Life Cycle Assessment Application to the Wine Sector: A Critical Review

Abstract

:1. Introduction

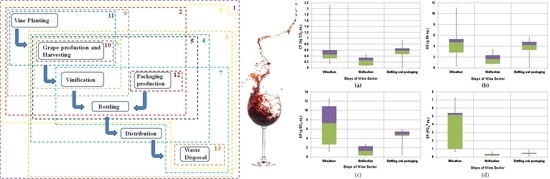

2. LCA Application to the Wine Sector: A Practical Point of View

2.1. Viticulture

2.2. Vinification

2.3. Bottling and Packaging

3. LCA Application to Wine Sector: Methodological Point of View

3.1. Goal and Scope Definition

3.2. Inventory Analysis

3.3. Life Cycle Impact Assessment

3.4. Interpretation

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AD | Abiotic Depletion |

| AP | Acidification Potential |

| B | Bottling |

| CF | Carbon Footprint |

| CO2 | Carbon dioxide |

| D | Distribution |

| EP | Eutrophication Potential |

| FU | Functional Unit |

| GP | Grape Production |

| GWP | Global Warming Potential |

| hl | hectoliters |

| IPCC | Intergovernmental Panel on Climate Change |

| ISO | International Standards Organization |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| OIV | International Organization of Vine and Wine |

| PO43− | Phosphate Ion |

| PP | Packaging Production |

| Sb | Antimony |

| SO2 | Sulfur dioxide |

| V | Vinification |

| VP | Vine planting |

| WD | Waste Disposal |

| WF | Water footprint |

| WFN | Water Footprint Network |

References

- Navarro, A.; Puig, R.; Fullana-i-Palmer, P. Product vs. corporate carbon footprint: Some methodological issues. A case study and review on the wine sector. Sci. Total Environ. 2017, 581–582, 722–733. [Google Scholar] [CrossRef]

- Devesa-Rey, R.; Vecino, X.; Varela-Allende, J.; Barral, M.T.; Cruz, J.M.; Moldes, A.B. Valorization of winery waste vs. the costs of not recycling. Waste Manag. 2011, 3, 2327–2335. [Google Scholar] [CrossRef]

- The International Organisation of Vine and Wine. 2016. Available online: http://www.oiv.int (accessed on 1 February 2018).

- Cunha, M.; Ribeiro, H.; Abreu, I. Pollen-based predictive modelling of wine production: Application to an arid regional. Eur. J. Agron. 2016, 73, 42–54. [Google Scholar] [CrossRef]

- Christ, K.L.; Buritt, R.L. Critical environmental concerns in wine production: An integrative review. J. Clean. Prod. 2013, 53, 232–242. [Google Scholar] [CrossRef]

- De Feo, G.; Ferrara, C. Investigation of the environmental impacts of municipal wastewater treatment plants through a Life Cycle Assessment software tool. Environ. Technol. 2017, 38, 1943–1948. [Google Scholar] [CrossRef]

- Curran, M.A. Life cycle assessment. Encycl. Ecol. 2008, 3, 2168–2174. [Google Scholar]

- Buccino, C.; Ferrara, C.; Malvano, C.; De Feo, G. LCA of an ice cream cup of Polyethylene Coated Paper: How does the choice of the end-of-life affect the results? Environ. Technol. 2017. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO 14040). Environmental Management—Life Cycle Assessment—Principles and Framework: International Standard 14040; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization (ISO 14044). Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Corominas, L.; Foley, J.; Guest, J.S.; Hospido, A.; Larsen, H.F.; Morera, S.; Shaw, A. Life cycle assessment applied to wastewater treatment: State of the art. Water Res. 2013, 47, 5480–5492. [Google Scholar]

- Amienyo, D.; Camilleri, C.; Azapagic, A. Environmental impacts of consumption of Australian red wine in the UK. J. Clean. Prod. 2014, 72, 110–119. [Google Scholar] [CrossRef]

- Ardente, F.; Beccali, G.; Cellura, M.; Marvuqlia, A. POEMS: A Case Study of an Italian Wine-Producing Firm. Environ. Manag. 2006, 38, 350–364. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; Raggi, A.; Petti, L. Considerations When Applying Simplified LCA Approaches in the Wine Sector. Sustainability 2014, 6, 5018–5028. [Google Scholar] [CrossRef]

- Benedetto, G. The environmental impact of a Sardinian wine by partial Life Cycle Assessment. Wine Econ. Policy 2013, 2, 33–41. [Google Scholar] [CrossRef]

- Bonamente, E.; Scrucca, F.; Asdrubali, F.; Cotana, F.; Presciutti, A. The Water Footprint of the Wine Industry: Implementation of an Assessment Methodology and Application to a Case Study. Sustainability 2015, 7, 12190–12208. [Google Scholar] [CrossRef]

- Bonamente, E.; Scrucca, F.; Rinaldi, S.; Merico, M.C.; Ardrubali, F.; Lamastra, L. Environmental impact of an Italian wine bottle: Carbon and water footprint assessment. Sci. Total Environ. 2016, 560–561, 274–283. [Google Scholar] [CrossRef]

- Bosco, S.; Di Bene, C.; Galli, M. Greenhouse gas emissions in the agricultural phase of wine production in the Maremma rural district in Tuscany, Italy. Ital. J. Agron. 2011, 6–15, 93–100. [Google Scholar]

- Bosco, S.; Di Bene, C.; Galli, M.; Remorini, D.; Massai, R.; Bonari, E. Soil organic matter accounting in the carbon footprint analysis of the wine chain. Int. J. Life Cycle Assess. 2013, 18, 973–989. [Google Scholar] [CrossRef]

- Chiusano, L.; Cerutti, A.K.; Cravero, M.C.; Bruun, S.; Gerbi, V. An Industrial Ecology approach to solve wine surpluses problem: The case study of an Italian winery. J. Clean. Prod. 2015, 91, 56–63. [Google Scholar] [CrossRef]

- Cichelli, A.; Pattara, C.; Petrella, A. Sustainability in mountain viticulture. The case of the Valle Peligna. Agric. Agric. Sci. Procedia 2016, 8, 65–72. [Google Scholar] [CrossRef]

- Clearly, J. Life cycle assessments of wine and spirit packaging at the product and the municipal scale: A Toronto, Canada case study. J. Clean. Prod. 2013, 44, 143–151. [Google Scholar] [CrossRef]

- Falcone, G.; De Luca, A.I.; Stillitano, T.; Strano, A.; Romeo, G.; Gulisano, G. Assessment of Environmental and Economic Impacts of Vine-Growing Combining Life Cycle Assessment, Life Cycle Costing and Multicriterial Analysis. Sustainability 2016, 8, 1–34. [Google Scholar] [CrossRef]

- Ferrari, A.M.; Pini, M.; Sassi, D.; Zerazion, E.; Neri, P. Effects of grape quality on the environmental profile of an Italian vineyard for Lambrusco red wine production. J. Clean. Prod. 2018, 172, 3760–3769. [Google Scholar] [CrossRef]

- Fusi, A.; Guidetti, R.; Benedetto, G. Delving into the environmental aspect of a Sardinian white wine: From partial to total life cycle assessment. Sci. Total Environ. 2014, 472, 989–1000. [Google Scholar] [CrossRef]

- Gazulla, C.; Raugei, M.; Fullana-i-Palmer, P. Taking a life cycle look at crianza wine production in Spain: Where are the bottlenecks? Int. J. Life Cycle Assess. 2010, 15, 330–337. [Google Scholar] [CrossRef]

- Herath, I.; Green, S.; Horne, D.; Singh, R.; Mclaren, S.; Clothier, B. Water footprinting of agricultural products: Evaluation of different protocols using a case study of New Zealand wine. J. Clean. Prod. 2013, 44, 159–167. [Google Scholar] [CrossRef]

- Iannone, R.; Miranda, S.; Riemma, S.; De Marco, I. Improving environmental performances in wine production by a life cycle assessment analysis. J. Clean. Prod. 2015, 111, 172–180. [Google Scholar] [CrossRef]

- Kounina, A.; Tatti, E.; Humbert, S.; Pfister, R.; Pike, A.; Menard, J.-F.; Loerincik, Y.; Jolliet, O. The Importance of Considering Product Loss Rates in Life Cycle Assessment: The Example of Closure Systems for Bottled Wine. Sustainability 2012, 4, 2673–2706. [Google Scholar] [CrossRef]

- Lamastra, L.; Suciu, N.A.; Novelli, E.; Trevisan, M. A new approach to assessing the water footprint of wine: An Italian case study. Sci. Total Environ. 2014, 490, 748–756. [Google Scholar] [CrossRef]

- Litskas, V.D.; Irakleous, T.; Tzortzakis, N.; Starvrinides, M.C. Determining the carbon footprint of indigenous and introduced grape varieties through Life Cycle Assessment using the island of Cyprus as a case study. J. Clean. Prod. 2017, 156, 418–425. [Google Scholar] [CrossRef]

- Marras, S.; Masia, S.; Duce, P.; Spano, D.; Sirca, C. Carbon footprint assessment on a mature vineyard. Agric. For. Meteorol. 2015, 214–215, 350–356. [Google Scholar] [CrossRef]

- Meneses, M.; Torres, C.M.; Castells, F. Sensitivity analysis in a life cycle assessment of an aged red wine production from Catalonia, Spain. Sci. Total Environ. 2016, 562, 571–579. [Google Scholar] [CrossRef]

- Neto, B.; Dias, A.C.; Machado, M. Life cycle assessment of the supply chain of a Portuguese wine: From viticulture to distribution. Int. J. Life Cycle Assess. 2013, 18, 590–602. [Google Scholar] [CrossRef]

- Pattara, C.; Raggi, A.; Cichelli, A. Life Cycle Assessment and Carbon Footprint in the Wine Supply-Chain. Environ. Manag. 2012, 49, 1247–1258. [Google Scholar] [CrossRef]

- Pizzigallo, A.C.I.; Granai, C.; Borsa, S. The joint use of LCA and emergy evaluation for the analysis of two Italian wine farms. J. Environ. Manag. 2008, 86, 396–406. [Google Scholar] [CrossRef]

- Point, E.; Tyedmers, P.; Naugler, C. Life cycle environmental impacts of wine production and consumption in Nova Scotia, Canada. J. Clean. Prod. 2012, 27, 11–20. [Google Scholar] [CrossRef]

- Quinterio, P.; Dias, A.C.; Pina, L.; Neto, B.; Ridoutt, B.G.; Arroja, L. Addressing the freshwater use of a Portuguese wine (‘vinho verde’) using different LCA methods. J. Clean. Prod. 2014, 68, 46–55. [Google Scholar] [CrossRef]

- Rinaldi, S.; Bonamente, E.; Scrucca, F.; Merico, M.C.; Asdrubali, F.; Cotana, F. Water and Carbon Footprint of Wine: Methodology Review and Application to a Case Study. Sustainability 2016, 8, 621. [Google Scholar] [CrossRef]

- Ruggieri, L.; Cadena, E.; Martìnez-Blanco, J.; Gasol, C.M.; Rieradevall, J.; Gabarrell, X.; Gea, T.; Sort, X.; Sanchez, A. Recovery of organic wastes in the Spanish wine industry. Technical, economic and environmental analyses of the composting process. J. Clean. Prod. 2009, 17, 830–838. [Google Scholar] [CrossRef]

- Steenwerth, K.L.; Strong, E.B.; Greenhut, R.F.; Williams, L.; Kendall, A. Life cycle greenhouse gas, energy, and water assessment of wine grape production in California. Int. J. Life Cycle Assess. 2015, 20, 1243–1253. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.M.; Villanueva-Rey, P.; Moreira, M.T. Environmental analysis of Ribeiro wine from a timeline perspective: Harvest year matters when reporting environmental impacts. J. Environ. Manag. 2012, 98, 73–83. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Iribarren, D.; Teresa Moreira, M.; Feijoo, G. Joint life cycle assessment and data envelopment analysis of grape production for vinification in the Rías Baixas appellation (NW Spain). J. Clean. Prod. 2012, 27, 92–102. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Rugani, B.; Benetto, E. Tapping carbon footprint variations in the European wine sector. J. Clean. Prod. 2013, 43, 146–155. [Google Scholar] [CrossRef]

- Villanueva-Rey, P.; Vázquez-Rowe, I.; Moreira, M.T.; Feijoo, G. Comparative life cycle assessment in the wine sector: Biodynamic vs. conventional viticulture activities in NW Spain. J. Clean. Prod. 2014, 65, 330–341. [Google Scholar] [CrossRef]

- Longbottom, M.L.; Petrie, P.R. Role of vineyard practices in generating and mitigating greenhouse gas emissions. Aust. J. Grape Wine Res. 2015, 21, 522–536. [Google Scholar] [CrossRef]

- Tuomisto, H.L.; Hodge, I.D.; Riordan, P.; Macdonald, D.W. Does organic farming reduce environmental impacts?—A meta-analysis of European research. J. Environ. Manag. 2012, 112, 309–320. [Google Scholar] [CrossRef]

- Oliveira, M.; Duarte, E. Integrated approach to winery waste: Waste generation and data consolidation. Front. Environ. Sci. Eng. 2016, 10, 168–176. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Ladas, D.; Mavromatis, A. Potential uses and applications of treated wine waste: A review. Int. J. Food Sci. Technol. 2006, 41, 475–487. [Google Scholar] [CrossRef]

- Benetto, E.; Kneip, G.; Jury, C.; Vázquez-Rowe, I.; Huck, V.; Frank, M. Life cycle assessment of heat production from grape marc pellets. J. Clean. Prod. 2015, 87, 149–158. [Google Scholar] [CrossRef]

- Ghidossi, R.; Poupot, C.; Thibon, C.; Pons, A.; Darriet, P.; Riquier, L.; De Revel, G.; Peuchot Mietton, M. The influence of packaging on wine conservation. Food Control 2012, 23, 302–311. [Google Scholar] [CrossRef]

- Guinèe, J. Handbook on life cycle assessment—Operational guide to the ISO standards. Int. J. Life Cycle Assess. 2001, 6, 225. [Google Scholar]

- CML-IA Characterisation Factors. Universiteit Leiden. 2018. Available online: http://cml.leiden.edu/software/data-cmlia.html (accessed on 24 January 2018).

- PRé. SimaPro Database Manual Methods Library. 2015. Available online: http://www.pre-sustainability.com/download/DatabaseManualMethods.pdf (accessed on 14 August 2015).

| References | Wine Type | Location | Objective c | F.U. | BOUNDARIES d |

|---|---|---|---|---|---|

| Amienyo et al., 2014 [12] | Red | Australia | LCA of a wine type | 0.75 L of wine | 3 (GP, V, PP, B, D, WD) |

| Ardente et al., 2006 [13] | Red | Italy | LCA of a wine type | 0.75 L of wine | 4 (GP, V, PP, B, D) |

| Arzoumanidis et al., 2014 [14] | Red | Italy | LCA of a wine type | 0.75 L of wine | 4 (GP, V, PP, B, D) |

| Benedetto, 2013 [15] | White | Italy | LCA of a wine type | 0.75 L of wine | 2 (VP, GP, V, PP, B) |

| Bonamente et al., 2015 [16] | Red | Italy | LCA of a wine type (WF) | 0.75 L of wine | 3 (GP, V, PP, B, D, WD) |

| Bonamente et al., 2016 [17] | Red | Italy | LCA of a wine type (CF; WF) | 0.75 L of wine | 3 (GP, V, PP, B, D, WD) |

| Bosco et al., 2011 [18] | White, red | Italy | LCA of different wine types (CF) | 0.75 L of wine | 1 (VP, GP, V, PP, B, D, WD) |

| Bosco et al., 2013 [19] | Red | Italy | LCA of a wine type (CF) | 0.75 L of wine | 1 (VP, GP, V, PP, B, D, WD) |

| Chiusano et al., 2015 [20] | Red | Italy | LCA comparison of grapes use only for wine production and grapes use also for fruit juice production | 1 L of wine | 9 (VP, GP, V) |

| Cichelli et al., 2016 [21] | Red | Italy | LCA of a wine grape (CF) | 1 t of grape | 6 (GP, V) |

| Cleary 2013 [22] | n.s. a | Canada | LCA of different types of wine packaging | 1 L of wine | 12 (PP) |

| Falcone et al., 2016 [23] | n.a. b | Italy | LCA and LCC of different wine-growing | 1 kg of grape | 11 (VP, GP) |

| Ferrari et al., 2017 [24] | n.a. b | Italy | LCA of a wine grape | 566 t of grape | 11 (VP, GP) |

| Fusi et al., 2014 [25] | White | Italy | LCA of a wine type | 0.75 L of wine | 1 (VP, GP, V, PP, B, D, WD) |

| Gazulla et al., 2010 [26] | Red | Spain | LCA of a wine type | 0.75 L of wine | 3 (GP, V, PP, B, D, WD) |

| Herath et al., 2013 [27] | n.s. a | New Zealand | LCA of different wine types (WF) | 0.75 L of wine | 6 (GP, V) |

| Iannone at al., 2015 [28] | White, Red | Italy | LCA of different wine types | 0.75 L of wine | 7 (V, PP, B, D, WD) |

| Kounina et al., 2012 [29] | n.s. a | n.sa | LCA of wine production in function of product loss rates | 0.75 L of “drinkable” wine | 1 (VP, GP, V, PP, B, D, WD) |

| Lamastra et al., 2014 [30] | White, red | Italy | LCA of different wine types (WF) | 1 L of wine | 5 (GP, V, PP, B) |

| Litskas et al., 2017 [31] | n.a. b | Cyprus | LCA of different wine grapes (CF) | 1 kg of grape | 10 (GP) |

| Marras et al., 2015 [32] | n.a. b | Italy | LCA of a wine grape | 1 kg of grape | 10 (GP) |

| Meneses et al., 2016 [33] | Red | Spain | LCA of a wine type | 0.75 L of wine | 8 (VP, GP, V, PP, B, WD) |

| Neto et al., 2013 [34] | White | Portugal | LCA of a wine type | 0.75 L of wine | 4 (GP, V, PP, B, D) |

| Pattara et al., 2012 [35] | Red | Italy | LCA of a wine type (comparison of LCA results and new CF methodology results) | 0.75 L of wine | 4 (GP, V, PP, B, D) |

| Pizzigallo et al., 2008 [36] | Red | Italy | LCA and emergy of different wine types | 1 t of wine | 8 (VP, GP, V, PP, B, WD) |

| Point et al., 2012 [37] | n.s. a | Canada | LCA of a wine type | 0.75 L of wine | 3 (GP, V, PP, B, D, WD) |

| Quinteiro et al., 2014 [38] | White | Portugal | LCA of a wine type (freshwater use evaluation) | 0.75 L of wine | 9 (VP, GP, V) |

| Rinaldi et al., 2016 [39] | White, red | Italy | LCA of different wine types (CF; WF) | 0.75 L of wine | 3 (GP, V, PP, B, D, WD) |

| Ruggieri et al., 2009 [40] | n.a. b | Spain | LCA of different alternatives to manage wine organic waste | 1 kg of nitrogen provided to vineyard lands | 13 (WD) |

| Steenwerth et al., 2015 [41] | n.a. b | USA | LCA of different wine-growing | 1 t of grape | 10 (GP) |

| Vázquez-Rowe et al., 2012 [42] | White | Spain | LCA of a wine type | 0.75 L of wine | 5 (GP, V, PP, B) |

| Vázquez-Rowe et al., 2012b [43] | n.a. b | Italy | LCA of a wine grape | 1.1 kg of grape | 10 (GP) |

| Vázquez-Rowe et al., 2013 [44] | White, red | Italy, Spain, Luxembourg | LCA of different wine types (CF) | 0.75 L of wine | 2 (VP, GP, V, PP, B) |

| Villanueva-Rey et al., 2014 [45] | n.a. b | Spain | LCA of a wine grape type | 1 kg of grape | 10 (GP) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrara, C.; De Feo, G. Life Cycle Assessment Application to the Wine Sector: A Critical Review. Sustainability 2018, 10, 395. https://0-doi-org.brum.beds.ac.uk/10.3390/su10020395

Ferrara C, De Feo G. Life Cycle Assessment Application to the Wine Sector: A Critical Review. Sustainability. 2018; 10(2):395. https://0-doi-org.brum.beds.ac.uk/10.3390/su10020395

Chicago/Turabian StyleFerrara, Carmen, and Giovanni De Feo. 2018. "Life Cycle Assessment Application to the Wine Sector: A Critical Review" Sustainability 10, no. 2: 395. https://0-doi-org.brum.beds.ac.uk/10.3390/su10020395