produces good quality base oils. Propane is used as a solvent to remove additives, metals, and tar. It operates at room temperature | Economical only for high plant capacity. Operates at higher pressure. Requires operating systems and qualified personnel. May involve operating losses of solvent. Propane can cause fires/explosion. High energy consumption |

| Hydro-treatment [66,67,68] | Dehydration. Vacuum distillation with conventional vacuum column. The oil treated with hydrogen in the presence of a catalyst removing sulfur, nitrogen, and oxygen. The combination of this process with solvent extraction strengthens the oil quality. Adsorption with clay. | Corrects the color and smell of the oil. The distillation process is commonly used to remove sulfur, nitrogen, metals, or unsaturated hydrocarbons | Expensive. Unsafe. Not suitable at small scale. High energy consumption. Operates at high temperature and pressure. |

| Technology | Raw Material | Investment Costs | Product Quality | Yield% | Waste | Plant Capacity (t/year) |

|---|---|---|---|---|---|---|

| Solvent Extraction | ||||||

| MRD process (Germany, Denmark and the Netherland) | It can contain up to 5% vegetable oils, complete preservation of synthetic oils. | Relatively low operating and capital costs. | Base oils of good quality. | 91 | It can use as fuel. | 120,000 |

| Interline (Spain and United Kingdom) | Motor mineral oil and industrial oils. | Relatively low operating and capital costs. | Low quality of base oil (API I). | 79 | Asphalt Modifier Production | Spain: 36,000, United Kingdom: 50,000 |

| Vacuum distillation/TFE + hydro-treatment, solvent extraction finishing or chemical treatment | ||||||

| Vaxon (Denmark and Spain) | Mineral motor and industrial oils and some stable synthetics in the presence of a strong base. | Financially attractive. | The average quality of the oil produced. | 65–70 | Asphalt extender, thermal energy production, or as a bitumen mix component. | Denmark: 40,000, Spain: 42,000 |

| EcoHuile (Sotulub) (France) | Mineral oils and some stable synthetics in the presence of alkaline additives. | It does not require a final step; this decreases the investment cost of the process. | A base oil of poor quality. | 82–92 | 125,000 | |

| Hydrotreatment | ||||||

| Hylube (Germany) | Accept used oil from different sources. | The capital investment and operational costs of the process are minimizing by eliminating superfluous equipment. | Pretty high oil quality (API II). | 85 | Stable and acceptable for asphalt mixing. | |

| TFE + hydro-treatment | ||||||

| CEP process (Finland) | It accepts used oil from different sources: industrial and motor, mineral and synthetic oils. | High operating and capital costs. | High quality base oils (API II). | 70 | 60,000 | |

| TDA+ hydro-treatment | ||||||

| Revivoil (Italy, Poland and Spain) | Use motor oil types. | Operation and capital costs higher. | Products of comparable quality to virgin base oils meet the requirements of API II. | 72 | Asphalt and bituminous membrane extender. Hydro-treatment catalyst regenerated and reused in the process. | Italy: 130,000, Poland: 80,000, Spain: 59,000 |

| Solvent extraction + hydro-treatment | ||||||

| Snamprogetti (Italy) | Use motor oil types. | Relatively expensive due to PDA (propane deasphalting) and hydro-treatment. | High quality base oils. | 74–80 | Asphalt production. | 84,000 |

| Cyclon process (Greece) | Use motor oil types. | Operation and capital costs higher. | High-quality base oils. | 72 | Light hydrocarbon fuel used in boiler oil heaters. | 40,000 |

| CleanOil ORT (China) | Use motor oil types. | Relatively expensive due to PDA (propane deasphalting), vacuum distillation and hydro-treatment. | High quality Group II/II + base oils, exceed performance standards (API) | 90 | Asphalt flux | 20,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Alvarracín, C.; Criollo-Bravo, J.; Albuja-Arias, D.; García-Ávila, F.; Pelaez-Samaniego, M.R. Characterization of Used Lubricant Oil in a Latin-American Medium-Size City and Analysis of Options for Its Regeneration. Recycling 2021, 6, 10. https://0-doi-org.brum.beds.ac.uk/10.3390/recycling6010010

Sánchez-Alvarracín C, Criollo-Bravo J, Albuja-Arias D, García-Ávila F, Pelaez-Samaniego MR. Characterization of Used Lubricant Oil in a Latin-American Medium-Size City and Analysis of Options for Its Regeneration. Recycling. 2021; 6(1):10. https://0-doi-org.brum.beds.ac.uk/10.3390/recycling6010010

Chicago/Turabian StyleSánchez-Alvarracín, Carlos, Jessica Criollo-Bravo, Daniela Albuja-Arias, Fernando García-Ávila, and M. Raúl Pelaez-Samaniego. 2021. "Characterization of Used Lubricant Oil in a Latin-American Medium-Size City and Analysis of Options for Its Regeneration" Recycling 6, no. 1: 10. https://0-doi-org.brum.beds.ac.uk/10.3390/recycling6010010