1. Introduction

Today, over 70 percent of oil and gas transportation relies on a total of over 3,500,000 km of pipelines in 120 countries, which is the safest, most reliable and efficient method, compared with highways, railways and marine transport, and so on [

1]. To meet the rapidly growing demand for oil and gas, the construction of trunk pipelines which can operate in high-pressure, high-speed and high-capacity conditions has been increasing in recent years, giving the pipelines larger diameters, thicker pipe walls, deeper burial depths and larger transportation distances [

2,

3,

4,

5]. Due to corrosion and high-pressure loadings on the pipe wall, pipeline failures including defects, deformations, blockages, leakages and explosions occur every year, resulting in serious risks to pipeline safety [

6,

7,

8]. In China, it was reported that there was a pipeline failure every 4 km [

9], and in the USA, the economic and human losses due to the significant pipeline incidents in the past 20-year period are

$7 billion and 330 fatalities along with 1292 injuries, respectively [

10]. Pipeline inspection gauges (PIGs) are periodically used for pipeline in-line inspections (ILIs) to minimize these risks and maintain pipeline integrity [

11,

12,

13,

14,

15,

16]. However, during the pipeline ILI operation, the PIG is likely to be blocked by the deformed pipelines, while an odometer installed in the PIG can only record the PIG position offline, because the shielding effect of the steel pipe wall makes it difficult to transmit the position information from inside the pipeline to the ground through wireless communication technologies, such as Wi-Fi, Bluetooth, or 3G and 4G networks [

17,

18]. Thus, the pipeline ILI usually needs the use of above-ground-marker (AGM) technologies to track the position of the PIG in real time [

19,

20].

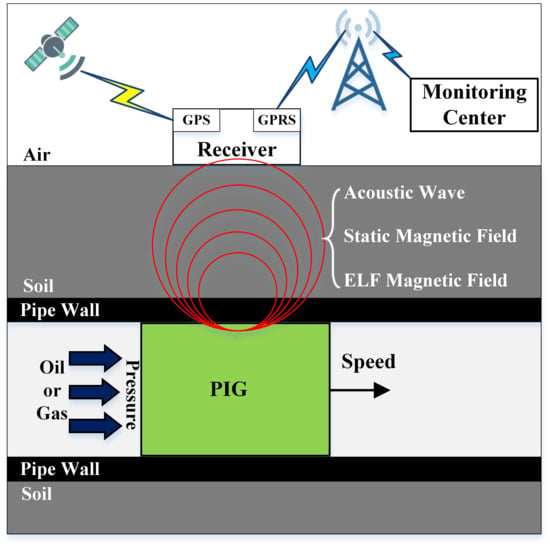

Existing AGM methods utilize acoustic wave, static magnetic field, extremely low frequency (ELF) magnetic fields for PIG localization and tracking, and have been widely practiced in the oil and gas industry [

21,

22,

23,

24,

25,

26,

27]. Here, the working principle of the AGM system is shown in

Figure 1. The PIG is propelled by the flowing medium and the speed is mainly determined by the pressure inside the pipeline. A receiver placed above the ground detects the tracking signals generated by the PIG moving right below, and records the PIG position simultaneously. With the help of the global position system (GPS) and general packet radio service (GPRS) technologies, all receivers along the pipeline usually with an interval of 1 km can send the current location and local time of the PIG to the monitoring center to form a tracking network, and the information will also be used to compensate for the accumulated locating error caused by the PIG odometer.

The acoustic wave method is used to detect the acoustic wave generated by the friction between the PIG and the pipe wall. In [

21,

22], it is used to improve the tracking precision of the underground PIG, and in [

23], a micro-electro-mechanical-system (MEMS) acoustic vector sensor is found to have advantages of high sensitivity for detecting low-frequency acoustic signals. However, the acoustic signals generated by the moving PIG are easily cluttered by the environmental acoustic sources, such as moving vehicles, trains and airplanes, and it produces a high number of false alarms. The static magnetic field method is used to detect the static magnetic field generated by the permanent magnets assembled in the PIG. In [

24,

25], experimental results showed that this method was effective when the magnetic signals emitted by the permanent magnets were strong enough. Furthermore, it is only applicable to certain types of PIG due to the requirement to carry heavy and bulky permanent magnets, thus limiting the scope of application. To overcome the aforementioned challenges, the ELF method is introduced, which is a single-frequency magnetic signal transmission and reception method that is suitable for most types of PIG [

26,

27]. A small and lightweight transmitter equipped in the PIG generates the ELF magnetic field and the receiver detects the ELF magnetic field using magnetic sensors and real-time signal detection methods. Comparing to high-frequency magnetic field, the ELF magnetic field with frequencies between 22 Hz and 24 Hz has a good penetrating ability for signal transmitting through steel pipe wall and soil, and is less susceptible to environmental interferences [

28,

29]. In [

30], the tracking and localization of the in-pipe PIG is realized by applying the equivalent magnetic dipole model and the inverse calculation of the ELF magnetic field. In [

27,

28,

30], experimental results showed that the existing ELF tracking systems worked well for long-duration and high-magnitude ELF magnetic signals. However, due to the higher speed of the PIG during the pipeline ILI operation, the received time-domain ELF signals become a transient signal with a very short duration [

29]. Due to the thicker pipe wall and deeper burial depth of pipelines, as well as the desired low power consumption requirement of the transmitter for the long working time, the magnitude of the received ELF magnetic field is very low and immersed in strong background noise, leading to a very poor signal-to-noise ratio (SNR) [

31]. The increases of the speed, pipe wall thickness, and burial depth means the existing ELF tracking systems still face the challenges of detecting the short transient very weak ELF magnetic signals.

According to the signal detection theory, solving these challenges requires the use of high-sensitivity magnetic sensors with advanced signal detection methods, so that the probability of detection (POD) of the short transient very weak ELF signals can be high enough for a given low probability of false alarm (PFA). There are several high-sensitivity magnetic sensors that can be used to detect very weak magnetic signals, such as the search coil sensor, fluxgate magnetometer and SQUID sensor [

32,

33]. A search coil sensor can detect magnetic fields as weak as 10

−2 pT with a frequency range from 1 Hz to 1 MHz. A fluxgate magnetometer can detect magnetic fields from 10 to 10

9 pT, while the frequency response is limited by the excitation field and response time of ferromagnetic materials. A SQUID sensor is more sensitive at low frequencies (<1 Hz) and the sensitivity is as low as 10

−2 pT. However, the need for liquid-helium coolant makes the SQUID sensor heavy and inconvenient. As for the signal detection, the generalized likelihood ratio (GLR) is considered to be one of the typical signal detection methods [

34,

35]. Poor et al. [

36] develops the quickest change detection method based on the distribution of test statistics. Wavelet transform becomes an effective tool for joint time-frequency analysis and has a broader application in the diagnosis of mechanical faults and the evaluation of non-destructive testing (NDT) signals [

37,

38,

39]. Marius Birsan et al. [

40] presents an underwater detection of ELF electromagnetic field signals from ships using the cross wavelet transform and wavelet coherence method for high SNR situations. Qin et al. [

41] present transient weak fault feature extraction based on an optimized Morlet wavelet transform and kurtosis index. Meanwhile, a maximum likelihood (ML) estimator is also developed to extract the amplitude from fault-generated transient impulses in [

42].

This paper proposes a high-sensitivity real-time tracking system for high-speed PIG to detect short transient very weak ELF magnetic signals. A 2-D finite-element method (FEM) simulation was conducted to understand the relationships between the time-domain ELF signals and the physical parameters of the pipeline, including transportation speed, wall thickness, and burial depth. According to the short transient very weak characteristics of ELF signals, a data fusion model was derived to well represent the ELF signals by fusing the envelope decay rates through a least square (LS) criterion. Then, a fast-decision-tree (FDT) method is proposed to detect the ELF signals. The main differences of the FDT method are: (1) it first estimates the fused envelope decay rate to maximize the orthogonal signal power of ELF signals, and the maximized orthogonal signal power is used as the test statistic for the signal detection, which provides an excellent detection performance; and (2) the deterministic topology and fast calculation process of the FDT method avoid massive matrix inversion and multiplication, which significantly reduces the computation costs and provides excellent real-time performance. The detection performance of the proposed FDT method is discussed, with a comparison between other existing detection methods as well as theoretical bounds through Monto-Carlo simulations. In consideration of high sensitivity as well as convenience, a pair of orthogonal search coil sensors was designed to receive the very weak ELF magnetic signals. Then, an ELF tracking system including an ELF transmitter, an ELF receiver and a pair of orthogonal search coil sensors was developed and tested, and the experimental results validate the effectiveness of the proposed FDT method. The main reason for the excellent detection performance obtained is discussed through the analyses of the normalized power spectrum, estimation performance of speed and SNR. Finally, the high-sensitivity detection and real-time implementation of high-speed PIG tracking system is achieved.

3. Fast decision Tree Method

The data fusion model sets up the relationship between the orthogonal ELF signals and the fused envelope decay rate. According to the Equations from (10) to (14), maximizing the orthogonal signal power is equivalent to estimating the fused envelope decay rate, which also improves the ability of extracting the ELF signals from strong narrow-band background noise. Thus, the optimal estimation of the fused envelope decay rate is critical, and the maximized orthogonal signal power can be used as the test statistic for the signal detection, which is also the detection principle of the proposed FDT method. First, the fast calculation process of the proposed FDT method is derived as follows. Take the

X-axis ELF signal as an example, according to the Equation (8), we have:

Thus, simplify the Equation (10) as:

where an approximate equation can be derived as:

where

is defined as the energy of

X-axis observation vector. Then, we have:

Similarly, the process of the

Y-axis ELF signal is as follows:

Next, the topology of the FDT method is derived as follows. The FDT method evenly divides the fused envelope decay rate into three categories at each of the tree nodes, and then calculates the normalized signal energy of the three child nodes, which is defined as:

where

Px =

xTx and

Py =

yTy are received signal energy of

X-axis and

Y-axis signals, respectively. From Equations of (10) and (12),

and

are always smaller than

Px and

Py, respectively, and that

η ∈ (0,1). The FDT method estimates the fused envelope decay rate through the decision rule, which is defined as determining the maximum

η of the three child nodes as the next iteration direction. Here, the evolution of the FDT method and the decision rule are clearly shown in

Figure 6. Variables

L and

n in

βL,n and

ηL,n represent the tree layer and tree node.

βmax corresponds to the maximum speed of the transmitter. As shown in

Figure 6, the FDT method sets the maximum

η as the next iteration direction, which is equivalent to selecting and estimating the fused enveloped decay rate that satisfies the LS criterion through the Equations (11) and (12).

The iteration stopping criterion is defined as follows: the FDT method calculates the

η of three child nodes and then distinguishes them into three values:

ηL,max,

ηL,med and

ηL,min. The iteration is stopped when the

η meets:

The varying trend of

η at each FDT layer through the iteration procedure is listed in

Table 4. The speed range of the FDT topology is set from 1 m/s to 15 m/s, and

βmax is set to 50.

Table 4 shows in detail that the FDT method estimates

βxy by comparing and determining the maximum (which is bold) of the

η in each layer. In layer 4, the iteration of the FDT meets the stopping criterion with small errors for Δ

η and Δ

βxy.

According to the topology and fast calculation process, once the maximum speed of the transmitter is confirmed,

βmax of the FDT and

βxy of each FDT nodes are both confirmed. Meanwhile, since the parameters including

Nx,

fs,

ω0 are priori knowledge,

and

are also priori knowledge by the equation as:

Therefore, the computation cost of the proposed FDT method is derived as:

where

Cm and

Ca are computation costs of multiplication and addition, respectively. It is worth noting that the proposed FDT method only requires the computation costs of

Cm = 3

Nx + 3

Ny + 3 and

Ca = 3

Nx + 3

Ny + 3 to calculate one

η at a time instead of massive matrix inversion and multiplication mentioned in (10) and (12), which is the key for ensuring a real-time performance.

Finally, the FDT method detects the ELF signals through a hypothesis test defined as:

where

is a threshold;

H0 is referred as the null hypothesis which shows nonexistence of signals and

H1 as the alternative hypothesis which shows existence of signals. The Newman-Pearson criterion is then used to build the threshold which maximizes POD for a given PFA, and the relationship between the threshold

and PFA is defined as:

where

and

are the mean and the variance of the test statistic due to narrow-band background noise, respectively,

Q(

x) is called the right-tail probability function. The threshold is calculated by (26) for a given PFA before the signal detection.

5. Discussions

The proposed FDT method and tracking system developed is summarized as the flow chart shown in

Figure 11. The tracking system mainly developed relies on high-sensitivity search coil sensors, a high-Q narrow-band filter and high-gain amplifier, and the proposed FDT detection method to realize real-time detection of short transient very weak ELF magnetic signals. The 2-D FEM simulation results indicate that the magnitude of the very weak ELF magnetic signals is as low as 10 pT, which is lower than one millionth of the magnitude of the Earth’s magnetic field. Thus, the orthogonal search coil sensors, which have high number of turns, high-permeability iron core, and narrow long structure, are designed and developed to measure the very weak ELF magnetic signals along the

X-axis and

Y-axis. Then, the narrow-band filter and amplifier effectively eliminates out-of-band noise and amplify 23 Hz target signals. Finally, as shown in

Figure 10d–f, even if the ELF signals are immersed in strong narrow-band background noise, the test statistics calculated from the FDT method are over the thresholds under a low PFA when the transmitter passes right below the receiver.

The normalized power spectrum of the three different signals, including noiseless ELF signals, narrow-band noise and ELF signals with noise are shown in

Figure 12. Since the frequency of narrow-band noise is concentrated at 23 Hz, it is difficult to discriminate between ELF signals and noise by frequency domain, which indicates that the frequency-domain information may not be useful for the detection. Thus, the performance of the time-frequency analysis based DWT method is lower than the time-domain characteristic based FDT method.

The probability density function (PDF) of

and estimated SNR is shown in

Figure 13.

Figure 13a shows a very concentrated distribution of

when the SNR is 6 dB or 3 dB, and even if the SNR is as low as 0 dB, the PDF also shows the concentrated distribution around 40~50 with a low variance (

βxy is 46.9 from

Table 4). The

is also used to estimate the real-time speed of the transmitter according to the relationship established between the 2-D FEM simulation results of ELF signals and the data fusion model. Then,

Table 6 shows the errors between the estimated speed and the true speed are less than 1.5 m/s. Thus, these results are the main reason that the detection performance of the FDT method is higher than the amplitude-estimation based ML method and close to the upper theoretical bound. Meanwhile, it can be seen from

Table 6 that the estimated SNR can effectively distinguish high SNR situations and low SNR situations, and can reflect the decrease of SNR as the speed increases because of the short transient characteristics. The reason for the good estimation performance of the SNR can also be verified by

Figure 13b.

The real-time performance of the ELF tracking system developed is based on the data fusion model, fast calculation process, and the determined topology of the FDT. The data fusion model sets up the linear relationship between the X-axis signal model and the Y-axis signal model by fusing the envelope decay rates. Thus, the fused envelope decay rate can match well with the speed of the transmitter. Then, the fast calculation process was derived to calculate the η without massive matrix inversion and multiplication, and the calculation amount was found to be low enough for the DSP chip. The most important factor is that each tree nodes of the FDT is determined when the maximum speed of the transmitter is given. It is worth noting that the matrices including and , and the values including and used for the calculation of the η and test statistic are both prior-known information because of the fast calculation process and determined FDT topology. Therefore, the proposed FDT method is very easily programmed, stored and calculated by the embedded DSP chip in practical applications. The experiments conducted by the receiver using a TMS320F28335 DSP chip finally validate the real-time performance of the FDT method.