Techno-Economic Assessment of Mobilized Thermal Energy Storage System Using Geothermal Source in Polish Conditions

Abstract

:1. Introduction

2. Methods and Assumptions

2.1. Total Heat Demand

- Heat demand for households using coal-based heat sources. In the first place, these sources should be replaced by renewable energy, due to carbon dioxide and pollution emission to the air [48]. For coal-based heat sources, the average heat demand per m2 of usable floor space is 222 kWh/(m2·year) for insulated buildings and 253 kWh/(m2·year) for non-insulated buildings [30]. The average usable floor space of households (in rural areas) is 108.3 m2 and the total energy demand is 216 kWh/(m2·year) [48]. At the same time, the area up to several km from Bańska Niżna is characterized by a large diversity of buildings (from small traditional one- and two-room houses to multi-story residential houses) as well as their energy efficiency. DHW demand was determined on the basis of average consumption of DHW per person 35 dm3/(person·day) [31] and the number of households in Lesser Poland Voivodeship [49], as well as on the basis of efficiency of heat production and transport for coal sources. The results are shown in Figure 4.

- The ratio of heat loss to THD (lower limit of THD range)—discussed in detail later in the article.

- Possibilities for the number of M.TES exchanges during the day—also discussed in detail later in the article.

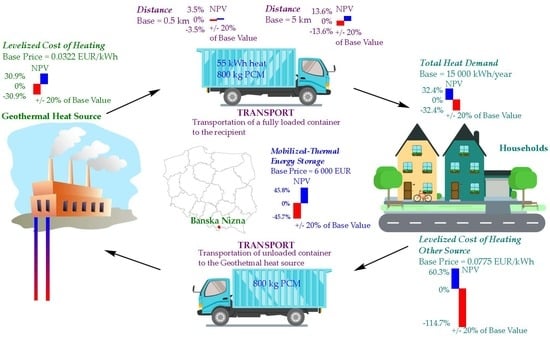

2.2. Economical Profitability and NPV

- Euro exchange rate 1 EUR = 4.5 PLN,

- The total costs of the driver’s work (and also the person servicing the M-TES exchange in the heat source location and at the buildings) for the employer, TWC = 5 Euro/hour,

- The total cost of transportation by the car with a trailer with a total permissible weight up to 3.5 Mg, TTC: 0.2 EUR/km. This cost includes the purchase of the fuel, service costs, inspections, and depreciation of the car,

- Unit transport time, UTT: 2 min/km,

- Container exchanging time at the heat source and at the recipient, together with time for changing magazines, TfCMs: 12 min,

- Geothermal heat price without distribution, GHP: 0.0322 EUR/kWh [42],

- lifetime of M-TES, n = 20 years

- discount rate (r) from 0% to 6% [55]

- M-TES.P = 6000 EUR

- initial investment cost IO = 2·M-TES.P

2.3. Carbon Dioxide Emission

- Transportation of the M-TES storage by car, on the trailer, EM.CO2.KM = 0.240 kg CO2/km [56]

- emission related to the current heat source (EM.CO2.OS) [57]:

- associated with auxiliary energy for the service of pumps and devices in a geothermal heating plant (1% of THD + HL(M-TES)) in a geothermal source (EM.CO2.G): 0.0078 kg CO2/kWh (it is about kWh of energy produced from a geothermal source) [60].

3. Results

3.1. Analysis of M-TES System Operation in Relation to the Total Heat Demand Size for the Building

3.2. Economical Profiltability

- 5000 kWh/year; at the price LCOH.OS = 0.21 EUR/kWh and distance = 0.5 km;

- 10,000 kWh/year; at the price LCOH.OS = 0.135 EUR/kWh and distance = 0.5 km; at the price 0.235 EUR/kWh and distance = 6 km;

- 15,000 kWh/year; at the price LCOH.OS = 0.11 EUR/kWh and distance = 0.5 km; at the price 0.205 EUR/kWh and distance = 6 km;

- 20,000 kWh/year; at the price LCOH.OS = 0.095 EUR/kWh and distance = 0.5 km; at the price 0.19 EUR/kWh and distance = 6 km;

- 25,000 kWh/year; at the price LCOH.OS = 0.085 EUR/kWh and distance = 0.5 km; at the price 0.18 EUR/kWh and distance = 6 km.

3.3. NPV Analysis

3.4. Carbon Dioxide Emission Reduction

- A total of 9 Mg CO2 emission reduction when replacing a coal-fueled heat source,

- A total of 4.8 Mg CO2 emission reduction when replacing a natural gas heat source. For a distance of 10 km and THD = 5000 kWh/year, and when replacing a source powered by natural gas, the reduction will be only 0.2 Mg CO2/year.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CGH | Cost of Geothermal Heat, EUR/year |

| chl | coefficient for heat losses, W/(K·dm3/2) |

| CF | Cash Flow, EUR |

| CH | Central heating |

| DHW | Domestic hot water |

| dist. | distance between building and Geothermal Base Station, km |

| DU | direct use |

| EM.CO2.G | Emission connected with Geothermal source, kg CO2/kWh |

| EM.CO2.KM | Emission from car per km, kg CO2/km |

| EM.CO2.OS | Emission from other than Geothermal source, kg CO2/kWh |

| EP | Economical profitability, EUR/year |

| EUR | Euro |

| FC.OS | total cost of fuel for other than Geothermal heat source, EUR/year |

| GHG | greenhouse gases |

| GHP | unit geothermal heat price, EUR/kWh |

| HL | Heat loss, kWh |

| IO | initial investment value, EUR |

| LCOH | Levelized Cost of Heating, EUR/kWh |

| LCOH.G | Levelized Cost of Heating (for n years) for Geothermal source |

| LCOH.OS | Levelized Cost of Heating (for n years) for other than Geothermal source |

| M-TES | Mobile Thermal Energy Storage |

| M-TES.EX | Mobile Thermal Energy Storage exchanged |

| M-TES.P | M-TES price, EUR |

| n | lifetime of M-TES, year |

| ni | number of M-TES for each house |

| nl | correction coefficient of lifetime for other source |

| NPV | Net present value, EUR |

| OS.P | other source price, EUR |

| Q | heat, kWh |

| r | discount rate, % |

| RE.CO2 | reduction of CO2 emissions, kgCO2/year |

| T | Temperature, °C |

| t | subsequent year |

| Ta | Outside temperature, °C |

| TC | Transport and work cost, EUR/kWh |

| TfCMs | Time for M-TES exchanging, min |

| th | thermal |

| THD | Total heat demand for the building, kWh/year |

| TPEH_GEO | Total price of energy for heating—geothermal source, EUR/kWh |

| TPEH_OS | Total price of energy for heating—other source (not geothermal), EUR/kWh |

| TTC | Total transport cost, EUR/km |

| TWC | Total work cost, EUR/h |

| V | volume, dm3 |

| UTT | unit transport time, min/km |

| WC | work cost, EUR/year |

| τ | time |

References

- McCay, A.T.; Harley, T.L.; Younger, P.L.; Sanderson, D.C.W.; Cresswell, A.J. Gamma-ray spectrometry in geothermal exploration: State of the art techniques. Energies 2014, 7, 4757–4780. [Google Scholar] [CrossRef] [Green Version]

- Stober, I.; Bucher, K. Geothermal energy: From theoretical models to exploration and development. In Geothermal Energy: From Theoretical Models to Exploration and Development; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 9783642133527. [Google Scholar]

- Li, K.; Bian, H.; Liu, C.; Zhang, D.; Yang, Y. Comparison of geothermal with solar and wind power generation systems. Renew. Sustain. Energy Rev. 2015, 42, 1464–1474. [Google Scholar] [CrossRef]

- Zhu, J.; Hu, K.; Lu, X.; Huang, X.; Liu, K.; Wu, X. A review of geothermal energy resources, development, and applications in China: Current status and prospects. Energy 2015, 93, 466–483. [Google Scholar] [CrossRef]

- Younger, P.L. Energy: All That Matters Paperback; Hodder and Stoughton/John Murray: London, UK, 2014. [Google Scholar]

- Moya, D.; Aldás, C.; Kaparaju, P. Geothermal energy: Power plant technology and direct heat applications. Renew. Sustain. Energy Rev. 2018, 94, 889–901. [Google Scholar] [CrossRef]

- Xia, L.; Zhang, Y. An overview of world geothermal power generation and a case study on China—The resource and market perspective. Renew. Sustain. Energy Rev. 2019, 112, 411–423. [Google Scholar] [CrossRef]

- Redko, A.; Redko, O.; DiPippo, R. Heating with geothermal systems. In Low-Temperature Energy Systems with Applications of Renewable Energy; Academic Press: London, UK, 2020; pp. 177–224. [Google Scholar]

- Gudmundsson, J.S.; Freeston, D.H.; Lienau, P.J. Lindal diagram. Trans. Geotherm. Resour. Counc. 1985, 9, 15–17. [Google Scholar]

- Kaczmarczyk, M.; Tomaszewska, B.; Operacz, A. Sustainable utilization of low enthalpy geothermal resources to electricity generation through a cascade system. Energies 2020, 13, 2495. [Google Scholar] [CrossRef]

- Dickson, M.H.; Fanelli, M. Geothermal Energy: Utilization and Technology; Earthscan: London, UK, 2013; ISBN 9781315065786. [Google Scholar]

- Younger, P.L. Geothermal energy: Delivering on the global potential. Energies 2015, 8, 11737–11754. [Google Scholar] [CrossRef] [Green Version]

- IRENA Geothermal Energy. Available online: https://www.irena.org/geothermal (accessed on 15 May 2020).

- Bertani, R. Geothermal power generation in the world 2010–2014 update report. Geothermics 2016, 60, 31–43. [Google Scholar] [CrossRef]

- DiPippo, R. Geothermal Power Plants: Principles, Applications, Case Studies and Environmental Impact, 3rd ed.; Butterworth-Heinemann: London, UK, 2012; ISBN 978-0-08-098206-9. [Google Scholar]

- Valdimarsson, P. Geothermal power plants and main components. In Proceedings of the Short Course on Geothermal Drilling, Resource Development and Power Plants, Santa Tecla, El Salvador, 16–22 January 2011. [Google Scholar]

- Anderson, D.N.; Lund, J.W. Direct Utilization of Geothermal Energy: A Technical Handbook; Geothermal Resources Council: Davis, CA, USA, 1979. [Google Scholar]

- Glassley, W.E. Geothermal Energy—Renewable Energy and the Environment, 2nd ed.; CRC Press/Taylor&Francis: Boca Raton, FL, USA, 2014; ISBN 9780429161988. [Google Scholar]

- Lund, J.W.; Freeston, D.H.; Boyd, T.L. Direct application of geothermal energy: 2005 Worldwide review. Geothermics 2005, 34, 691–727. [Google Scholar] [CrossRef]

- Lund, J.W.; Freeston, D.H.; Boyd, T.L. Direct utilization of geothermal energy 2010 worldwide review. Geothermics 2011, 40, 159–180. [Google Scholar] [CrossRef]

- Lund, J.W.; Boyd, T.L. Direct utilization of geothermal energy 2015 worldwide review. Geothermics 2016, 60, 66–93. [Google Scholar] [CrossRef]

- Marrasso, E.; Roselli, C.; Sasso, M.; Tariello, F. Global and local environmental and energy advantages of a geothermal heat pump interacting with a low temperature thermal micro grid. Energy Convers. Manag. 2018, 172, 540–553. [Google Scholar] [CrossRef]

- Alkhwildi, A.; Elhashmi, R.; Chiasson, A. Parametric modeling and simulation of low temperature energy storage for cold-climate multi-family residences using a geothermal heat pump system with integrated phase change material storage tank. Geothermics 2020, 86, 101864. [Google Scholar] [CrossRef]

- Mangi, P. Geothermal direct use application: A case of geothermal Spa and demonstration centre at olkaria geothermal project, Kenya. In Proceedings of the Short Course IX on Exploration for Geothermal Resources, Naivasha, Kenya, 2–23 November 2014. [Google Scholar]

- Matuszewska, D.; Olczak, P. Evaluation of using gas turbine to increase efficiency of the Organic Rankine Cycle (ORC). Energies 2020, 13, 1499. [Google Scholar] [CrossRef] [Green Version]

- Carotenuto, A.; Figaj, R.D.; Vanoli, L. A novel solar-geothermal district heating, cooling and domestic hot water system: Dynamic simulation and energy-economic analysis. Energy 2017, 141, 2652–2669. [Google Scholar] [CrossRef]

- Hepbasli, A.; Canakci, C. Geothermal district heating applications in Turkey: A case study of Izmir-Balcova. Energy Convers. Manag. 2003, 44, 1285–1301. [Google Scholar] [CrossRef]

- Sander, M. Geothermal district heating systems: Country case studies from China, Germany, Iceland, and United States of america, and schemes to overcome the gaps. Trans. Geotherm. Resour. Counc. 2016, 40, 769–776. [Google Scholar]

- Miró, L.; Gasia, J.; Cabeza, L.F. Thermal energy storage (TES) for industrial waste heat (IWH) recovery: A review. Appl. Energy 2016, 179, 284–301. [Google Scholar] [CrossRef] [Green Version]

- CSO. Energy Consumption in Households in 2018; CSO: Warsaw, Poland, 2019. [Google Scholar]

- Ministry of Development Regulation of the Minister of Infrastructure and Development of 27 February 2015 on the Methodology for Determining the Energy Performance of a Building or Part of a Building, and Energy Performance Certificates. Available online: http://prawo.sejm.gov.pl/isap.nsf/download.xsp/WDU20150000376/O/D20150376.pdf (accessed on 22 March 2020).

- Kryzia, D.; Kuta, M.; Matuszewska, D.; Olczak, P. Analysis of the potential for gas micro-cogeneration development in Poland using the Monte Carlo method. Energies 2020, 13, 3140. [Google Scholar] [CrossRef]

- Specjał, A.; Lipczynska, A.; Hurnik, M.; Król, M.; Palmowska, A.; Popiołek, Z. Case study of thermal diagnostics of single-family house in temperate climate. Energies 2019, 12, 4549. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Yu, K.; Ling, X. Experimental study on thermal performance of a mobilized thermal energy storage system: A case study of hydrated salt latent heat storage. Energy Build. 2020, 210, 109744. [Google Scholar] [CrossRef]

- Wang, W.; Guo, S.; Li, H.; Yan, J.; Zhao, J.; Li, X.; Ding, J. Experimental study on the direct/indirect contact energy storage container in mobilized thermal energy system (M-TES). Appl. Energy 2014, 119, 181–189. [Google Scholar] [CrossRef]

- Deckert, M.; Scholz, R.; Binder, S.; Hornung, A. Economic efficiency of mobile latent heat storages. Energy Procedia 2014, 46, 171–177. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, X.; Han, Z.; Xu, W. Study on phase change interface for erythritol with nano-copper in spherical container during heat transport. Int. J. Heat Mass Transf. 2016, 92, 490–496. [Google Scholar] [CrossRef]

- Krönauer, A.; Lävemann, E.; Brückner, S.; Hauer, A. Mobile sorption heat storage in industrial waste heat recovery. Energy Procedia 2015, 73, 272–280. [Google Scholar] [CrossRef] [Green Version]

- Igliński, B.; Buczkowski, R.; Kujawski, W.; Cichosz, M.; Piechota, G. Geoenergy in Poland. Renew. Sustain. Energy Rev. 2012, 16, 2545–2557. [Google Scholar] [CrossRef]

- Bujakowski, W.; Tomaszewska, B.; Miecznik, M. The Podhale geothermal reservoir simulation for long-term sustainable production. Renew. Energy 2016, 99, 420–430. [Google Scholar] [CrossRef]

- Tomaszewska, B.; Pająk, L. Cooled and desalinated thermal water utilization in the Podhale heating system. Miner. Resour. Manag. 2013, 29, 127–139. (In Polish) [Google Scholar] [CrossRef] [Green Version]

- URE Tariffs Published in 2019. (In Polish). Available online: https://bip.ure.gov.pl/bip/taryfy-i-inne-decyzje-b/cieplo/3784,Taryfy-opublikowane-w-2019-r.html (accessed on 22 April 2020).

- Kępińska, B. A review of geothermal energy uses in Poland in 2016−2018. Tech. Pozyskiwań Geol. Geoterm. Zrównoważony Rozw. 2018, 1, 11–27. [Google Scholar]

- Puretemp Global Authority on Phase Change Material. Available online: http://www.puretemp.com/ (accessed on 8 April 2020).

- Axiotherm Axiotherm PCM. Available online: www.axiotherm.de/en/produkte/axiotherm-pcm/ (accessed on 10 April 2020).

- GlobalESystem Phase Change Materials. Available online: www.global-e-systems.com/en/phase-change-materials/ (accessed on 9 April 2020).

- Rubitherm PCM RT Line. Available online: www.rubitherm.eu/en/index.php/productcategory/organische-pcm-rt (accessed on 10 April 2020).

- Kaczmarczyk, M.; Sowizdzał, A.; Tomaszewska, B. Energetic and environmental aspects of individual heat generation for sustainable development at a local scale—A case study from Poland. Energies 2020, 13, 454. [Google Scholar] [CrossRef] [Green Version]

- CSO. National Census; Central Statistical Office: Warsaw, Poland, 2014. [Google Scholar]

- CSO. Household Forecast for 2016–2050. Available online: https://stat.gov.pl/obszary-tematyczne/ludnosc/prognoza-ludnosci/prognoza-gospodarstw-domowych-na-lata-2016-2050,9,4.html (accessed on 19 April 2020).

- En, B.S. Heating systems in buildings—Method for calculation of system energy requirements and system efficiencies. Management 2007. [Google Scholar] [CrossRef]

- Ministry of Development Typical Reference Year. Available online: https://www.gov.pl/web/fundusze-regiony/dane-do-obliczen-energetycznych-budynkow (accessed on 18 December 2019).

- Olczak, P.; Zabagło, J.; Kandefer, S.; Dziedzic, J. Influence of solar installation with flat-plate collectors in a detached house on pollutants emission and waste stream. In Between Evolution and Revolution—In Search of an energy Strategy; WAT: Poznań, Poland, 2015; pp. 739–752. [Google Scholar]

- Doračić, B.; Novosel, T.; Pukšec, T.; Duić, N. Evaluation of excess heat utilization in district heating systems by implementing levelized cost of excess heat. Energies 2018, 11, 575. [Google Scholar] [CrossRef] [Green Version]

- Kryzia, D.; Kopacz, M.; Kryzia, K. The valuation of the operational flexibility of the energy investment project based on a gas-fired power plant. Energies 2020, 13, 1567. [Google Scholar] [CrossRef] [Green Version]

- Kryzia, D.; Kopacz, M.; Orzechowska, M. Estimation of carbon dioxide emissions and diesel consumption in passenger cars. Bull. Miner. Energy Econ. Res. Inst. Polish Acad. Sci. 2015, 90, 79–92. [Google Scholar]

- Pająk, L.; Tomaszewska, B.; Bujakowski, W.; Bielec, B.; Dendys, M. Review of the low-enthalpy lower cretaceous geothermal energy resources in Poland as an environmentally friendly source of heat for urban district heating systems. Energies 2020, 13, 1302. [Google Scholar] [CrossRef] [Green Version]

- IoEP-NRI. Inventory of Greenhouse Gases in Poland for 1988–2017; The National Centre for Emissions Management: Warsaw, Poland, 2019. [Google Scholar]

- Olczak, P.; Olek, M.; Kryzia, D. The ecological impact of using photothermal and photovoltaic installations for DHW preparation. Polityka Energ. Energy Policy J. 2020, 23, 65–74. [Google Scholar] [CrossRef]

- WSKAŹNIKI EMISYJNOŚCI CO2, SO2, NOx, CO i pyłu całkowitego DLA ENERGII ELEKTRYCZNEJ. Available online: https://www.kobize.pl/uploads/materialy/materialy_do_pobrania/wskazniki_emisyjnosci/Wskazniki_emisyjnosci_grudzien_2019.pdf (accessed on 7 April 2020).

- Copernicus Climate Change Service (C3S). ERA5: Fifth Generation of ECMWF Atmospheric Reanalyses of the Global Climate. Copernicus Climate Change Service Climate Data Store (CDS). Available online: https://climate.copernicus.eu/climate-data-store (accessed on 24 March 2020).

- European Centre for Medium-Range Weather Forecasts (ECMWF) ERA5. Available online: https://cds.climate.copernicus.eu/cdsapp#!/dataset/reanalysis-era5-land-monthly-means?tab=form (accessed on 24 March 2020).

- Ogimet Synop Based Summary by States form 2019. Available online: http://ogimet.com/resynops.phtml.en (accessed on 24 April 2020).

| Parameter | Base Value | Unit | Change of Parameter Base Value | |

|---|---|---|---|---|

| −20% | 20% | |||

| NPV Change | ||||

| LCOH.OS | 0.0775 | EUR/kWh | −114.7% | 60.3% |

| M.TES.P | 6000 | EUR | 45.8% | −45.7% |

| THD | 15000 | kWh/year | −32.4% | 32.4% |

| LCOH.G | 0.0322 | EUR/kWh | 30.9% | −30.9% |

| distance* | 5 | km | 13.6% | −13.6% |

| distance | 0.5 | km | 3.5% | −3.5% |

| r | 4 | % | 8.9% | −7.8% |

| Q(H)/Q(DHW) | 1.5 | - | 0.0% | 0.0% |

| Distance, km | Carbon Dioxide Emission of M-TES Transport, kg/year for THD: | ||

|---|---|---|---|

| 5000 | 15,000 | 25,000 | |

| 0.5 | 38 | 87 | 137 |

| 1 | 76 | 174 | 275 |

| 2 | 152 | 347 | 550 |

| 3 | 227 | 521 | 824 |

| 4 | 303 | 695 | 1099 |

| 5 | 379 | 869 | 1374 |

| 6 | 455 | 1042 | 1649 |

| 7 | 531 | 1216 | 1924 |

| 8 | 606 | 1390 | 2198 |

| 9 | 682 | 1564 | 2473 |

| 10 | 758 | 1737 | 2748 |

| Distance, km | Reduction of Carbon Dioxide Emission, kg/year | |||||

|---|---|---|---|---|---|---|

| for Replacement of Coal Source, for THD: | for Replacement of Natural Gas Source, for THD: | |||||

| 5000 | 15,000 | 25,000 | 5000 | 15,000 | 25,000 | |

| 0.5 | 1774 | 5394 | 9009 | 928 | 2854 | 4777 |

| 1 | 1736 | 5307 | 8872 | 890 | 2767 | 4639 |

| 2 | 1660 | 5133 | 8597 | 814 | 2594 | 4365 |

| 3 | 1585 | 4959 | 8322 | 738 | 2420 | 4090 |

| 4 | 1509 | 4785 | 8047 | 662 | 2246 | 3815 |

| 5 | 1433 | 4612 | 7772 | 587 | 2072 | 3540 |

| 6 | 1357 | 4438 | 7498 | 511 | 1899 | 3265 |

| 7 | 1281 | 4264 | 7223 | 435 | 1725 | 2991 |

| 8 | 1206 | 4090 | 6948 | 359 | 1551 | 2716 |

| 9 | 1130 | 3917 | 6673 | 283 | 1377 | 2441 |

| 10 | 1054 | 3743 | 6398 | 208 | 1204 | 2166 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matuszewska, D.; Kuta, M.; Olczak, P. Techno-Economic Assessment of Mobilized Thermal Energy Storage System Using Geothermal Source in Polish Conditions. Energies 2020, 13, 3404. https://0-doi-org.brum.beds.ac.uk/10.3390/en13133404

Matuszewska D, Kuta M, Olczak P. Techno-Economic Assessment of Mobilized Thermal Energy Storage System Using Geothermal Source in Polish Conditions. Energies. 2020; 13(13):3404. https://0-doi-org.brum.beds.ac.uk/10.3390/en13133404

Chicago/Turabian StyleMatuszewska, Dominika, Marta Kuta, and Piotr Olczak. 2020. "Techno-Economic Assessment of Mobilized Thermal Energy Storage System Using Geothermal Source in Polish Conditions" Energies 13, no. 13: 3404. https://0-doi-org.brum.beds.ac.uk/10.3390/en13133404