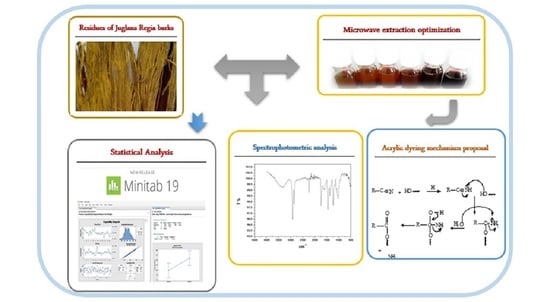

Valorization of Juglans regia. L Bark Residues as a Natural Colorant Based on Response Surface Methodology: A Challenging Approach to a Sustainable Dyeing Process for Acrylic Fabrics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Textile Material

2.2. Preparation of Plant Material

2.3. Microwave Extraction Process

2.4. Microwave Dyeing Process

2.5. Determination of the Content of Colored Compounds

2.5.1. Determination of the Content of Flavonoids

2.5.2. Determination of the Content of Condensed Tannins

2.5.3. Determination of the Content of Hydrolyzable Tannins

2.6. Dyeing Quality Evaluation

2.7. Dyeing Fastness Properties

2.8. Spectral Infrared Characterization (FTIR)

2.9. Statistical Analysis

3. Results and Discussion

3.1. Development of a Microwave Extraction Process

3.1.1. Effect of the Extraction Microwave Power

3.1.2. Effect of the Extraction pH

3.1.3. Effect of the Extraction Duration

3.1.4. Effect of the Dry Mass of Juglans regia Bark Residues

3.2. Optimization of the Microwave Extraction Process

3.2.1. Response Surface Design

3.2.2. Establishment of the Mathematical Model

3.2.3. Main Effects Diagram of Microwave Extraction Conditions

- -

- The power positively affected the dyeing quality of the acrylic fabrics from 150 to 500 W. This effect decreased from 500 to 850 W.

- -

- From 0.5 to 2 min, the duration of the extraction slightly affected the dyeing quality obtained.

- -

- The pH intensely affected the dyeing quality of the acrylic fabrics from 3 to 7. This effect became quite significant from a neutral pH to a basic pH.

3.2.4. Analysis of the Effects of the Main Interactions

3.2.5. Contour Plots

3.2.6. Response Optimization

3.2.7. Validation of Optimal Extraction Conditions

3.3. Fastness Properties Estimation

3.4. Spectral Infrared Characterization (FTIR) of Dyed and Undyed Acrylic Fabrics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adeel, S.; Hussaan, M.; Rehman, F.-U.; Habib, N.; Salman, M.; Naz, S.; Amin, N.; Akhtar, N. Microwave-assisted sustainable dyeing of acrylic fabric using cochineal-based carminic acid as natural colorant. J. Nat. Fibers 2019, 16, 1026–1034. [Google Scholar] [CrossRef]

- Ben Ticha, M.; Slama, N.; Dhouibi, N.; Boudokhane, C.; Dhaouadi, H. Bark Residues Recovery of Juglans Regia. L For the Dyeing of Wool Fabrics: Development of Microwave-assisted Extraction and Dyeing Processes. J. Nat. Fibers 2021. [Google Scholar] [CrossRef]

- Ul Hasan, M.; Adeel, S.; Batool, F.; Ahmad, T.; Cheng-Tang, R.; Amin, N.; Khan, S.R. Sustainable Application of Cassia Obovata Based Chrysophanic Acid as Potential Source of Yellow Natural Colourant for Textile Dyeing. Environ. Sci. Pollut. Res. 2022, 29, 10740–10753. [Google Scholar] [CrossRef] [PubMed]

- Adeel, S.; Kiran, S.; Shahid, M.; Habib, S.R.; Habib, N.; Hussaan, M. Ecofriendly application of coconut coir (Cocos nucifera) extract for silk dyeing. Environ. Sci. Pollut. Res. 2022, 29, 564–572. [Google Scholar] [CrossRef] [PubMed]

- Adeel, S.; Habib, N.; Batool, F.; Rahman, A.; Ahmad, T.; Amin, N. Eco-friendly Approach towards Isolation of Colourant from Esfand for Bio-mordanted Silk Dyeing. Environ. Sci. Pollut. Res. 2022, 29, 13523–13533. [Google Scholar] [CrossRef]

- Dhouibi, N.; Ben Ticha, M.; Raddaoui, H.; Boudokhane, C.; Dhaouadi, H. Valorization and Reuse of Centaurea Kroumeriensis Hydrodistillation Effluent: A Sustainable Phytodyeing Process for Wool Fabrics. Fibers Polym. 2021, 22, 2238–2250. [Google Scholar] [CrossRef]

- Adeel, S.; Ur-Rehman, F.; Khosa, M.K.; Rajab, S.; Ziaa, K.M.; Zuber, M.; Batool, F. Eco-Friendly Isolation of Colorant From Arjun Bark for Dyeing of Bio-Mordanted Cotton Fabric. J. Nat. Fibers 2021. [Google Scholar] [CrossRef]

- Le Floc’h, E. Contribution à une étude Ethnobotanique de la Flore Tunisienne; Publications Scientifiques Tunisiennes: Tunis, Tunisia, 1983. [Google Scholar]

- Baaka, N.; Ben Ticha, M.; Guesmi, A. Valorization of Anthocyanin Pigments Extracted from Phytolacca Americanna L. Fruits as Bio-Colorant to Dye Acrylic Yarns. Fibers Polym. 2019, 20, 2522–2528. [Google Scholar]

- Guesmi, A.; Ben Hamadi, N. Study on optimizing dyeing of cotton using date pits extract as a combined source of coloring matter and bio-mordant. Nat. Prod. Res. 2018, 2, 810–814. [Google Scholar] [CrossRef]

- Akram, W.; Adeel, S.; Amin, N.; Habib, N.; Inayat, A.; Mirnezhad, S. Impact of MW rays on extraction and application of Ficus religosia bark based natural colorant for cotton dyeing. J. Eng. Fibers Fabr. 2022, 17, 1–17. [Google Scholar]

- Marcus, Y. Solvatochromic probes in supercritical fluids. J. Phys. Org. Chem. 2005, 18, 373–384. [Google Scholar] [CrossRef]

- Adeel, S.; Ur-Rehman, F.; Zia, K.M.; Azeem, M.; Kiran, S.; Zuber, M.; Irfan, M.; Qayyum, M.B. Microwave supported green dyeing of mordanted wool fabric with Arjun bark extracts. J. Nat. Fibers 2021, 18, 136–150. [Google Scholar] [CrossRef]

- Ben Ticha, M.; Meksi, N.; Attia, H.E.; Haddar, W.; Guesmi, A.; Ben Jannet, H.; Mhenni, M.F. Ultrasonic extraction of Parthenocissus quinquefolia colorants: Extract identification by HPLC-MS analysis and cleaner application on the phytodyeing of natural fibres. Dyes Pigm. 2017, 141, 103–111. [Google Scholar] [CrossRef]

- Ben Ticha, M.; Meksi, N. Exploitation of Ultrasonic Waves to Develop and Model a Sustainable Process for Washing Denim Fabrics. J. Nat. Fibers 2021. [Google Scholar] [CrossRef]

- Veggi, P.C.; Martinez, J.; Meireles, M.A.A. Fundamentals of Microwave Extraction. In Microwave-Assisted Extraction for Bioactive Compounds; Springer: Boston, MA, USA, 2012. [Google Scholar] [CrossRef]

- Swain, T.; Hillis, W.E. The phenolic constituents of Prunus domestica. I.—The quantitative analysis of phenolic constituents. J. Sci. Food Agric. 1959, 10, 63–68. [Google Scholar] [CrossRef]

- Butler, L.G.; Price, M.L.; Brotherton, J.E. Vanillin assay for proanthocyanidins (condensed tannins): Modification of the solvent for estimation of the degree of polymerization. J. Agric. Food Chem. 1982, 30, 1087–1089. [Google Scholar] [CrossRef]

- Mole, S.; Waterman, P.G. A critical analysis of techniques for measuring tannins in ecological studies. Oecologia 1987, 72, 137–147. [Google Scholar] [CrossRef]

- Ben Ticha, M.; Meksi, N.; Drira, N.; Kechida, M.; Mhenni, M.F. A promising route to dye cotton by indigo with an ecological exhaustion process: A dyeing process optimization based on a response surface methodology. Ind. Crops Prod. 2013, 46, 350–358. [Google Scholar] [CrossRef]

- Ben Ticha, M.; Meksi, N.; Kechida, M.; Mhenni, M.F. Green process for indigo dyeing: Effect and modeling of physico-chemical parameters using statistical analysis. Int. J. Environ. Res. 2013, 7, 697–708. [Google Scholar]

- Abdelileh, M.; Ticha, M.B.; Moussa, I.; Meksi, N. Pretreatment optimization process of cotton to overcome the limits of its dyeability with indigo carmine. Chem. Ind. Chem. Eng. Q. 2019, 25, 277–288. [Google Scholar] [CrossRef] [Green Version]

- Çelik, M.; Qudrat, M.L.; Akyüz, E.; Açik, L. Synthesis and characterization of acrylic fibers-g-polyacrylamide. Fibers Polym. 2012, 13, 145–152. [Google Scholar] [CrossRef]

- Danciu, C.; Pavel, L.Z.; Babuta, R.; Ersilia, A.; Suciu, O.; Pop, G.; Soica1, C.; Dehelean, C.; Radulov, I. Total phenolic content, FTIR analysis, and antiproliferative evaluation of lupin seeds harvest from western Romania. Ann. Agric. Environ. Med. 2017, 24, 726–731. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, R.N.; Mancini1, M.C.; de Oliveira, F.C.S.; Passos, T.M.; Quilty, B.; Thiré, R.M.D.S.; McGuinness, G.B. FTIR analysis and quantification of phenols and flavonoids of five commercially available plants extracts used in wound healing. Matéria 2016, 21, 767–779. [Google Scholar] [CrossRef] [Green Version]

| N° | Factors | Response | ||

|---|---|---|---|---|

| pH | P(W) | t (min) | K/S | |

| 1 | 3 | 500 | 4 | 15.8 |

| 2 | 7 | 150 | 0.5 | 10.7 |

| 3 | 7 | 500 | 2 | 12.9 |

| 4 | 9 | 500 | 0.5 | 12.7 |

| 5 | 7 | 850 | 4 | 13.7 |

| 6 | 3 | 500 | 0.5 | 13.0 |

| 7 | 9 | 850 | 2 | 12.7 |

| 8 | 7 | 150 | 4 | 10.9 |

| 9 | 7 | 500 | 2 | 12.9 |

| 10 | 9 | 500 | 4 | 12.8 |

| 11 | 3 | 850 | 2 | 15.0 |

| 12 | 7 | 500 | 2 | 12.9 |

| 13 | 9 | 150 | 2 | 12.8 |

| 14 | 7 | 850 | 0.5 | 13.2 |

| 15 | 3 | 150 | 2 | 11.2 |

| Fiber | Sample | Rubbing Fastness | Light Fastness | Washing Fastness | |

|---|---|---|---|---|---|

| Wet | Dry | ||||

| Acrylic |  | 3 | 3 | 3 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben Ticha, M.; Slama, N.; Dhouibi, N.; Boudokhane, C.; Dhaouadi, H. Valorization of Juglans regia. L Bark Residues as a Natural Colorant Based on Response Surface Methodology: A Challenging Approach to a Sustainable Dyeing Process for Acrylic Fabrics. Sustainability 2022, 14, 4134. https://0-doi-org.brum.beds.ac.uk/10.3390/su14074134

Ben Ticha M, Slama N, Dhouibi N, Boudokhane C, Dhaouadi H. Valorization of Juglans regia. L Bark Residues as a Natural Colorant Based on Response Surface Methodology: A Challenging Approach to a Sustainable Dyeing Process for Acrylic Fabrics. Sustainability. 2022; 14(7):4134. https://0-doi-org.brum.beds.ac.uk/10.3390/su14074134

Chicago/Turabian StyleBen Ticha, Manel, Nourhene Slama, Nedra Dhouibi, Chedly Boudokhane, and Hatem Dhaouadi. 2022. "Valorization of Juglans regia. L Bark Residues as a Natural Colorant Based on Response Surface Methodology: A Challenging Approach to a Sustainable Dyeing Process for Acrylic Fabrics" Sustainability 14, no. 7: 4134. https://0-doi-org.brum.beds.ac.uk/10.3390/su14074134