A Note about Crosslinking Density in Imprinting Polymerization

Abstract

:1. Introduction

2. Common Syntheses for Imprinting Polymerizations

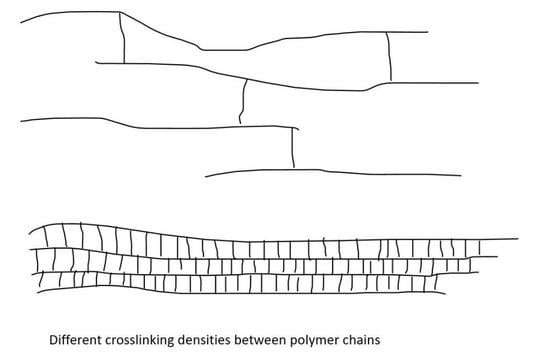

3. The Effect of Porogen and Crosslinking on Imprinted Materials

4. Summary and Future Outlook

Funding

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Ramstrom, O. Synthesis and selection of functional and structural monomers. In Molecularly Imprinted Materials, Science and Technology; Yan, M., Ramstrom, O., Eds.; Marcel Dekker: New York, NY, USA, 2005; pp. 181–224. [Google Scholar]

- Arshady, R.; Mosbach, K. Synthesis of substrate-selective polymers by host-guest polymerization. Makromol. Chem. 1981, 182, 687. [Google Scholar]

- Vlatikis, G.; Andersson, I.; Muller, R.; Mosbach, K. Drug assay using antibody mimics made by molecular imprinting. Nature 1993, 261, 645. [Google Scholar] [CrossRef] [PubMed]

- Szumski, M.; Buszewski, B. Molecularly imprinted polymers: A new tool for separation of steroid isomers. J. Sep. Sci. 2004, 27, 837–842. [Google Scholar] [CrossRef] [PubMed]

- Technical Guide to Chiral HPLC Separations. Available online: http://phx.phenomenex.com/lib/ChiralGuide.pdf (accessed on 29 June 2021).

- Soufi, G.J.; Iravani, S.; Varma, R.S. Molecularly imprinted polymers for the detection of viruses: Challenges and opportunities. Analyst 2021, 146, 3087–3100. [Google Scholar] [CrossRef]

- Villa, C.S.; Sanchez, L.T.; Ayala Valencia, G.; Ahmed, S.; Gutierrez, T.J. Molecularly imprinted polymers for food applications: A review. Trends Food Sci. Technol. 2021, 111, 642–669. [Google Scholar] [CrossRef]

- Wang, X.; Chen, G.; Zhang, P.; Jia, Q. Advances in epitope molecularly imprinted polymers for protein detection: A review. Anal. Methods 2021, 13, 1660–1671. [Google Scholar] [CrossRef]

- Abass, A.M.; Rzaij, J.M. A review on: Molecularly imprinting polymers by ion selective electrodes for determination of drugs. J. Chem. Rev. 2020, 2, 148–156. [Google Scholar]

- Romanholo, P.V.V.; Razzina, C.A.; Raymundo-Pereira, P.A.; Prado, T.M.; Machado, S.A.S.; Sgobbi, L.F. Biomimetic electrochemical sensors: New horizon’s and challenges in biosensing applications. Biosens. Bioelectron. 2021, 185, 113242. [Google Scholar] [CrossRef]

- Herrera-Chacon, A.; Ceto, X.; del Valle, M. Molecularly-imprinted polymers–towards electrochemical sensors and electronic tongues. Anal. Bioanal. Chem. 2021, 1–24. [Google Scholar] [CrossRef]

- Gao, M.; Gao, Y.; Chen, G.; Huang, X.; Xu, X.; Lv, J.; Wang, J.; Xu, D.; Liu, G. Recent advances and future trends in the detection of contaminants by molecularly imprinted polymers in food samples. Front. Chem. 2020, 8, 616326. [Google Scholar] [CrossRef]

- Arreguin-Campus, R.; Jimenez-Monroy, K.L.; Dilien, H.; Cleij, T.J.; van Grinsven, B.; Eersels, K. Imprinted polymers as synthetic receptors in sensors for food safety. Biosensors 2021, 11, 46. [Google Scholar]

- Appell, M.; Mueller, A. Mycotoxin analysis using imprinted materials technology: Recent developments. J. AOAC Int. 2016, 99, 861–864. [Google Scholar] [CrossRef]

- BelBruno, J.J. Molecularly imprinted polymers. Chem. Rev. 2019, 119, 94–119. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Jagminas, A.; Ramanavicius, A. Advances in molecularly imprinted polymers based affinity sensors (Review). Polymers 2021, 13, 974. [Google Scholar] [CrossRef]

- Janczura, M.; Lulinski, P.; Sobiech, M. Imprinting technology for effective sorbent fabrication: Current state-of-the-art and future prospects. Materials 2021, 14, 1850. [Google Scholar] [CrossRef]

- Leibl, N.; Haupt, K.; Gonzato, C.; Duma, L. Molecularly imprinted polymers for chemical sensing: A tutorial review. Chemosensors 2021, 9, 123. [Google Scholar] [CrossRef]

- Hu, T.; Chen, R.; Wang, Q.; He, C.; Liu, S. Recent advances and applications of molecularly imprinted polymers in solid-phase extraction for real sample analysis. J. Sep. Sci. 2021, 44, 274–309. [Google Scholar] [CrossRef]

- Aylaz, G.; Kuhn, J.; Lau, E.C.H.T.; Yeung, C.-C.; Al Roy, V.; Duman, M.; You, H.H.P. Recent developments on magnetic molecular imprinted polymers (MMIPS) for sensing, capturing, and monitoring pharmaceutical and agricultural pollutants. J. Chem. Technol. Biotechnol. 2021, 96, 1151–1160. [Google Scholar] [CrossRef]

- Torres-Cartas, S.; Catala-Icardo, M.; Meseguer-Lloret, S.; Simo-Alfonso, E.F.; Herrero-Martinez, J.M. Recent advances in molecularly imprinted membranes for sample treatment and separation. Separations 2020, 7, 69. [Google Scholar] [CrossRef]

- Arabi, M.; Ostovan, A.; Bagheri, A.R.; Guo, X.; Wang, L.; Li, J.; Wang, X.; Li, B.; Chen, L. Strategies of molecular imprinting-based solid-phase extraction prior to chromatographic analysis. Trends Anal. Chem. 2020, 128, 115923. [Google Scholar] [CrossRef]

- Iresh Fernando, P.U.A.; Glascott, M.W.; Pokrzywinski, K.; Fernando, B.M.; Kosgei, G.K.; Moores, L.C. Analytical methods incorporating molecularly imprinted polymers (mips) for the quantification of microcystins: A review. Crit. Rev. Anal. Chem. 2021, 1–15. [Google Scholar] [CrossRef]

- Lanza, F.; Sellergren, B. The application of molecula imprinting technology to solid phase extraction. Chromatographia 2001, 53, 599–611. [Google Scholar] [CrossRef]

- Sellergren, B. Separation of enantiomers using molecularly imprinted polymers. In Chiral Separation Techniques, 3rd ed.; Subramanian, G., Ed.; Wiley-VCH Verlag: Weinheim, Germany, 2007; pp. 399–431. [Google Scholar]

- Ndunda, E.N. Moleculalarly imprinted polymers–a closer look at the control polymer used in determining the imprinting effect: A mini review. J. Mol. Recogn. 2020, 33, e2855. [Google Scholar] [CrossRef]

- Jamieson, O.; Mecozzi, F.; Crapnell, R.D.; Battell, W.; Hudson, A.; Novakovic, K.; Sachdeva, A.; Confarotta, F.; Herdes, C.; Banks, C.E.; et al. Approaches to the rational design of molecularly imprinted polymers developed for the selective extraction and detection of antibiotics in environmental and food samples. Phys. Status Solidi A 2021, 2100021. [Google Scholar] [CrossRef]

- Dong, C.; Shi, H.; Han, Y.; Yang, Y.; Wang, R.; Men, J. Molecularly imprinted polymers by the surface imprinting technique. Eur. Polym. J. 2021, 145, 110231. [Google Scholar] [CrossRef]

- Lofgreen, J.E.; Ozin, G.A. Controlling morphology and porosity to improve performance of molecularly imprinted sol-gel silica. Chem. Soc. Rev. 2014, 43, 911–933. [Google Scholar] [CrossRef] [PubMed]

- Rico-Yuste, A.; Carrasco, S. Molecularly imprinted polymer-based hybrid materials for the development of optical sensors. Polymers 2019, 11, 1173. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fresco-Cala, B.; Batista, A.D.; Cardenas, S. Molecularly imprinted polymer micro- and nano-particles: A review. Molecules 2020, 25, 4740. [Google Scholar] [CrossRef]

- Yilmaz, E.; Schmidt, R.H.; Mosbach, K. The noncovalent approach. In Molecularly Imprinted Materials, Science and Technology; Yan, M., Ramstrom, O., Eds.; Marcel Dekker: New York, NY, USA, 2005; pp. 25–58. [Google Scholar]

- Lanza, F.; Dirion, B.; Sellergren, B. Combinatorial approaches to molecular imprinting. In Molecularly Imprinted Materials, Science and Technology; Yan, M., Ramstrom, O., Eds.; Marcel Dekker: New York, NY, USA, 2005; pp. 225–248. [Google Scholar]

- Cunliffe, D.; Alexander, C. Surface imprinting. In Molecularly Imprinted Materials, Science and Technology; Yan, M., Ramstrom, O., Eds.; Marcel Dekker: New York, NY, USA, 2005; pp. 249–284. [Google Scholar]

- Liu, J.; Chen, M.; Cui, H. Synthesis of ion-imprinted materials with amidoxime groups for enhanced UO22+ adsorption. Inorgan. Chim. Acta 2020, 517, 120196. [Google Scholar]

- Chaipuang, A.; Phungpanya, C.; Thongpoon, C.; Watla-iad, K.; Inkaew, P.; Machan, T.; Suwantong, O. Effect of ethylene diamine tetra-acetic acid and functional monomers on the structure and adsorption properties of copper(II) ion-imprinted polymers. Polym. Adv. Technol. 2021, 32, 3000–3007. [Google Scholar] [CrossRef]

- Rosellini, E.; Madeddu, D.; Barbani, N.; Frati, C.; Graiano, G.; Falco, A.; Lagrasta, C.; Quaini, F.; Cascone, M.G. Development of biomimetic alginate/gelatin/elastin sponges with recognition properties toward bioactive peptides for cardiac tissue engineering. Biomimetics 2020, 5, 67. [Google Scholar] [CrossRef]

- Gornik, T.; Shinde, S.; Lamovsek, L.; Koblar, M.; Heath, E.; Sellergren, B.; Kosjek, T. Molecularly imprinted polymers for the removal of antidepressants from contaminated wastewater. Polymers 2020, 13, 120. [Google Scholar] [CrossRef]

- Cai, T.; Zhou, Y.; Liu, H.; Li, J.; Wang, X.; Zhao, S.; Gong, B. Preparation of monodisperse, restricted-access, media-molecularly imprinted polymers using bi-functional monomers for solid-phase extraction of sarafloxacin from complex samples. J. Chromatogr. A 2021, 1642, 462009. [Google Scholar] [CrossRef]

- Mavliutova, L.; Verduci, E.; Shinde, S.A.; Sellergren, B. Combinatorial design of a sialic acid-imprinted binding site. ACS Omega 2021, 6, 1229–1237. [Google Scholar] [CrossRef]

- Feng, G.; Sun, J.; Wang, M.; Wang, M.; Li, Z.; Wang, S.; Zheng, L.; Wang, J.; She, X.; El-Aty, A.M.A. Preparation of molecularly imprinted polymer with class-specific recognition for determination of 29 sulfonylurea herbicides in agro-products. J. Chromatogr. A 2021, 1647, 462143. [Google Scholar] [CrossRef]

- Lulinski, P.; Maciewska, D. Impact of functional monomers, cross-linkers and porogens on morphology and recognition properties of 2-(3,4-dimethoxyphenyl)ethylamine imprinted polymers. Mater. Sci. Eng. C 2011, 31, 281–289. [Google Scholar] [CrossRef]

- Lah, N.F.C.; Ahmad, A.L.; Low, S.C.; Shoparwe, N.F. The role of porogen-polymer complexation in atrazine imprinted polymer to work as an electrochemical sensor in water. J. Environ. Chem. Eng. 2019, 7, 103500. [Google Scholar]

- Janczure, M.; Sobiech, M.; Lulinski, P. Insight into the morphology, pore structure and sorption properties of 4-hydroxy-3-nitrophenylacetic acid imprinted poly(acrylic acid-co-ethylene glycol dimethacrylate) sorbent. Polym. Test. 2021, 93, 106983. [Google Scholar]

- Xie, A.; Dai, J.; Chen, X.; Zou, T.; He, J.; Chang, Z.; Li, C.; Yan, Y. Hollow imprinted polymer nanorods with a tunable shell using hallosyte nanotubes as a sacrificial template for selective recognition and separation of chloramphenicol. RSC Adv. 2016, 6, 51014–51023. [Google Scholar] [CrossRef]

- Tang, A.; Duan, L.; Liu, M.; Dong, X. An epitope imprinted polymer with affinity for kininogen fragments prepared by metal coordination interaction for cancer biomarker analysis. J. Mater. Chem. B 2016, 4, 7464–7471. [Google Scholar] [CrossRef]

- Öngün, E.; Akgönüllü, S.; Yavuz, H.; Denizli, A. Synthesis of molecularly imprinted magnetic nanoparticles for selective cytindine adsorption. Sep. Sci. Plus 2021, 4, 147–156. [Google Scholar] [CrossRef]

- Xi, Y.; Shi, H.; Liu, R.; Yin, X.; Yang, L.; Huang, M.; Luo, X. Insights in ion imprinted membrane with a delayed permeation mechanism for enhancing Cd2+ selective separation. J. Hazard. Mater. 2021, 416, 125772. [Google Scholar] [CrossRef]

- Zhao, X.; Cheng, Y.; Xu, H.; Hao, Y.; Lv, Y.; Li, X. Design and preparation of molecularly imprinted membranes for selective separation of acteosides. Front. Chem. 2020, 8, 775. [Google Scholar] [CrossRef]

- An, F.-Q.; Li, H.-F.; Guo, X.-D.; Gao, B.-J.; Hu, T.-P.; Gao, J.-F. Novel ionic surface imprinting technology: Design and application for selectively recognizing heavy metal ions. RSC Adv. 2019, 9, 2431–2440. [Google Scholar] [CrossRef] [Green Version]

- Lamaoui, A.; Palacios-Santander, J.M.; Amine, A.; Cubiliana-Aguilera, L. Fast microwave-assisted synthesis of magnetic molecularly imprinted polymer of sulfamethoxazole. Talanta 2021, 232, 122439. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Lu, L.; Zhu, M.; Liu, H.; He, J.; Zheng, F. Development of hydrophilic magnetic molecularly imprinted polymers for the dispersive solid-phase extraction of sulfonamides from animal-derived samples before HPLC detection. J. Sep. Sci. 2021, 44, 2399–2407. [Google Scholar] [CrossRef]

- Florea, A.-M.; Iordache, T.-V.; Branger, C.; Brisset, H.; Zaharia, A.; Radu, A.-L.; Hubea, G.; Sarbu, A. One-step preparation of molecularly imprinted hollow beads for pseudohypericin separation from Hypericum perforatum L. extracts. Eur. Polym. J. 2018, 100, 48–56. [Google Scholar] [CrossRef]

- Chen, W.; Xue, M.; Xue, F.; Mu, X.; Xu, Z.; Meng, Z.; Zhu, G.; Shea, K.J. Molecularly imprinted hollow spheres for the solid phase extraction of estrogens. Talanta 2015, 140, 68–72. [Google Scholar] [CrossRef]

- Ansari, S. Application of hollow porous molecularly imprinted polymers using K2Ti4O9 coupled with spe-hplc for the determination of celecoxib in human urine samples: Optimization by central composite design (CCD). Anal. Methods 2017, 9, 3200. [Google Scholar] [CrossRef]

- Fang, L.; Ding, L.; Ren, W.; Hu, H.; Huang, Y.; Shao, P.; Yang, L.; Shi, H.; Ren, Z.; Han, K.; et al. High exposure effect of the adsorption site significantly enhanced the adsorption capacity and removal rate: A case of adsorption of hexavalent chromium by quaternary ammonium polymers (QAP). J. Hazard. Mater. 2021, 416, 125829. [Google Scholar] [CrossRef]

- Goyal, G.; Bhakta, S.; Mishra, P. Surface molecularly imprinted biomimetic magnetic nanoparticles for enantioseparation. Appl. Nano Mater. 2019, 2, 6747–6756. [Google Scholar] [CrossRef]

- Lin, Y.; Liu, Y.; Rui, L.; Ou, J.; Wu, Q.; He, J. Template-directed preparation of three-dimensionally ordered macroporous molecularly imprinted microspheres for selective recognition and separation of quinine from cinchona extract. J. Polym. Res. 2021, 28, 179. [Google Scholar] [CrossRef]

- Wu, Y.; Lin, R.; Ma, F.; Jiang, Z. Membrane-associated molecularly imprinted surfaces with tailor-made SiO2@polydopamine-based recognition sites for selective separation of artemisin. Coll. Surf. A 2021, 622, 126645. [Google Scholar] [CrossRef]

- Perera, R.; Ashraf, S.; Mueller, A. The binding of metal ions to molecularly-imprinted polymers. Water Sci. Technol. 2017, 75, 1643–1650. [Google Scholar] [CrossRef]

- Schmidt, R.; Belmont, A.-S.; Haupt, K. Porogen formulations for obtaining molecularly imprinted polymers with optimized binding properties. Anal. Chim. Acta 2005, 542, 118–124. [Google Scholar] [CrossRef]

- Liang, S.; Wan, J.; Zhu, J.; Cao, X. Effects of porogens on the morphology and enantioselectivity of core-shell molecularly imprinted polymers with ursodeoxycholic acid. Sep. Purif. Technol. 2010, 72, 208–216. [Google Scholar] [CrossRef]

- Meier, F.; Schott, B.; Riedel, S.; Mizaikoff, B. Computational and experimental study on the influence of the porogen on the selectivity of 4-nitrophenol molecularly imprinted polymers. Anal. Chim. Acta 2012, 744, 68–74. [Google Scholar] [CrossRef]

- Marc, M.; Panuszko, A.; Namiesnik, J.; Wieczorek, P.P. Preparation and characterization of dummy-template molecularly imprinted polymers as potential sorbents for the recognition of selected polybrominated diphenyl ethers. Anal. Chim. Acta 2018, 1030, 77–95. [Google Scholar] [CrossRef]

- Rosengren, A.; Golker, K.; Karlsson, J.G.; Nicholls, I. Dielectric constants are not enough: Principal component analysis of the influence of solvent properties on molecularly imprinted polymer-ligand rebinding. Biosens. Bioelectron. 2009, 25, 553–557. [Google Scholar] [CrossRef]

- Olsson, G.; Karlsson, B.C.G.; Shoravi, S.; Wiklander, J.G.; Nicholls, I.A. Mechanisms underlying molecularly imprinted polymer molecular memory and the role of crosslinker: Resolving debate on the nature of template recognition in phenylalanine anilide imprinted polymers. J. Mol. Recognit. 2012, 25, 69–73. [Google Scholar] [CrossRef]

- Olsson, G.D.; Karlsson, B.C.G.; Schillinger, E.; Sellergren, B.; Nicholls, I.A. Theoretical studies of 17-b-estradiol-imprinted prepolymerization mixtures: Insights concerning the roles of cross-linking and functional monomers in template complexation and polymerization. Ind. Eng. Chem. Res. 2013, 52, 1365–1370. [Google Scholar] [CrossRef]

- Shoravi, S.; Olsson, G.D.; Karlsson, B.C.G.; Nicholls, I.A. On the influence of crosslinker on template complexation in molecularly imprinted polymers: A computational study of prepolymerization mixture events with correlations to template-polymer recognition behavior and NMR spectroscopic studies. Int. J. Mol. Sci. 2014, 15, 10622–10634. [Google Scholar] [CrossRef] [Green Version]

- Golker, K.; Karlsson, B.C.G.; Rosengren, A.M.; Nicholls, I.A. A functional monomer is not enough: Principal component analysis of the influence of template complexation in pre-polymerization mixtures on imprinted polymer recognition and morphology. Int. J. Mol. Sci. 2014, 15, 20572–20584. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Klejn, D.; Lulinski, P.; Maciejewska, D. Desorption of 3,3’-diindolylmethane from imprinted particles: An impact of cross-linker structure on binding capacity and selectivity. Mater. Sci. Eng. C 2015, 56, 233–240. [Google Scholar] [CrossRef]

- Golker, K.; Nicholls, I.A. The effect of crosslinking density on molecularly imprinted polymer morphology and recognition. Eur. Polym. J. 2016, 75, 423–430. [Google Scholar] [CrossRef]

- Karlsson, B.C.G.; O’Mahony, J.; Karlsson, J.G.; Bengtsson, H.; Eriksson, L.A.; Nicholls, I.A. Structure and dynamics of monomer-template complexation: An explanation for molecularly imprinted polymer recognition site heterogeneity. J. Am. Chem. Soc. 2009, 131, 13297–13304. [Google Scholar] [CrossRef]

- Golker, K.; Karlsson, B.C.G.; Olsson, G.D.; Rosengren, A.M.; Nicholls, I.A. Influence of composition and morphology on template recognition in molecularly imprinted polymers. Macromolecules 2013, 46, 1408–1414. [Google Scholar] [CrossRef]

- Andrade Teixeira, R.; Angulo Flores, D.H.; Santos da Silva, R.C.; Avelar Dutra, F.V.; Bastos Borges, K. Pipette-Tip solid-phase extraction using poly(1-vinylimidazole-co-trimetylolpropane trimethacrylate) as a new molecularly imprinted polymer in the determination of avermectins and milbemycins in fruit juice and water samples. Food Chem. 2018, 262, 86–93. [Google Scholar] [CrossRef]

- Cowen, T.; Stefanucci, E.; Piletska, E.; Marrazza, G.; Vanfarotta, F.; Piletsky, S.A. Synthetic mechanism of molecular imprinting at the solid phase. Macromolecules 2020, 53, 1435–1442. [Google Scholar] [CrossRef]

- Painter, P.C.; Coleman, M.M. Statistics of step-growth polymerization. In Fundamentals of Polymer Science, an Introductory Text, 2nd ed.; CRC Press: Boca Raton, FL, USA, 1997; pp. 83–106. [Google Scholar]

- Odian, G. Principles of Polymerization, 3rd ed.; Wiley-Intersciences: New York, NY, USA, 1993. [Google Scholar]

- Kida, S.; Kitano, K.; Kyuno, S. Thermally Expandable Microcapsule and Its Production. Patent No. JPH05285376A, 2 November 1993. [Google Scholar]

- Mueller, A.; O’Brien, D.F. Polymerization of mesophases of hydrated amphiphiles. Chem. Rev. 2002, 102, 727–757. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fugolin, A.P.P.; Pfeifer, C.S. New resins for dental composites. Crit. Rev. Oral Biol. Med. 2017, 96, 1058–1091. [Google Scholar] [CrossRef]

- Kawaguchi, Y.; Oishi, T. Synthesis and properties of thermoplastic expandable microspheres: The relation between crosslinking density and expandable property. J. Appl. Polym. Sci. 2004, 93, 505–512. [Google Scholar] [CrossRef]

- Hatakeyama, T.; Hatakeyama, H. Thermal Properties of Green Polymers and Biocomposites; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2010. [Google Scholar]

- Krosky, D.J.; Song, F.; Stivers, J.T. The origins of high-affinity enzyme binding to an extrahelical DNA base. Biochemistry 2005, 44, 5949–5959. [Google Scholar] [CrossRef]

- Chouard, T. Breaking the protein rules. Nature 2011, 471, 151–153. [Google Scholar] [CrossRef] [Green Version]

- Johnson, T. Removal of Zinc from Water Utilizing Pressure-Stable, Imprinted Polymer Resins. Master’s Thesis, Central Michigan University, Mt. Pleasant, MI, USA, February 2016. [Google Scholar]

| Monomer:Crosslinker Molar Ratio | Template Crosslinker | Maximum Capacity (mg/g) | Comments | Reference |

|---|---|---|---|---|

| 1:2.7 | UO22+ EGDMA 2 | 125 | Bulk imprinting BET A2 670 m2/g, pore vol. 1.439 mL/g, avg. pore Ø 2.2 nm 1 Adsorption dependent on pH, initial conc., regeneration | [35] |

| 1:5 | Cu(II) Pentaerythrol triacrylate 3 | 2.16 | Bulk imprinting BET A2 6.7 m2/g, pore vol. 0.0088 mL/g, avg. pore Ø 5.2 nm 1 | [36] |

| 1:4.5 | Extracellular matrix peptides Pentaerythrol triacrylate 3 | 49.55 | Bulk imprinting Most templates trapped | [37] |

| 1:3, 1:5 | Serotonin reuptake inhibitors EGDMA 2 | 27.3 | Bulk imprinting BET A2 193.8 m2/g, pore vol. 0.37 mL/g, pore Ø 7.7 nm 1 | [38] |

| 1:3, 1:4, 1:5 | Sarafloxacin EGDMA 2 | 58.6 | Bulk imprinting Several functional monomers More crosslinking, less capacity | [39] |

| 1:4 to 1:20 | Sialic acid EGDMA 2 | 24.7 | Bulk imprinting Specialized acrylates 1:4 highest capacity | [40] |

| 1:2.5 | Sulfonylurea pesticides Divinylbenzene | 1.6 | Bulk imprinting BET A2: 409.7 m2/g 1 | [41] |

| 1:4 | 2-(3,4-dimethoxyphenyl)ethylamine Trimethylopropane trimethacrylate 3 | 24.5 | Bulk imprinting Optimized crosslinker and porogen | [42] |

| 1:0.38 | Atrazine EGDMA 2 | 3.45 | Bulk Imprinting Investigating porogen BET A2 237.5 m2/g, pore vol. 0.0268 mL/g, pore Ø 0.57 nm 1 | [43] |

| 1:5 | 4-Hydroxy-3-nitrophenylacetic acid EGDMA 2 | 0.106 | Bulk Imprinting Porogen, pore structure, and sorption investigation | [44] |

| 1:5 | Chloramphenicol EGDMA 2 | 64.3 | Surface imprinting, hollow rods 1–3 μm long, Ø 50–180 nm 1 | [45] |

| 1:4.5 | Peptide EDMA 4 | 76.9 | Surface imprinting, hollow | [46] |

| 1:1.2 | Cytidine EGDMA 2 | 33.39 | Surface imprinting, magnetic MIP BET A2: 980 m2/g 1 | [47] |

| 1:2.5, 1:5 | Cd(NO3)2 EGDMA2 | 32 | Membrane Less crosslinking, more adsorption Less imprinting molecule, less adsorption | [48] |

| 1:1 | Acteoside EGDMA2 | 62.83 | Surface imprinting, membrane | [49] |

| 1:1.3 | Cd(NO3)2 Ethylene diamine | 250.7 | Surface imprinting Surface crosslinking only BET: A2 192.2 m2/g, pore vol. 0.052 cm3/g, pore Ø 113 nm 1 | [50] |

| 1: 0.68 | Sulfa-methoxasole EGDMA 2 | 20.0 | Surface imprinting, magnetic MIP Computational study | [51] |

| 1:0.44 | Sulfonamides EDMA 4 | 0.559 | Surface imprinting, magnetic MIP Hybrid with silicon | [52] |

| 1:4 | Pseudohepericin EDMA 4 | 450 | Hollow particle Prepared by emulsion polymerization Inner Ø ca. 30 μm 1 | [53] |

| 1:5 | Estrogens EGDMA 2 | 12.1 | Hollow particle Ca. 250 nm inside Ø 1 | [54] |

| 1:5 | Celecoxib EGDMA 2 | 43.29 | Hollow particle | [55] |

| 1:0.2 | Cr(VI) Trimethylopropane trimethacrylate 3 | 66.6 | Bulk imprinting BET: A2 4.78 m2/g, pore vol. 0.00554 cm3/g, pore Ø 2.35 nm 1 | [56] |

| 1:0.0079 | (S)-Naproxen EGDMA 2 | 127 | Surface imprinting, magnetic MIP Enantioselectivity 4:1 | [57] |

| 1:2.5 | Quinine Trimethylopropane trimethacrylate 3 | 15.38 | Start with colloidal silica crystal microsphere Coat MIP on porous crystal, then remove crystal BET: A2 216 m2/g, pore vol. 0.66 cm3/g, avg pore Ø 12.2 nm | [58] |

| 1:1.05 | Artimisin 3-Aminopropyltriethoxysilane | 45.89 | Start with polydopamine as the core Coat imprinted Si around by the sol-gel method Phase inversion, then cast as membrane | [59] |

| 1:0.005 | Cd(II) EGDMA 2 | 950 | Bulk Imprinting Increased porosity by bubbling N through the reaction | [60] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mueller, A. A Note about Crosslinking Density in Imprinting Polymerization. Molecules 2021, 26, 5139. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26175139

Mueller A. A Note about Crosslinking Density in Imprinting Polymerization. Molecules. 2021; 26(17):5139. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26175139

Chicago/Turabian StyleMueller, Anja. 2021. "A Note about Crosslinking Density in Imprinting Polymerization" Molecules 26, no. 17: 5139. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26175139