Review of Carnot Battery Technology Commercial Development

Abstract

:1. Introduction

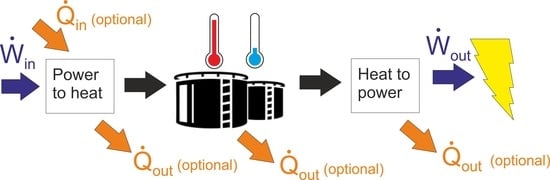

1.1. Carnot Battery Principles

1.2. Purpose of the Review

1.3. Classification of CB Technologies

2. Carnot Battery Development by Technologies

2.1. Rankine Cycle Systems

2.1.1. Electrically Heated RC Systems

2.1.2. Reversible RC Systems

2.2. Brayton Cycle Systems

2.2.1. Electrically Heated BC Systems

2.2.2. Reversible BC Systems

2.3. Other Cycles & Hybrid Systems

2.3.1. Electrically Heated Other & Hybrid Systems

2.3.2. Reversible Cycle and Other Hybrid Systems

2.4. TES Systems for CB

3. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| heat flow [kW] | |

| work power [kW] | |

| T | thermodynamic temperature [K] |

| Q | heat [kJ] |

| W | work [kJ] |

| efficiency [-] | |

| Subscripts | |

| amb | ambient |

| in | Inlet |

| out | outlet |

| UE | useful energy |

| Abbreviations | |

| AA-CAES | advanced adiabatic compressed air energy storage |

| A-CAES | adiabatic compressed air energy storage |

| BC | Brayton cycle |

| CAES | compressed air energy storage |

| CAPEX | capital expenditures |

| CB | Carnot battery/batteries |

| COP | coefficient of performance |

| CSP | concentrated solar power plants |

| ETES | electric thermal energy storage/electro—thermal energy storage |

| H2P | heat to power |

| HRSG | heat recovery steam generators |

| HTF | heat transfer fluid |

| HTMH | high temperature metal hydride |

| CHEST | compressed heat energy storage |

| CHP | combined heat and power production |

| I-CAES | isothermal compressed air energy storage |

| IEA | international energy agency |

| LAES | liquid air energy storage |

| LCOE | levelized cost of energy |

| LCOS | levelized cost of storage |

| LTMH | low temperature metal hydride |

| MGA | miscibility gap alloy |

| MISP | Masdar Institute Solar Platform |

| OPTES | optimized pumped thermal energy storage |

| ORC | organic Rankine cycles |

| P2H | power to heat |

| P2H2P | power to heat to power |

| PCM | phase change material |

| PHES | pumped hydro energy storage |

| PHS | pumped hydro storage |

| PTES | pumped thermal energy storage |

| PV | photovoltaic |

| R&D | research and development |

| RC | Rankine cycle |

| RTE | roundtrip efficiency |

| TES | thermal energy storage |

| TESS | thermal energy storage system |

| TRL | technology readiness level |

References

- Hansen, K.; Mathiesen, B.V.; Skov, I.R. Full energy system transition towards 100% renewable energy in Germany in 2050. Renew. Sustain. Energy Rev. 2019, 102, 1–13. [Google Scholar] [CrossRef]

- Brown, T.W.; Bischof-Niemz, T.; Blok, K.; Breyer, C.; Lund, H.; Mathiesen, B.V. Response to “Burden of proof: A comprehensive review of the feasibility of 100% renewable-electricity systems”. Renew. Sustain. Energy Rev. 2018, 92, 834–847. [Google Scholar] [CrossRef]

- Aghahosseini, A.; Bogdanov, D.; Breyer, C. Towards sustainable development in the MENA region: Analysing the feasibility of a 100% renewable electricity system in 2030. Energy Strat. Rev. 2020, 28, 100466. [Google Scholar] [CrossRef]

- Redondo-Iglesias, E.; Venet, P.; Pelissier, S. Efficiency Degradation Model of Lithium-Ion Batteries for Electric Vehicles. IEEE Trans. Ind. Appl. 2019, 55, 1932–1940. [Google Scholar] [CrossRef] [Green Version]

- Schimpe, M.; Naumann, M.; Truong, N.; Hesse, H.C.; Santhanagopalan, S.; Saxon, A.; Jossen, A. Energy efficiency evaluation of a stationary lithium-ion battery container storage system via electro-thermal modeling and detailed component analysis. Appl. Energy 2018, 210, 211–229. [Google Scholar] [CrossRef]

- Cárdenas, B.; Swinfen-Styles, L.; Rouse, J.; Hoskin, A.; Xu, W.; Garvey, S. Energy storage capacity vs. renewable penetration: A study for the UK. Renew. Energy 2021, 171, 849–867. [Google Scholar] [CrossRef]

- Garvey, S.D. Medium-Duration Energy Storage Explained. Mediu. Durat. Energy Storage Net Zero UK, Nottingham: Supergen Energy Storage. 2021. Available online: https://www.era.ac.uk/Medium-Duration-Energy-Storage (accessed on 10 November 2021).

- Smith, K.; Saxon, A.; Keyser, M.; Lundstrom, B.; Cao, Z.; Roc, A. Life prediction model for grid-connected Li-ion battery energy storage system. In Proceedings of the 2017 American Control Conference (ACC), Seattle, WA, USA, 24–26 May 2017. [Google Scholar] [CrossRef]

- Moore, J.; Henbest, S. New Energy Outlook 2020. Available online: https://assets.bbhub.io/professional/sites/24/928908_NEO2020-Executive-Summary.pdf (accessed on 22 November 2021).

- Gyuk, I. DOE Global Energy Storage Database. Sandia Natl Lab 2021. Available online: https://sandia.gov/ess-ssl/gesdb/public/index.html (accessed on 22 November 2021).

- Benato, A.; Stoppato, A. Pumped Thermal Electricity Storage: A technology overview. Therm. Sci. Eng. Prog. 2018, 6, 301–315. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M. Pumped hydro energy storage system: A technological review. Renew. Sustain. Energy Rev. 2015, 44, 586–598. [Google Scholar] [CrossRef]

- Benato, A. Performance and cost evaluation of an innovative Pumped Thermal Electricity Storage power system. Energy 2017, 138, 419–436. [Google Scholar] [CrossRef]

- Aghahosseini, A.; Breyer, C. Assessment of geological resource potential for compressed air energy storage in global electricity supply. Energy Convers. Manag. 2018, 169, 161–173. [Google Scholar] [CrossRef]

- Sterner, M.; Stadler, I. Handbook of Energy Storage; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Budt, M.; Wolf, D.; Span, R.; Yan, J. A review on compressed air energy storage: Basic principles, past milestones and recent developments. Appl. Energy 2016, 170, 250–268. [Google Scholar] [CrossRef]

- Projects—Hydrostor 2021. Available online: https://www.hydrostor.ca/projects/ (accessed on 15 October 2021).

- King, M.; Jain, A.; Bhakar, R.; Mathur, J.; Wang, J. Overview of current compressed air energy storage projects and analysis of the potential underground storage capacity in India and the UK. Renew. Sustain. Energy Rev. 2021, 139, 110705. [Google Scholar] [CrossRef]

- Lourenssen, K.; Williams, J.; Ahmadpour, F.; Clemmer, R.; Tasnim, S. Vanadium redox flow batteries: A comprehensive review. J. Energy Storage 2019, 25, 100844. [Google Scholar] [CrossRef]

- Botha, C.; Kamper, M. Capability study of dry gravity energy storage. J. Energy Storage 2019, 23, 159–174. [Google Scholar] [CrossRef]

- Fyke, A. The Fall and Rise of Gravity Storage Technologies. Joule 2019, 3, 625–630. [Google Scholar] [CrossRef] [Green Version]

- Abdon, A.; Zhang, X.; Parra, D.; Patel, M.K.; Bauer, C.; Worlitschek, J. Techno-economic and environmental assessment of stationary electricity storage technologies for different time scales. Energy 2017, 139, 1173–1187. [Google Scholar] [CrossRef]

- Dumont, O.; Frate, G.F.; Pillai, A.; Lecompte, S.; De Paepe, M.; Lemort, V. Carnot battery technology: A state-of-the-art review. J. Energy Storage 2020, 32, 101756. [Google Scholar] [CrossRef]

- Frate, G.F.; Ferrari, L.; Desideri, U. Energy storage for grid-scale applications: Technology review and economic feasibility analysis. Renew. Energy 2021, 163, 1754–1772. [Google Scholar] [CrossRef]

- Dumont, O.; Lemort, V. Mapping of performance of pumped thermal energy storage (Carnot battery) using waste heat recovery. Energy 2020, 211, 118963. [Google Scholar] [CrossRef]

- Laughlin, R.B. Pumped thermal grid storage with heat exchange. J. Renew. Sustain. Energy 2017, 9, 044103. [Google Scholar] [CrossRef] [Green Version]

- Steinmann, W.-D. Thermo-mechanical concepts for bulk energy storage. Renew. Sustain. Energy Rev. 2017, 75, 205–219. [Google Scholar] [CrossRef]

- Marguerre, F. Thermodynamic Energy Storage. U.S. Patent US2065974A, 29 December 1936. [Google Scholar]

- iea Energy Storage Task 36—Carnot Batteries 2021. Available online: https://www.eces-a36.org/ (accessed on 25 October 2021).

- Schneider, G.; Maier, H.; Häcker, J.; Siegele, S. Electricity Storage with a Solid Bed High Temperature Thermal Energy Storage System (HTTES)—A Methodical Approach to Improve the Pumped Thermal Grid Storage Concept. In Atlantis Highlights in Engineering; Atlantis Press: Paris, France, 2021; Volume 6, pp. 26–33. [Google Scholar]

- Jacquemoud, E. Electro-Thermal Energy Storage System (ETES) Based on CO2 Cycles. Ref. Modul. Earth Syst. Environ. Sci. 2021. [Google Scholar] [CrossRef]

- ETES-Electric Thermal Energy Storage-Technology and Commercial Proposition. Siemens Gamesa Renew Energy GmbH Co KG n.d. Available online: https://www.siemensgamesa.com/en-int/-/media/siemensgamesa/downloads/en/products-and-services/hybrid-power-and-storage/etes/siemens-gamesa-etes-general-introduction-3d.pdf (accessed on 11 October 2021).

- Barmeier, T. Electric Thermal Energy Storage (ETES) Transition of Energy Supply. 26. Wind. Warn., Warnemünde, Germany. 2017. Available online: https://windenergietage.de/wp-content/uploads/sites/2/2017/11/26WT0811_F11_1120_Dr_Barmeier.pdf (accessed on 22 November 2021).

- Electric Thermal Energy Storage (ETES) ETES:SWITCH 2021. Available online: https://www.siemensgamesa.com/en-int/products-and-services/hybrid-and-storage/thermal-energy-storage-with-etes-switch (accessed on 4 November 2021).

- Witold, A. StoreToPower Pilot Plant for the Development of a Heat Storage Power Plant. 2nd Int. Work. Carnot Batter; DLR: Stuttgart, Germany, 2020. [Google Scholar]

- E2S Power|2020. Available online: http://e2s-power.com/ (accessed on 4 November 2021).

- Schäfer, T. Thermo-MechanischerSpeicher (CARNOT-Batterie). Zittau, Germany. 2020. Available online: https://www.cleantech-ost.de/fileadmin/user_upload/chefredakteur1/AK_Energiespeicher/IV_IPM_Thermomechanischer_Speicher_Schaefer.pdf (accessed on 15 November 2021).

- Spilling Technologies: About Spilling 2021. Available online: https://www.spilling.de/about-spilling/about-spilling.html (accessed on 21 October 2021).

- Aga, V.; Conte, E.; Carroni, R.; Burcker, B.; Ramond, M. Supercritical CO2-Based Heat Pump Cycle for Electrical Energy Storage for Utility Scale Dispatchable Renewable Energy Power Plants. In Proceedings of the 5th International Symposium—Supercritical CO2 Power Cycles, San Antonio, TX, USA, 28–31 March 2016. [Google Scholar]

- Chester Project|Compressed Heat Energy Storage for Energy from Renewable Sources n.d. Available online: https://www.chester-project.eu/ (accessed on 21 October 2021).

- Karthäuser, J. The Low Tempeature (80–120 °C) Carnot Battery and its Potential for the Integrated Energy System. 2nd Int. Work. Carnot Batter; DLR: Stuttgart, Germany, 2020. [Google Scholar]

- Novotny, V.; Mach, S.; Rathan, M.; Basta, V.; Spale, J. Modelling and experimental development of a waste heat upgrade integrated ORC Carnot battery with stone dust thermal storage. In Proceedings of the 6th International Seminar on ORC Power Systems, Munich, Germany, 11–13 October 2021. [Google Scholar]

- FutureBay—Energy Storage, Hvac 2021. Available online: https://futurebay.uk.com/ (accessed on 22 October 2021).

- Plants|Highview Power 2021. Available online: https://highviewpower.com/plants/ (accessed on 2 October 2021).

- Morgan, R.; Nelmes, S.; Gibson, E.; Brett, G. Liquid air energy storage—Analysis and first results from a pilot scale demonstration plant. Appl. Energy 2015, 137, 845–853. [Google Scholar] [CrossRef]

- Ross, K. Highview Hires MAN Energy for UK Cryogenic Energy Storage Project. Power Eng. Int. 2021. Available online: https://www.powerengineeringint.com/smart-grid-td/energy-storage/highview-hires-man-energy-for-uk-cryogenic-energy-storage-project/ (accessed on 24 November 2021).

- Sanz Garcia, L.; Jacquemoud, E.; Jenny, P. Thermo-Economic Heat Exchanger Optimization for Electro-Thermal Energy Storage Based on Transcritical CO2 CYCLES. In Proceedings of the 3rd European supercritical CO2 Conference, Paris, France, 19–20 September 2019; p. 2019-sCO2.eu-151. [Google Scholar] [CrossRef]

- Morandin, M.; Mercangöz, M.; Hemrle, J.; Maréchal, F.; Favrat, D. Thermoeconomic design optimization of a thermo-electric energy storage system based on transcritical CO2 cycles. Energy 2013, 58, 571–587. [Google Scholar] [CrossRef]

- Mercangöz, M.; Hemrle, J.; Kaufmann, L.; Z’Graggen, A.; Ohler, C. Electrothermal energy storage with transcritical CO2 cycles. Energy 2012, 45, 407–415. [Google Scholar] [CrossRef]

- ETES System Overview|Echogen Power Systems. 2021. Available online: https://www.echogen.com/energy-storage/etes-system-overview (accessed on 3 November 2021).

- Echogen Energy Storage. Supercritical CO2-Based Long-Duration Electrical Energy Storage Technical Overview. 2019. Available online: https://www.echogen.com/_CE/pagecontent/Documents/Echogen-TechnicalOverview7.18.19-3.pdf (accessed on 15 November 2021).

- Echogen Storage Systems|Distributed Systems|F6S Profile. 2022. Available online: https://www.f6s.com/echogenstoragesystems (accessed on 14 January 2022).

- Held, T. Systems and Methods for Generating Electricity Via a Pumped Thermal Energy Storage System. U.S. Patent US10883388B2, 5 January 2021. [Google Scholar]

- Held, T. Low-Cost, Long-Duration Electrical Energy Storage Using a CO2-Based Electro Thermal Energy Storage (ETES) System. In Arpa-E DAYS Annu. Meet.; 2021. Available online: https://arpa-e.energy.gov/sites/default/files/2021-03/03Day1-TimHeld_Echogen.pdf (accessed on 5 October 2021).

- Energy Dome|Groundbreaking Long Duration Energy Storage 2021. Available online: https://energydome.com/ (accessed on 2 November 2021).

- Astolfi, M.; Rizzi, D.; Macchi, E.; Spadacini, C. A Novel Energy Storage System Based on Carbon Dioxide Unique Thermodynamic Properties. Proc. ASME Turbo Expo. 2021, 4. [Google Scholar] [CrossRef]

- Moore, J.; Cich, S.; Day-Towler, M.; Mortzheim, J. Development and Testing of a 10 MWe Supercritical CO2 Turbine in a 1 MWe Flow Loop. Proc. ASME Turbo Expo. 2020, 11. [Google Scholar] [CrossRef]

- Allam, R.; Martin, S.; Forrest, B.; Fetvedt, J.; Lu, X.; Freed, D.; Brown, G.W.; Sasaki, T.; Itoh, M.; Manning, J. Demonstration of the Allam Cycle: An Update on the Development Status of a High Efficiency Supercritical Carbon Dioxide Power Process Employing Full Carbon Capture. Energy Procedia 2017, 114, 5948–5966. [Google Scholar] [CrossRef]

- Steinmann, W.-D.; Jockenhöfer, H.; Bauer, D. Thermodynamic Analysis of High-Temperature Carnot Battery Concepts. Energy Technol. 2020, 8, 1900895. [Google Scholar] [CrossRef] [Green Version]

- von der Heyde, M.; Schmitz, G. Electric Thermal Energy Storage Based on Packed Bed. Ref. Modul. Earth Syst. Environ. Sci. 2021. [Google Scholar] [CrossRef]

- Soprani, S.; Marongiu, F.; Christensen, L.; Alm, O.; Petersen, K.D.; Ulrich, T.; Engelbrecht, K. Design and testing of a horizontal rock bed for high temperature thermal energy storage. Appl. Energy 2019, 251, 113345. [Google Scholar] [CrossRef]

- Prieto, C.; Osuna, R.; Fernandez, A.I.; Cabeza, L.F. Thermal storage in a MW scale. Molten salt solar thermal pilot facility: Plant description and commissioning experiences. Renew. Energy 2016, 99, 852–866. [Google Scholar] [CrossRef]

- Relloso, S.; Gutiérrez, Y. SENER molten salt tower technology. Ouarzazate NOOR III case. AIP Conf. Proc. 2017, 1850, 030041. [Google Scholar] [CrossRef] [Green Version]

- Bell, S.; Steinberg, T.; Will, G. Corrosion mechanisms in molten salt thermal energy storage for concentrating solar power. Renew. Sustain. Energy Rev. 2019, 114, 109328. [Google Scholar] [CrossRef]

- Kruizenga, A.M.; Gill, D.D.; LaFord, M.E. Corrosion of High Temperature Alloys in Solar Salt at 400, 500, and 680 °C. 2013. Available online: https://www.osti.gov/biblio/1104752/ (accessed on 5 October 2021).

- Copus, M.; Fraser, B.; Reece, R.; Hands, S.; Cuskelly, D.; Sugo, H.; Reed, S.; Bradley, J.; Post, A.; Kisi, E. On-sun testing of Miscibility Gap Alloy thermal storage. Sol. Energy 2019, 177, 657–664. [Google Scholar] [CrossRef]

- Reed, S.; Sugo, H.; Kisi, E.; Richardson, P. Extended thermal cycling of miscibility gap alloy high temperature thermal storage materials. Sol. Energy 2019, 185, 333–340. [Google Scholar] [CrossRef]

- Steinmann, W. The CHEST (Compressed Heat Energy STorage) concept for facility scale thermo mechanical energy storage. Energy 2014, 69, 543–552. [Google Scholar] [CrossRef]

- Steinmann, W.-D.; Eck, M. Buffer storage for direct steam generation. Sol. Energy 2006, 80, 1277–1282. [Google Scholar] [CrossRef] [Green Version]

- Krüger, M.; Muslubas, S.; Loeper, T.; Klasing, F.; Knödler, P.; Mielke, C. Potentials of Thermal Energy Storage Integrated into Steam Power Plants. Energies 2020, 13, 2226. [Google Scholar] [CrossRef]

- Terrajoule|24/7 Clean Energy 2021. Available online: http://www.terrajoulecorp.com/ (accessed on 21 October 2021).

- Frate, G.F.; Ferrari, L.; Desideri, U. Rankine Carnot Batteries with the Integration of Thermal Energy Sources: A Review. Energies 2020, 13, 4766. [Google Scholar] [CrossRef]

- Macchi, E.; Astolfi, M. Organic Rankine Cycle (ORC) Power Systems: Technologies and Applications; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Dumont, O.; Charalampidis, A.; Lemort, V.; Karellas, S. Experimental Investigation of a Thermally Integrated Carnot Battery Using a Reversible Heat Pump/Organic Rankine Cycle. In Proceedings of the 18th International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 24–28 May 2021. [Google Scholar]

- Trebilcock, F.; Ramirez, M.; Pascual, C.; Weller, T.; Lecompte, S.; Hassan, A.H. Development of a compressed heat energy storage system prototype. IIR Rank Conf. 2020, 400–409. [Google Scholar] [CrossRef]

- Steger, D.; Karl, J.; Schlücker, E. Launch and first experimental results of a reversible heat pump-orc pilot plant as carnot battery. In Proceedings of the 6th International Seminar on ORC Power Systems, Munich, Germany, 11–13 October 2021. [Google Scholar]

- Glushenkov, M.; Kronberg, A.; Knoke, T.; Kenig, E.Y. Isobaric Expansion Engines: New Opportunities in Energy Conversion for Heat Engines, Pumps and Compressors. Energies 2018, 11, 154. [Google Scholar] [CrossRef] [Green Version]

- O’Callaghan, O.; Donnellan, P. Liquid air energy storage systems: A review. Renew. Sustain. Energy Rev. 2021, 146, 111113. [Google Scholar] [CrossRef]

- Chino, K.; Araki, H. Evaluation of energy storage method using liquid air. Heat Transfer-Asian Res. 2000, 29, 347–357. [Google Scholar] [CrossRef]

- Li, Y.; Cao, H.; Wang, S.; Jin, Y.; Li, D.; Wang, X.; Ding, Y. Load shifting of nuclear power plants using cryogenic energy storage technology. Appl. Energy 2014, 113, 1710–1716. [Google Scholar] [CrossRef]

- Mikolajczak, A.; Wolowicz, M.; Kurkus-Gruszecka, M.; Badyda, K.; Krawczyk, P. Improving the efficiency of Liquid Air Energy Storage by organic rankine cycle module application. In Proceedings of the 2018 International Interdisciplinary PhD Workshop (IIPhDW), Świnouście, Poland, 9–12 May 2018. [Google Scholar] [CrossRef]

- Peng, X.; She, X.; Li, Y.; Ding, Y. Thermodynamic analysis of Liquid Air Energy Storage integrated with a serial system of Organic Rankine and Absorption Refrigeration Cycles driven by compression heat. Energy Procedia 2017, 142, 3440–3446. [Google Scholar] [CrossRef]

- She, X.; Peng, X.; Zhang, T.; Ding, Y. Configuration optimization of stand-alone Liquid Air Energy Storage for efficiency improvement. IOP Conf. Ser. Mater. Sci. Eng. 2019, 502, 012015. [Google Scholar] [CrossRef]

- Highview Enlasa Developing 50MW/500MWh Liquid Air Energy Storage Facility in the Atacama Region of Chile|Highview Power 2021. Available online: https://highviewpower.com/news_announcement/highview-enlasa-developing-50mw-500mwh-liquid-air-energy-storage-facility-in-the-atacama-region-of-chile/ (accessed on 20 October 2021).

- Highview Power to Develop Multiple Cryogenic Energy Storage Facilities in the UK and to Build Europe’s Largest Storage System|Highview Power 2019. Available online: https://highviewpower.com/news_announcement/highview-power-to-develop-multiple-cryogenic-energy-storage-facilities-in-the-uk-and-to-build-europes-largest-storage-system/ (accessed on 20 September 2021).

- Jacquemoud, E. CO2 Basierte Industrielle Heatpump und Carnot—Batterie. Carnot-Batterien Thermische Stromspeicher für die Energiewende; Energie Campus Nürnberg: Nurnberg, Germany, 2021; Available online: https://www.encn.de/fileadmin/user_upload/Flyer_Carnot-Batterie-Workshop_final_V2.pdf (accessed on 25 October 2021).

- Wang, M.; Zhao, P.; Yang, Y.; Dai, Y. Performance analysis of energy storage system based on liquid carbon dioxide with different configurations. Energy 2015, 93, 1931–1942. [Google Scholar] [CrossRef]

- Colthorpe, A. ‘CO2 Battery’ Startup Energy Dome Gets US$11m Financing, First Agreement to Deploy 100MWh Project-Energy Storage News. Energy Storage News. 2021. Available online: https://www.energy-storage.news/co2-battery-startup-energy-dome-gets-us11m-financing-first-agreement-to-deploy-100mwh-project/ (accessed on 7 December 2021).

- Parham, J.; Vrettos, P.; Levinson, N. Commercialisation of ultra-high temperature energy storage applications: The 1414 Degrees approach. Ultra-High Temp. Therm. Energy Storage Transf. Convers. 2021, 2021, 331–346. [Google Scholar] [CrossRef]

- Anderson, B.N. Modular Solar Systems for 24/7 Scalable, Flexible, Affordable Electricity. In Proceedings of the ASME Power Conference, Charlotte, NC, USA, 26–30 June 2017; Volume 2, p. V002T09A002. [Google Scholar]

- Moriarty, K. Prospectus 1414 DEGREES 2018. Available online: http://1414degrees.com.au/wp-content/uploads/2018/12/1414Degrees-Limited-Replacement-Prospectus-14D.pdf (accessed on 7 November 2021).

- Technology—Peregrine Turbine Technologies 2021. Available online: https://www.peregrineturbine.com/technology/ (accessed on 6 December 2021).

- Howes, J. Concept and Development of a Pumped Heat Electricity Storage Device. Proc. IEEE 2012, 100, 493–503. [Google Scholar] [CrossRef]

- The GridScale Technology Explained|Stiesdal n.d. Available online: https://www.stiesdal.com/storage/the-gridscale-technology-explained/ (accessed on 31 October 2021).

- WindTP—Wind Driven Thermal Pumping 2021. Available online: https://www.wind-tp.com/ (accessed on 6 December 2021).

- Heatstore. 247Solar 2020. Available online: https://www.247solar.com/247Solar/heatstore.html (accessed on 1 November 2021).

- Maisch, M. 1414 Degrees to Power Abandoned Aurora CSP Site with PV and Thermal Storage—Pv Magazine Australia. Pv Mag 2019. Available online: https://www.pv-magazine-australia.com/2019/11/29/1414-degrees-to-power-abandoned-aurora-csp-site-with-pv-and-thermal-storage/ (accessed on 9 November 2021).

- Aurora Energy Project. 1414 DEGREES 2021. Available online: https://1414degrees.com.au/auroraenergyproject/ (accessed on 9 November 2021).

- Stapp, D.S. A Novel SCO2 Primary Cycle for Air-Combustible Fuels. 4th Int. Symp. CO2 Power Cycles, Pittsburgh, Pennsylvania: 2014. Available online: http://sco2symposium.com/papers2014/systemConcepts/72-Stapp.pdf (accessed on 9 November 2021).

- Dewis, D. PTT’s Thermal Energy Storage (TES) Application Utilizes the Power Block Comprising Proprietary Turbo-Machinery and PCHE Technology. 2021. Available online: https://www.peregrineturbine.com/wp-content/uploads/2021/10/Peregrine-white-paper-EPRI.pdf (accessed on 9 November 2021).

- Smallbone, A. Experimental Results and Modelling of a Grid-scale Pumped Heat Energy Storage Demonstrator. Int. Work. Carnot Batter. 2020. [Google Scholar]

- Ameen, M.T.; Smallbone, A.; Roskilly, A.P.; Carpenter, E. The development of a screen valve for reciprocating heat pump/engine applications. J. Renew. Sustain. Energy 2020, 12, 054101. [Google Scholar] [CrossRef]

- Smallbone, A.; Jülch, V.; Wardle, R.; Roskilly, A.P. Levelised Cost of Storage for Pumped Heat Energy Storage in comparison with other energy storage technologies. Energy Convers. Manag. 2017, 152, 221–228. [Google Scholar] [CrossRef]

- Laughlin Battery—Google Recuperator. Brayt Energy 2021. Available online: https://www.braytonenergy.net/our-projects/malta-program-google-recuperator/ (accessed on 31 July 2020).

- Our Story—From Theory to a Successful Proof of Concept. Malta Inc. 2021. Available online: https://www.maltainc.com/our-story/ (accessed on 30 October 2021).

- Bollinger, B.R. Malta Pumped Heat Electricity Storage (PHES) for Coal Exit and Energy Transition from Fossil to Renewable Energies. 2nd Int. Work. Carnot Batter. 2020. Available online: https://iwcb2020.welcome-manager.de/archiv/web/userfiles/iwcb2020/Downloads/Presentations/IWCB20_VI_3_MaltaPHESCoal_BOLLINGER.pdf (accessed on 17 October 2020).

- Smith, N. Small-Scale PHES Demonstration. Arpa-E DAYS Annu. Meet. 2021. Available online: https://arpa-e.energy.gov/sites/default/files/2021-03/04Day1-NatalieSmith_SwRI.pdf (accessed on 30 October 2021).

- Fredericton, N.B.; Cambridge, M.A. Malta and NB Power Announce Collaboration Towards Development of Province’s LDES. Malta Inc. 2021. Available online: https://www.maltainc.com/maltanbpowerannouncement (accessed on 30 October 2021).

- Andel and Stiesdal Join Forces on Large-Scale Energy Storage. Andel 2021. Available online: https://andel.dk/en/news/andel-and-stiesdal-join-forces-on-large-scale-energy-storage/# (accessed on 31 October 2021).

- König-Haagen, A.; Höhlein, S.; Brüggemann, D. Detailed exergetic analysis of a packed bed thermal energy storage unit in combination with an Organic Rankine Cycle. Appl. Therm. Eng. 2020, 165, 114583. [Google Scholar] [CrossRef]

- Schlipf, D.; Faust, E.; Schneider, G.; Maier, H. First operational results of a high temperature energy storage with packed bed and integration potential in CSP plants. AIP Conf. Proc. 2017, 1850, 080024. [Google Scholar] [CrossRef] [Green Version]

- Garvey, S.D.; Pimm, A.; Buck, A.J.; Woolhead, S.; Liew, K.W.; Kantharaj, B.; Garvey, E.J.; Brewster, B.D. Analysis of a Wind Turbine Power Transmission System with Intrinsic Energy Storage Capability. Wind. Eng. 2015, 39, 149–173. [Google Scholar] [CrossRef]

- Garvey, S.D. Multi-Stage High-Efficiency Adiabatic Compressor/Expander Uses Covered Liquid Pistons. U.S. Patent US20160356268A1, 8 December 2016. [Google Scholar] [CrossRef]

- Swinfen-Styles, L.; Garvey, S.D.; Giddings, D. Combining wind-driven air compression with underwater compressed air energy storage. In Proceedings of the 2019 Offshore Energy and Storage Summit (OSES), Brest, France, 13–12 July 2019. [Google Scholar] [CrossRef]

- Azelio—Clean Power When & Where You Need It 2021. Available online: https://www.azelio.com/ (accessed on 15 November 2021).

- CCT Energy|Thermal Energy Storage Specialists, n.d. Available online: https://www.cctenergystorage.com/ (accessed on 18 October 2021).

- Blain, L. ‘World’s First Working Thermal Battery’ Promises Cheap, Eco-Friendly, Grid-Scalable Energy Storage. New Atlas 2019. Available online: https://newatlas.com/cct-silicon-energy-battery-thermal-energy-storage/59098/ (accessed on 30 September 2021).

- TECHNOLOGY—TEXEL. Texel Energy Storage n.d. Available online: https://www.texeles.com/technology/ (accessed on 7 October 2021).

- Herrmann, U. Projects Energy Storage: FH Aachen. Solar-Institut Jülich n.d. Available online: https://www.fh-aachen.de/en/research/solar-institute-juelich/focus-areas/projects-energy-storage (accessed on 5 September 2021).

- Ma, Z.; Hofer, D.; Tallman, J.; Zhang, R.; Lambert, M.M. Economic Long-Duration Electricity Storage Using Low-Cost Thermal Energy Storage and a High-Efficiency Power Cycle (ENDURING). Arpa-E DAYS Annu. Meet, Advanced Research Projects Agency—Energy. 2021. Available online: https://arpa-e.energy.gov/sites/default/files/2021-03/07%20Day1-Zhiwen%20Ma_NREL.pdf (accessed on 4 October 2021).

- Liquid Salt Combined Cycle. Pint Power 2019. Available online: https://www.pintailpower.com/technology/liquid-salt-combined-cycle/ (accessed on 7 December 2021).

- Liquid Air Combined Cycle. Pint Power 2019. Available online: https://www.pintailpower.com/technology/liquid-air-combined-cycle/ (accessed on 7 December 2021).

- Briggs, J. Antora Energy: Solid State Thermal Battery. Arpa-E DAYS Annu. Meet., Advanced Research Projects Agency—Energy. 2021. Available online: https://arpa-e.energy.gov/sites/default/files/2021-03/09Day1-JustinBriggs_AntoraEnergy-reducedfilesize.pdf (accessed on 4 October 2021).

- Nacompex. 2021. Available online: https://feredox.de/ (accessed on 11 October 2021).

- Nacompex Thermal Heating Power Plant 2019. Available online: http://nacompex.com/ (accessed on 30 May 2020).

- Colthorpe, A. Long-Duration Thermal Energy Storage Startup Azelio Wins First Commercial Order—Energy Storage News 2020. Available online: https://www.energy-storage.news/long-duration-thermal-energy-storage-startup-azelio-wins-first-commercial-order/ (accessed on 4 October 2021).

- Nilsson, M.; Abou-Taouk, A.; Sandberg, H.; Lindh, J. A Stirling engine for thermal energy storage. AIP Conf. Proc. 2019, 2126, 140005. [Google Scholar] [CrossRef]

- Lindquist, T.; Karlsson, J.; Wallmander, J.; Guedez, R.; Hedlund, M.-L.; Jamot, J.; Gloss, D.; Lindh, J.; Hertin, A.; Nilsson, M.; et al. A novel modular and dispatchable CSP Stirling system: Design, validation, and demonstration plans. AIP Conf. Proc. 2019, 2126, 06005. [Google Scholar] [CrossRef]

- Nilsson, H. Submarine Power Systems Using the V4-275R Stirling Engine. Proc. Inst. Mech. Eng. Part A Power Process. Eng. 1988, 202, 257–267. [Google Scholar] [CrossRef]

- Tetteh, S.; Yazdani, M.R.; Santasalo-Aarnio, A. Cost-effective Electro-Thermal Energy Storage to balance small scale renewable energy systems. J. Energy Storage 2021, 41, 102829. [Google Scholar] [CrossRef]

- Acharya, S.; Bhattacharjee, S. Stirling engine based solar-thermal power plant with a thermo-chemical storage system. Energy Convers. Manag. 2014, 86, 901–915. [Google Scholar] [CrossRef]

- Rea, J.E.; Oshman, C.; Singh, A.; Alleman, J.; Buchholz, G.; Parilla, P.A.; Adamczyk, J.M.; Fujishin, H.-N.; Ortiz, B.R.; Braden, T.; et al. Prototype latent heat storage system with aluminum-silicon as a phase change material and a Stirling engine for electricity generation. Energy Convers. Manag. 2019, 199, 111992. [Google Scholar] [CrossRef]

- Thermal Battery Producer Heats up Storage Market n.d. Available online: https://theleadsouthaustralia.com.au/industries/mining-resources/thermal-battery-producer-heats-up-storage-market/ (accessed on 18 October 2021).

- Griffond, A.C.M.; Sofianos, M.V.; Sheppard, D.A.; Humphries, T.D.; Sargent, A.L.; Dornheim, M.; Aguey-Zinsou, K.-F.; Buckley, C.E. High-temperature thermochemical energy storage using metal hydrides: Destabilisation of calcium hydride with silicon. J. Alloys Compd. 2021, 858, 158229. [Google Scholar] [CrossRef]

- Corgnale, C.; Hardy, B.; Motyka, T.; Zidan, R.; Teprovich, J.; Peters, B. Screening analysis of metal hydride based thermal energy storage systems for concentrating solar power plants. Renew. Sustain. Energy Rev. 2014, 38, 821–833. [Google Scholar] [CrossRef]

- Miller, M.A.; Petrasch, J.; Randhir, K.; Rahmatian, N.; Klausner, J. Chemical energy storage. Therm. Mech. Hybrid Chem. Energy Storage Syst. 2021, 249–292. [Google Scholar] [CrossRef]

- IEA ES TCP Newsletter September 2021. Available online: https://iea-es.org/news/es-tcp-newsletter-september-2021/ (accessed on 5 October 2021).

- Ma, Z.; Wang, X.; Davenport, P.; Gifford, J.; Martinek, J. Economic Analysis of a Novel Thermal Energy Storage System Using Solid Particles for Grid Electricity Storage: Preprint. 15th Int. Conf. Energy Sustain., Virtual, Online: The American Society of Mechanical Engineers. 2021. Available online: https://www.nrel.gov/docs/fy21osti/79014.pdf (accessed on 6 October 2021).

- Ma, Z.; Mehos, M.; Glatzmaier, G.; Sakadjian, B.B. Development of a Concentrating Solar Power System Using Fluidized-bed Technology for Thermal Energy Conversion and Solid Particles for Thermal Energy Storage. Energy Procedia 2015, 69, 1349–1359. [Google Scholar] [CrossRef] [Green Version]

- Patel, P. White-Hot Blocks as Renewable Energy Storage?—IEEE Spectrum 2021. Available online: https://0-spectrum-ieee-org.brum.beds.ac.uk/could-storing-electricity-in-whitehot-blocks-give-supercheap-renewables-storage (accessed on 19 October 2021).

- Datas, A.; Zeneli, M.; Cañizo, C.; Malgarinos, I.; Nikolopoulos, A.; Nikolopoulos, N.; Karellas, S.; Marti, A. Molten silicon storage of concentrated solar power with integrated thermophotovoltaic energy conversion. AIP Conf. Proc. 2018, 2033, 090005. [Google Scholar] [CrossRef] [Green Version]

- Ramos, A.; Datas, A.; Cañizo, C.D.; Martí, A. Molten Silicon at the hearth of a novel energy storage system. Silicon Chem. Sol. Ind. XI Svolvaer Norwa 2018. [Google Scholar] [CrossRef]

- Datas, A.; Vaillon, R. Thermionic-enhanced near-field thermophotovoltaics. Nano Energy 2019, 61, 10–17. [Google Scholar] [CrossRef] [Green Version]

- Bullis, K. Molten Salts Might Provide Half-Price Grid Energy Storage—MIT Technology Review. MIT Technol Rev 2014. Available online: https://www.technologyreview.com/s/525121/molten-salts-might-provide-half-price-grid-energy-storage/ (accessed on 26 June 2018).

- Amy, C.; Seyf, H.R.; Steiner, M.A.; Friedman, D.J.; Henry, A. Thermal energy grid storage using multi-junction photovoltaics. Energy Environ. Sci. 2019, 12, 334–343. [Google Scholar] [CrossRef] [Green Version]

- Schulte, K.L.; France, R.M.; Friedman, D.J.; LaPotin, A.D.; Henry, A.; Steiner, M.A. Inverted metamorphic AlGaInAs/GaInAs tandem thermophotovoltaic cell designed for thermal energy grid storage application. J. Appl. Phys. 2020, 128, 143103. [Google Scholar] [CrossRef]

- Thiele, E.; Jahnke, A.; Ziegler, F. Efficiency of the Lamm–Honigmann thermochemical energy storage. Therm. Sci. Eng. Prog. 2020, 19, 100606. [Google Scholar] [CrossRef]

- EW GmbH—Technology, n.d. Available online: http://www.o-ew.de/technologie/ (accessed on 11 October 2021).

- Jahnke, A. Untersuchung des Honigmann-Prozesses zur Thermochemischen Energiespeicherung [Investigation of the Honigmann Process for Thermochemical Energy Storage]. Ph.D. Thesis, Technische Universität Berlin, Berlin, Germany, 2019. [Google Scholar] [CrossRef]

- Hoivik, N.; Greiner, C.; Barragan, J.; Iniesta, A.C.; Skeie, G.; Bergan, P.; Blanco-Rodriguez, P.; Calvet, N. Long-term performance results of concrete-based modular thermal energy storage system. J. Energy Storage 2019, 24. [Google Scholar] [CrossRef]

- Storworks Power—Our Technology 2020. Available online: https://storworks.com/our-technology/ (accessed on 7 December 2021).

- Electrical Power|Kraftblock n.d. Available online: https://kraftblock.com/en/applications/electrical-power.html (accessed on 10 November 2021).

- Green Energy Solutions|Magaldi Green Energy. Magaldi Green Energy n.d. Available online: https://www.magaldigreenenergy.com/en/technology (accessed on 10 November 2021).

- Thermal Processes for Air Pollution Control—Dürr n.d. Available online: https://www.durr.com/en/products/environmental-technology/exhaust-gas-and-air-pollution-control/oxi-x-thermal-processes (accessed on 10 November 2021).

- Philipp, R. Carbonclean and EEW Strengthen Collaboration in Carnot Batteries: Developing Thermal Waste Utilisation Plants into Flexible Storage Power Plants—EEW Energy from Waste 2021. Available online: https://www.eew-energyfromwaste.com/en/news/media/detail/news/carbonclean-und-eew-vertiefen-zusammenarbeit-bei-carnot-batterie-ausbau-energetischer-abfallverwertungsanlagen-zu-flexiblen-speicherkraftwerken/ (accessed on 10 November 2021).

- Electrified Thermal Solutions|Joule Hive 2021. Available online: https://www.electrifiedthermal.com/ (accessed on 5 November 2021).

- Brenmiller Energy|Carbon-Free Thermal Energy Storage n.d. Available online: https://bren-energy.com/ (accessed on 10 November 2021).

- LUMENION Builds Storage for an Efficient CO2-Free Energy Supply 2021. Available online: https://lumenion.com/?lang=en (accessed on 5 November 2021).

- The Norwegian Thermal Battery Company. Kyoto Gr AS 2021. Available online: https://www.kyoto.group/ (accessed on 24 November 2021).

- Hyme. Energy Storage in Molten Hydroxides 2021. Available online: https://www.hyme.energy/ (accessed on 4 January 2022).

- SaltX Technology—Energy Storage with Nano Coated Salt. SaltX Technol Hold 2021. Available online: https://saltxtechnology.com/ (accessed on 5 November 2021).

- Thermal Battery Technology|Modular, Scalable, Recycable. EnergyNest 2018. Available online: https://energy-nest.com/technology/ (accessed on 20 September 2021).

- Hoivik, N.; Greiner, C.; Tirado, E.B.; Barragan, J.; Skeie, G.; Calvet, N.; Bergan, P.; Blanco, P. Demonstration of EnergyNest thermal energy storage (TES) technology. AIP Conf. Proc. 2017, 1850, 080011. [Google Scholar] [CrossRef] [Green Version]

- Jacqui, G. Innovative Eenergy Storage. Compass Mag—Renew Energy Innov 2021. Available online: https://compassmag.3ds.com/innovative-energy-storage/?fbclid=IwAR1_GNU5PDIPFoF0rYmT7Sj9MtTKaPX0EjcvsKXxCXJyx92ZLbquF-dAwSI (accessed on 10 November 2021).

- Acri, R.; Bassetti, F.; Falvo, M.C.; Magaldi, L.; Manganelli, M.; Romagnoli, L.; Santi, F.; Scafuri, A. A new thermal energy storage technology for power system services. In Proceedings of the 2021 IEEE International Conference on Environment and Electrical Engineering and 2021 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Bari, Italy, 7–10 September 2021. [Google Scholar] [CrossRef]

- Green Heat Module—Kraftanlagen 2021. Available online: https://www.kraftanlagen.com/en/solutions/energy/green-heat-module/ (accessed on 10 November 2021).

- Baumann, T.; Göhring, F.; Stadler, H.; Doerbeck, T. Jülich solar power tower—System behavior during downtime. AIP Conf. Proc. 2017, 1850, 030004. [Google Scholar] [CrossRef] [Green Version]

- Kronhardt, V.; Alexopoulos, S.; Reißel, M.; Sattler, J.; Hoffschmidt, B.; Hänel, M.; Doerbeck, T. High-temperature Thermal Storage System for Solar Tower Power Plants with Open-volumetric Air Receiver Simulation and Energy Balancing of a Discretized Model. Energy Procedia 2014, 49, 870–877. [Google Scholar] [CrossRef] [Green Version]

- Präsentation Carnot Batterien für Kraftwerke. Carbonclean 2019. Available online: https://www.innovationsforum-energiewende.de/fileadmin/user_upload/2019-01-28-Firmenpraesentation-carbonclean-Speicherkraftwerk.pdf (accessed on 10 November 2021).

- Preiss, S. EEW cooperates with Carbon Clean on electricity storage|EUWID New Energy News 2021. Available online: https://www.euwid-energie.de/eew-kooperiert-mit-carbon-clean-bei-stromspeicherung/ (accessed on 10 November 2021).

- Forsberg, C.W.; Stack, D.C.; Curtis, D.; Haratyk, G.; Sepulveda, N.A. Converting excess low-price electricity into high-temperature stored heat for industry and high-value electricity production. Electr. J. 2017, 30, 42–52. [Google Scholar] [CrossRef]

- Stack, D.C.; Curtis, D.; Forsberg, C. Performance of firebrick resistance-heated energy storage for industrial heat applications and round-trip electricity storage. Appl. Energy 2019, 242, 782–796. [Google Scholar] [CrossRef]

- Ondrey, G. Storing Excess Electricity as High-Temperature Heat. Chem. Eng. 2021, 1. Available online: https://www.chemengonline.com/storing-excess-electricity-high-temperature-heat/#disqus_thread (accessed on 5 November 2021).

- Billing. Mimi. Salt Breakthrough Could Halve the Cost of Storing Solar Energy. Sifted 2021. Available online: https://sifted.eu/articles/salt-energy-storage-seaborg-hyme/ (accessed on 4 January 2022).

- Kanzawa, A.; Arai, Y. Thermal energy storage by the chemical reaction augmentation of heat transfer and thermal decomposition in the CaOCa(OH)2 powder. Sol. Energy 1981, 27, 289–294. [Google Scholar] [CrossRef]

- Dai, L.; Long, X.F.; Lou, B.; Wu, J. Thermal cycling stability of thermochemical energy storage system Ca(OH)2/CaO. Appl. Therm. Eng. 2018, 133, 261–268. [Google Scholar] [CrossRef]

- Alovisio, A.; Chacartegui, R.; Ortiz, C.; Valverde, J.M.; Verda, V. Optimizing the CSP-Calcium Looping integration for Thermochemical Energy Storage. Energy Convers. Manag. 2017, 136, 85–98. [Google Scholar] [CrossRef]

- Li, D.; Wang, J. Study of supercritical power plant integration with high temperature thermal energy storage for flexible operation. J. Energy Storage 2018, 20, 140–152. [Google Scholar] [CrossRef]

- Wang, Y.; Lou, S.; Wu, Y.; Wang, S. Flexible Operation of Retrofitted Coal-Fired Power Plants to Reduce Wind Curtailment Considering Thermal Energy Storage. IEEE Trans Power Syst. 2020, 35, 1178–1187. [Google Scholar] [CrossRef]

- Angerer, M.; Djukow, M.; Riedl, K.; Gleis, S.; Spliethoff, H. Simulation of Cogeneration-Combined Cycle Plant Flexibilization by Thermochemical Energy Storage. J. Energy Resour. Technol. Trans. ASME 2018, 140. [Google Scholar] [CrossRef] [Green Version]

| Company, System | Charging Method | TES | Discharging Method | Power Output | Storage Capacity/Duration | Roundtrip Efficiency | State | Ref. |

|---|---|---|---|---|---|---|---|---|

| Siemens Gamesa, ETES | Resistance heaters to air | Volcanic rock bed~600 °C | steam Rankine cycle | units to 100s MW | 24 h | 25% to >40% | Demo | [32,33,34] |

| RWE, Store2Power | Resistance heaters | molten salt | steam Rankine cycle | 100s MW | hours | ~40% | n.a. | [35] |

| E2S Power | Resistance heaters | Graphite-aluminium alloy at 700 °C | steam Rankine cycle | 1–100s MW | hours | 25–40% | lab proof of concept | [36] |

| Spilling | Steam compression & liquefaction | Saturated water (steam accumulators) | Steam expander (steam engine) | up to MW | hours | n.a. | n.a. | [37,38] |

| GE, AMSESS | CO2 Brayton + el. heating | Molten salt, water tank | Steam cycle with extraction | 20–100 MW | 8 h | 42–62% | Concept | [39] |

| Consortium CHESTER | Heat pump (organic fluid) | PCM and water | ORC | MW scale (8 kW exper.) | hours to days | n.a. | lab proof of concept | [40] |

| Climeon | Heat pump (organic fluid) | water (e.g., district heating system) | ORC | 80 kW to MW | hours | 25–60% | concept with existing ORC | [41] |

| TC Mach | Heat pump (organic fluid) | Stone dust TES | ORC | kW | hours | n.a. | construction of proof of concept | [42] |

| Future Bay | Heat pump (organic fluid) | water (hot) and PCM (cold) | ORC | 10s kW | hours | n.a. | Demo | [43] |

| Highview | Air liquifaction | Liquid air + other TES | Vaporization, expansion turbine | 50–350 MW | about 6 | 60–70% | Pilot, full scale construction | [44,45,46] |

| MAN/ABB, ETES | CO2 heat pump | 120 °C water + cold (ice) storage | CO2 Rankine cycle | several MWe | ~5 h | ~45% | lab demo | [31,47,48,49] |

| Echogen, ETES | CO2 heat pump, fluidized bed heat exchange | Sand (hot) and ice (cold) | CO2 Rankine cycle | 25 MW | 250 MWh | ~60% | design | [50,51,52,53,54] |

| Energydome, CO2 battery | CO2 compression & liquefaction | Liquid CO2 + other TES | Vaporization, expansion turbine | 10–80 MW modules | 20–200 MWh | 77% | Pilot construction | [55,56] |

| Company, System | Charging Method | TES | Discharging Method | Power Output | Storage Capacity/Duration | Roundtrip Efficiency | State | Ref. |

|---|---|---|---|---|---|---|---|---|

| 247Solar, Heat2Power Turbine | Electric resistance heaters | Silica sand | Gas turbine (Brayton cycle) | 200 kWe–100s MW | 6–20 h | 30% | Concept, design | [89,90] |

| 1414Degrees, TESS | Electric resistance heaters | Silicon based alloy, melting temperature 1414 °C | Gas turbine (also steam turbine, Stirling engine, direct heat) | 10 MW-GW | n.a. | n.a. | Demos (done) Planning grid scale pilot | [91] |

| Peregrine Turbine Technologies | Electric resistance heaters | Graphite-aluminium alloy (MGA), 800 °C | CO2 Brayton cycle | 1 MW | 8 MWh | 45% | CO2 turbine/compressor tests | [92] |

| Isoentropic | Heat pump (Brayton cycle -reciprocating devices) | Crushed rock packed bed | Brayton cycle (reciprocating devices) | 2 MW (exper. 150 kW) | 16 MWh | 72% | Demo (bankruptcy) | [93] |

| Malta, Pumped Heat Energy Storage | Heat pump (reverse Brayton cycle) | Molten salt + hydrocarbon antifreeze | Recuperated Brayton cycle | 10–100 MW | 80 MWh–1 GWh | n.a. | Concept, design | [26] |

| Stiesdal, GridScale | Heat pump (reverse Brayton cycle) | Crushed basalt rock packed bed | Brayton cycle | 2 MW–1 GW | 100,000 MWh | 35–60% | Pilot construction | [94] |

| Enolcon, OPTES | Heat pump (reverse Brayton cycle), N2 or Ar | Silica sand packed bed (silica sand, iron based sand, basalt) | Brayton cycle, N2 (or Ar) | ~8 MW | ~80 MWh | 58–66% | Concept, design (Pilot designing/ constructing) | [30] |

| WindTP | Heat pump (reverse Brayton cycle) | Gravel bed, indirect heat transfer | Brayton cycle | 3–20 MW | up to 100 h | up to 85% | component demo | [95] |

| Company, System | Charging Method | TES | Discharging Method | Power Output | Storage Capacity/Duration | Roundtrip Efficiency | State | Ref. |

|---|---|---|---|---|---|---|---|---|

| Azelio | Electric resistance heaters | Aluminium based PCM (600 °C) | Stirling engine | 13 kW | 13 h | ~30% | Multiple pilots, production line, commercial | [115] |

| CCT Energy Storage | Electric resistance heaters | Silicon based PCM (1400 °C) | Stirling engine | 5–100 kW | up to 1.2 MWh per module | n.a. | Pilot | [116,117] |

| TEXEL Energy Storage | Electric resistance heaters | Metal hydrides (MH)/metal carbonates | Stirling engine | 30 kW | 15–720 kWh | 40% | commercial installation effort | [118] |

| Kraftlagenn München | Electric resistance heaters/waste heat | Ceramic system (1000 °C) | Stirling engine and ORC | 60 kW (demo) | 1.4 MWhth (demo) | n.a. | demo | [119] |

| NREL ENDURING LDES (GE, PEI, Allied) | Electric resistance heaters | Fluidized packed bed with solid materials (1100 °C) | Combined Brayton and Rankine cycle | 50–400 MW | 10–100 h | 50–55% | Components prototypes, demo preparation | [120] |

| Pintail Power, Liquid Salt Combined Cycle | Electric resistance heaters | molten salt | Combustion combined cycle integration | from dozens MW | 24 h | 82–96% (+ fuel) | Patented concepts | [121] |

| Pintail Power, Liquid Air Combined Cycle | Compressor for air liquefaction | liquid air | Combustion combined cycle integration | from dozens MW | 24 h | 118% (+ fuel) | Patented concepts | [122] |

| Antora Energy | Electric resistance heaters | Graphite blocks (1500 °C) | Thermophotovoltaic cell | 0.1–1 MW | 10 MWhe | 40% | Proof of concept | [123] |

| NaCompEx | Compresed heat followed by desorption | NaOH-H2O solutions via concentration difference | Expansion followed by absorption | 10–100 MW | 60 kWh/m3 storage | 80% | Concept, design | [124,125] |

| Company, System | TES Type (Temperature Limit) | Thermal Capacity | State | Ref. |

|---|---|---|---|---|

| EnergyNest | High temperature concrete modules (up to 380 °C) | Scalable to hundreds of MWh | Pilot plant, preparing commercial project | [150] |

| Storworks power, BolderBloc | High temperature concrete modules (up to 600 °C) | from 30 MWh | 200 kWh demo, construction of 10 MWh | [151] |

| Kraftblock | High temperature concrete granules (up to 1300 °C) | Scalable | Pilot industrial applications | [152] |

| Magaldi Green Energy | Silica sand fluidized bed (up to 1000 °C) | 5 to 100 MWh | full size demonstrator | [153] |

| Dürr & Kraftanlagen | Ceramic blocks with gas heat exchange | MWh to GWh | Demonstrator as CB | [154] |

| Carboclean | Ceramic blocks with direct heating (above 1000 °C) | up to 1 GWh | Laboratory proof of concept | [155] |

| Joule Hive (Electrified Thermal Solutions) | Ceramic firebricks (up to 1700 °C) | n.a. | n.a. | [156] |

| BrenmillerEnergy | Rock bed | 6–750 MWh | Pilot applications | [157] |

| Lumenion | Steel rods (up to 650 °C) | up to 500 MWh | Pilot applications | [158] |

| Kyoto, Heatcube | Molten salt (525 °C produced steam) | 4–100 MWh | Pilot applications, commercial order | [159] |

| Hyme | Molten hydroxide up to 700 °C | Scalable | Patents, laboratory experiments | [160] |

| SaltX | Thermochemical | from 10 MWh | Pilot applications | [161] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Novotny, V.; Basta, V.; Smola, P.; Spale, J. Review of Carnot Battery Technology Commercial Development. Energies 2022, 15, 647. https://0-doi-org.brum.beds.ac.uk/10.3390/en15020647

Novotny V, Basta V, Smola P, Spale J. Review of Carnot Battery Technology Commercial Development. Energies. 2022; 15(2):647. https://0-doi-org.brum.beds.ac.uk/10.3390/en15020647

Chicago/Turabian StyleNovotny, Vaclav, Vit Basta, Petr Smola, and Jan Spale. 2022. "Review of Carnot Battery Technology Commercial Development" Energies 15, no. 2: 647. https://0-doi-org.brum.beds.ac.uk/10.3390/en15020647