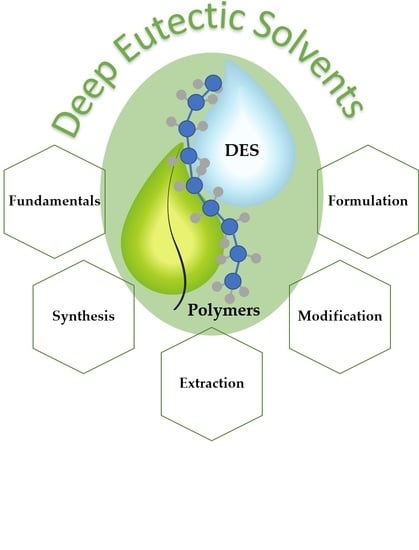

Polymer Science and Engineering Using Deep Eutectic Solvents

Abstract

:1. Introduction

2. Fundamental Studies Involving DES and Polymers

3. Polymeric Synthesis Using DES

3.1. DES as Functional Monomers

3.2. Electrochemical Polymerization

3.3. Polycondensation

3.4. Molecular Imprinted Polymers with DES

3.5. Other Types of Polymer Synthesis

4. Extraction of Polymers with DES

5. DES as Polymer Modification Agents

5.1. Derivatization

5.2. Plasticization

5.3. Other Modifications

6. Formulation of DES Materials Using Polymers

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Abbott, A.P.; Capper, G.; Davies, D.L.; Rasheed, R.K.; Tambyrajah, V. Novel solvent properties of choline chloride/urea mixtures. Chem. Commun. 2003, 70–71. [Google Scholar] [CrossRef]

- Guthrie, F. On eutexia. Proc. Phys. Soc. London 1884, 6, 124–146. [Google Scholar] [CrossRef]

- Martins, M.A.R.; Pinho, S.P.; Coutinho, J.A.P. Insights into the Nature of Eutectic and Deep Eutectic Mixtures. J. Solution Chem. 2018. [Google Scholar] [CrossRef]

- Zdanowicz, M.; Wilpiszewska, K.; Spychaj, T. Deep eutectic solvents for polysaccharides processing. A review. Carbohydr. Polym. 2018, 200, 361–380. [Google Scholar] [CrossRef]

- Francisco, M.; van den Bruinhorst, A.; Zubeir, L.F.; Peters, C.J.; Kroon, M.C. A new low transition temperature mixture (LTTM) formed by choline chloride+lactic acid: Characterization as solvent for CO2 capture. Fluid Phase Equilib. 2013, 340, 77–84. [Google Scholar] [CrossRef]

- Zahn, S.; Kirchner, B.; Mollenhauer, D. Charge Spreading in Deep Eutectic Solvents. ChemPhysChem 2016, 17, 3354–3358. [Google Scholar] [CrossRef] [PubMed]

- Ashworth, C.R.; Matthews, R.P.; Welton, T.; Hunt, P.A. Doubly ionic hydrogen bond interactions within the choline chloride–urea deep eutectic solvent. Phys.Chem.Chem.Phys. 2016, 18, 18145–18160. [Google Scholar] [CrossRef] [Green Version]

- Stefanovic, R.; Ludwig, M.; Webber, G.B.; Atkin, R.; Page, A.J. Nanostructure, hydrogen bonding and rheology in choline chloride deep eutectic solvents as a function of the hydrogen bond donor. Phys. Chem. Chem. Phys. 2017, 19, 3297–3306. [Google Scholar] [CrossRef]

- Mano, F.; Aroso, I.M.; Barreiros, S.; Borges, J.P.; Reis, R.L.; Duarte, A.R.C.; Paiva, A. Production of poly(vinyl alcohol) (PVA) fibers with encapsulated natural deep eutectic solvent (NADES) using electrospinning. ACS Sustain. Chem. Eng. 2015, 3, 2504–2509. [Google Scholar] [CrossRef]

- Castro, V.I.B.; Mano, F.; Reis, R.L.; Paiva, A.; Duarte, A.R.C. Synthesis and Physical and Thermodynamic Properties of Lactic Acid and Malic Acid-Based Natural Deep Eutectic Solvents. J. Chem. Eng. Data 2018, 63, 2548–2556. [Google Scholar] [CrossRef]

- del Monte, F.; Carriazo, D.; Serrano, M.C.; Gutiérrez, M.C.; Ferrer, M.L. Deep eutectic solvents in polymerizations: A greener alternative to conventional syntheses. ChemSusChem 2014, 7, 999–1009. [Google Scholar] [CrossRef]

- Anastas, P.T.; Warner, J.C. Green chemistry: theory and practice. Oxford Univ. Press. New York 1998, 30. [Google Scholar]

- Choi, Y.H.; van Spronsen, J.; Dai, Y.; Verberne, M.; Hollmann, F.; Arends, I.W.C.E.; Witkamp, G.-J.; Verpoorte, R. Are Natural Deep Eutectic Solvents the Missing Link in Understanding Cellular Metabolism and Physiology? Plant Physiol. 2011, 156, 1701–1705. [Google Scholar] [CrossRef]

- Paiva, A.; Craveiro, R.; Aroso, I.; Martins, M.; Reis, R.L.; Duarte, A.R.C. Natural deep eutectic solvents-Solvents for the 21st century. ACS Sustain. Chem. Eng. 2014, 2, 1063–1071. [Google Scholar] [CrossRef]

- Vanda, H.; Dai, Y.; Wilson, E.G.; Verpoorte, R.; Choi, Y.H. Green solvents from ionic liquids and deep eutectic solvents to natural deep eutectic solvents. Comptes Rendus Chim. 2018, 21, 628–638. [Google Scholar] [CrossRef]

- García-Álvarez, J. Deep Eutectic Mixtures: Promising Sustainable Solvents for Metal-Catalysed and Metal-Mediated Organic Reactions. Eur. J. Inorg. Chem. 2015, 2015, 5147–5157. [Google Scholar] [CrossRef]

- Alonso, D.A.; Baeza, A.; Chinchilla, R.; Guillena, G.; Pastor, I.M.; Ramón, D.J. Deep Eutectic Solvents: The Organic Reaction Medium of the Century. European J. Org. Chem. 2016, 2016, 612–632. [Google Scholar] [CrossRef] [Green Version]

- Web of Science. Available online: https://apps.webofknowledge.com (accessed on 6 March 2019).

- Sapir, L.; Stanley, C.B.; Harries, D. Properties of Polyvinylpyrrolidone in a Deep Eutectic Solvent. J. Phys. Chem. A 2016, 120, 3253–3259. [Google Scholar] [CrossRef]

- Chen, Z.; Mcdonald, S.; Fitzgerald, P.; Warr, G.G.; Atkin, R. Small angle neutron scattering study of the conformation of poly(ethylene oxide) dissolved in deep eutectic solvents. J. Colloid Interface Sci. 2017, 506, 486–492. [Google Scholar] [CrossRef]

- Hammond, O.S.; Bowron, D.T.; Edler, K.J. Liquid structure of the choline chloride-urea deep eutectic solvent (reline) from neutron diffraction and atomistic modelling. Green Chem. 2016, 18, 2736–2744. [Google Scholar] [CrossRef] [Green Version]

- Stefanovic, R.; Webber, G.B.; Page, A.J. Polymer solvation in choline chloride deep eutectic solvents modulated by the hydrogen bond donor. J. Mol. Liq. 2019, 279, 584–593. [Google Scholar] [CrossRef]

- Hillman, A.R.; Ryder, K.S.; Ismail, H.K.; Unal, A.; Voorhaar, A. Fundamental aspects of electrochemically controlled wetting of nanoscale composite materials. Faraday Discuss. 2017, 199, 75–99. [Google Scholar] [CrossRef] [Green Version]

- Freire, M.G.; Cláudio, F.M.; Coutinho, J.A.P.; Marrucho, I.M.; Lopes, J.N.C.; Rebelo, L.P.N. Aqueous biphasic systems: A boost brought about by using ionic liquids. Chem. Soc. Rev. 2012, 41, 4966–4995. [Google Scholar] [CrossRef] [PubMed]

- Genies, E.M.; Tsintavis, C. Redox mechanism and electrochemical behayiour of polyaniline deposits. J. Electroanal. Chem. 1985, 195, 109–128. [Google Scholar] [CrossRef]

- Dhanalakshmi, K.; Saraswathi, R.; Srinivasan, C. Synthesis and electrochemical stability of polyaniline and polypyrrole in an ambient temperature acetamide-urea-ammonium nitrate eutectic melt. Synth. Met. 1996, 82, 237–243. [Google Scholar] [CrossRef]

- Liao, J.; Wu, P.; Bai, Y. Eutectic mixture of choline chloride/urea as a green solvent in synthesis of a coordination polymer: [Zn(O3PCH2CO2)]·NH4. Inorg. Chem. Commun. 2005, 8, 390–392. [Google Scholar] [CrossRef]

- Monnard, P.A.; Kanavarioti, A.; Deamer, D.W. Eutectic Phase Polymerization of Activated Ribonucleotide Mixtures Yields Quasi-Equimolar Incorporation of Purine and Pyrimidine Nucleobases. J. Am. Chem. Soc. 2003, 125, 13734–13740. [Google Scholar] [CrossRef]

- Mota-Morales, J.D.; Gutiérrez, M.C.; Sanchez, I.C.; Luna-Bárcenas, G.; del Monte, F. Frontal polymerizations carried out in deep-eutectic mixtures providing both the monomers and the polymerization medium. Chem. Commun. 2011, 47, 5328–5330. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Wang, Y.; Li, Y.; Lin, Y.; Zhang, H.; Zhou, Y. A novel poly(deep eutectic solvent)-based magnetic silica composite for solid-phase extraction of trypsin. Anal. Chim. Acta 2016, 946, 64–72. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Li, W.; Chen, Z. Solid phase microextraction with poly(deep eutectic solvent) monolithic column online coupled to HPLC for determination of non-steroidal anti-inflammatory drugs. Anal. Chim. Acta 2018, 1018, 111–118. [Google Scholar] [CrossRef]

- Wang, R.; Mao, Z.; Chen, Z. Monolithic column with polymeric deep eutectic solvent as stationary phase for capillary electrochromatography. J. Chromatogr. A 2018, 1577, 66–71. [Google Scholar] [CrossRef]

- Isik, M.; Zulfiqar, S.; Edhaim, F.; Ruipérez, F.; Rothenberger, A.; Mecerreyes, D. Sustainable Poly(ionic liquid)s for CO2 Capture based on Deep Eutectic Monomers. ACS Sustain. Chem. Eng. 2016, 4, 7200–7208. [Google Scholar] [CrossRef]

- Wei, X.; Wang, Y.; Chen, J.; Xu, P.; Xu, W.; Ni, R.; Meng, J.; Zhou, Y. Poly(deep eutectic solvent)-functionalized magnetic metal-organic framework composites coupled with solid-phase extraction for the selective separation of cationic dyes. Anal. Chim. Acta 2019, 1056, 47–61. [Google Scholar] [CrossRef]

- De Leon, A.; Advincula, R.C. Conducting Polymers with Superhydrophobic Effects as Anticorrosion Coating. In Intelligent Coatings for Corrosion Control; Tiwari, A., Rawlins, J., Hihara, L.H., Eds.; Elsevier: Woburn, UK, 2015; pp. 409–430. ISBN 9780124114678. [Google Scholar]

- Hillman, A.R.; Ryder, K.S.; Zaleski, C.J.; Fullarton, C.; Smith, E.L. Ion Transfer Mechanisms Accompanying p-doping of Poly(3,4-ethylenedioxythiophene) Films in Deep Eutectic Solvents. Z. Phys. Chem. 2012, 226, 1049–1068. [Google Scholar] [CrossRef]

- Prathish, K.P.; Carvalho, R.C.; Brett, C.M.A. Electrochemical characterisation of poly(3,4-ethylenedioxythiophene) film modified glassy carbon electrodes prepared in deep eutectic solvents for simultaneous sensing of biomarkers. Electrochim. Acta 2016, 187, 704–713. [Google Scholar] [CrossRef]

- Fernandes, P.M. V.; Campiña, J.M.; Pereira, C.M.; Silva, F. Electrosynthesis of Polyaniline from Choline-Based Deep Eutectic Solvents: Morphology, Stability and Electrochromism. J. Electrochem. Soc. 2012, 159, G97–G105. [Google Scholar] [CrossRef]

- Prathish, K.P.; Carvalho, R.C.; Brett, C.M.A. Highly sensitive poly(3,4-ethylenedioxythiophene) modified electrodes by electropolymerisation in deep eutectic solvents. Electrochem. Commun. 2014, 44, 8–11. [Google Scholar] [CrossRef] [Green Version]

- Zou, F.; Huang, X. Electropolymerization in proton-functionalized anilinium salts/glycol deep eutectic solvents. J. Mater. Sci. 2018, 53, 8132–8140. [Google Scholar] [CrossRef]

- Hosu, O.; Bârsan, M.M.; Cristea, C.; Săndulescu, R.; Brett, C.M.A. Nanostructured electropolymerized poly(methylene blue) films from deep eutectic solvents. Optimization and characterization. Electrochim. Acta 2017, 232, 285–295. [Google Scholar] [CrossRef]

- Hosu, O.; Barsan, M.M.; Cristea, C.; Robert, S.; Brett, C.M.A. Nanocomposites based on carbon nanotubes and redox-active polymers synthesized in a deep eutectic solvent as a new electrochemical sensing platform. Microchim. Acta 2017, 184, 3919–3927. [Google Scholar] [CrossRef]

- Bhat, G.; Kandagor, V. Synthetic polymer fibers and their processing requirements. In Advances in Filament Yarn Spinning of Textiles and Polymers; Zhang, D., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2014; pp. 3–30. ISBN 9780857099174. [Google Scholar]

- Carriazo, D.; Serrano, M.C.; Gutiérrez, M.C.; Ferrer, M.L.; del Monte, F. Deep-eutectic solvents playing multiple roles in the synthesis of polymers and related materials. Chem. Soc. Rev. 2012, 41, 4996–5014. [Google Scholar] [CrossRef]

- Patiño, J.; Gutiérrez, M.C.; Carriazo, D.; Ania, C.O.; Fierro, J.L.G.; Ferrer, M.L.; del Monte, F. DES assisted synthesis of hierarchical nitrogen-doped carbon molecular sieves for selective CO2 versus N2 adsorption. J. Mater. Chem. A 2014, 2, 8719–8729. [Google Scholar] [CrossRef]

- Chen, L.; Deng, J.; Hong, S.; Lian, H. Deep eutectic solvents-assisted cost-effective synthesis of nitrogen-doped hierarchical porous carbon xerogels from phenol-formaldehyde by two-stage polymerization. J. Sol-Gel Sci. Technol. 2018, 86, 795–806. [Google Scholar] [CrossRef]

- López-Salas, N.; Carriazo, D.; Gutiérrez, M.C.; Ferrer, M.L.; Ania, C.O.; Rubio, F.; Tamayo, A.; Fierro, J.L.G.; del Monte, F. Tailoring the textural properties of hierarchical porous carbons using deep eutectic solvents. J. Mater. Chem. A 2016, 4, 9146–9159. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Wang, Y.; Wei, X.; Chen, J.; Xu, P.; Ni, R.; Meng, J. Fabrication of magnetic polymers based on deep eutectic solvent for separation of bovine hemoglobin via molecular imprinting technology. Anal. Chim. Acta 2019, 1048, 1–11. [Google Scholar] [CrossRef]

- Viveiros, R.; Rebocho, S.; Casimiro, T. Green Strategies for Molecularly Imprinted Polymer Development. Polymers 2018, 10, 306. [Google Scholar] [CrossRef]

- Liang, S.; Yan, H.; Cao, J.; Han, Y.; Shen, S.; Bai, L. Molecularly imprinted phloroglucinol–formaldehyde–melamine resin prepared in a deep eutectic solvent for selective recognition of clorprenaline and bambuterol in urine. Anal. Chim. Acta 2016, 951, 68–77. [Google Scholar] [CrossRef]

- Liu, X.-L.; He, W.; Huang, Y.-P.; Yao, H.-F.; Liu, Z.-S.; Chai, M.-H. Green Synthesis of Carbon Nanotubes-Reinforced Molecularly Imprinted Polymer Composites for Drug Delivery of Fenbufen. AAPS PharmSciTech 2018, 19, 3895–3906. [Google Scholar] [CrossRef]

- Li, X.; Row, K.H. Purification of antibiotics from the millet extract using hybrid molecularly imprinted polymers based on deep eutectic solvents. RSC Adv. 2017, 7, 16997–17004. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Wang, W.; Wang, Q.; Zhu, T. Deep Eutectic Solvents Modified Molecular Imprinted Polymers for Optimized Purification of Chlorogenic Acid from Honeysuckle. J. Chromatogr. Sci. 2016, 54, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Ahn, W.S.; Row, K.H. Hybrid molecularly imprinted polymers modified by deep eutectic solvents and ionic liquids with three templates for the rapid simultaneous purification of rutin, scoparone, and quercetin from Herba Artemisiae Scopariae. J. Sep. Sci. 2016, 39, 4465–4473. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Wang, X.; Row, K.H. Magnetic Solid-phase extraction with Fe3O4/Molecularly Imprinted Polymers Modified by Deep Eutectic Solvents and Ionic Liquids for the Rapid Purification of Alkaloid Isomers (Theobromine and Theophylline) from Green Tea. Molecules 2017, 22, 1061. [Google Scholar] [CrossRef]

- Li, G.; Dai, Y.; Wang, X.; Row, K. Molecularly Imprinted Polymers Modified by Deep Eutectic Solvents and Ionic Liquids with Two Templates for the Simultaneous Solid-Phase Extraction of Fucoidan and Laminarin from Marine Kelp. Anal. Lett. 2018, 2719, 1–15. [Google Scholar] [CrossRef]

- Li, G.; Zhu, T.; Row, K.H. Deep eutectic solvents for the purification of chloromycetin and thiamphenicol from milk. J. Sep. Sci. 2017, 40, 625–634. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Row, K.H. Application of Deep Eutectic Solvents in Hybrid Molecularly Imprinted Polymers and Mesoporous Siliceous Material for Solid-Phase Extraction of Levofloxacin from Green Bean Extract. Anal. Sci. 2017, 33, 611–617. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, G.; Row, K.H. Magnetic hybrid imprinted polymers with three-templates modified by DESs for the rapid purification of monosaccharide from seaweed. J. Liq. Chromatogr. Relat. Technol. 2017, 40, 1037–1046. [Google Scholar] [CrossRef]

- Li, G.; Row, K.H. Magnetic molecularly imprinted polymers for recognition and enrichment of polysaccharides from seaweed. J. Sep. Sci. 2017, 40, 4765–4772. [Google Scholar] [CrossRef]

- Li, G.; Wang, X.; Row, K.H. Magnetic molecularly imprinted polymers based on silica modified by deep eutectic solvents for the rapid simultaneous magnetic-based solid-phase extraction of Salvia miltiorrhiza bunge, Glycine max (Linn.) Merr and green tea. Electrophoresis 2018, 39, 1111–1118. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Gao, F.; Duan, Y.; Zhu, T.; Ho Row, K. Exploration of deep eutectic solvent-based molecularly imprinted polymers as solid-phase extraction sorbents for screening chloramphenicol in milk. J. Chromatogr. Sci. 2017, 55, 654–661. [Google Scholar] [CrossRef] [PubMed]

- Meng, J.; Wang, X. Microextraction by Packed Molecularly Imprinted Polymer Combined Ultra-High-Performance Liquid Chromatography for the Determination of Levofloxacin in Human Plasma. J. Chem. 2019, 2019, 1–9. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Dai, Q.; Zhou, Y. Magnetic deep eutectic solvents molecularly imprinted polymers for the selective recognition and separation of protein. Anal. Chim. Acta 2016, 936, 168–178. [Google Scholar] [CrossRef]

- Li, X.; Row, K.H. Application of novel ternary deep eutectic solvents as a functional monomer in molecularly imprinted polymers for purification of levofloxacin. J. Chromatogr. B 2017, 1068–1069, 56–63. [Google Scholar] [CrossRef]

- Xu, K.; Wang, Y.; Wei, X.; Chen, J.; Xu, P.; Zhou, Y. Preparation of magnetic molecularly imprinted polymers based on a deep eutectic solvent as the functional monomer for specific recognition of lysozyme. Microchim. Acta 2018, 185. [Google Scholar] [CrossRef]

- Li, G.; Row, K.H. Selective extraction of 3,4-dihydroxybenzoic acid in Ilex chinensis Sims by meticulous mini-solid-phase microextraction using ternary deep eutectic solvent-based molecularly imprinted polymers. Anal. Bioanal. Chem. 2018, 410, 7849–7858. [Google Scholar] [CrossRef]

- Li, G.; Row, K.H. Ternary deep eutectic solvent magnetic molecularly imprinted polymers for the dispersive magnetic solid-phase microextraction of green tea. J. Sep. Sci. 2018, 41, 3424–3431. [Google Scholar] [CrossRef]

- Fu, N.; Li, L.; Liu, X.; Fu, N.; Zhang, C.; Hu, L. Specific recognition of polyphenols by molecularly imprinted polymers based on a ternary deep eutectic solvent. J. Chromatogr. A 2017, 1530, 23–34. [Google Scholar] [CrossRef]

- Ma, W.; Dai, Y.; Row, K.H. Molecular imprinted polymers based on magnetic chitosan with different deep eutectic solvent monomers for the selective separation of catechins in black tea. Electrophoresis 2018, 39, 2039–2046. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, H.; Huang, Q.; Liu, X.; Zhang, H. Isolation of transferrin by imprinted nanoparticles with magnetic deep eutectic solvents as monomer. Anal. Bioanal. Chem. 2018, 410, 6237–6245. [Google Scholar] [CrossRef]

- Fu, N.; Li, L.; Liu, K.; Kim, C.K.; Li, J.; Zhu, T.; Li, J.; Tang, B. A choline chloride-acrylic acid deep eutectic solvent polymer based on Fe3O4 particles and MoS2 sheets (poly(ChCl-AA DES)@Fe3O4@MoS2) with specific recognition and good antibacterial properties for β-lactoglobulin in milk. Talanta 2019, 197, 567–577. [Google Scholar] [CrossRef]

- Ma, W.; Tang, B.; Row, K.H. Exploration of a ternary deep eutectic solvent of methyltriphenylphosphonium bromide/chalcone/formic acid for the selective recognition of rutin and quercetin in Herba Artemisiae Scopariae. J. Sep. Sci. 2017, 40, 3248–3256. [Google Scholar] [CrossRef]

- Mota-Morales, J.D.; Sánchez-Leija, R.J.; Carranza, A.; Pojman, J.A.; del Monte, F.; Luna-Bárcenas, G. Free-radical polymerizations of and in deep eutectic solvents: Green synthesis of functional materials. Prog. Polym. Sci. 2018, 78, 139–153. [Google Scholar] [CrossRef]

- Ferreira, V.R.A.; Azenha, M.A.; Pinto, A.C.; Santos, P.R.M.; Pereira, C.M.; Silva, A.F. Development of mesoporous polysaccharide/sol-gel composites with two different templating agents: Surfactants and choline chloride-based deep eutectic solvents. Express Polym. Lett. 2019, 13, 261–275. [Google Scholar] [CrossRef]

- Maximiano, P.; Mendonça, P. V.; Santos, M.R.E.; Costa, J.R.C.; Guliashvili, T.; Serra, A.C.; Coelho, J.F.J. Eutectic mixtures as a green alternative for efficient catalyst recycling in atom transfer radical polymerizations. J. Polym. Sci. Part A Polym. Chem. 2017, 55, 371–381. [Google Scholar] [CrossRef]

- Wang, J.; He, D.; Peng, H.; Khan, M.Y.; Chen, D.; Han, J.; Xie, X.; Xue, Z. Deep eutectic solvents for green and efficient iron-mediated ligand-free atom transfer radical polymerization. Polym. Chem. 2017, 8, 1616–1627. [Google Scholar] [CrossRef]

- Mendonça, P. V.; Lima, M.S.; Guliashvili, T.; Serra, A.C.; Coelho, J.F.J. Deep eutectic solvents (DES): Excellent green solvents for rapid SARA ATRP of biorelevant hydrophilic monomers at ambient temperature. Polymer 2017, 132, 114–121. [Google Scholar] [CrossRef]

- Li, X.-X.; Zhang, L.-S.; Wang, C.; Huang, Y.-P.; Liu, Z.-S. Green synthesis of monolithic column incorporated with graphene oxide using room temperature ionic liquid and eutectic solvents for capillary electrochromatography. Talanta 2018, 178, 763–771. [Google Scholar] [CrossRef]

- Zhou, X.-J.; Zhang, L.-S.; Song, W.-F.; Huang, Y.-P.; Liu, Z.-S. A polymer monolith incorporating stellate mesoporous silica nanospheres for use in capillary electrochromatography and solid phase microextraction of polycyclic aromatic hydrocarbons and organic small molecules. Microchim. Acta 2018, 185, 1–10. [Google Scholar] [CrossRef]

- Park, T.-J.; Lee, S.H. Deep eutectic solvent systems for FeCl3-catalyzed oxidative polymerization of 3-octylthiophene. Green Chem. 2017, 19, 910–913. [Google Scholar] [CrossRef]

- Xiong, W.; Wang, Y.; Liu, Q.; Yao, Y.; Xiong, L. Two lanthanide coordination polymers with helical chain structures synthesized ionothermally from a deep-eutectic solvent: Syntheses, structures and luminescence. Inorg. Chem. Commun. 2014, 46, 282–284. [Google Scholar] [CrossRef]

- Xiong, W.; Liu, Q.; Liu, C.; Wang, Y. Slow magnetization relaxation in a one-dimensional dysprosium-carboxylate compound based on the linear Dy4 units synthesized ionothermally from a deep-eutectic solvent. Inorg. Chem. Commun. 2014, 48, 18–21. [Google Scholar] [CrossRef]

- Meng, Y.; Chen, Y.; Zhang, Z.; Lin, Z.; Tong, M. Gadolinium Oxalate Derivatives with Enhanced Magnetocaloric Effect via Ionothermal Synthesis. Inorg. Chem. 2014, 53, 9052–9057. [Google Scholar] [CrossRef]

- Sousa, A.M.M.; Souza, H.K.S.; Latona, N.; Liu, C.; Gonc, M.P. Choline chloride based ionic liquid analogues as tool for the fabrication of agar films with improved mechanical properties. Carbohydr. Polym. 2014, 111, 206–214. [Google Scholar] [CrossRef]

- Sousa, A.M.M.; Souza, H.K.S.; Uknalis, J.; Liu, S.; Gonc, M.P. Improving agar electrospinnability with choline-based deep eutectic solvents. Int. J. Biol. Macromol. 2015, 80, 139–148. [Google Scholar] [CrossRef]

- Orelma, H.; Virtanen, T.; Spoljaric, S.; Lehmonen, J.; Seppa, J.; Rojas, O.J.; Harlin, A. Cyclodextrin-Functionalized Fiber Yarns Spun from Deep Eutectic Cellulose Solutions for Nonspecific Hormone Capture in Aqueous Matrices. Biomacromolecules 2018, 19, 652–661. [Google Scholar] [CrossRef]

- Lin, K.; Ma, R.; Wang, P.; Xin, J.; Zhang, J.; Wolcott, M.P.; Zhang, X. Deep Eutectic Solvent Assisted Facile Synthesis of Lignin-Based Cryogel. Macromolecules 2019, 52, 227–235. [Google Scholar] [CrossRef]

- Willberg-Keyriläinen, P.; Hiltunen, J.; Ropponen, J. Production of cellulose carbamate using urea-based deep eutectic solvents. Cellulose 2018, 25, 195–204. [Google Scholar] [CrossRef]

- Sánchez-condado, A.; Carriedo, G.A.; Soto, A.P.; Rodríguez-Álvarez, M.J.; García-Álvarez, J.; Hevia, E. Organolithium Initiated Polymerization of Olefins in Deep Eutectic Solvents under Aerobic Conditions. Sustainable Route to Homopolymers, Random Copolymers and Block Copolymers. ChemSusChem 2019. [Google Scholar] [CrossRef]

- Loow, Y.L.; New, E.K.; Yang, G.H.; Ang, L.Y.; Foo, L.Y.W.; Wu, T.Y. Potential use of deep eutectic solvents to facilitate lignocellulosic biomass utilization and conversion. Cellulose 2017, 24, 3591–3618. [Google Scholar] [CrossRef]

- Tang, X.; Zuo, M.; Li, Z.; Liu, H.; Xiong, C.; Zeng, X.; Sun, Y.; Hu, L.; Liu, S.; Lei, T.; et al. Green Processing of Lignocellulosic Biomass and Its Derivatives in Deep Eutectic Solvents. ChemSusChem 2017, 10, 2695. [Google Scholar] [CrossRef]

- Van Osch, D.J.G.P.; Kollau, L.J.B.M.; Van Den Bruinhorst, A.; Asikainen, S.; Rocha, M.A.A.; Kroon, M.C. Ionic liquids and deep eutectic solvents for lignocellulosic biomass fractionation. Phys. Chem. Chem. Phys. 2017, 19, 2636–2665. [Google Scholar] [CrossRef]

- Saravana, P.S.; Ho, T.C.; Chae, S.-J.; Cho, Y.-J.; Park, J.-S.; Lee, H.-J.; Chun, B.-S. Deep eutectic solvent-based extraction and fabrication of chitin films from crustacean waste. Carbohydr. Polym. 2018, 195, 622–630. [Google Scholar] [CrossRef]

- Bai, C.; Wei, Q.; Ren, X. Selective Extraction of Collagen Peptides with High Purity from Cod Skins by Deep Eutectic Solvents. ACS Sustain. Chem. Eng. 2017, 5, 7220–7227. [Google Scholar] [CrossRef]

- Mamilla, J.L.K.; Novak, U.; Grilc, M.; Likozar, B. Natural deep eutectic solvents (DES) for fractionation of waste lignocellulosic biomass and its cascade conversion to value-added bio-based chemicals. Biomass Bioenergy 2019, 120, 417–425. [Google Scholar] [CrossRef]

- Melro, E.; Alves, L.; Antunes, F.E.; Medronho, B. A brief overview on lignin dissolution. J. Mol. Liq. 2018, 265, 578–584. [Google Scholar] [CrossRef]

- Duan, B.; Huang, Y.; Lu, A.; Zhang, L. Recent advances in chitin based materials constructed via physical methods. Prog. Polym. Sci. 2018, 82, 1–33. [Google Scholar] [CrossRef]

- Wang, D.; Tang, R. Dissolution of wool in the choline chloride/oxalic acid deep eutectic solvent. Mater. Lett. 2018, 231, 217–220. [Google Scholar] [CrossRef]

- Wang, D.; Yang, X.H.; Tang, R.C.; Yao, F. Extraction of Keratin from Rabbit Hair by a Deep Eutectic Solvent and its Characterization. Polymers 2018, 10, 993. [Google Scholar] [CrossRef]

- Huang, W.C.; Zhao, D.; Guo, N.; Xue, C.; Mao, X. Green and Facile Production of Chitin from Crustacean Shells Using a Natural Deep Eutectic Solvent. J. Agric. Food Chem. 2018, 66, 11897–11901. [Google Scholar] [CrossRef]

- Esmaeili, M.; Anugwom, I.; Mänttäri, M.; Kallioinen, M. Utilization of DES-Lignin as a Bio-Based Hydrophilicity Promoter in the Fabrication of Antioxidant Polyethersulfone Membranes. Membranes 2018, 8, 80. [Google Scholar] [CrossRef]

- Wang, X.; Li, G.; Ho Row, K. Extraction and Determination of Quercetin from Ginkgo biloba by DESs-Based Polymer Monolithic Cartridge. J. Chromatogr. Sci. 2017, 55, 866–871. [Google Scholar] [CrossRef]

- Gan, K.; Tang, W.; Zhu, T.; Li, W.; Wang, H.; Liu, X. Enhanced extraction of cleistanthol from Phyllanthus flexuosus by deep eutectic solvent-modified anion-exchange resin. J. Liq. Chromatogr. Relat. Technol. 2016, 39, 882–888. [Google Scholar] [CrossRef]

- Li, X.; Row, K.H. Separation of Polysaccharides by SEC Utilizing Deep Eutectic Solvent Modified Mesoporous Siliceous Materials. Chromatographia 2017, 80, 1–9. [Google Scholar] [CrossRef]

- Bangde, P.S.; Jain, R.D.; Dandekar, P. Alternative approach to synthesize methylated chitosan using deep eutectic solvents, biocatalyst and ‘green’ methylating agents. ACS Sustain. Chem. Eng. 2016, 4, 3552–3557. [Google Scholar] [CrossRef]

- Feng, M.; Lu, X.; Zhang, J.; Li, Y.; Shi, C.; Lu, L.; Zhang, S. Direct conversion of shrimp shells to O-acylated chitin with antibacterial and anti-tumor effects by natural deep eutectic solvents. Green Chem. 2019, 21, 87–98. [Google Scholar] [CrossRef]

- Abbott, A.P.; Bell, T.J.; Handa, S.; Stoddart, B. Cationic functionalisation of cellulose using a choline based ionic liquid analogue. Green Chem. 2006, 8, 784–786. [Google Scholar] [CrossRef]

- Vuoti, S.; Narasimha, K.; Reinikainen, K. Green wastewater treatment flocculants and fixatives prepared from cellulose using high-consistency processing and deep eutectic solvents. J. Water Process Eng. 2018, 26, 83–91. [Google Scholar] [CrossRef]

- Wong, C.Y.; Wong, W.Y.; Loh, K.S.; Mohamad, A.B. Study of the plasticising effect on polymer and its development in fuel cell application. Renew. Sustain. Energy Rev. 2017, 79, 794–805. [Google Scholar] [CrossRef]

- Sirviö, J.A.; Visanko, M.; Ukkola, J.; Liimatainen, H. Effect of plasticizers on the mechanical and thermomechanical properties of cellulose-based biocomposite films. Ind. Crop. Prod. 2018, 122, 513–521. [Google Scholar] [CrossRef]

- Wong, W.Y.; Wong, C.Y.; Rashmi, W.; Khalid, M. Choline Chloride:Urea-Based Deep Eutectic Solvent As Additive To Proton Conducting Chitosan Films. J. Eng. Sci. Technol. 2018, 13, 2995–3006. [Google Scholar]

- Galvis-Sanchéz, A.C.; Castro, M.C.R.; Biernacki, K.; Gonçalves, M.P.; Biernacki, K.; Souza, H.K.S. Natural deep eutectic solvents as green plasticizers for chitosan thermoplastic production with controlled/desired mechanical and barrier properties. Food Hydrocoll. 2018, 82, 478–489. [Google Scholar] [CrossRef]

- Sokolova, M.P.; Smirnov, M.A.; Samarov, A.A.; Bobrova, N. V; Vorobiov, V.K.; Popova, E.N.; Filippova, E.; Geydt, P.; Lahderanta, E.; Toikka, A.M. Plasticizing of chitosan films with deep eutectic mixture of malonic acid and choline chloride. Carbohydr. Polym. 2018, 197, 548–557. [Google Scholar] [CrossRef]

- Abbott, A.P.; Abolibda, T.Z.; Qu, W.; Wise, W.R.; Wright, L.A. Thermoplastic starch-polyethylene blends homogenised using deep eutectic solvents. RSC Adv. 2017, 7, 7268–7273. [Google Scholar] [CrossRef]

- Martins, M.; Aroso, I.M.; Reis, R.L.; Duarte, A.R.C.; Craveiro, R.; Paiva, A. Enhanced performance of supercritical fluid foaming of natural-based polymers by deep eutectic solvents. AIChE J. 2014, 60, 3701–3706. [Google Scholar] [CrossRef] [Green Version]

- Shafie, H.M.; Samsudin, D.; Yusof, R.; Gan, C.-Y. Characterization of bio-based plastic made from a mixture of Momordica charantia bioactive polysaccharide and choline chloride/glycerol based deep eutectic solvent. Int. J. Biol. Macromol. 2018, 118, 1183–1192. [Google Scholar] [CrossRef]

- Zdanowicz, M.; Spychaj, T.; Honorata, M. Imidazole-based deep eutectic solvents for starch dissolution and plasticization. Carbohydr. Polym. 2016, 140, 416–423. [Google Scholar] [CrossRef]

- Adamus, J.; Spychaj, T.; Zdanowicz, M.; Jędrzejewski, R.; Roman, J. Thermoplastic starch with deep eutectic solvents and montmorillonite as a base for composite materials. Ind. Crop. Prod. 2018, 123, 278–284. [Google Scholar] [CrossRef]

- Almeida, M.R.; Magalh, J.M.C.S.; Química, D.D.E.; Engenharia, F. De; Porto, U.; Frias, R.R. The role of choline chloride-based deep eutectic solvent and curcumin on chitosan fi lms properties. Food Hydrocoll. 2018, 81, 456–466. [Google Scholar] [CrossRef]

- Wong, C.Y.; Wong, W.Y.; Walvekar, R.; Loh, K.S.; Khalid, M.; Lim, K.L. Effect of deep eutectic solvent in proton conduction and thermal behaviour of chitosan-based membrane. J. Mol. Liq. 2018, 269, 675–683. [Google Scholar] [CrossRef]

- Tan, X.; Zhao, W.; Mu, T. Controllable exfoliation of natural silk fibers into nanofibrils by protein denaturant deep eutectic solvent: Nanofibrous strategy for multifunctional membranes. Green Chem. 2018, 20, 3625–3633. [Google Scholar] [CrossRef]

- Lian, H.; Hong, S.; Carranza, A.; Mota-Morales, J.D.; Pojman, J.A. Processing of lignin in urea–zinc chloride deep-eutectic solvent and its use as a filler in a phenol-formaldehyde resin. RSC Adv. 2015, 5, 28778–28785. [Google Scholar] [CrossRef]

- Jordan, T.; Yu, Z.L.; Yu, S.H.; Antonietti, M.; Fechler, N. Porous nitrogen-doped carbon monoliths derived from biopolymer-structured liquid precursors. Microporous Mesoporous Mater. 2018, 255, 53–60. [Google Scholar] [CrossRef]

- Duarte, A.R.C.; Ferreira, A.S.D.; Barreiros, S.; Cabrita, E.; Reis, R.L.; Paiva, A. A comparison between pure active pharmaceutical ingredients and therapeutic deep eutectic solvents: Solubility and permeability studies. Eur. J. Pharm. Biopharm. 2017, 114, 296–304. [Google Scholar] [CrossRef] [Green Version]

- Santos, F.; PS Leitão, M.; C Duarte, A. Properties of Therapeutic Deep Eutectic Solvents of L-Arginine and Ethambutol for Tuberculosis Treatment. Molecules 2018, 24, 55. [Google Scholar] [CrossRef]

- Tuntarawongsa, S.; Phaechamud, T. Polymeric Eutectic System. Adv. Mater. Res. 2012, 528, 180–183. [Google Scholar] [CrossRef]

- Tuntarawongsa, S.; Phaechamud, T. Polymeric Eutectic Drug Delivery System. J. Met. Mater. Miner. 2012, 22, 27–32. [Google Scholar]

- Aroso, I.M.; Craveiro, R.; Rocha, Â.; Dionísio, M.; Barreiros, S.; Reis, R.L.; Paiva, A.; Duarte, A.R.C. Design of controlled release systems for THEDES—Therapeutic deep eutectic solvents, using supercritical fluid technology. Int. J. Pharm. 2015, 492, 73–79. [Google Scholar] [CrossRef] [Green Version]

- Mano, F.; Martins, M.; Sá-nogueira, I.; Barreiros, S.; Borges, J.P.; Reis, R.L.; Duarte, A.R.C.; Paiva, A. Production of Electrospun Fast-Dissolving Drug Delivery Systems with Therapeutic Eutectic Systems Encapsulated in Gelatin. AAPS PharmSciTech 2017, 18, 2579–2585. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.; Zhang, Y.; Chen, S.N.; Friesen, J.B.; Nikolić, D.; Choules, M.P.; McAlpine, J.B.; Lankin, D.C.; Gemeinhart, R.A.; Pauli, G.F. The influence of natural deep eutectic solvents on bioactive natural products: Studying interactions between a hydrogel model and Schisandra chinensis metabolites. Fitoterapia 2018, 127, 212–219. [Google Scholar] [CrossRef]

- Silva, J.M.; Akkache, S.; Araújo, A.C.; Masmoudi, Y.; Reis, R.L.; Badens, E.; Duarte, A.R.C. Development of innovative medical devices by dispersing fatty acid eutectic blend on gauzes using supercritical particle generation processes. Mater. Sci. Eng. C 2019, 99, 599–610. [Google Scholar] [CrossRef]

- Qin, H.; Owyeung, R.E.; Sonkusale, S.R.; Panzer, M.J. Highly stretchable and nonvolatile gelatin-supported deep eutectic solvent gel electrolyte-based ionic skins for strain and pressure sensing. J. Mater. Chem. C 2019, 7, 601–608. [Google Scholar] [CrossRef]

| DES (molar ratio) | Function | Polymer synthesized | Application | Ref. |

|---|---|---|---|---|

| ChCl:ethylene glycol 1:2 ChCl:urea 1:2 ChCl:glycerol 1:2 | Solvent Electro-modifier | Polyaniline | Electrochromic devices, supercapacitors | [38] |

| ChCl:ethylene glycol 1:2 ChCl:urea 1:2 ChCl:glycerol 1:2 | Solvent Influence in PEDOT properties | Poly(3,4-ethylenedioxythiophene) (PEDOT) | Sensing of biomarkers | [37,39] |

| ChCl:ethylene glycol 1:2 | Solvent | Poly(methylene blue) | Electrochemical sensors biomarkers | [41,42] |

| Proton-functionalized anilinium hydrochloride ([HANI]Cl) or anilinium nitrate ([HANI]NO3) with glycol 1:10 | Solvent | Polyaniline | Capacitors | [40] |

| DES (molar ratio) | Function | Application | Description | Ref. |

|---|---|---|---|---|

| ChCl:glycerol 1:2 | MIPs modifier: interaction with a functional monomer | Selective recognition and separation of chlorogenic acid from honeysuckle | DES-MIPs are more rigid, preventing shrinking or swelling; DES-MIP showed higher adsorption capacity than MIP | [53] |

| ChCl:methacrylic acid 1:2 | Functional monomer for polymerization | Selective recognition and separation of bovine hemoglobin (BHb) protein | DES-MIPs showed a much higher adsorption capacity, rapid binding kinetics, and high imprinting factor for the BHb, compared with the magnetic DES-NIPs (NIP = nonimprinted polymers); Magnetic DES-MIPs presented highly recognition, specificity and selectivity | [64] |

| ChCl:ethylene glycol 1:3 ChCl:glycerol 1:3, 1:2, 1:4, 1:6 ChCl:1,4-butanediol 1:3 | MIPs modifier: interaction with a functional monomer | Selective recognition and extraction of rutin, scoparone, and quercetin from Herba Artemisiae Scopariae | DES-MIPs of ChCl:glycerol 1:3 showed the best results, in comparison to other DES and MIPs | [54] |

| ChCl:ethylene glycol 1:2 | Solvent | Recognition of clorprenaline and bambuterol in urine | The polymeric resins prepared in DES had higher adsorption capacity than the ones prepared in alcoholic solvents; 100% DES used as a polymerization solvent | [50] |

| ChCl:glycerol 1:2 | MIPs modifier: interaction with a functional monomer | Purification of chloromycetin and thiamphenicol from milk | Higher extraction recoveries for DES-MIPs, than for MIPs and NIPs | [57] |

| ChCl:ethylene glycol 1:1 ChCl:glycerol 1:1 ChCl:propylene glycol 1:1 | MIPs modifier: interaction with a functional monomer | Screening chloramphenicol in milk | Adsorption capacity of DES-MIPs better than MIPs; ChCl:EG-based DES-MIPs had the best adsorption ability and higher recoveries than MIPs and C18 | [62] |

| Betain:ethylene glycol:water 1:2:1 | MIPs modifier: interaction with a functional monomer | Adsorption of levoflaxacin or tetracycline from a millet extraction with a mixture of other antibiotics | The DES-MIPs showed better efficiency in recognition and specific adsorption than MIPs | [52] |

| Betaine:ethylene glycol:water 1:2:1 | MIPs modifier: interaction with a copolymer | Recovery of levofloxacin from green bean extract, through SPE | DES-MIPs showed better adsorption capacity and higher recoveries of levofloxacin than MIPs, NIPs, Mesoporous Siliceous Material (MSM), DES-MSM, and C18 | [58] |

| ChCl:ethylene glycol 1:2 ChCl:glycerol 1:2 ChCl:1,4-butanediol 1:2 ChCl:formic acid 1:2 ChCl:acetic acid 1:2 ChCl:propionic acid 1:2 ChCl:urea 1:2 | MIPs modifier: interaction with a functional monomer | Purification of alkaloid isomers (theobromine and theophylline) from green tea | DES-MIPs of ChCl-urea 1:2 showed the best results, in comparison to other DES and ionic liquid modified-MIPs | [55] |

| Formic acid: methylltriphenylphosphonium bromide: chalcone (FA:Mtpp:Chal) 1:0.5:0.04, 1:0.5:0.05, 1:0.5:0.06, | Functional monomer and dummy template | Selective recognition of rutin and quercetin from molecular mixtures | 1:0.5:0.05-based DES-MIP had the best adsorption capacity | [73] |

| Caffeic acid: ChCl:Formic acid (CA:ChCl:FA) 1:3:1.5, 1:4:2, 1:6:3 | Functional monomer for polymerization | Adsorption of levofloxacin from millet extract | DES-MIPs of 1:3:1.5 CA:ChCl:FA more selective for detection and purification of levofloxacin | [65] |

| ChCl:ethylene glycol 1:3 ChCl:glycerol 1:3 ChCl:1,4-butanediol 1:3 ChCl:urea 1:3 ChCl:formic acid 1:3 ChCl:acetic acid 1:3 ChCl:propionic acid 1:2 | MIPs modifier | Recognition of fucoidan and alginic acid from seaweed by magnetic solid-phase extraction | Best recovery using the ChCl:urea based DESs-magnetic MIPs The best DESs-magnetic MIPs was better than the respective MIPs and NIPs | [60] |

| ChCl: caffeic acid:ethylene glycol 1:0.1:1, 1:0.2: 1, 1: 0.3:1, 1:0.4:1 | Template and functional monomer | Recognition of polyphenols | 1:0.4:1-based DES-MIPs had the best adsorption capacity; DES-MIPs had better specific recognition and larger adsorption abilities than NIP, C18, and C8; Recognition of CA from polyphenol mixtures and in a real sample | [69] |

| ChCl:ethylene glycol 1:2 ChCl:glycerol 1:2 ChCl:1,4-butanediol 1:2 ChCl:urea 1:2 ChCl:formic acid 1:2 ChCl:acetic acid 1:2 ChCl:propionic acid 1:2 | MIPs modifier | Purification of D-(+)-galactose, L-(−)-fucose, and D-(+)-mannose from seaweed, though SPE | Best recovery for the ChCl:urea-based DESs-Fe3O4@hybridMIPs; The best DESs-Fe3O4@HMIPs system was better than the respective Fe3O4@HMIPs, DES-HMIPs, and DES-NIPs | [59] |

| Allyltriethylammonium Chloride ([ATEAm]Cl):glycerol 1:1 | Functional monomer for polymerization | Adsorption of lysozyme | DES-MIPs showed a good adsorption capacity, with a higher imprinting factor and higher specificity than other MIPs for lysozyme purification; 4 times recyclable | [66] |

| ChCl:urea 1:2 ChCl:ethylene glycol 1:2 ChCl:1,4-butanediol 1:2 ChCl:glycerol 1:2 | MIPs modifier | Extraction of tanshinone I, IIA, and cryptotanshinone from Salvia miltiorrhiza bunge; glycitein, genistein, and daidzein from Glycine max (Linn.) Merr; and epicatechin, epigallocatechin gallate, and epicatechin gallate from green tea | Multiple template DES-MIPs reduced the experimental steps; The DES-MIPs tested were better than NIPs and MIPs, except for the ChCl-urea-based DES-MIP; Best extraction recoveries for ChCl-glycerol-based DES-MIP; DES-MIPs can be reused | [61] |

| ChCl:methacrylic acid (MAA) 1:2 Betaine/MAA/H2O 1:2:1 | Functional monomer | Separation of (+)-catechin, (−)-epicatechin, and (−)-epigallocatechin gallate from black tea | Higher recoveries with DES-MIPs than MAA-MIPs or NIPs; The ChCl-MAA bases DES-MIP had slightly better results | [70] |

| ChCl:oxalic acid:ethylene glycol 1:1:1, 1:1:2, 1:1:3 ChCl:oxalic acid:glycerol 1:1:3 ChCl:oxalic acid:propylene glycol 1:1:1 ChCl:caffeic acid:ethylene glycol 1:1:1 | Functional monomer | Selective recognition and separation of theophylline, theobromine, (+)-catechin hydrate, and caffeic acid from green tea | The ChCl:OA:PG based DES-MIPs has the best recovery results and was better than the respective DES-NIP, MIP, NIP, and MIPs made from conventional monomers (MAA and AM) | [68] |

| ChCl:acrylic acid 1:2 | Additive functional monomer | Isolation of transferrin from human serum | Selective adsorption over protein mixtures | [71] |

| ChCl:formic acid 1:2 ChCl:acetic acid 1:2 ChCl:propionic acid 1:2 ChCl:urea 1:2 | MIPs modifier: interaction with a functional monomer | Selective recognition and separation of Fucoidan and Laminarin | DES used for modification of MIPs by interaction with the functional monomer; DES-MIPs of ChCl-urea 1:2 showed the best results, in comparison to other DES, ionic liquid modified-MIPs and nonmodified MIPs | [56] |

| ChCl:DHBA:EG 1:1:1, 1:1:2, 1:1:3 | Template and functional monomer | Extraction of 3,4-dihydroxybenzoic acid (DHBA) | DES-MIPs showed higher recoveries than MIPs, NIPs, and the corresponding DES-NIPs; 1:1:2 ChCl:DHBA:EG-based DES-MIPs showed the highest recoveries of 3,4-DHBA and better adsorption capacity, imprinted factor, and selectivity than the conventional functional monomer 4-vinylpyridine | [67] |

| (APTMACl):urea 1:2 | Functional monomer for polymerization | Separation of bovine hemoglobin from a complex sample | DES-MIPs separated effectively BHb from calf blood; DES-MIPs could be recycled at least 3 times | [48] |

| ChCl:ethylene glycol 1:2, 1:3, 1:4 | Binary green solvent and MIP modifier: porogen (mixture with ionic liquid) | Drug delivery of Fenbufen | The binary green system was the unique solvent used for all the polymerization reagents; It was also a good dispersant for the single-walled carbon nanotubes | [51] |

| ChCl:ethylene glycol 1:2 | MIPs modifier: porogen | Determination of Levofloxacin in human plasma | DES-MIPs better than DES-NIPs; DES-MIPs efficiently applied to examine levofloxacin from human plasma of hospitalized patients | [63] |

| ChCl:acrylic acid 1:2 | Functional monomer | Recognition and good antibacterial properties for β-lactoglobulin in milk | Surface DES-MIPs prepared to facilitate further template removal; The produced polymeric system presented good adsorption and selectivity for β-lactoglobulin, was reusable, and showed antibacterial activity | [72] |

| DES (molar ratio) | Polymer extracted | Raw material | Description | Ref. |

|---|---|---|---|---|

| ChCl:urea (U) 1:2 ChCl:ethylene glycol (EG) 1:2 ChCl:glycerol (GOH) 1:2 ChCl:lactic acid (LA) 1:2 ChCl:acetic acid (HAc) 1:2 ChCl:oxalic acid (OA) 1:1, 1:0.8, 1:0.6, 1:1.2 | Collagen | Cod skin | Extraction abilities: ChCl:OA > ChCl:HAc > ChCl:La > ChCl:EG > ChCl:GOH > ChCl:U; Better extraction efficiency for 1:1 ChCl:oxalic acid; Extraction influenced by the DES viscosity, acidity, and free hydrogen protons | [95] |

| 1:2 of ChCl with lactic acid, 1,4-butanediol, ethylene glycol, urea, 1,6-hexanediol, glycerol, oxalic acid, malonic acid, citric acid, malic acid, propylene glycol, L-(+)-tartaric acid, maleic anhydride, or thiourea | Chitin | Shrimp shells (Marsupenaeus japonicas) | Highest yield obtained for the DES of ChCl:oxalic acid, but the most selective (purest chitin) was ChCl:malonic acid DES; Higher yields than conventional extraction for all DES tested; Extracted chitin formed films with similar properties to films from commercial chitin | [94] |

| ChCl:oxalic acid 1:2 | Keratin | Wool | Extraction assisted with dialysis High solubility of wool in the DES | [99] |

| ChCl:oxalic acid 1:2 | Keratin | Rabbit Hair | Efficient dissolution and extraction of keratin from rabbit hair; Extraction assisted with dialysis | [100] |

| ChCl:malic acid 1:1 | Chitin | Shrimp shells | Efficient extraction of chitin, demineralized and deproteinized | [101] |

| ChCl:lactic acid (LA) 1:2 ChCl:urea (UA) 1:2 ChCl:oxalic acid (OA) 1:1, 1:2 ChCl:potassium hydroxide 1:4 | Lignin and cellulose | Wood sawdust of beech (Fagus sylvatica) | Oxalic acid and urea-based DES (acidic) were selective for lignin extraction, while ChCl:KOH (alkaline) was selective for extracting cellulose | [96] |

| ChCl:lactic acid 1:9 | Lignin | Wood | Lignin 80% pure | [102] |

| Plasticizers characteristics | Influence of plasticizers in polymers |

|---|---|

| • Inert | • Decrease the melting or glass transition temperature (Tg) of polymers |

| • Low molecular weight | • Preservation of the polymer elasticity |

| • Low vapor pressure | • Higher thermostability |

| Polymer plasticized | DES | Properties conferred | Ref. |

|---|---|---|---|

| Starch | ChCl:imidazole 3:7, 2:3 Glycerol:imidazole 1:1, 3:7 | Lower tendency to retrogradation Transparent and elastic films (thermoplasticized) | [118] |

| Citric acid:imidazole 3:7 Malic acid:imidazole 3:7 | Not suitable for starch plasticizing | ||

| ChCl:urea 1:2 ChCl:imidazole 3:7 | Dependent of additive (consult article) | [119] | |

| Chitosan films | ChCl:malic acid 1:1 | Tailored ductility with DES content Lower Tg Good solubility in water | [114] |

| ChCl:lactic acid 1:1 | Transparent films Lower tensile strength and Young’s modulus (higher flexibility) Higher water vapor permeability (WVP), water solubility, and water sorption | [120] | |

| ChCl:urea 1:2 | Enhanced film flexibility Reduced water uptake Improved ionic conductivity | [112] | |

| ChCl:malic acid 1:1, ChCl:lactic acid 1:1, ChCl:citric acid acid 1:1, ChCl:glycerol 1:2 | Transparent films Elasticity, tensile strength, and WVP tuned by chitosan type and DES composition | [113] | |

| Chitosan-carboxymethyl cellulose membrane | ChCl:urea 1:2 | Higher thermal stability Improved flexibility | [121] |

| Agar films | ChCl:urea 1:2 | Good mechanical resistance and improved elasticity in comparison to aqueous agar films | [85] |

| Cellulose films | ChCl:glycerol 1:2 ChCl:glucose 1:2 ChCl:urea 1:2 | Highly improved ductility | [111] |

| Tetrabutylammonium bromide:propylene carbonate 1:2 Tetrabutylammonium bromide:ethylene carbonate 1:2 | Improved thermoformability | ||

| Blend of starch and poly-ε-caprolactone (SPCL) | Glucose:citric acid 1:1 ChCl:sucrose 1:1, 4:1 ChCl:citric acid 1:1 ChCl:xylose 2:1, 3:1 Glucose:tartaric acid 1:1 Citric acid:sucrose 1:1 | Lower Young’s modulus and ductility Enhancement of supercritical foaming | [116] |

| Momordica charantia bioactive polysaccharide | ChCl:glycerol 1.5:1, 1:1, 1:1.5, 1:2, 1:3 | Improved flexibility (higher tensile stress and Young’s modulus) Higher thermal stability Higher water adsorption and WVP Antioxidant and antimicrobial activity | [117] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roda, A.; Matias, A.A.; Paiva, A.; Duarte, A.R.C. Polymer Science and Engineering Using Deep Eutectic Solvents. Polymers 2019, 11, 912. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11050912

Roda A, Matias AA, Paiva A, Duarte ARC. Polymer Science and Engineering Using Deep Eutectic Solvents. Polymers. 2019; 11(5):912. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11050912

Chicago/Turabian StyleRoda, Ana, Ana A. Matias, Alexandre Paiva, and Ana Rita C. Duarte. 2019. "Polymer Science and Engineering Using Deep Eutectic Solvents" Polymers 11, no. 5: 912. https://0-doi-org.brum.beds.ac.uk/10.3390/polym11050912